Can't set MIN_FERROR less than 0.5mm..

- machete

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 0

27 Sep 2013 19:24 #39264

by machete

Can't set MIN_FERROR less than 0.5mm.. was created by machete

I'm trying to tune PID for my servos (mill 1.5 tones).

And I have noticed that following error on graph is near zero only then it's mooving, after that it became ±0.1mm of desired position.

For example, when i perform in MDI-mode: G0 Y215, when it stops, i will have real value 215.075.

Maybe it's ok, when axis is not in use??

But! I always have FOLLOWING ERROR when jogging, if MIN_FERROR in my .ini file is less 0.5mm!

I have encoders with 2000 impulses on 1mm, so i expected to have teoretical accuracy ~0.005mm or less on my servos....

What am I doing wrong?

And I have noticed that following error on graph is near zero only then it's mooving, after that it became ±0.1mm of desired position.

For example, when i perform in MDI-mode: G0 Y215, when it stops, i will have real value 215.075.

Maybe it's ok, when axis is not in use??

But! I always have FOLLOWING ERROR when jogging, if MIN_FERROR in my .ini file is less 0.5mm!

I have encoders with 2000 impulses on 1mm, so i expected to have teoretical accuracy ~0.005mm or less on my servos....

What am I doing wrong?

[AXIS_2]

TYPE = LINEAR

HOME = 200

FERROR = 1

MIN_FERROR = 0.5

MAX_VELOCITY = 80

MAX_ACCELERATION = 100

P = 1

I = 0

D = 0

FF0 = 0

FF1 = 0.0117

FF2 = 0.00058

BIAS = 0

DEADBAND = 0.001

OUTPUT_SCALE = -1

OUTPUT_OFFSET = 0.0

MAX_OUTPUT = 10

INPUT_SCALE = 2000Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 18843

- Thank you received: 5203

27 Sep 2013 21:18 #39267

by PCW

Replied by PCW on topic Can't set MIN_FERROR less than 0.5mm..

What type of drives (velocity or torque mode)?

This makes a big difference in tuning

This makes a big difference in tuning

Please Log in or Create an account to join the conversation.

- machete

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 0

28 Sep 2013 04:29 #39292

by machete

I use direct current motors 550W 6.5Nm powered by Mesa 7i29 supplied from power transformer with rectifier.

Feedback from quadrature encoders 2500p/rev attached directly on drives.

As i understand, it is torque mode?

Replied by machete on topic Can't set MIN_FERROR less than 0.5mm..

What type of drives (velocity or torque mode)?

This makes a big difference in tuning

I use direct current motors 550W 6.5Nm powered by Mesa 7i29 supplied from power transformer with rectifier.

Feedback from quadrature encoders 2500p/rev attached directly on drives.

As i understand, it is torque mode?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 18843

- Thank you received: 5203

28 Sep 2013 06:12 #39297

by PCW

Replied by PCW on topic Can't set MIN_FERROR less than 0.5mm..

A bare HBridge(like the 7I29) is somewhere between a torque and

velocity mode drive.

One thing that's clearly missing is any D term.

I would add as much D term as you can (it will get "buzzy" with too much)

Having sufficient D term should allow you to increase the P term

and improve your following error.

FF1 should be then adjusted for minimum error during medium speed cruise

When tuning is very close, you can add some I term to null out any static error

note that you must zero the I term when tuning the previous terms as its effects will

mask the effects of adjusting the other terms.

velocity mode drive.

One thing that's clearly missing is any D term.

I would add as much D term as you can (it will get "buzzy" with too much)

Having sufficient D term should allow you to increase the P term

and improve your following error.

FF1 should be then adjusted for minimum error during medium speed cruise

When tuning is very close, you can add some I term to null out any static error

note that you must zero the I term when tuning the previous terms as its effects will

mask the effects of adjusting the other terms.

Please Log in or Create an account to join the conversation.

- machete

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 0

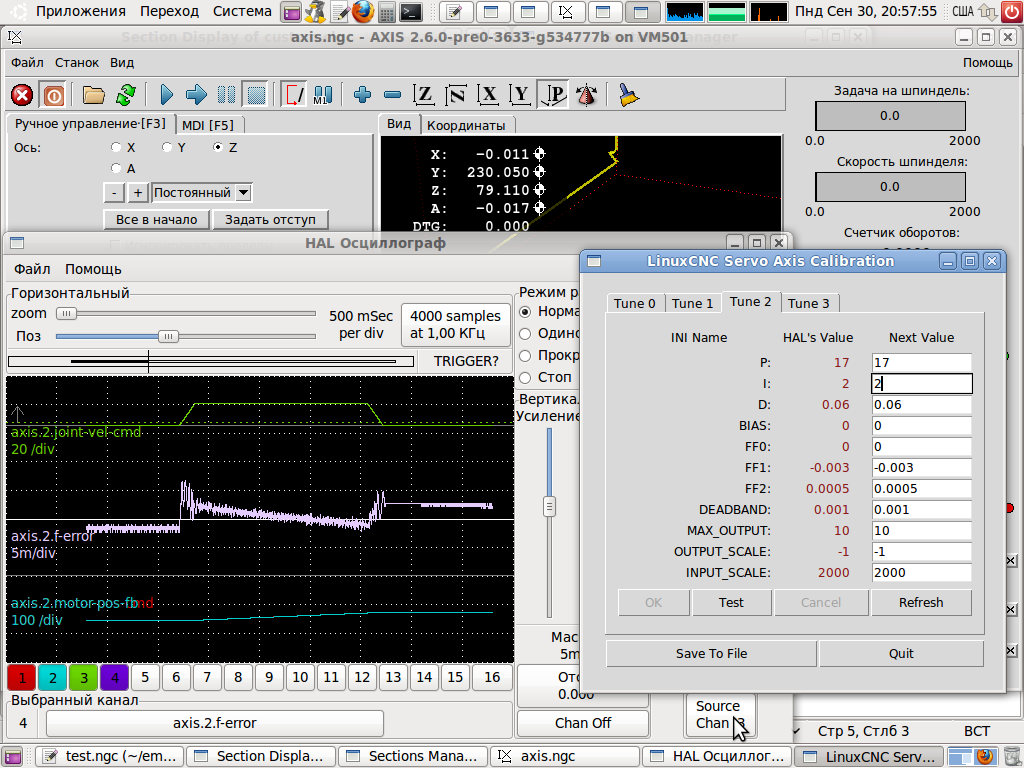

29 Sep 2013 06:21 #39338

by machete

Replied by machete on topic Can't set MIN_FERROR less than 0.5mm..

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 18843

- Thank you received: 5203

29 Sep 2013 10:02 #39339

by PCW

Replied by PCW on topic Can't set MIN_FERROR less than 0.5mm..

If you have oscillations you may need to decrease P/D a bit

I would increase the I term until you can see it pull in the

static error in a small fraction of a second

You seen to be within about +-10 U which is not bad

but more integral term should help with the static error

Consider that your static error (~5u) is about 1/200 of full output scale.

This error is multiplied by your I term of .001 and summed every servo thread

(asumming 1 KHz) If the error did not change, it would take 200 seconds

for the 5u error to add up to full output drive. So you need quite a bit more

I term for the integral term to be more responsive.

I would increase the I term until you can see it pull in the

static error in a small fraction of a second

You seen to be within about +-10 U which is not bad

but more integral term should help with the static error

Consider that your static error (~5u) is about 1/200 of full output scale.

This error is multiplied by your I term of .001 and summed every servo thread

(asumming 1 KHz) If the error did not change, it would take 200 seconds

for the 5u error to add up to full output drive. So you need quite a bit more

I term for the integral term to be more responsive.

Please Log in or Create an account to join the conversation.

- machete

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 0

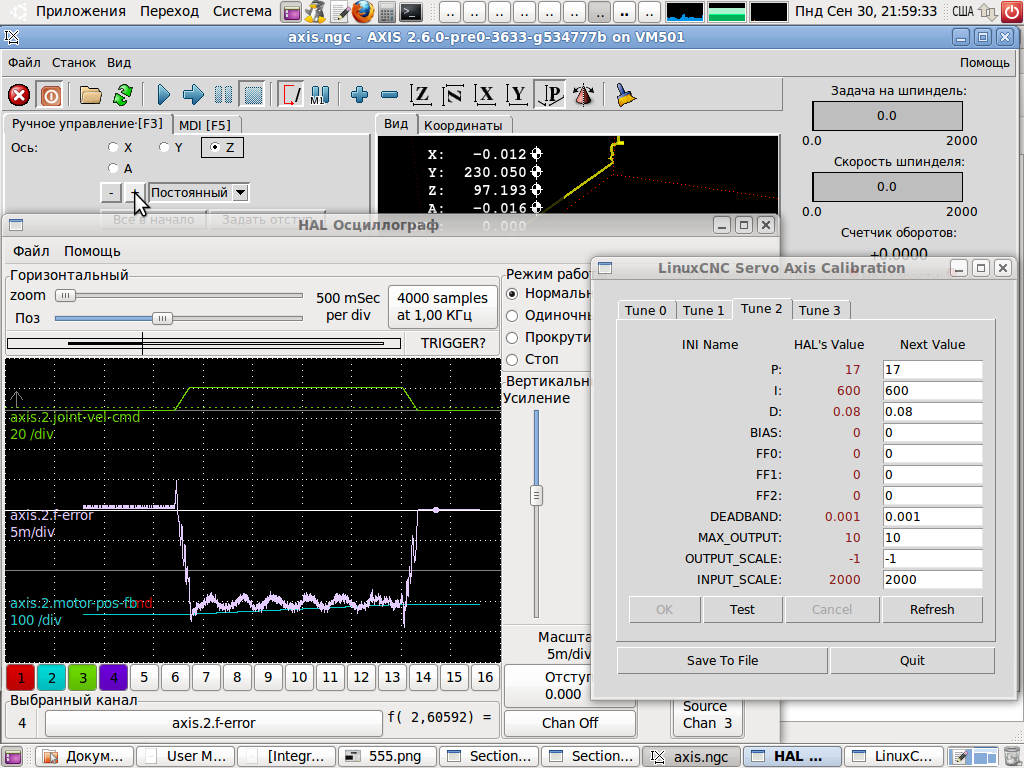

01 Oct 2013 02:24 - 01 Oct 2013 02:29 #39419

by machete

Replied by machete on topic Can't set MIN_FERROR less than 0.5mm..

I have tested different I terms - from 0.4 up to 600(!):

But any way one of 3-5 moves i have oscilation: sound and small vibration of motor body.

And.. sorry: i should tell you that my motor is connected through a gear (but the encoder is attached directly to the motor shaft!):

I was thinking it is only important to the final axis accuracy (not for motor).

I'm stuck...

But any way one of 3-5 moves i have oscilation: sound and small vibration of motor body.

And.. sorry: i should tell you that my motor is connected through a gear (but the encoder is attached directly to the motor shaft!):

I was thinking it is only important to the final axis accuracy (not for motor).

I'm stuck...

Last edit: 01 Oct 2013 02:29 by machete.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 18843

- Thank you received: 5203

01 Oct 2013 02:49 #39420

by PCW

Replied by PCW on topic Can't set MIN_FERROR less than 0.5mm..

OK Notice how the I term of 600 has eliminated the static error?

thats mainly what its for... (even 600 may be too low, too much will result is large slow oscillations)

When any significant I term is used, you may have to set the

pid.N.error-previous-target bit true on the PID loop to avoid

getting the velocity dependent error that you see in the last plot

If you cannot reduce your following error any further with tuning, you might

try speeding up the servo thread a bit (to 2 KHZ or even 4 KHz if your system can manage it)

If your gears have any significant backlash this may cause some tuning difficulties

(Since motors intertial load may change suddenly)

thats mainly what its for... (even 600 may be too low, too much will result is large slow oscillations)

When any significant I term is used, you may have to set the

pid.N.error-previous-target bit true on the PID loop to avoid

getting the velocity dependent error that you see in the last plot

If you cannot reduce your following error any further with tuning, you might

try speeding up the servo thread a bit (to 2 KHZ or even 4 KHz if your system can manage it)

If your gears have any significant backlash this may cause some tuning difficulties

(Since motors intertial load may change suddenly)

Please Log in or Create an account to join the conversation.

- machete

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 0

01 Oct 2013 05:41 #39424

by machete

Replied by machete on topic Can't set MIN_FERROR less than 0.5mm..

Actually i almost satisfied with my following error, even from first picture (sure, i'll try to make it even lower).

Thing that i don't know how to deal with, is oscillation in static. Do you mean, I term higher than 600 can help me with that?

I don't think so, especially when axis in static.

Thing that i don't know how to deal with, is oscillation in static. Do you mean, I term higher than 600 can help me with that?

If your gears have any significant backlash this may cause some tuning difficulties

(Since motors intertial load may change suddenly)

I don't think so, especially when axis in static.

Please Log in or Create an account to join the conversation.

- machete

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 0

02 Oct 2013 00:11 - 02 Oct 2013 00:25 #39457

by machete

Replied by machete on topic Can't set MIN_FERROR less than 0.5mm..

I'm trying to activate this setting in my .hal-file: setp pid.2.error-previous-target true

But it's says: "parameter or pin 'pid.2.error-previous-target' not found"

My version is: 2.6.0-pre0-3633-g534777b

As i understand, this feature enabled in version 2.5.2, how can i mix it with my 2.6.0??

(i use 2.6.0 to be able remap M6 for my toolchange NGC program - is it possible in 2.5.2? Maybe i should just setup 2.5.2 on my machine?)

But it's says: "parameter or pin 'pid.2.error-previous-target' not found"

My version is: 2.6.0-pre0-3633-g534777b

As i understand, this feature enabled in version 2.5.2, how can i mix it with my 2.6.0??

(i use 2.6.0 to be able remap M6 for my toolchange NGC program - is it possible in 2.5.2? Maybe i should just setup 2.5.2 on my machine?)

Last edit: 02 Oct 2013 00:25 by machete.

Please Log in or Create an account to join the conversation.

Time to create page: 0.748 seconds