Retrofit: Maho MH400E to LinuxCNC

- workshop54

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 8

10 Mar 2025 15:24 #323613

by workshop54

Retrofit: Maho MH400E to LinuxCNC was created by workshop54

Retrofit: Maho MH400E naar LinuxCNC

Hi everyone,

I’ve recently started converting my Maho MH400E to LinuxCNC, and I’d like to share my progress here. I was inspired by RotarySMP—his posts gave me the courage to take on this project. Initially, I tried to get the original Philips control system working, but unfortunately, I couldn't get it to function. That led me to take the plunge and retrofit the machine with LinuxCNC.

Understanding the machine

To better understand how everything works, I fully translated the original manual into English. This has made it much easier to follow, especially when cross-referencing signals and system behavior.

Additionally, I’ve been diving into the control cabinet wiring and schematics, making sense of the machine's logic and how it all ties together.

Mesa hardware choices

RotarySMP used PCI-based Mesa cards, but since those are becoming outdated, I went with a different setup. After some research and trial and error, I decided on the following Mesa cards:

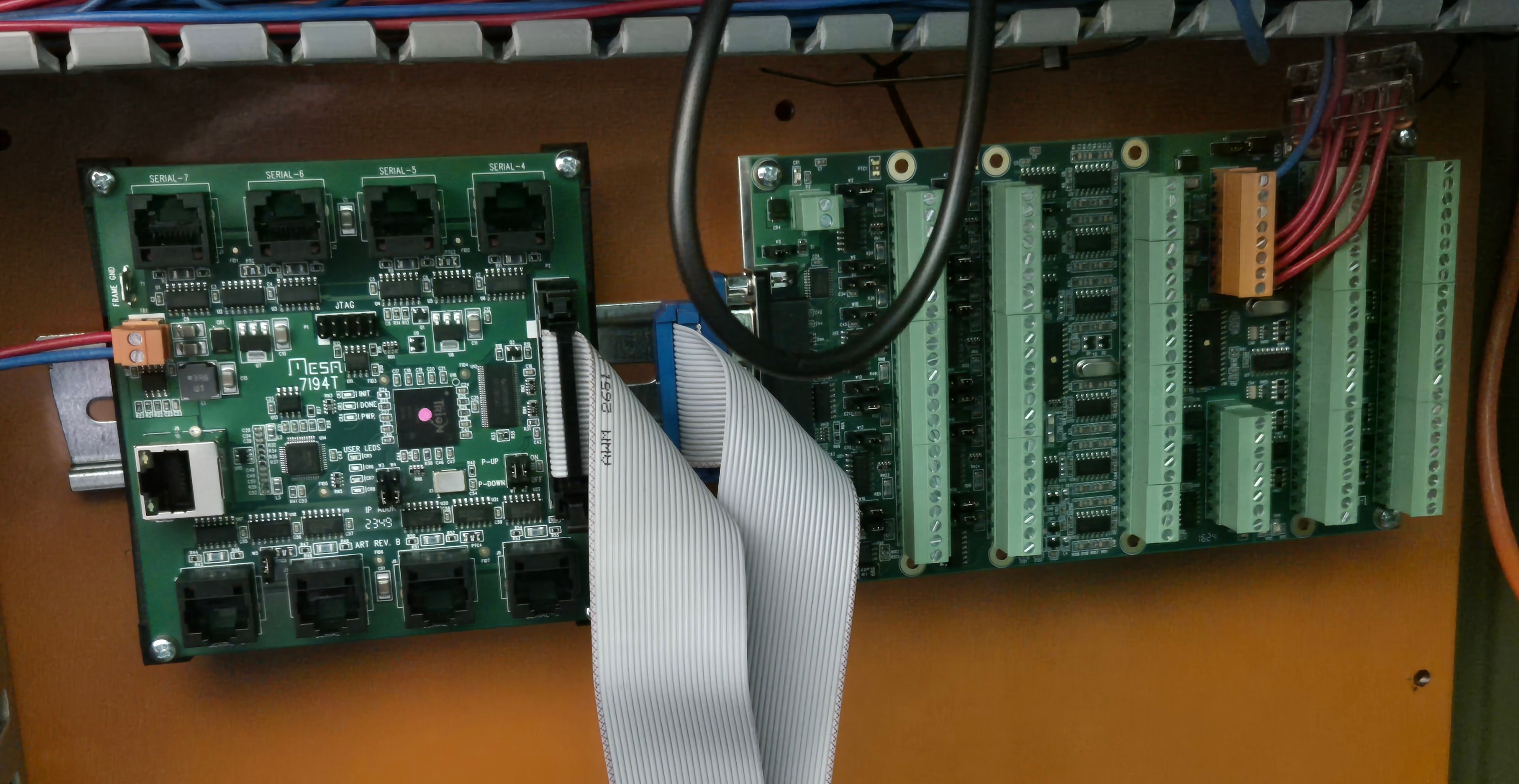

✅ 7i94T (Ethernet FPGA card)

✅ 7i77 (Analog servo interface)

✅ 7i84 (I/O expander)

So far, this combination seems to be working well, though I'm still troubleshooting some issues.

Current LinuxCNC setup

For now, I'm running LinuxCNC on an old laptop. It works, but eventually, I plan to upgrade to a dedicated PC.

As for the user interface, I’m currently leaning towards QtDragon, but that choice is still open for discussion.

What has been done so far:

1️⃣ Completely cleaned the machine (it was necessary!).

2️⃣ Organized the wiring in the control cabinet—technically not needed, but very satisfying.

3️⃣ Removed the original Philips CNC controller and monitor.

4️⃣ Translated the full machine manual into English.

5️⃣ Started analyzing the control cabinet logic and making sense of the schematics.

Current status of the Mesa cards/LinuxCNC setup:

✔️ I successfully established a connection with the 7i94T, which is in turn connected to the 7i77 via ribbon cable.

⚠️ However, I’m currently facing an issue, for which I have an open question on the forum.

I’ll be adding some photos of the machine and the Mesa cards soon. Looking forward to sharing more progress and learning from the community!

Hi everyone,

I’ve recently started converting my Maho MH400E to LinuxCNC, and I’d like to share my progress here. I was inspired by RotarySMP—his posts gave me the courage to take on this project. Initially, I tried to get the original Philips control system working, but unfortunately, I couldn't get it to function. That led me to take the plunge and retrofit the machine with LinuxCNC.

Understanding the machine

To better understand how everything works, I fully translated the original manual into English. This has made it much easier to follow, especially when cross-referencing signals and system behavior.

Additionally, I’ve been diving into the control cabinet wiring and schematics, making sense of the machine's logic and how it all ties together.

Mesa hardware choices

RotarySMP used PCI-based Mesa cards, but since those are becoming outdated, I went with a different setup. After some research and trial and error, I decided on the following Mesa cards:

✅ 7i94T (Ethernet FPGA card)

✅ 7i77 (Analog servo interface)

✅ 7i84 (I/O expander)

So far, this combination seems to be working well, though I'm still troubleshooting some issues.

Current LinuxCNC setup

For now, I'm running LinuxCNC on an old laptop. It works, but eventually, I plan to upgrade to a dedicated PC.

As for the user interface, I’m currently leaning towards QtDragon, but that choice is still open for discussion.

What has been done so far:

1️⃣ Completely cleaned the machine (it was necessary!).

2️⃣ Organized the wiring in the control cabinet—technically not needed, but very satisfying.

3️⃣ Removed the original Philips CNC controller and monitor.

4️⃣ Translated the full machine manual into English.

5️⃣ Started analyzing the control cabinet logic and making sense of the schematics.

Current status of the Mesa cards/LinuxCNC setup:

✔️ I successfully established a connection with the 7i94T, which is in turn connected to the 7i77 via ribbon cable.

⚠️ However, I’m currently facing an issue, for which I have an open question on the forum.

I’ll be adding some photos of the machine and the Mesa cards soon. Looking forward to sharing more progress and learning from the community!

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1553

- Thank you received: 573

11 Mar 2025 21:27 #323707

by RotarySMP

Replied by RotarySMP on topic Retrofit: Maho MH400E to LinuxCNC

Good on you for saving another 400E,

Mark

Mark

Please Log in or Create an account to join the conversation.

- workshop54

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 8

23 Mar 2025 20:02 - 23 Mar 2025 20:13 #324687

by workshop54

Replied by workshop54 on topic Retrofit: Maho MH400E to LinuxCNC

Last edit: 23 Mar 2025 20:13 by workshop54.

Please Log in or Create an account to join the conversation.

- workshop54

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 8

23 Mar 2025 20:11 - 23 Mar 2025 20:29 #324688

by workshop54

Replied by workshop54 on topic Retrofit: Maho MH400E to LinuxCNC

Got the Mesa 7i94T and 7i77 boards powered up today, and it’s great to finally see the pins show up in LinuxCNC.

Also managed to remove the tool holder that had been stuck in the spindle since I got the machine — definitely satisfying to get that out of the way.I’ll shorten the IDC25 ribbon once the board layout is finalized. For now, I’ve ordered breakout boards to avoid cutting cables too early: three for the Heidenhain DB15s, two for the Indramat DB9s, and two for the IDC40 ribbons.

The original Philips 432 hardware is completely gone. I briefly considered replacing the whole cabinet to avoid upgrading the mains fuse, but in the end I’m likely going for a proper electrical upgrade: increasing the main connection from 25A to 40A and switching from a B16 to a C25 breaker (still waiting on the electrician to confirm this setup).Once the wiring takes shape, I plan to capture everything neatly in EPLAN to avoid spaghetti later on. Slowly but surely, things are coming together.

Also managed to remove the tool holder that had been stuck in the spindle since I got the machine — definitely satisfying to get that out of the way.I’ll shorten the IDC25 ribbon once the board layout is finalized. For now, I’ve ordered breakout boards to avoid cutting cables too early: three for the Heidenhain DB15s, two for the Indramat DB9s, and two for the IDC40 ribbons.

The original Philips 432 hardware is completely gone. I briefly considered replacing the whole cabinet to avoid upgrading the mains fuse, but in the end I’m likely going for a proper electrical upgrade: increasing the main connection from 25A to 40A and switching from a B16 to a C25 breaker (still waiting on the electrician to confirm this setup).Once the wiring takes shape, I plan to capture everything neatly in EPLAN to avoid spaghetti later on. Slowly but surely, things are coming together.

Attachments:

Last edit: 23 Mar 2025 20:29 by workshop54.

The following user(s) said Thank You: RotarySMP, tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.184 seconds