how to synchronize two servomotors

- Jasper 3

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

15 Jun 2017 14:41 #94539

by Jasper 3

Replied by Jasper 3 on topic how to synchronize two servomotors

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4694

- Thank you received: 1439

15 Jun 2017 15:05 - 15 Jun 2017 15:09 #94542

by Todd Zuercher

Replied by Todd Zuercher on topic how to synchronize two servomotors

Did you change the pid.z.maxerror to zero?

or better yet just comment out this line in your hal file.Don't forget to do this for all of your PID loops.

There are times when having appropriately sized limits on the PID error can be useful, just that this isn't one of them. Nor is that an appropriately sized limit for your system.

or better yet just comment out this line in your hal file.

setp pid.z.maxerror .0005There are times when having appropriately sized limits on the PID error can be useful, just that this isn't one of them. Nor is that an appropriately sized limit for your system.

Last edit: 15 Jun 2017 15:09 by Todd Zuercher.

Please Log in or Create an account to join the conversation.

- Jasper 3

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

15 Jun 2017 15:56 #94544

by Jasper 3

Replied by Jasper 3 on topic how to synchronize two servomotors

outch! that hurts! thank you very much!

Please Log in or Create an account to join the conversation.

- Jasper 3

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

20 Jun 2017 15:59 #94729

by Jasper 3

Replied by Jasper 3 on topic how to synchronize two servomotors

hey,

i updated to Linuxcnc Master branch. I'm still trying to synchronize my Y-Axis servomotors. In my actual Hal I'm using the Tandemmode but as you already told me this is not the ideal solution.

So I think I need to set an extra Joint in my INI and Hal file for my Y-Axis?

I tryed to set my Inifile like in this link github.com/LinuxCNC/linuxcnc/blob/master.../sim/axis/gantry.ini

But where should I put the PID part? Also I'm not sure how to set up the Halfile.

here are my Hal and Ini files (using the Tandemmode)

here are my configfiles (using the link method)

thanks alot

i updated to Linuxcnc Master branch. I'm still trying to synchronize my Y-Axis servomotors. In my actual Hal I'm using the Tandemmode but as you already told me this is not the ideal solution.

So I think I need to set an extra Joint in my INI and Hal file for my Y-Axis?

I tryed to set my Inifile like in this link github.com/LinuxCNC/linuxcnc/blob/master.../sim/axis/gantry.ini

But where should I put the PID part? Also I'm not sure how to set up the Halfile.

here are my Hal and Ini files (using the Tandemmode)

here are my configfiles (using the link method)

thanks alot

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4694

- Thank you received: 1439

20 Jun 2017 17:28 #94736

by Todd Zuercher

Replied by Todd Zuercher on topic how to synchronize two servomotors

These are the first obvious problems I see in the INI file. (I haven't looked real close at the hal file yet.)

To start with in your ini fine I think [KINS] section needs changed to

Then In your joint sections, the joints that you have slaved together, need to have the HOME_SEQUENCE set to matching negative numbers. The negative is important, it indicates joints that are to home in a slaved fashion.

The joints are homed in the order specified by the absolute values of the HOME_SEQUENCE numbers. On a mill or router it is generally best to home the Z axis first, to get it up and out of the way. So for your config I'd suggest using home sequence values of Z=0 X=1 and Y and Y2 = -1 or -2 (I usually home my X and Y at the same time). If X=1 and the Ys=-1 X and both Ys will home at the same time but the Ys will home slaved together. and wait for each other at the limit switch and any changes of direction. (If the Ys and X can't home at the same time for any reason, such as shared switch inputs, then use -2 for the Ys.)

Finally, I am not certain if this will cause a problem, but I highly recommend putting all of the joint/axis sections in the numerical order of the joints. I think how it is now with Y2-Joint3 before Z-Joint2 could cause problems.

To start with in your ini fine I think [KINS] section needs changed to

[KINS]

JOINTS = 4

KINEMATICS = trivkins coordinates=XYZYThen In your joint sections, the joints that you have slaved together, need to have the HOME_SEQUENCE set to matching negative numbers. The negative is important, it indicates joints that are to home in a slaved fashion.

The joints are homed in the order specified by the absolute values of the HOME_SEQUENCE numbers. On a mill or router it is generally best to home the Z axis first, to get it up and out of the way. So for your config I'd suggest using home sequence values of Z=0 X=1 and Y and Y2 = -1 or -2 (I usually home my X and Y at the same time). If X=1 and the Ys=-1 X and both Ys will home at the same time but the Ys will home slaved together. and wait for each other at the limit switch and any changes of direction. (If the Ys and X can't home at the same time for any reason, such as shared switch inputs, then use -2 for the Ys.)

Finally, I am not certain if this will cause a problem, but I highly recommend putting all of the joint/axis sections in the numerical order of the joints. I think how it is now with Y2-Joint3 before Z-Joint2 could cause problems.

Please Log in or Create an account to join the conversation.

- Jasper 3

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

22 Jun 2017 09:11 #94782

by Jasper 3

Replied by Jasper 3 on topic how to synchronize two servomotors

hey,

now I can open Linuxcnc. But I had to # something out.

(

#net y-output => hm2_5i25.0.stepgen.06.velocity-cmd

#net y-enable => hm2_5i25.0.stepgen.06.enable

and the same for

#net y2-output => hm2_5i25.0.stepgen.06.velocity-cmd

#net y2-enable => hm2_5i25.0.stepgen.06.enable

)

I'm not sure where I should connect the Joints. Is there any example hal file?

When I run the homing it tells my that my kinematic settings are worng.

greets Jasper

now I can open Linuxcnc. But I had to # something out.

(

#net y-output => hm2_5i25.0.stepgen.06.velocity-cmd

#net y-enable => hm2_5i25.0.stepgen.06.enable

and the same for

#net y2-output => hm2_5i25.0.stepgen.06.velocity-cmd

#net y2-enable => hm2_5i25.0.stepgen.06.enable

)

I'm not sure where I should connect the Joints. Is there any example hal file?

When I run the homing it tells my that my kinematic settings are worng.

greets Jasper

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4694

- Thank you received: 1439

22 Jun 2017 12:27 #94784

by Todd Zuercher

Replied by Todd Zuercher on topic how to synchronize two servomotors

You have most of the mesa card connections for Y and Y2 set to the same stepgenerator in your hal file. This is very wrong. Linuxcnc failed to start because some of those duplication were trying to connect the same hal pins to different signal names.

You need to figure out which stepgens (and which physical pins on the Mesa card) you have the step driver connected to. If you have Y2 connected to the output that is controlled by stepgen.07 (is that right?) then you need to change everything in the Y2 section from hm2_5i25.0.stepgen.06 to hm2_5i25.0.stepgen.07.

Something like this.

You need to figure out which stepgens (and which physical pins on the Mesa card) you have the step driver connected to. If you have Y2 connected to the output that is controlled by stepgen.07 (is that right?) then you need to change everything in the Y2 section from hm2_5i25.0.stepgen.06 to hm2_5i25.0.stepgen.07.

Something like this.

#*******************

# JOINT Y2

#*******************

setp pid.y2.Pgain [JOINT_3]P

setp pid.y2.Igain [JOINT_3]I

setp pid.y2.Dgain [JOINT_3]D

setp pid.y2.bias [JOINT_3]BIAS

setp pid.y2.FF0 [JOINT_3]FF0

setp pid.y2.FF1 [JOINT_3]FF1

setp pid.y2.FF2 [JOINT_3]FF2

setp pid.y2.deadband [JOINT_3]DEADBAND

setp pid.y2.maxoutput [JOINT_3]MAX_OUTPUT

setp pid.y2.error-previous-target true

#setp pid.y2.maxerror .0005

net y2-index-enable <=> pid.y2.index-enable

net y2-enable => pid.y2.enable

net y2-pos-cmd => pid.y2.command

net y2-vel-cmd => pid.y2.command-deriv

net y2-pos-fb => pid.y2.feedback

net y2-output => pid.y2.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.07.dirsetup [JOINT_3]DIRSETUP

setp hm2_5i25.0.stepgen.07.dirhold [JOINT_3]DIRHOLD

setp hm2_5i25.0.stepgen.07.steplen [JOINT_3]STEPLEN

setp hm2_5i25.0.stepgen.07.stepspace [JOINT_3]STEPSPACE

setp hm2_5i25.0.stepgen.07.position-scale [JOINT_3]STEP_SCALE

setp hm2_5i25.0.stepgen.07.step_type 0

setp hm2_5i25.0.stepgen.07.control-type 1

setp hm2_5i25.0.stepgen.07.maxaccel [JOINT_3]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.07.maxvel [JOINT_3]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y2-pos-cmd <= joint.3.motor-pos-cmd

net y2-vel-cmd <= joint.3.vel-cmd

net y2-output <= hm2_5i25.0.stepgen.07.velocity-cmd

#net y2-pos-fb <= hm2_5i25.0.stepgen.07.position-fb

net y2-pos-fb => joint.3.motor-pos-fb

net y2-enable <= joint.3.amp-enable-out

net y2-enable => hm2_5i25.0.stepgen.06.enable

# ---closedloop stepper signals---

net y2-output => hm2_5i25.0.stepgen.07.velocity-cmd

net y2-enable => hm2_5i25.0.stepgen.07.enable

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.04.counter-mode 0

setp hm2_5i25.0.encoder.04.filter 1

setp hm2_5i25.0.encoder.04.index-invert 0

setp hm2_5i25.0.encoder.04.index-mask 0

setp hm2_5i25.0.encoder.04.index-mask-invert 0

setp hm2_5i25.0.encoder.04.scale [JOINT_1]ENCODER_SCALE

net y2-pos-fb <= hm2_5i25.0.encoder.04.position

net y2-vel-fb <= hm2_5i25.0.encoder.04.velocity

net y2-pos-fb => joint.3.motor-pos-fb

net y2-index-enable joint.3.index-enable <=> hm2_5i25.0.encoder.04.index-enable

net y2-pos-rawcounts <= hm2_5i25.0.encoder.04.rawcounts

# ---setup home / limit switch signals---

#net y2-neg-limit <= hm2_5i25.0.7i76.0.0.input-05-not

#net y2-pos-limit <= hm2_5i25.0.7i76.0.0.input-04-not

net y2-home-sw <= hm2_5i25.0.7i76.0.0.input-17

net y2-home-sw => joint.3.home-sw-in

#net y2-neg-limit => joint.3.neg-lim-sw-in

#net y2-pos-limit => joint.3.pos-lim-sw-inPlease Log in or Create an account to join the conversation.

- Jasper 3

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

22 Jun 2017 14:17 #94785

by Jasper 3

Replied by Jasper 3 on topic how to synchronize two servomotors

thanks that was defentiv one mistake (y is stepgen6 and y2 is stepgen 7). So know I still get following errors.

I discovered. that one motor rotates backwards. Also this motor has under calibration (in axis) no encoder feedback. If I change the sign. (y stays - ; y2 becomes +) than both motors turn in the same direction. But there still must be an error. Imidetly after moving the y-axis I get either following error 1 or 3.

I discovered. that one motor rotates backwards. Also this motor has under calibration (in axis) no encoder feedback. If I change the sign. (y stays - ; y2 becomes +) than both motors turn in the same direction. But there still must be an error. Imidetly after moving the y-axis I get either following error 1 or 3.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4694

- Thank you received: 1439

22 Jun 2017 16:12 #94794

by Todd Zuercher

Replied by Todd Zuercher on topic how to synchronize two servomotors

The first thing you are going to need to do is get the encoder feedback straightened out for each joint.

It might be useful while setting things up if you can see the DROs in Joint mode. To enable that, in your ini file under the [KINS] section change the Kinimatics line to

KINEMATICS = trivkins coordinates=XYZY kinstype=BOTH

Then the joint values will be shown in the DRO.

DO NOT try to jog the y axis joints while in joint mode. As they will not be slaved together in joint mode and doing so will rack your gantry.

Just remember to take that out after the machine is setup so you can't rack the gantry.

With the drives disabled, push the gantry and see if the DROs for both Y joints moves correctly.

Then make the nessisary adjustments to the scales for those joints. (assuming the encoders are wired up and working correctly.) Also be sure that you have the right encoder connected to Y1 and Y2. (that they are not crossed)

It might be useful while setting things up if you can see the DROs in Joint mode. To enable that, in your ini file under the [KINS] section change the Kinimatics line to

KINEMATICS = trivkins coordinates=XYZY kinstype=BOTH

Then the joint values will be shown in the DRO.

DO NOT try to jog the y axis joints while in joint mode. As they will not be slaved together in joint mode and doing so will rack your gantry.

Just remember to take that out after the machine is setup so you can't rack the gantry.

With the drives disabled, push the gantry and see if the DROs for both Y joints moves correctly.

Then make the nessisary adjustments to the scales for those joints. (assuming the encoders are wired up and working correctly.) Also be sure that you have the right encoder connected to Y1 and Y2. (that they are not crossed)

Please Log in or Create an account to join the conversation.

- Jasper 3

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

22 Jun 2017 18:01 #94796

by Jasper 3

Replied by Jasper 3 on topic how to synchronize two servomotors

really awesome!

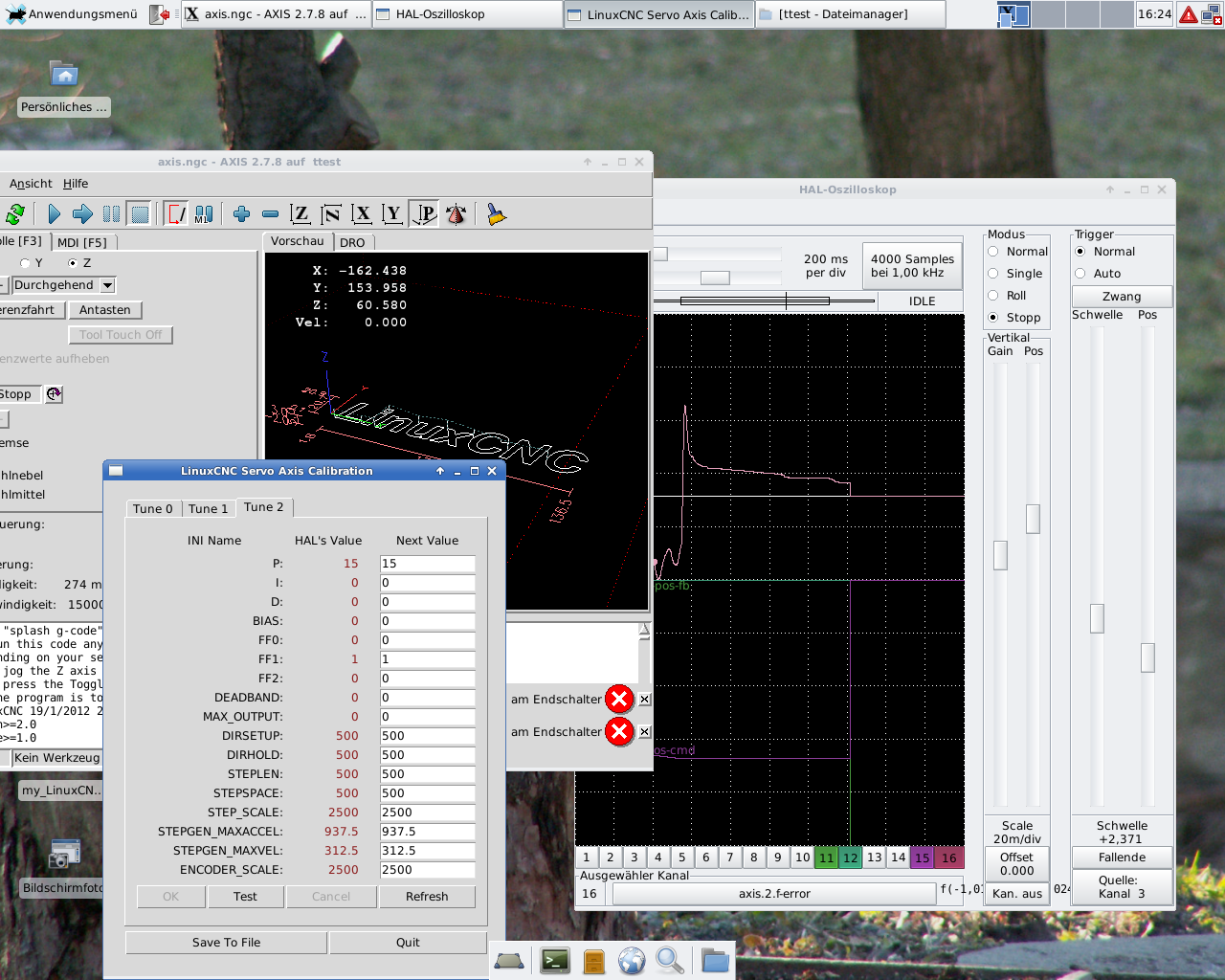

thanks found out that the encoder cables were switched. So no it is working. Just need to tune the axis because the axis oscillates. Or can there be another reason for that oscillations.

Greets

thanks found out that the encoder cables were switched. So no it is working. Just need to tune the axis because the axis oscillates. Or can there be another reason for that oscillations.

Greets

Please Log in or Create an account to join the conversation.

Time to create page: 0.153 seconds