PID tuning of Rexroth Ecodrive

- hardware_crash

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 80

- Thank you received: 1

04 Nov 2014 21:41 - 04 Nov 2014 21:52 #52768

by hardware_crash

PID tuning of Rexroth Ecodrive was created by hardware_crash

He guys,

I have set up my cnc machine with Rexroth Indramat Ecodrive units with +/-10 V inputs.

I have connected the drives with a shielded cable to the 7i33TA which is mounted in an aluminum case .

The shielding of the cable is connected one time with the aluminum case which is connected to ground and on the other side its connected with the drive case which is also connected to ground.

The Ecodrive unit is an closed loop drive by itself with an emulated encoder output which Im using to get the encoder position back to linuxcnc. I set the encoder count per turn output of the Ecodrive to 6000 lines per turn as its possible to use any value for the encoder emulation output.

Now im planing on how to get these drives to work fine for me .

I tried to use the drives in velocity mode but with bad results as i think.

My settings are:

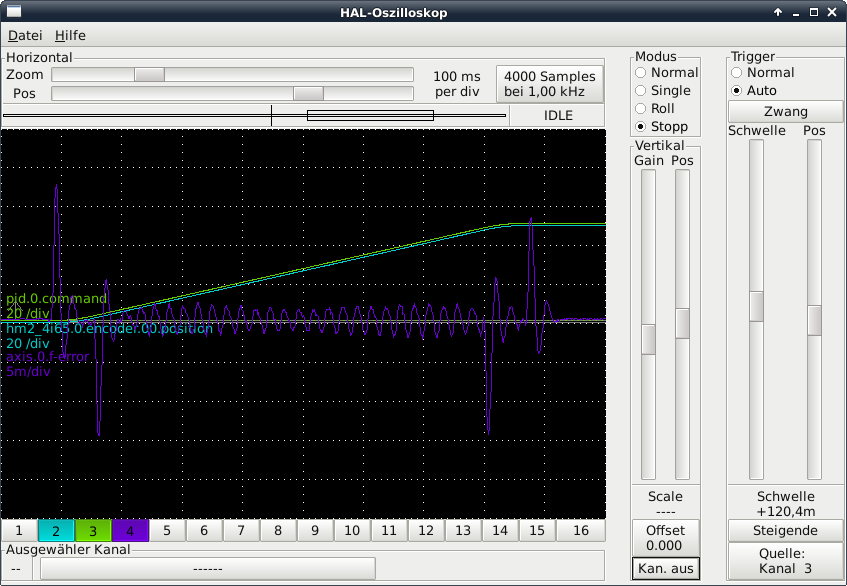

but i cant decrease the following error of this axis any better :

I made a run from 0 to 50mm with the max velocity of 4000mm/min

I think that the error is too large at the start and end of the motion but FF2 does not affect the hight of the spikes showing in the picture... theres also a ripple on the ferror line with a hight of 0,5m the whole time the motor is at position

What other way can I ty to make this dives work fine ? torque mode ?

The ecodrives can handle different input modes as velocity , torque and positioning control

Should i try to set the drive to torque mode ??

I have set up my cnc machine with Rexroth Indramat Ecodrive units with +/-10 V inputs.

I have connected the drives with a shielded cable to the 7i33TA which is mounted in an aluminum case .

The shielding of the cable is connected one time with the aluminum case which is connected to ground and on the other side its connected with the drive case which is also connected to ground.

The Ecodrive unit is an closed loop drive by itself with an emulated encoder output which Im using to get the encoder position back to linuxcnc. I set the encoder count per turn output of the Ecodrive to 6000 lines per turn as its possible to use any value for the encoder emulation output.

Now im planing on how to get these drives to work fine for me .

I tried to use the drives in velocity mode but with bad results as i think.

My settings are:

# PID tuning params

DEADBAND = 0.000088

P = 10

I = 0

D = 1e-05

FF0 = 0

FF1 = 0.061

FF2 = 0.00022

BIAS = 0but i cant decrease the following error of this axis any better :

I made a run from 0 to 50mm with the max velocity of 4000mm/min

I think that the error is too large at the start and end of the motion but FF2 does not affect the hight of the spikes showing in the picture... theres also a ripple on the ferror line with a hight of 0,5m the whole time the motor is at position

What other way can I ty to make this dives work fine ? torque mode ?

The ecodrives can handle different input modes as velocity , torque and positioning control

Should i try to set the drive to torque mode ??

Last edit: 04 Nov 2014 21:52 by hardware_crash.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

04 Nov 2014 22:35 #52769

by BigJohnT

Replied by BigJohnT on topic PID tuning of Rexroth Ecodrive

If I understand you correctly you have the shield conneced at both ends! This creates a current loop and will drive your signals nuts. Shielding is grounded ONLY at one end to make a drain and not a loop.

JT

JT

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 18958

- Thank you received: 5236

04 Nov 2014 22:49 #52770

by PCW

Replied by PCW on topic PID tuning of Rexroth Ecodrive

Velocity mode should be easier to tune than torque mode

Is the velocity loop of the drive tuned? Thats the first step...

Also any velocity command input filtering should be turned off

Is the velocity loop of the drive tuned? Thats the first step...

Also any velocity command input filtering should be turned off

Please Log in or Create an account to join the conversation.

- hardware_crash

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 80

- Thank you received: 1

05 Nov 2014 00:20 #52774

by hardware_crash

Replied by hardware_crash on topic PID tuning of Rexroth Ecodrive

@BigJohnT

Okay i also tried with shlieding on just one side but that didnt change anything ...

@PCW

The velocity lopp of the drive should be okay as the Ecodrive seem to use their own parameters for each fitting motor ..

Okay i also tried with shlieding on just one side but that didnt change anything ...

@PCW

The velocity lopp of the drive should be okay as the Ecodrive seem to use their own parameters for each fitting motor ..

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 18958

- Thank you received: 5236

05 Nov 2014 00:39 - 05 Nov 2014 00:40 #52775

by PCW

Replied by PCW on topic PID tuning of Rexroth Ecodrive

Velocity loop tuning is load dependent so you must tune the drives velocity loop

(with final mechanics)

(with final mechanics)

Last edit: 05 Nov 2014 00:40 by PCW.

Please Log in or Create an account to join the conversation.

- hardware_crash

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 80

- Thank you received: 1

05 Nov 2014 02:27 #52783

by hardware_crash

Replied by hardware_crash on topic PID tuning of Rexroth Ecodrive

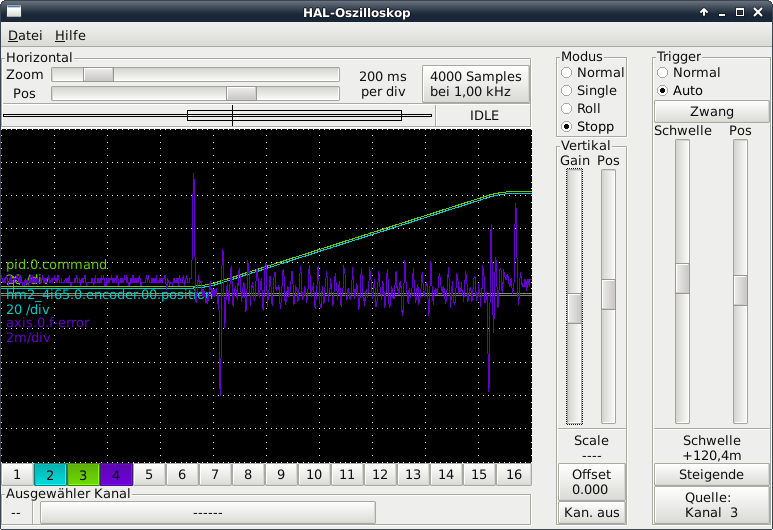

So I tried optimizing the pid loop fo a fw hous now and cant gt better results than this :

When the motor isnt in motion theres always an ferror of about 1m visible on the scope does anybody have an idea where this can come from?

The spikes while de/acceleration also dont change with my modifikations

When the motor isnt in motion theres always an ferror of about 1m visible on the scope does anybody have an idea where this can come from?

The spikes while de/acceleration also dont change with my modifikations

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

05 Nov 2014 06:38 #52787

by BigJohnT

Replied by BigJohnT on topic PID tuning of Rexroth Ecodrive

Are you using a method to tune the PID or just guessing?

gnipsel.com/linuxcnc/tuning/servo.html

Make sure ALL of your shields are only grounded on one end.

JT

gnipsel.com/linuxcnc/tuning/servo.html

Make sure ALL of your shields are only grounded on one end.

JT

Please Log in or Create an account to join the conversation.

- DaBit

- Offline

- Platinum Member

-

Less

More

- Posts: 446

- Thank you received: 35

05 Nov 2014 06:52 - 05 Nov 2014 07:15 #52788

by DaBit

Replied by DaBit on topic PID tuning of Rexroth Ecodrive

Is that following error in millimeters? So that's 2 milli-millimeters or 2 microns per division. And a micron really is not much at all.

That is not bad, or is it?

A couple of spikes at the beginning and ending of the move don't surprise me either; the LinuxCNC trajectory generator does infinite jerk (jerk=derivative of acceleration). Real motors do not do infinite jerk, the connected mechanics are not infinitely stiff and the drive electronics are not infinitely fast.

Your Igain seems to be zero, so that might explain the residual following error. If the ferror stays at 1 micron at rest I would not care too much about adding Igain.

That is not bad, or is it?

A couple of spikes at the beginning and ending of the move don't surprise me either; the LinuxCNC trajectory generator does infinite jerk (jerk=derivative of acceleration). Real motors do not do infinite jerk, the connected mechanics are not infinitely stiff and the drive electronics are not infinitely fast.

Your Igain seems to be zero, so that might explain the residual following error. If the ferror stays at 1 micron at rest I would not care too much about adding Igain.

Last edit: 05 Nov 2014 07:15 by DaBit.

Please Log in or Create an account to join the conversation.

- hardware_crash

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 80

- Thank you received: 1

05 Nov 2014 21:30 - 05 Nov 2014 21:32 #52817

by hardware_crash

Replied by hardware_crash on topic PID tuning of Rexroth Ecodrive

Dear DaBit,

I now added some I gain and the ferror while motor stands still is now significant better

I have now a ferror while no motion of about 200μ which I think is aceptable ?!

But the spikes at de/acceleration wont get any smaller

My actual settings are:

Will it be better to set a higher Encoder rate on the Ecorive unit ? Actually I set it to 6000 lines per turn ..

I also set the drive to 4000 rpm per 10V input signal... its possible to set this value to max 8000 rpm per 10V

Is this a point where I can optimize things ?

I now added some I gain and the ferror while motor stands still is now significant better

I have now a ferror while no motion of about 200μ which I think is aceptable ?!

But the spikes at de/acceleration wont get any smaller

My actual settings are:

DEADBAND = 0.000025

P = 5

I = 10

D = 0.005

FF0 = 0

FF1 = 0.03055

FF2 = 6e-05

BIAS = 0Will it be better to set a higher Encoder rate on the Ecorive unit ? Actually I set it to 6000 lines per turn ..

I also set the drive to 4000 rpm per 10V input signal... its possible to set this value to max 8000 rpm per 10V

Is this a point where I can optimize things ?

Last edit: 05 Nov 2014 21:32 by hardware_crash.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

05 Nov 2014 22:25 #52819

by BigJohnT

Replied by BigJohnT on topic PID tuning of Rexroth Ecodrive

If you look at the link I posted you will see that I and D are usually not needed for a velocity servo.

JT

JT

Please Log in or Create an account to join the conversation.

Time to create page: 0.303 seconds