Fanuc-Style Toolchange

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4616

- Thank you received: 2043

22 Sep 2024 13:30 - 22 Sep 2024 13:33 #310599

by Aciera

Replied by Aciera on topic Fanuc-Style Toolchange

1. regarding documentation:

linuxcnc.org/docs/devel/html/remap/remap.html

2. I'm afraid that error message is somewhat out if my depth.

3. Question: Before we started modifying 'index_lathe_tool_with_wear' did the adding of wear tool offsets work for you but just the physical toolchange on the lathe did not work?

4. I've had a play around with 'index_lathe_tool_with_wear ' as remap for T on my simulation PC and I've noticed that the wear offset would only be added to the tool offset for a moment and then revert back to the pure tool offset. Do you get this as well?

linuxcnc.org/docs/devel/html/remap/remap.html

2. I'm afraid that error message is somewhat out if my depth.

3. Question: Before we started modifying 'index_lathe_tool_with_wear' did the adding of wear tool offsets work for you but just the physical toolchange on the lathe did not work?

4. I've had a play around with 'index_lathe_tool_with_wear ' as remap for T on my simulation PC and I've noticed that the wear offset would only be added to the tool offset for a moment and then revert back to the pure tool offset. Do you get this as well?

Attachments:

Last edit: 22 Sep 2024 13:33 by Aciera.

Please Log in or Create an account to join the conversation.

- Jakemestre1

-

- Offline

- Junior Member

-

Less

More

- Posts: 25

- Thank you received: 4

27 Sep 2024 17:04 #310907

by Jakemestre1

Replied by Jakemestre1 on topic Fanuc-Style Toolchange

I Solved it! Holy cow! it was crazy simple. So here's the lowdown of what needed to happen. The ngc in the remap had to be lowercase. That's it. I had no idea that you couldn't use an upper case ngc name when remapping. Is this a bug or it's supposed to be that way? Goodness that would have saved me about a year of challenge.

I believe Andy has a more elegant solution using pure python as: index_lathe_tool_with_wear but I can't write in python so I was in too deep.

So here's my road to success with T. Paths and directories are very important and you need to pay attention to where your python and subroutine code lives (mine is home/jake/linuxcnc/python, and ./) respectively.

Since I had already put together a M6 remap it got pretty tricky with what to do. I kept thinking that remapping with the fanucy lathe example was creating a circular loop but it wasn't.

My turret has a closed loop stepper with fault output an air cylinder to lock/unlock the turret, an index, and a inductive sensor to see if the hirth joint is locked. With that my m6 remap ngc just goes through and rotates the stepper motor as joint 2/axis A and I scaled everything so that one tool pocket is equal to one unit on A. ex: T0=A0 T1=A1.0 T4=A4.0 It has an exit if the stepper is faulted for whatever reason, or the turret hirth fails to lock. The downside to using this method and not a carosel component is that g30 causes the A axis to want to go home so use G28 instead. In the end I leave the remapped M6 alone.

Next up was making sure the remap.py in the python directory had the remap.py with has an added"get_t_number" from the fanucy_lathe example config.

Also make sure you've got stdglue.py and toplevel.py in that same directory.

Modify your ini file to remap T using the prolog=get_t_number and then this is where I made the fatal mistake I named an ngc Ttotool.ngc

(I always got this weird error "file not open" with that name) the name ended up ttotool.ngc and it worked perfectly.

Next make sure you copy the toolchange.ngc that's called out in the lathe_fanucy example remap T but rename it with the exact subroutine you plan on having in your subroutine directory. MAKE SURE IT IS ALL LOWERCASE.

Remapped T should theoretically work after you complete these steps. If you get issues with python crashes, just go through the remap linuxcnc.org/docs/devel/html/remap/remap.html and reimport the python directories and try again editinging with the lathe_fanucy python changes.

Good luck.

I believe Andy has a more elegant solution using pure python as: index_lathe_tool_with_wear but I can't write in python so I was in too deep.

So here's my road to success with T. Paths and directories are very important and you need to pay attention to where your python and subroutine code lives (mine is home/jake/linuxcnc/python, and ./) respectively.

Since I had already put together a M6 remap it got pretty tricky with what to do. I kept thinking that remapping with the fanucy lathe example was creating a circular loop but it wasn't.

My turret has a closed loop stepper with fault output an air cylinder to lock/unlock the turret, an index, and a inductive sensor to see if the hirth joint is locked. With that my m6 remap ngc just goes through and rotates the stepper motor as joint 2/axis A and I scaled everything so that one tool pocket is equal to one unit on A. ex: T0=A0 T1=A1.0 T4=A4.0 It has an exit if the stepper is faulted for whatever reason, or the turret hirth fails to lock. The downside to using this method and not a carosel component is that g30 causes the A axis to want to go home so use G28 instead. In the end I leave the remapped M6 alone.

Next up was making sure the remap.py in the python directory had the remap.py with has an added"get_t_number" from the fanucy_lathe example config.

Also make sure you've got stdglue.py and toplevel.py in that same directory.

Modify your ini file to remap T using the prolog=get_t_number and then this is where I made the fatal mistake I named an ngc Ttotool.ngc

(I always got this weird error "file not open" with that name) the name ended up ttotool.ngc and it worked perfectly.

Next make sure you copy the toolchange.ngc that's called out in the lathe_fanucy example remap T but rename it with the exact subroutine you plan on having in your subroutine directory. MAKE SURE IT IS ALL LOWERCASE.

Remapped T should theoretically work after you complete these steps. If you get issues with python crashes, just go through the remap linuxcnc.org/docs/devel/html/remap/remap.html and reimport the python directories and try again editinging with the lathe_fanucy python changes.

Good luck.

The following user(s) said Thank You: Aciera

Please Log in or Create an account to join the conversation.

- endian

-

- Offline

- Elite Member

-

Less

More

- Posts: 252

- Thank you received: 74

20 Jun 2025 08:06 #330556

by endian

Replied by endian on topic Fanuc-Style Toolchange

Hello gentelmen,

how is it with the manual tool change...

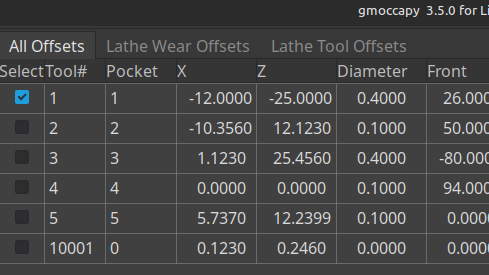

I have sometime issue with precision after tool change +-0.01mm with OWT grinded tool post fixtures with manual toolchange .hal stuff.. I noticed that in the default tool table for lathe is not the waer offsets .. I can switch on them by

where I can define them for the each tool separately

And then add the the remapping ?

Then I will need to change T1 G43 to T01XX in the postprocessor I think ..

Thanks,

Regards

how is it with the manual tool change...

I have sometime issue with precision after tool change +-0.01mm with OWT grinded tool post fixtures with manual toolchange .hal stuff.. I noticed that in the default tool table for lathe is not the waer offsets .. I can switch on them by

LATHE_WEAR_OFFSETS = 1where I can define them for the each tool separately

And then add the the remapping ?

Then I will need to change T1 G43 to T01XX in the postprocessor I think ..

Thanks,

Regards

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4616

- Thank you received: 2043

20 Jun 2025 11:49 #330568

by Aciera

Replied by Aciera on topic Fanuc-Style Toolchange

Attachments:

The following user(s) said Thank You: endian

Please Log in or Create an account to join the conversation.

- endian

-

- Offline

- Elite Member

-

Less

More

- Posts: 252

- Thank you received: 74

23 Jun 2025 11:56 #330753

by endian

Replied by endian on topic Fanuc-Style Toolchange

okay thanks ...

If I want to fanuc style tool offsets .. I will do remapchange tool tablethen allow the wear offsets

all other files have to be in the same folder too?

I want to move from 2.8.4 to 2.9.4 and I am searching for updates which should improve my life

thanks

If I want to fanuc style tool offsets .. I will do remap

[RS274NGC]

SUBROUTINE_PATH = ./:../

REMAP = T prolog=get_T_number ngc=toolchange

PARAMETER_FILE = sim-lathe.var

[EMCIO]

TOOL_TABLE = lathe-fanucy.tbl# for details see nc_files/subroutines/maco_instructions.txt

[DISPLAY]

LATHE = 1

BACK_TOOL_LATHE = 0

LATHE_WEAR_OFFSETS = TRUEall other files have to be in the same folder too?

I want to move from 2.8.4 to 2.9.4 and I am searching for updates which should improve my life

thanks

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4616

- Thank you received: 2043

23 Jun 2025 12:55 #330757

by Aciera

Replied by Aciera on topic Fanuc-Style Toolchange

usually you would have the files in your config folder but the main thing is that they can be found where the file paths in the ini file point to, so don't forget to add the [PYTHON] section and contents to your ini file and set the appropriate paths.

See the sim configs for how to set things up.

See the sim configs for how to set things up.

The following user(s) said Thank You: endian

Please Log in or Create an account to join the conversation.

Time to create page: 0.083 seconds