Search Results (Searched for: raspberry)

16 Jul 2023 15:44

Replied by andypugh on topic RPI4b Revision 7 not supported by HAL_PI_GIO

RPI4b Revision 7 not supported by HAL_PI_GIO

Category: HAL

16 Jul 2023 15:39

Replied by elovalvo on topic RPI4 Raspbian 64 bit & LinuxCNC

RPI4 Raspbian 64 bit & LinuxCNC

Category: Installing LinuxCNC

16 Jul 2023 15:17

Replied by elovalvo on topic RPI4b Revision 7 not supported by HAL_PI_GIO

RPI4b Revision 7 not supported by HAL_PI_GIO

Category: HAL

15 Jul 2023 11:11

Replied by Stef on topic RPI4 Raspbian 64 bit & LinuxCNC

RPI4 Raspbian 64 bit & LinuxCNC

Category: Installing LinuxCNC

14 Jul 2023 08:29 - 14 Jul 2023 08:32

First sparks - Thanks everyone! was created by alangibson

First sparks - Thanks everyone!

Category: Plasma & Laser

12 Jul 2023 15:24

RPI4b Revision 7 not supported by HAL_PI_GIO was created by itsme

RPI4b Revision 7 not supported by HAL_PI_GIO

Category: HAL

03 Jul 2023 14:25

29 Jun 2023 00:54

28 Jun 2023 09:52

Raspberry Pi 4 model B 4Gb RAM now available was created by emcPT

Raspberry Pi 4 model B 4Gb RAM now available

Category: User Exchange

27 Jun 2023 18:52

18 Jun 2023 12:53

Replied by tommylight on topic Installing LinuxCNC 2.9 or Master on Linux Mint 21

Installing LinuxCNC 2.9 or Master on Linux Mint 21

Category: Installing LinuxCNC

17 Jun 2023 22:00

Replied by tommylight on topic Keeping Linuxcnc 2.9 current on Debian Bookworm

Keeping Linuxcnc 2.9 current on Debian Bookworm

Category: Installing LinuxCNC

15 Jun 2023 16:25

Replied by Donno on topic Schematics for 7c81

Schematics for 7c81

Category: General LinuxCNC Questions

13 Jun 2023 17:11

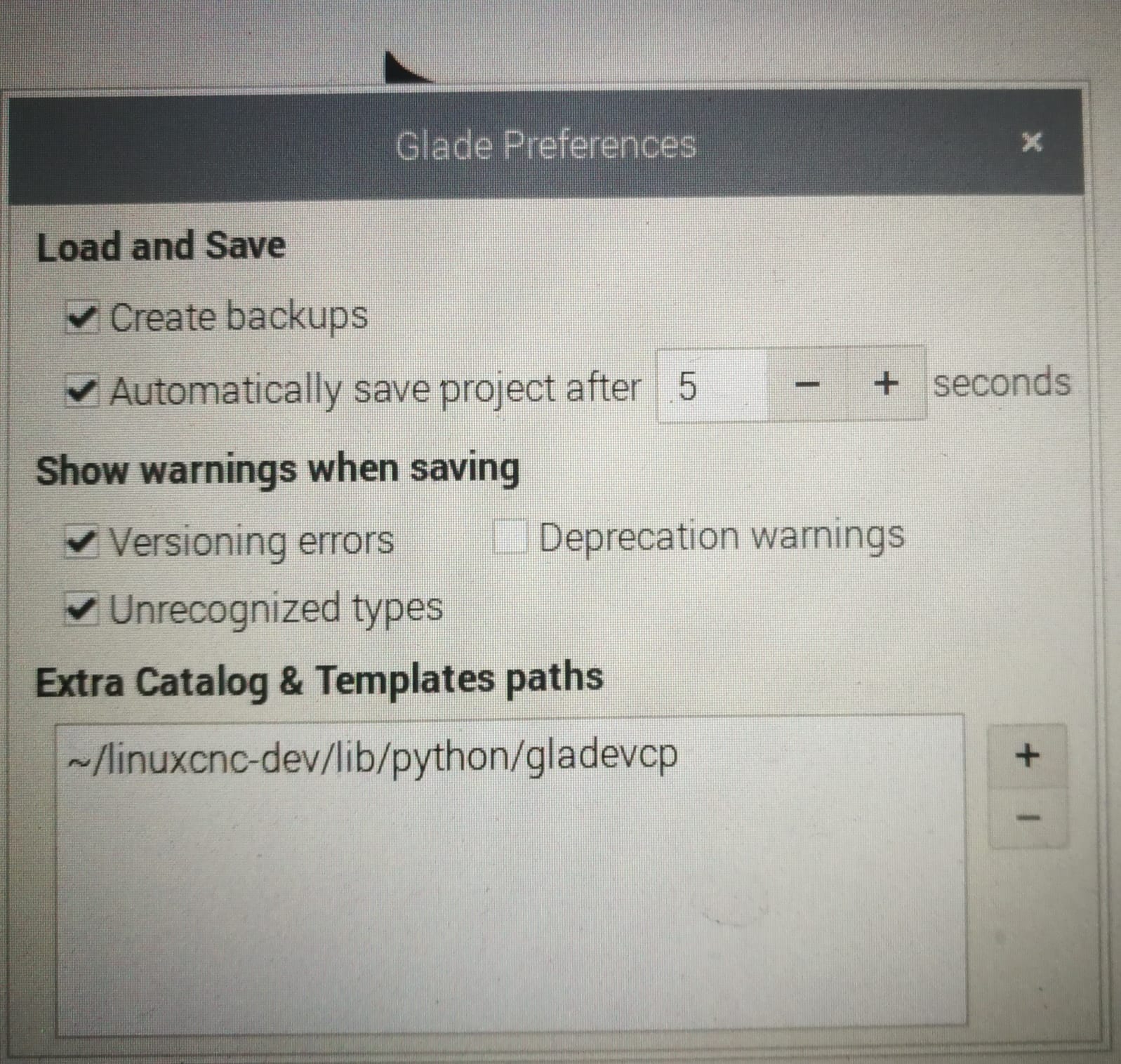

Replied by COFHAL on topic Install GladeVCP on Raspberry Pi 4

Install GladeVCP on Raspberry Pi 4

Category: GladeVCP

13 Jun 2023 11:26

Replied by rft on topic Homebrew Sinker EDM with 3 axis control

Homebrew Sinker EDM with 3 axis control

Category: Milling Machines

Time to create page: 1.993 seconds