Teco FM50 and Mesa 7i77

18 Apr 2020 01:13 #164377

by Catch22

Yes it looks like it's 0-10v so do I select a positive spindle speed in the Pncconfig?

Replied by Catch22 on topic Teco FM50 and Mesa 7i77

Notice that you are commanding a negative spindle speed?

This will likely not work with the TECO as it probably expects 0 to 10V

_not_ -10 to +10

So to test further, select a positive spindle speed

If the TECO VFD is 0 to 10V you will need to connect the spindle

to the absolute RPM pin in hal rather than the signed RPM pin

Yes it looks like it's 0-10v so do I select a positive spindle speed in the Pncconfig?

Attachments:

Please Log in or Create an account to join the conversation.

18 Apr 2020 01:23 #164378

by PCW

Replied by PCW on topic Teco FM50 and Mesa 7i77

For testing just select a clockwise spindle direction:

m3 s1000

in pncconf, uncheck the "Use +- voltage for direction" check box

_BUT_ you may want to make the changes in the hal file so you dont lose any tuning values you have adjusted

m3 s1000

in pncconf, uncheck the "Use +- voltage for direction" check box

_BUT_ you may want to make the changes in the hal file so you dont lose any tuning values you have adjusted

The following user(s) said Thank You: Catch22

Please Log in or Create an account to join the conversation.

18 Apr 2020 18:46 #164483

by Catch22

I tried to add to the HAL file as I found something that it said to do but now i just get an error.

addf scale.0 servo-thread

setp scale.0.gain 0.0027

net spindle-speed-scale motion.spindle-speed-out => scale.0.in

net spindle-speed-DAC scale.0.out => <your DAC pin name>

# Generated by PNCconf at Sat Apr 18 14:20:32 2020

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt trivkins

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=6 num_pwmgens=0 num_stepgens=0 sserial_port_0=000xxx"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

# external input signals

# --- ESTOP-EXT ---

net estop-ext <= hm2_5i25.0.7i77.0.0.input-00

# --- BOTH-HOME-X ---

net both-home-x <= hm2_5i25.0.7i77.0.0.input-11-not

# --- BOTH-HOME-Y ---

net both-home-y <= hm2_5i25.0.7i77.0.0.input-12-not

# --- BOTH-HOME-Z ---

net both-home-z <= hm2_5i25.0.7i77.0.0.input-13-not

# --- BOTH-HOME-A ---

net both-home-a <= hm2_5i25.0.7i77.0.0.input-14-not

#*******************

# AXIS X

#*******************

setp pid.x.Pgain [AXIS_0]P

setp pid.x.Igain [AXIS_0]I

setp pid.x.Dgain [AXIS_0]D

setp pid.x.bias [AXIS_0]BIAS

setp pid.x.FF0 [AXIS_0]FF0

setp pid.x.FF1 [AXIS_0]FF1

setp pid.x.FF2 [AXIS_0]FF2

setp pid.x.deadband [AXIS_0]DEADBAND

setp pid.x.maxoutput [AXIS_0]MAX_OUTPUT

setp pid.x.error-previous-target true

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout0-scalemax [AXIS_0]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout0-minlim [AXIS_0]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout0-maxlim [AXIS_0]OUTPUT_MAX_LIMIT

net x-output => hm2_5i25.0.7i77.0.1.analogout0

net x-pos-cmd axis.0.motor-pos-cmd

net x-enable axis.0.amp-enable-out

# enable _all_ sserial pwmgens

net x-enable hm2_5i25.0.7i77.0.1.analogena

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.00.counter-mode 0

setp hm2_5i25.0.encoder.00.filter 1

setp hm2_5i25.0.encoder.00.index-invert 0

setp hm2_5i25.0.encoder.00.index-mask 0

setp hm2_5i25.0.encoder.00.index-mask-invert 0

setp hm2_5i25.0.encoder.00.scale [AXIS_0]ENCODER_SCALE

net x-pos-fb <= hm2_5i25.0.encoder.00.position

net x-vel-fb <= hm2_5i25.0.encoder.00.velocity

net x-pos-fb => axis.0.motor-pos-fb

net x-index-enable axis.0.index-enable <=> hm2_5i25.0.encoder.00.index-enable

net x-pos-rawcounts <= hm2_5i25.0.encoder.00.rawcounts

# ---setup home / limit switch signals---

net both-home-x => axis.0.home-sw-in

net both-home-x => axis.0.neg-lim-sw-in

net both-home-x => axis.0.pos-lim-sw-in

#*******************

# AXIS Y

#*******************

setp pid.y.Pgain [AXIS_1]P

setp pid.y.Igain [AXIS_1]I

setp pid.y.Dgain [AXIS_1]D

setp pid.y.bias [AXIS_1]BIAS

setp pid.y.FF0 [AXIS_1]FF0

setp pid.y.FF1 [AXIS_1]FF1

setp pid.y.FF2 [AXIS_1]FF2

setp pid.y.deadband [AXIS_1]DEADBAND

setp pid.y.maxoutput [AXIS_1]MAX_OUTPUT

setp pid.y.error-previous-target true

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output => pid.y.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout1-scalemax [AXIS_1]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout1-minlim [AXIS_1]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout1-maxlim [AXIS_1]OUTPUT_MAX_LIMIT

net y-output => hm2_5i25.0.7i77.0.1.analogout1

net y-pos-cmd axis.1.motor-pos-cmd

net y-enable axis.1.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.01.counter-mode 0

setp hm2_5i25.0.encoder.01.filter 1

setp hm2_5i25.0.encoder.01.index-invert 0

setp hm2_5i25.0.encoder.01.index-mask 0

setp hm2_5i25.0.encoder.01.index-mask-invert 0

setp hm2_5i25.0.encoder.01.scale [AXIS_1]ENCODER_SCALE

net y-pos-fb <= hm2_5i25.0.encoder.01.position

net y-vel-fb <= hm2_5i25.0.encoder.01.velocity

net y-pos-fb => axis.1.motor-pos-fb

net y-index-enable axis.1.index-enable <=> hm2_5i25.0.encoder.01.index-enable

net y-pos-rawcounts <= hm2_5i25.0.encoder.01.rawcounts

# ---setup home / limit switch signals---

net both-home-y => axis.1.home-sw-in

net both-home-y => axis.1.neg-lim-sw-in

net both-home-y => axis.1.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [AXIS_2]P

setp pid.z.Igain [AXIS_2]I

setp pid.z.Dgain [AXIS_2]D

setp pid.z.bias [AXIS_2]BIAS

setp pid.z.FF0 [AXIS_2]FF0

setp pid.z.FF1 [AXIS_2]FF1

setp pid.z.FF2 [AXIS_2]FF2

setp pid.z.deadband [AXIS_2]DEADBAND

setp pid.z.maxoutput [AXIS_2]MAX_OUTPUT

setp pid.z.error-previous-target true

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout2-scalemax [AXIS_2]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout2-minlim [AXIS_2]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout2-maxlim [AXIS_2]OUTPUT_MAX_LIMIT

net z-output => hm2_5i25.0.7i77.0.1.analogout2

net z-pos-cmd axis.2.motor-pos-cmd

net z-enable axis.2.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.02.counter-mode 0

setp hm2_5i25.0.encoder.02.filter 1

setp hm2_5i25.0.encoder.02.index-invert 0

setp hm2_5i25.0.encoder.02.index-mask 0

setp hm2_5i25.0.encoder.02.index-mask-invert 0

setp hm2_5i25.0.encoder.02.scale [AXIS_2]ENCODER_SCALE

net z-pos-fb <= hm2_5i25.0.encoder.02.position

net z-vel-fb <= hm2_5i25.0.encoder.02.velocity

net z-pos-fb => axis.2.motor-pos-fb

net z-index-enable axis.2.index-enable <=> hm2_5i25.0.encoder.02.index-enable

net z-pos-rawcounts <= hm2_5i25.0.encoder.02.rawcounts

# ---setup home / limit switch signals---

net both-home-z => axis.2.home-sw-in

net both-home-z => axis.2.neg-lim-sw-in

net both-home-z => axis.2.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_9]P

setp pid.s.Igain [SPINDLE_9]I

setp pid.s.Dgain [SPINDLE_9]D

setp pid.s.bias [SPINDLE_9]BIAS

setp pid.s.FF0 [SPINDLE_9]FF0

setp pid.s.FF1 [SPINDLE_9]FF1

setp pid.s.FF2 [SPINDLE_9]FF2

setp pid.s.deadband [SPINDLE_9]DEADBAND

setp pid.s.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-output <= pid.s.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout5-scalemax [SPINDLE_9]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout5-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout5-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

net spindle-output => hm2_5i25.0.7i77.0.1.analogout5

net spindle-enable => hm2_5i25.0.7i77.0.1.spinena

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-enable <= motion.spindle-on

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

loadrt scale count=1

addf scale.0 servo-thread

setp scale.0.gain 0.0027

net spindle-speed-scale motion.spindle-speed-out => scale.0.in

net spindle-speed-DAC scale.0.out => <your DAC pin name>

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

net jog-x-pos halui.jog.0.plus

net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.jog.0.analog

net joint-select-b halui.joint.1.select

net y-is-homed halui.joint.1.is-homed

net jog-y-pos halui.jog.1.plus

net jog-y-neg halui.jog.1.minus

net jog-y-analog halui.jog.1.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

net jog-z-pos halui.jog.2.plus

net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.jog.2.analog

net jog-selected-pos halui.jog.selected.plus

net jog-selected-neg halui.jog.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

Replied by Catch22 on topic Teco FM50 and Mesa 7i77

For testing just select a clockwise spindle direction:

m3 s1000

in pncconf, uncheck the "Use +- voltage for direction" check box

_BUT_ you may want to make the changes in the hal file so you dont lose any tuning values you have adjusted

I tried to add to the HAL file as I found something that it said to do but now i just get an error.

addf scale.0 servo-thread

setp scale.0.gain 0.0027

net spindle-speed-scale motion.spindle-speed-out => scale.0.in

net spindle-speed-DAC scale.0.out => <your DAC pin name>

# Generated by PNCconf at Sat Apr 18 14:20:32 2020

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt trivkins

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=6 num_pwmgens=0 num_stepgens=0 sserial_port_0=000xxx"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

# external input signals

# --- ESTOP-EXT ---

net estop-ext <= hm2_5i25.0.7i77.0.0.input-00

# --- BOTH-HOME-X ---

net both-home-x <= hm2_5i25.0.7i77.0.0.input-11-not

# --- BOTH-HOME-Y ---

net both-home-y <= hm2_5i25.0.7i77.0.0.input-12-not

# --- BOTH-HOME-Z ---

net both-home-z <= hm2_5i25.0.7i77.0.0.input-13-not

# --- BOTH-HOME-A ---

net both-home-a <= hm2_5i25.0.7i77.0.0.input-14-not

#*******************

# AXIS X

#*******************

setp pid.x.Pgain [AXIS_0]P

setp pid.x.Igain [AXIS_0]I

setp pid.x.Dgain [AXIS_0]D

setp pid.x.bias [AXIS_0]BIAS

setp pid.x.FF0 [AXIS_0]FF0

setp pid.x.FF1 [AXIS_0]FF1

setp pid.x.FF2 [AXIS_0]FF2

setp pid.x.deadband [AXIS_0]DEADBAND

setp pid.x.maxoutput [AXIS_0]MAX_OUTPUT

setp pid.x.error-previous-target true

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout0-scalemax [AXIS_0]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout0-minlim [AXIS_0]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout0-maxlim [AXIS_0]OUTPUT_MAX_LIMIT

net x-output => hm2_5i25.0.7i77.0.1.analogout0

net x-pos-cmd axis.0.motor-pos-cmd

net x-enable axis.0.amp-enable-out

# enable _all_ sserial pwmgens

net x-enable hm2_5i25.0.7i77.0.1.analogena

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.00.counter-mode 0

setp hm2_5i25.0.encoder.00.filter 1

setp hm2_5i25.0.encoder.00.index-invert 0

setp hm2_5i25.0.encoder.00.index-mask 0

setp hm2_5i25.0.encoder.00.index-mask-invert 0

setp hm2_5i25.0.encoder.00.scale [AXIS_0]ENCODER_SCALE

net x-pos-fb <= hm2_5i25.0.encoder.00.position

net x-vel-fb <= hm2_5i25.0.encoder.00.velocity

net x-pos-fb => axis.0.motor-pos-fb

net x-index-enable axis.0.index-enable <=> hm2_5i25.0.encoder.00.index-enable

net x-pos-rawcounts <= hm2_5i25.0.encoder.00.rawcounts

# ---setup home / limit switch signals---

net both-home-x => axis.0.home-sw-in

net both-home-x => axis.0.neg-lim-sw-in

net both-home-x => axis.0.pos-lim-sw-in

#*******************

# AXIS Y

#*******************

setp pid.y.Pgain [AXIS_1]P

setp pid.y.Igain [AXIS_1]I

setp pid.y.Dgain [AXIS_1]D

setp pid.y.bias [AXIS_1]BIAS

setp pid.y.FF0 [AXIS_1]FF0

setp pid.y.FF1 [AXIS_1]FF1

setp pid.y.FF2 [AXIS_1]FF2

setp pid.y.deadband [AXIS_1]DEADBAND

setp pid.y.maxoutput [AXIS_1]MAX_OUTPUT

setp pid.y.error-previous-target true

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output => pid.y.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout1-scalemax [AXIS_1]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout1-minlim [AXIS_1]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout1-maxlim [AXIS_1]OUTPUT_MAX_LIMIT

net y-output => hm2_5i25.0.7i77.0.1.analogout1

net y-pos-cmd axis.1.motor-pos-cmd

net y-enable axis.1.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.01.counter-mode 0

setp hm2_5i25.0.encoder.01.filter 1

setp hm2_5i25.0.encoder.01.index-invert 0

setp hm2_5i25.0.encoder.01.index-mask 0

setp hm2_5i25.0.encoder.01.index-mask-invert 0

setp hm2_5i25.0.encoder.01.scale [AXIS_1]ENCODER_SCALE

net y-pos-fb <= hm2_5i25.0.encoder.01.position

net y-vel-fb <= hm2_5i25.0.encoder.01.velocity

net y-pos-fb => axis.1.motor-pos-fb

net y-index-enable axis.1.index-enable <=> hm2_5i25.0.encoder.01.index-enable

net y-pos-rawcounts <= hm2_5i25.0.encoder.01.rawcounts

# ---setup home / limit switch signals---

net both-home-y => axis.1.home-sw-in

net both-home-y => axis.1.neg-lim-sw-in

net both-home-y => axis.1.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [AXIS_2]P

setp pid.z.Igain [AXIS_2]I

setp pid.z.Dgain [AXIS_2]D

setp pid.z.bias [AXIS_2]BIAS

setp pid.z.FF0 [AXIS_2]FF0

setp pid.z.FF1 [AXIS_2]FF1

setp pid.z.FF2 [AXIS_2]FF2

setp pid.z.deadband [AXIS_2]DEADBAND

setp pid.z.maxoutput [AXIS_2]MAX_OUTPUT

setp pid.z.error-previous-target true

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout2-scalemax [AXIS_2]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout2-minlim [AXIS_2]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout2-maxlim [AXIS_2]OUTPUT_MAX_LIMIT

net z-output => hm2_5i25.0.7i77.0.1.analogout2

net z-pos-cmd axis.2.motor-pos-cmd

net z-enable axis.2.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.02.counter-mode 0

setp hm2_5i25.0.encoder.02.filter 1

setp hm2_5i25.0.encoder.02.index-invert 0

setp hm2_5i25.0.encoder.02.index-mask 0

setp hm2_5i25.0.encoder.02.index-mask-invert 0

setp hm2_5i25.0.encoder.02.scale [AXIS_2]ENCODER_SCALE

net z-pos-fb <= hm2_5i25.0.encoder.02.position

net z-vel-fb <= hm2_5i25.0.encoder.02.velocity

net z-pos-fb => axis.2.motor-pos-fb

net z-index-enable axis.2.index-enable <=> hm2_5i25.0.encoder.02.index-enable

net z-pos-rawcounts <= hm2_5i25.0.encoder.02.rawcounts

# ---setup home / limit switch signals---

net both-home-z => axis.2.home-sw-in

net both-home-z => axis.2.neg-lim-sw-in

net both-home-z => axis.2.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_9]P

setp pid.s.Igain [SPINDLE_9]I

setp pid.s.Dgain [SPINDLE_9]D

setp pid.s.bias [SPINDLE_9]BIAS

setp pid.s.FF0 [SPINDLE_9]FF0

setp pid.s.FF1 [SPINDLE_9]FF1

setp pid.s.FF2 [SPINDLE_9]FF2

setp pid.s.deadband [SPINDLE_9]DEADBAND

setp pid.s.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-output <= pid.s.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout5-scalemax [SPINDLE_9]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout5-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout5-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

net spindle-output => hm2_5i25.0.7i77.0.1.analogout5

net spindle-enable => hm2_5i25.0.7i77.0.1.spinena

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-enable <= motion.spindle-on

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

loadrt scale count=1

addf scale.0 servo-thread

setp scale.0.gain 0.0027

net spindle-speed-scale motion.spindle-speed-out => scale.0.in

net spindle-speed-DAC scale.0.out => <your DAC pin name>

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

net jog-x-pos halui.jog.0.plus

net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.jog.0.analog

net joint-select-b halui.joint.1.select

net y-is-homed halui.joint.1.is-homed

net jog-y-pos halui.jog.1.plus

net jog-y-neg halui.jog.1.minus

net jog-y-analog halui.jog.1.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

net jog-z-pos halui.jog.2.plus

net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.jog.2.analog

net jog-selected-pos halui.jog.selected.plus

net jog-selected-neg halui.jog.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

Please Log in or Create an account to join the conversation.

18 Apr 2020 19:26 #164489

by PCW

Replied by PCW on topic Teco FM50 and Mesa 7i77

You do not need a scale component to scale the spindle output

This is done in pncconf when you setup the spindle or can be done by

editing the spindle section of the INI file

Can you post the spindle section of your INI file here?

This is done in pncconf when you setup the spindle or can be done by

editing the spindle section of the INI file

Can you post the spindle section of your INI file here?

The following user(s) said Thank You: Catch22

Please Log in or Create an account to join the conversation.

18 Apr 2020 20:37 #164510

by Catch22

here it is.

Spindle

#********************

[SPINDLE_9]

P = 0.0

I = 0.0

D = 0.0

FF0 = 1.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 3600.0

OUTPUT_SCALE = 3600

OUTPUT_MIN_LIMIT = 0

OUTPUT_MAX_LIMIT = 3600

Replied by Catch22 on topic Teco FM50 and Mesa 7i77

You do not need a scale component to scale the spindle output

This is done in pncconf when you setup the spindle or can be done by

editing the spindle section of the INI file

Can you post the spindle section of your INI file here?

here it is.

Spindle

#********************

[SPINDLE_9]

P = 0.0

I = 0.0

D = 0.0

FF0 = 1.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 3600.0

OUTPUT_SCALE = 3600

OUTPUT_MIN_LIMIT = 0

OUTPUT_MAX_LIMIT = 3600

Please Log in or Create an account to join the conversation.

18 Apr 2020 23:16 #164538

by PCW

Replied by PCW on topic Teco FM50 and Mesa 7i77

Right so that is setup for 3600 RPM at 10V

so is you do a M3 S1800 you should get 5V out of AOUT5

so is you do a M3 S1800 you should get 5V out of AOUT5

The following user(s) said Thank You: Catch22

Please Log in or Create an account to join the conversation.

18 Apr 2020 23:44 - 18 Apr 2020 23:58 #164542

by Catch22

Ok so I did what you said and got 4v at 1800 and 1v at 900 but the spindle speed doesn't change, it was running at full rpm.

The multimeter I'm using isn't really good and I think the batteries might be getting low so that could factor in on the volts being a bit off.

Replied by Catch22 on topic Teco FM50 and Mesa 7i77

Right so that is setup for 3600 RPM at 10V

so is you do a M3 S1800 you should get 5V out of AOUT5

Ok so I did what you said and got 4v at 1800 and 1v at 900 but the spindle speed doesn't change, it was running at full rpm.

The multimeter I'm using isn't really good and I think the batteries might be getting low so that could factor in on the volts being a bit off.

Last edit: 18 Apr 2020 23:58 by Catch22.

Please Log in or Create an account to join the conversation.

19 Apr 2020 01:23 #164558

by PCW

Replied by PCW on topic Teco FM50 and Mesa 7i77

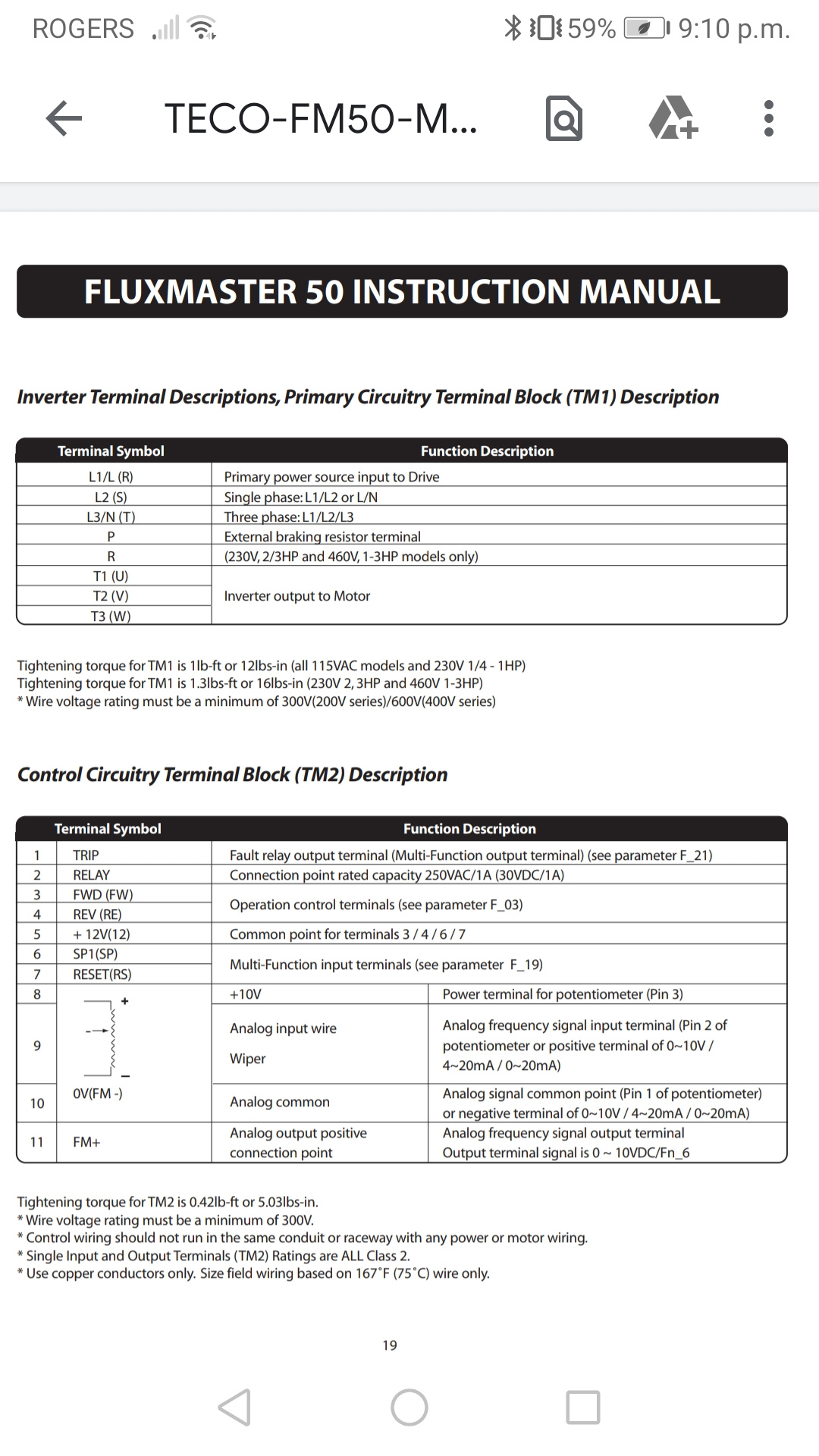

It sounds like the drive is not listening to the analog input.

That's likely a drive a setup issue

That's likely a drive a setup issue

The following user(s) said Thank You: Catch22

Please Log in or Create an account to join the conversation.

19 Apr 2020 01:52 #164563

by Catch22

Ok thanks, I will go through the parameters again and see if I missed something.

Replied by Catch22 on topic Teco FM50 and Mesa 7i77

It sounds like the drive is not listening to the analog input.

That's likely a drive a setup issue

Ok thanks, I will go through the parameters again and see if I missed something.

Please Log in or Create an account to join the conversation.

19 Apr 2020 02:17 #164567

by Catch22

That's what it was, had to change one parameter and it's working.

But reverse still don't work, is this something that has to be added to the HAL file or possibly the INI file?

Replied by Catch22 on topic Teco FM50 and Mesa 7i77

It sounds like the drive is not listening to the analog input.

That's likely a drive a setup issue

Ok thanks, I will go through the parameters again and see if I missed something.

That's what it was, had to change one parameter and it's working.

But reverse still don't work, is this something that has to be added to the HAL file or possibly the INI file?

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.401 seconds