rectangle3 for mill / router

- Rick G

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 155

22 Sep 2013 15:12 - 01 Feb 2015 16:23 #39101

by Rick G

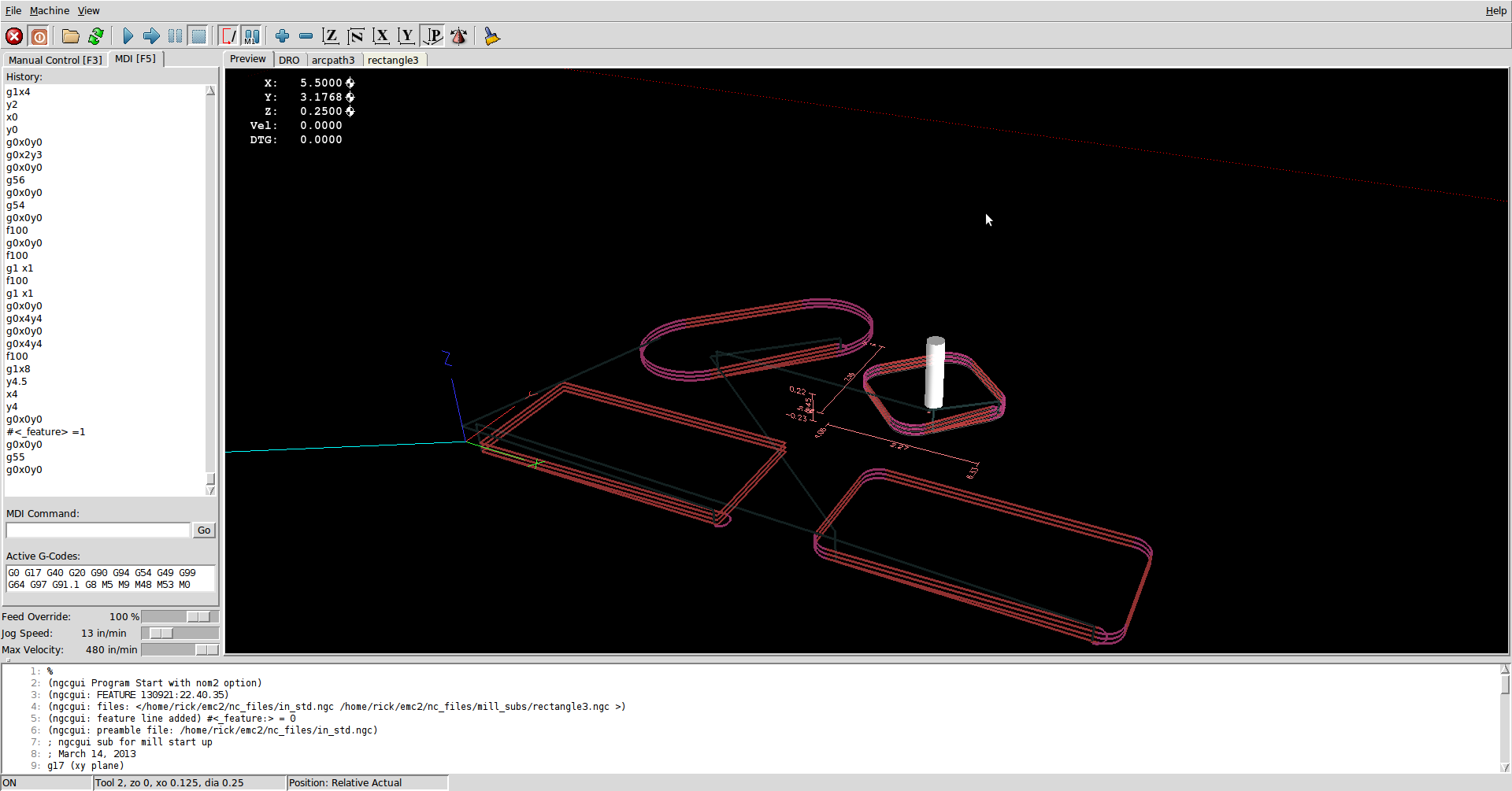

rectangle3 for mill / router was created by Rick G

For rectangles on the mill / router with square or radius corners.

Uses cutter radius compensation, multiple pass for deep cut.

Rectangle can be rotated.

Cuts inside or outside of path, clockwise or counter clockwise tool path.

Location of rectangle set with X start and Y start.

X start Y start is lower left of rectangle before any rotation

Select Main and Temp coordinate systems.

Uses check_cord3.ngc and M110

Newer version below.

Rick G

Uses cutter radius compensation, multiple pass for deep cut.

Rectangle can be rotated.

Cuts inside or outside of path, clockwise or counter clockwise tool path.

Location of rectangle set with X start and Y start.

X start Y start is lower left of rectangle before any rotation

Select Main and Temp coordinate systems.

Uses check_cord3.ngc and M110

Newer version below.

Rick G

Last edit: 01 Feb 2015 16:23 by Rick G. Reason: Newer version below

The following user(s) said Thank You: Mike_Eitel, BigJohnT

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

22 Sep 2013 17:52 #39105

by BigJohnT

Replied by BigJohnT on topic rectangle3 for mill / router

Pretty neat Rick,

I really need to get a probe built for my mill...

JT

I really need to get a probe built for my mill...

JT

Please Log in or Create an account to join the conversation.

- johns00056

- Offline

- Premium Member

-

Less

More

- Posts: 110

- Thank you received: 2

01 Feb 2015 04:02 #55524

by johns00056

Replied by johns00056 on topic rectangle3 for mill / router

I can't get this one to work.

( Actually I can't get any of the NGCGUI programs to work, but I thought that I would start with this one)

The error message is- length of cutter compensation move is not greater than tool radius.

I want to start in the middle and mill an inside rectangle.

I have tried a bunch of starting positions, but it only works if the tool diameter is 0.

Also- I don't know what #17 (= 54 Main G cord) and #18 (=55 Temp G cord) are.

( Actually I can't get any of the NGCGUI programs to work, but I thought that I would start with this one)

The error message is- length of cutter compensation move is not greater than tool radius.

I want to start in the middle and mill an inside rectangle.

I have tried a bunch of starting positions, but it only works if the tool diameter is 0.

Also- I don't know what #17 (= 54 Main G cord) and #18 (=55 Temp G cord) are.

Please Log in or Create an account to join the conversation.

- Rick G

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 155

01 Feb 2015 16:20 #55544

by Rick G

Replied by Rick G on topic rectangle3 for mill / router

Here is a newer version, This one you reference from the center of the rectangle.

#17 and #18 are the coordinate systems to use for the sub.

On a mill you might have more than one vise or work area, the first uses say coordinate systems 54 and 55, the second may use 56 and 57. If you always work in 54 just ignore them.

Rick G

#17 and #18 are the coordinate systems to use for the sub.

On a mill you might have more than one vise or work area, the first uses say coordinate systems 54 and 55, the second may use 56 and 57. If you always work in 54 just ignore them.

o<rectangle33> sub

; rectangle3 for mill to cut rectangles with square or radius corners. Uses cutter radius compensation, multiple pass for deep cut.

; Cuts inside or outside of path, clockwise or counter clockwise tool path.

; Location of rectangle set with X start and Y start.

;X_start Y_start is the center of rectangle

; Rectangle can be rotated.

; Select Main and Temp coordinate systems.

; uses check_cord3.ngc and M110

; from office 12/28/13

(UNTESTED CONCEPT ONLY, EDIT AND TEST BEFORE USING)

#<x_length> = #1 (= 4 X length)

#<y_length> = #2 (= 2 Y length)

#<x_center> = #3 (= X center)

#<y_center> = #4 (= Y center)

#<z_start> = #5 (= .010 Z start)

#<rotate> = #6 (= 0 Angle)

#<Corner_Rad> = #7 (= 0 Corner Radius)

#<Depth> = #8 (= .20 Depth)

#<z_safe> = #9 (= .25 Z safe)

#<z_rate> = #10 (= 10 Plunge rate)

#<z_step> = #11 (= .025 Z step)

#<Feed_rate> = #12 (= 100 Feed rate)

#<clockwise> = #13 (= 1 Clockwise 1 , CCW 0)

#<Tool_no> = #14 (= 2 Tool Number)

#<Inside> = #15 (= 1 Inside 1, Outside 0)

#<RPM> = #16 (= 500 Spindle RPM)

#<Main_cord> = #17 (= 54 Main G cord)

#<Temp_cord> = #18 (= 55 Temp G cord)

G17 (xy plane)

G20 (inches)

G40 (cancel cutter radius compensation)

G49 (cancel tool length offset)

G90 (absolute distance mode)

G94 (units/min feed rate)

G64 P.001 Q.001 (set path tolerance)

;set global parameters

#<_m:cord> = 0

#<_t:cord> = 0

o201 if [[#<Inside> LT 0] OR [#<Inside> GT 1]]

(debug, bad Inside input, must be 1 for inside or 0 for Outside #<Inside>)

o200 return

o201 endif

o301 if [#<Corner_Rad> LT 0]

(debug, bad Corner Radius input, must be 0 or greater #<Corner_Rad>)

o300 return

o301 endif

o311 if [[[#<Corner_Rad> * 2] GT #<x_length>] OR [[#<Corner_Rad> * 2] GT #<y_length>]]

(debug, Corner Radius too large for path Corner radius #<Corner_Rad>,)

o310 return

o311 endif

o401 if [#<Depth> LT 0]

(debug, bad Depth input, must be 0 or greater #<Depth>)

o400 return

o401 endif

o501 if [[#<clockwise> LT 0] OR [#<clockwise> GT 1]]

(debug, bad clockwise input, must be 1 for clockwise or 0 for counterclockwise #<clockwise>)

o500 return

o501 endif

o601 if [#<z_step> LE 0]

(debug, bad Z step, must be greater than 0 #<z_step>)

o600 return

o601 endif

o701 if [#<Temp_cord> EQ #<Main_cord>]

(debug, Main cord and temp cord cannot be the same Main #<Main_cord> Temp #<Temp_cord>)

o700 return

o701 endif

o<check_cord3> call [#<Main_cord>] [#<Temp_cord>]

#<Main_cord_n> = #<_m:cord>

#<Temp_cord_n> = #<_t:cord>

;reset global parameters

#<_m:cord> = 0

#<_t:cord> = 0

o801 if [#<Temp_cord_n> EQ 0]

(debug, bad Temp cord #<Temp_cord_n>)

o800 return

o801 endif

o901 if [#<Main_cord_n> EQ 0]

(debug, bad Main cord #<Main_cord_n>)

o900 return

o901 endif

(debug, Main cord #<Main_cord> and #<Main_cord_n>)

(debug, Temp cord #<Temp_cord> and #<Temp_cord_n>)

G#<Main_cord>

#<x_length>=[#<x_length> - [#<Corner_Rad> * 2]]

#<y_length>=[#<y_length> - [#<Corner_Rad> * 2]]

#<x_start> = [#<x_length> / 2]

#<y_start> = [#<y_length> / 2]

#<Cut_Amount> = [#<Depth> + #<z_start>] ; deepest Z cut

#<Cuts> = FUP [[#<Cut_Amount> / #<z_step>]] ; round up the number of passes to reach deepest cut

#<z_step> = [#<Cut_Amount> / #<Cuts>] ; amount to take off Z each pass

F#<Feed_rate>

M6 T#<Tool_no>

M3 (spindle on forward)

G4 P.2 (pause for spindle to reach speed)

G0 Z#<z_safe>

G0 X#<x_center> Y#<y_center> (go to center location)

(debug, go to center location X #<x_center> Y #<y_center>)

(debug, x start #<x_start> y start #<y_start>)

G4 P2

G10 L20 P#<Temp_cord_n> X0 Y0 Z#<z_safe> (set Temp cord)

G#<Temp_cord>

G10 L2 P#<Temp_cord_n> R#<rotate> (rotate for angle G_temp)

G0 X-#<x_start> Y-[#<y_start> + #<Corner_Rad>]

G91 (relative distance mode)

o<c100> if [#<clockwise> EQ 1]

o<i100> if [#<Inside> EQ 0] (cut offset to inside path)

G41 D#<Tool_no>

o<i100> endif

o<i200> if [#<Inside> EQ 1] (cut offset to outside of path)

G42 D#<Tool_no>

o<i200> endif

G0 X#<x_length>

G90 (absolute distance mode)

G0 Z[#<z_start> + .025]

G1 Z#<z_start>F#<z_rate>

G91 (relative distance mode)

F#<Feed_rate>

o<z100> while [#<Cuts>]

o<r1100> if [#<Corner_Rad> GT 0]

G1 X-#<x_length>Z-#<z_step>

G2 X-#<Corner_Rad> Y#<Corner_Rad> R#<Corner_Rad>

G1 Y#<y_length> ;up

G2 X#<Corner_Rad> Y#<Corner_Rad> R#<Corner_Rad>

G1 X#<x_length> ;right

G2 X#<Corner_Rad> Y-#<Corner_Rad>R#<Corner_Rad>

G1 Y-#<y_length>

G2 X-#<Corner_Rad> Y-#<Corner_Rad> R#<Corner_Rad>

o<r1100> else

G1 X-#<x_length>Z-#<z_step>

G1 Y#<y_length> ;up

G1 X#<x_length> ;right

G1 Y-#<y_length>

o<r1100> endif

#<Cuts> = [#<Cuts> - 1]

o<z100> endwhile ;Cuts

G1 X-[#<x_length> - #5401]

o<c100> else ;counter clockwise

o<i1100> if [#<Inside> EQ 0] (cut offset to inside path)

G42 D#<Tool_no>

o<i1100> endif

o<i2200> if [#<Inside> EQ 1] (cut offset to outside of path)

G41 D#<Tool_no>

o<i2200> endif

G0 X[#5401 *2]

G0 X-[#5401 *2]

G90

G0 Z[#<z_start> + .025]

G1 Z#<z_start>F#<z_rate>

G91

F#<Feed_rate>

o<z200> while[#<Cuts>]

o<r100> if [#<Corner_Rad> GT 0]

G1 X#<x_length>Z-#<z_step>

G3 X#<Corner_Rad> Y#<Corner_Rad> R#<Corner_Rad>

G1 Y#<y_length> ;up

G3 X-#<Corner_Rad> Y#<Corner_Rad>R#<Corner_Rad>

G1 X-#<x_length> ;left

G3 X-#<Corner_Rad> Y-#<Corner_Rad>R#<Corner_Rad>

G1 Y-#<y_length> ;down

G3 X#<Corner_Rad> Y-#<Corner_Rad>R#<Corner_Rad>

o<r100> else

G1 X#<x_length>Z-#<z_step>

G1 Y#<y_length> ;up

G1 X-#<x_length> ;left

G1 Y-#<y_length> ;down

o<r100> endif

#<Cuts> = [#<Cuts> - 1]

o<z200> endwhile ;Cuts

G1 X[#<x_length> - #5401]

o<c100> endif

G90

G0 Z#<z_safe>

G40

G10 L2 P#<Temp_cord_n> R0 (reset rotate)

G#<Main_cord>

M5

M110 (clear messages)

o<rectangle33> endsubRick G

Please Log in or Create an account to join the conversation.

- johns00056

- Offline

- Premium Member

-

Less

More

- Posts: 110

- Thank you received: 2

01 Feb 2015 22:25 - 02 Feb 2015 06:53 #55551

by johns00056

Replied by johns00056 on topic rectangle3 for mill / router

Thanks for the response.

It still only works if the tool diameter is zero.

It is a cool program and I can just use it without cutter diameter compensation.

It still only works if the tool diameter is zero.

It is a cool program and I can just use it without cutter diameter compensation.

Last edit: 02 Feb 2015 06:53 by johns00056.

Please Log in or Create an account to join the conversation.

- Rick G

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 155

02 Feb 2015 17:09 #55574

by Rick G

Replied by Rick G on topic rectangle3 for mill / router

Perhaps you can give a little more detail on what you are trying to do, and what is happening.

Size of rectangle, location, starting point, tool size, metric/inch, (the sub is set for inch) etc.

Try setting it up with a larger rectangle and or smaller tool.

Seems to works fine here on sim.

Rick G

Size of rectangle, location, starting point, tool size, metric/inch, (the sub is set for inch) etc.

Try setting it up with a larger rectangle and or smaller tool.

Seems to works fine here on sim.

Rick G

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23451

- Thank you received: 4989

02 Feb 2015 21:22 #55581

by andypugh

I suspect you might be getting tangled up with a mm pocket and something assuming an inch tool diameter.

Replied by andypugh on topic rectangle3 for mill / router

It still only works if the tool diameter is zero

I suspect you might be getting tangled up with a mm pocket and something assuming an inch tool diameter.

Please Log in or Create an account to join the conversation.

- johns00056

- Offline

- Premium Member

-

Less

More

- Posts: 110

- Thank you received: 2

02 Feb 2015 22:07 - 02 Feb 2015 22:38 #55584

by johns00056

Replied by johns00056 on topic rectangle3 for mill / router

Thank you, I really appreciate the help.

It still will not work even with a tool diameter as small as .001 inch ,or a rectangle as large as 100 inches.

I am feeding counter clockwise, inside.

If the tool diameter is zero,the plot displays OK in Axis, with the tool feeding z minus straight down to the starting point at the beginning of the first straight segment.

I would think that the spindle center line needs to be away from the start of the first segment by 1/2 the cutter diameter before the cutter diameter compensation is applied.

I am not going to spend any more time on this right now.

It still will not work even with a tool diameter as small as .001 inch ,or a rectangle as large as 100 inches.

I am feeding counter clockwise, inside.

If the tool diameter is zero,the plot displays OK in Axis, with the tool feeding z minus straight down to the starting point at the beginning of the first straight segment.

I would think that the spindle center line needs to be away from the start of the first segment by 1/2 the cutter diameter before the cutter diameter compensation is applied.

I am not going to spend any more time on this right now.

Last edit: 02 Feb 2015 22:38 by johns00056.

Please Log in or Create an account to join the conversation.

Time to create page: 0.194 seconds