coaxial axes / offset comp how to

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19793

- Thank you received: 4605

12 Dec 2015 16:06 #66874

by andypugh

Replied by andypugh on topic coaxial axes

I still don't know what you are trying to do.

Is the situation that you have two 180 degree actuators and want 360 degrees of motion, or is it something more complex than that?

You could consider simply setting the encoder scale so that the PID components think that each axis has moved twice as far as it actually has. Then have two PID, both connected to the A-axis position command.

Is the situation that you have two 180 degree actuators and want 360 degrees of motion, or is it something more complex than that?

You could consider simply setting the encoder scale so that the PID components think that each axis has moved twice as far as it actually has. Then have two PID, both connected to the A-axis position command.

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1111

- Thank you received: 114

12 Dec 2015 19:30 - 12 Dec 2015 19:38 #66884

by bkt

Replied by bkt on topic coaxial axes

the offset comp is +/- as i need... i think possible to do that in hal usig sum+gain(-1) .... but simply i have not clear the relationship of the signal (encoder-pos, encder.veocity, joint-cmp-pos, oint.os-fb,pid ec etc...) ....

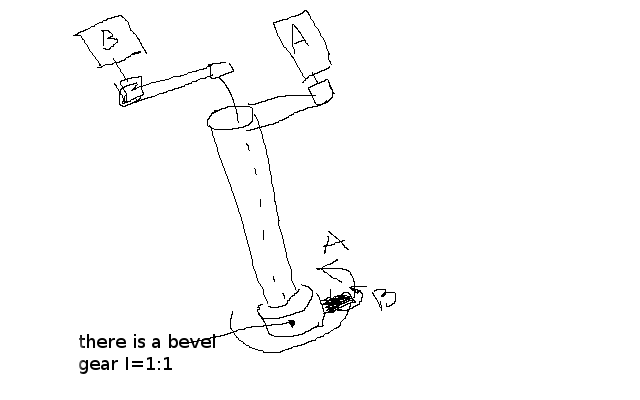

The mechanical .... 2 shaft, every one is an axes. one rotate the end effector 360° around x plave, the second one rotate the end effector of 180° around Z plane. The hollow shaft A axes is external shaft, the normal shaft and inside to A axes is B axes. when rotate A and B is stopped, the end effector rotare around X and Z plane too. To avoid this I must rotate both at the same speed and position. So B axes is stopped in relation to A axes.

A very bad draw (real sorry) of mechanical schemas ...note the pulley reduction and motor is the same for axes A and B.

The mechanical .... 2 shaft, every one is an axes. one rotate the end effector 360° around x plave, the second one rotate the end effector of 180° around Z plane. The hollow shaft A axes is external shaft, the normal shaft and inside to A axes is B axes. when rotate A and B is stopped, the end effector rotare around X and Z plane too. To avoid this I must rotate both at the same speed and position. So B axes is stopped in relation to A axes.

A very bad draw (real sorry) of mechanical schemas ...note the pulley reduction and motor is the same for axes A and B.

Last edit: 12 Dec 2015 19:38 by bkt.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19793

- Thank you received: 4605

12 Dec 2015 22:59 #66898

by andypugh

So, the A-position is an offset to the B-position.

A-motor-position-cmd -> pid.A.command and B.offset.offset

A-encoder -> pid.A.feedback and axis.A.feedback

B-motor-position -> B.offset -> B.pid

B-encoder -> B.pid and B.offset.feedback

B.offset.feedback -> axis.B.feedback

Replied by andypugh on topic coaxial axes

Even that picture is worth 1000 words.A very bad draw (real sorry) of mechanical schemas

So, the A-position is an offset to the B-position.

A-motor-position-cmd -> pid.A.command and B.offset.offset

A-encoder -> pid.A.feedback and axis.A.feedback

B-motor-position -> B.offset -> B.pid

B-encoder -> B.pid and B.offset.feedback

B.offset.feedback -> axis.B.feedback

The following user(s) said Thank You: bkt

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1111

- Thank you received: 114

13 Dec 2015 18:24 #66926

by bkt

thanks a lot .... this " code " I clarified many things ... thanks again

Regards

Giorgio

Replied by bkt on topic coaxial axes

A-motor-position-cmd -> pid.A.command and B.offset.offset

A-encoder -> pid.A.feedback and axis.A.feedback

B-motor-position -> B.offset -> B.pid

B-encoder -> B.pid and B.offset.feedback

B.offset.feedback -> axis.B.feedback

thanks a lot .... this " code " I clarified many things ... thanks again

Regards

Giorgio

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1111

- Thank you received: 114

10 Jan 2016 05:38 #68147

by bkt

Replied by bkt on topic coaxial axes

for anyone who had difficulty understanding offset.9 component and use with feedback signals and command, similar to what happened to me ...

The following user(s) said Thank You: Beezerlm

Please Log in or Create an account to join the conversation.

Time to create page: 0.075 seconds