Gantry homing witch XHC_HB04 HandWheel enabled.

- Blumax

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

07 Oct 2018 14:24 #118512

by Blumax

Gantry homing witch XHC_HB04 HandWheel enabled. was created by Blumax

Hello

I have a 4-axis machine, with two driver / motor / endstop on the Y axis, and LinuxCNC 2.8 (On official LinuxNC 2.7 ISO).

When I start the machine, the user interface displays 0/1/2/3/4 joint for XYYZA, when I do homing it turns into X / Y / Z / A.

All is well, all works!

When I add the line

#INCLUDE XHC_HB04.inc

in the [HAL] section of the file machine.ini,

And after activating this patch manually : github.com/LinuxCNC/linuxcnc/commit/cb93...515812f48d79bf09bcbf

The machine after the homing remains lock on the joints 0/1/2/3/4 and not XYZA.

There are small targets that indicate that the origins have been found.

I would specify, that before I used the handwheel with this same machine but without the kinstype = BOTH and with linuxcnc 2.7

Do you have a solution ?

I have a 4-axis machine, with two driver / motor / endstop on the Y axis, and LinuxCNC 2.8 (On official LinuxNC 2.7 ISO).

When I start the machine, the user interface displays 0/1/2/3/4 joint for XYYZA, when I do homing it turns into X / Y / Z / A.

All is well, all works!

When I add the line

#INCLUDE XHC_HB04.inc

in the [HAL] section of the file machine.ini,

And after activating this patch manually : github.com/LinuxCNC/linuxcnc/commit/cb93...515812f48d79bf09bcbf

The machine after the homing remains lock on the joints 0/1/2/3/4 and not XYZA.

There are small targets that indicate that the origins have been found.

I would specify, that before I used the handwheel with this same machine but without the kinstype = BOTH and with linuxcnc 2.7

Do you have a solution ?

machine.ini

# Generated by stepconf 1.1 at Mon Sep 10 13:20:12 2018

# Si vous modifiez ce fichier, il sera

# écrasé quand vous relancerez Stepconf

[EMC]

MACHINE = TableCNC

DEBUG = 0

VERSION = 1.0

[DISPLAY]

DISPLAY = axis

EDITOR = gedit

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

ARCDIVISION = 64

GRIDS = 10mm 20mm 50mm 100mm 1in 2in 5in 10in

MAX_FEED_OVERRIDE = 1.2

MIN_SPINDLE_OVERRIDE = 0.5

MAX_SPINDLE_OVERRIDE = 1.2

DEFAULT_LINEAR_VELOCITY = 11.00

MIN_LINEAR_VELOCITY = 0

MAX_LINEAR_VELOCITY = 110.00

DEFAULT_ANGULAR_VELOCITY = 1.00

MIN_ANGULAR_VELOCITY = 0

MAX_ANGULAR_VELOCITY = 10.00

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm .001mm

PROGRAM_PREFIX = /home/blumax/linuxcnc/nc_files

[KINS]

JOINTS = 5

KINEMATICS = trivkins coordinates=XYYZA kinstype=BOTH

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

PROGRAM_EXTENSION = .nc,.tap G-Code File

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

BASE_PERIOD = 100000

SERVO_PERIOD = 1000000

[HAL]

HALFILE = TableCNC.hal

HALFILE = custom.hal

POSTGUI_HALFILE = postgui_call_list.hal

#INCLUDE XHC_HB04.inc

[TRAJ]

COORDINATES = XYZA

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 1.00

MAX_LINEAR_VELOCITY = 110.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

[AXIS_X]

MAX_VELOCITY = 110.0

MAX_ACCELERATION = 500.0

MIN_LIMIT = -0.001

MAX_LIMIT = 838.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

MIN_LIMIT = -0.001

MAX_LIMIT = 838.0

MAX_VELOCITY = 110.0

MAX_ACCELERATION = 500.0

STEPGEN_MAXACCEL = 625.0

SCALE = 33.3767964377

FERROR = 1

MIN_FERROR = .25

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = -25.000000

HOME_LATCH_VEL = 14.980467

HOME_SEQUENCE = 1

[AXIS_Y]

MAX_VELOCITY = 110.0

MAX_ACCELERATION = 500.0

MIN_LIMIT = -0.001

MAX_LIMIT = 1425.0

[JOINT_1]

TYPE = LINEAR

HOME = 1425.0

MIN_LIMIT = -0.001

MAX_LIMIT = 1425.0

MAX_VELOCITY = 110.0

MAX_ACCELERATION = 500.0

STEPGEN_MAXACCEL = 625.0

SCALE = 33.2805316344

FERROR = 1

MIN_FERROR = .25

HOME_OFFSET = 1425.000000

HOME_SEARCH_VEL = 25.000000

HOME_LATCH_VEL = -15.000000

HOME_SEQUENCE = 2

[JOINT_2]

TYPE = LINEAR

HOME = 1425.0

MIN_LIMIT = -0.001

MAX_LIMIT = 1425.0

MAX_VELOCITY = 110.0

MAX_ACCELERATION = 500.0

STEPGEN_MAXACCEL = 625.0

SCALE = 33.2805316344

FERROR = 1

MIN_FERROR = .25

HOME_OFFSET = 1425.000000

HOME_SEARCH_VEL = 25.000000

HOME_LATCH_VEL = -15.000000

HOME_SEQUENCE = 2

[AXIS_Z]

MAX_VELOCITY = 29.6875

MAX_ACCELERATION = 100.0

MIN_LIMIT = -0.001

MAX_LIMIT = 340.0

[JOINT_3]

TYPE = LINEAR

HOME = 0.0

MIN_LIMIT = -0.001

MAX_LIMIT = 340.0

MAX_VELOCITY = 29.6875

MAX_ACCELERATION = 100.0

STEPGEN_MAXACCEL = 125.0

SCALE = 320.0

FERROR = 1

MIN_FERROR = .25

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = -5.000000

HOME_LATCH_VEL = 1.562500

HOME_SEQUENCE = 0

[AXIS_A]

MAX_VELOCITY = 10.0

MAX_ACCELERATION = 1200.0

MIN_LIMIT = -9999.0

MAX_LIMIT = 9999.0

[JOINT_4]

TYPE = ANGULAR

HOME = 0.0

MIN_LIMIT = -9999.0

MAX_LIMIT = 9999.0

MAX_VELOCITY = 10.0

MAX_ACCELERATION = 1200.0

STEPGEN_MAXACCEL = 1500.0

SCALE = 800.0

FERROR = 1

MIN_FERROR = .25

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 0.00000

HOME_LATCH_VEL = 0.00000

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = 3

machine.hal

# Generated by stepconf 1.1 at Mon Sep 10 13:20:12 2018

# Si vous modifiez ce fichier, il sera

# écrasé quand vous relancerez Stepconf

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT base_period_nsec=[EMCMOT]BASE_PERIOD servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hal_parport cfg="0 out"

setp parport.0.reset-time 2500

loadrt stepgen step_type=0,0,0,0,0

addf parport.0.read base-thread

addf stepgen.make-pulses base-thread

addf parport.0.write base-thread

addf parport.0.reset base-thread

addf stepgen.capture-position servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf stepgen.update-freq servo-thread

net spindle-cmd-rpm <= motion.spindle-speed-out

net spindle-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-cmd-rps <= motion.spindle-speed-out-rps

net spindle-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-at-speed => motion.spindle-at-speed

net probe-in => motion.probe-input

setp parport.0.pin-01-out-invert 1

net xstep => parport.0.pin-01-out

setp parport.0.pin-01-out-reset 1

setp parport.0.pin-02-out-invert 1

net adir => parport.0.pin-02-out

setp parport.0.pin-05-out-invert 1

net astep => parport.0.pin-05-out

setp parport.0.pin-05-out-reset 1

setp parport.0.pin-06-out-invert 1

net yddir => parport.0.pin-06-out

setp parport.0.pin-07-out-invert 1

net zstep => parport.0.pin-07-out

setp parport.0.pin-07-out-reset 1

setp parport.0.pin-08-out-invert 1

net zdir => parport.0.pin-08-out

setp parport.0.pin-09-out-invert 1

net ydstep => parport.0.pin-09-out

setp parport.0.pin-09-out-reset 1

net ygdir => parport.0.pin-14-out

net xdir => parport.0.pin-16-out

setp parport.0.pin-17-out-invert 1

net ygstep => parport.0.pin-17-out

setp parport.0.pin-17-out-reset 1

net probe-in <= parport.0.pin-10-in

net home-x <= parport.0.pin-11-in-not

net home-z <= parport.0.pin-13-in-not

net home-yg <= parport.0.pin-12-in

net home-yd <= parport.0.pin-15-in

setp stepgen.0.position-scale [JOINT_0]SCALE

setp stepgen.0.steplen 1

setp stepgen.0.stepspace 0

setp stepgen.0.dirhold 40000

setp stepgen.0.dirsetup 80000

setp stepgen.0.maxaccel [JOINT_0]STEPGEN_MAXACCEL

net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.position-cmd

net xpos-fb stepgen.0.position-fb => joint.0.motor-pos-fb

net xstep <= stepgen.0.step

net xdir <= stepgen.0.dir

net xenable joint.0.amp-enable-out => stepgen.0.enable

net home-x => joint.0.home-sw-in

setp stepgen.1.position-scale [JOINT_1]SCALE

setp stepgen.1.steplen 1

setp stepgen.1.stepspace 0

setp stepgen.1.dirhold 40000

setp stepgen.1.dirsetup 80000

setp stepgen.1.maxaccel [JOINT_1]STEPGEN_MAXACCEL

net ygpos-cmd joint.1.motor-pos-cmd => stepgen.1.position-cmd

net ygpos-fb stepgen.1.position-fb => joint.1.motor-pos-fb

net ygstep <= stepgen.1.step

net ygdir <= stepgen.1.dir

net ygenable joint.1.amp-enable-out => stepgen.1.enable

net home-yg => joint.1.home-sw-in

setp stepgen.2.position-scale [JOINT_2]SCALE

setp stepgen.2.steplen 1

setp stepgen.2.stepspace 0

setp stepgen.2.dirhold 40000

setp stepgen.2.dirsetup 80000

setp stepgen.2.maxaccel [JOINT_2]STEPGEN_MAXACCEL

net ydpos-cmd joint.2.motor-pos-cmd => stepgen.2.position-cmd

net ydpos-fb stepgen.2.position-fb => joint.2.motor-pos-fb

net ydstep <= stepgen.2.step

net yddir <= stepgen.2.dir

net ydenable joint.2.amp-enable-out => stepgen.2.enable

net home-yd => joint.2.home-sw-in

setp stepgen.3.position-scale [JOINT_3]SCALE

setp stepgen.3.steplen 1

setp stepgen.3.stepspace 0

setp stepgen.3.dirhold 40000

setp stepgen.3.dirsetup 80000

setp stepgen.3.maxaccel [JOINT_3]STEPGEN_MAXACCEL

net zpos-cmd joint.3.motor-pos-cmd => stepgen.3.position-cmd

net zpos-fb stepgen.3.position-fb => joint.3.motor-pos-fb

net zstep <= stepgen.3.step

net zdir <= stepgen.3.dir

net zenable joint.3.amp-enable-out => stepgen.3.enable

net home-z => joint.3.home-sw-in

setp stepgen.4.position-scale [JOINT_4]SCALE

setp stepgen.4.steplen 1

setp stepgen.4.stepspace 0

setp stepgen.4.dirhold 40000

setp stepgen.4.dirsetup 80000

setp stepgen.4.maxaccel [JOINT_4]STEPGEN_MAXACCEL

net apos-cmd joint.4.motor-pos-cmd => stepgen.4.position-cmd

net apos-fb stepgen.4.position-fb => joint.4.motor-pos-fb

net astep <= stepgen.4.step

net adir <= stepgen.4.dir

net aenable joint.4.amp-enable-out => stepgen.4.enable

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

loadusr -W hal_manualtoolchange

net tool-change iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-changed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

XHC_HB04.inc

#*********************************************************************************************************************

#

# Utilisation d'une Handwheel xhc-hb04 avec LinuxCNC 2.7 (Debian)

#

# Dans le répertoire home/<utilisateur>/linuxcnc/configs/<ma-machine>

#

# 1- Placez une copie du fichier XHC_HB04.inc

#

# 2- Modifiez le fichier <ma-machine>.ini en insérant la ligne ci-dessous (caractère # compris) après la dernière ligne

# de la section [HAL] (probablement en dessous de la ligne "POSTGUI_HALFILE = custom_postgui.hal").

#

# #INCLUDE XHC_HB04.inc

#

# Attention, il faut effectuer cette modification à chaque fois que Stepconf est utilisé car le fichier <ma-machine>.ini

# est réinitialisé par Stepconf.

#

# 3- Dans le fichier XHC_HB04.inc, adaptez à vos préférences les dispositions et commandes et réalisez une nouvelle

# sérigraphie des boutons. La configuration proposée ici me convient pour des découpes de plaques (ctp, balsa, expoxy,

# carbone, etc.) avec une machine 3 axes dont le Gcode provient essentiellment de CamBam (= pas d'axe A).

# J'ai pris l'option de n'utiliser que des valeurs X et Y positives, et en découpe la surface de la plaque étant

# à Z=0 la valeur négative de Z mini est de -30.

#

# Pour plus de détails, consultez :

# - le fichier readme du répertoire usr/share/doc/linuxcnc/examples/sample-configs/sim/axis/xhc-hb04

# on y trouve des informations concernant l'installation sur une distribution autre que Debian

# - http://linuxcnc.org/docs/html/hal/halui_fr.html

# - http://linuxcnc.org/docs/html/man/man1/xhc-hb04.1.html

# - http://wiki.linuxcnc.org/cgi-bin/wiki.pl?Using_A_XHC-HB04_Wireless_MPG_Pendant

# ...Attention toutefois aux infos antérieures à LinuxCNC 2.6 qui peuvent être obsolètes

#

#*********************************************************************************************************************

HALUI = halui

HALFILE = LIB:xhc-hb04.tcl

[XHC_HB04_CONFIG]

layout = 2

coords = x y z a

coefs = 1 1 1 1

scales = 10 10 10 10

threadname = servo-thread

sequence = 3

jogmode = vnormal

require_pendant = yes

inch_or_mm = mm

[XHC_HB04_BUTTONS]

# BOUTONS MACH3

# -------------- --------------

# | reset | stop |

# -------------- -------------- -------------- --------------

# | goto-zero(-i)| start-pause | rewind | probe-z |

# -------------- -------------- -------------- --------------

# | spindle | half(-i) | zero(-i) | safe-z |

# -------------- -------------- -------------- --------------

# | home | macro-1 | macro-2 | macro-3 |

# -------------- -------------- -------------- --------------

# | step | mode | macro-6 | macro-7 |

# -------------- -------------- -------------- --------------

# BOUTONS LINUXCNC

# -------------- --------------

# | A/URGENT | Mode Manuel |

# -------------- -------------- -------------- --------------

# | POM (x/y/z) | START/PAUSE | PASaPAS | STOP |

# -------------- -------------- -------------- --------------

# | BROCHE Start | X maxi | Y maxi | Z maxi |

# -------------- -------------- -------------- --------------

# | BROCHE Stop | X mini | Y mini | Z mini |

# -------------- -------------- -------------- --------------

# | STEP + | STEP - | HOME1 | HOME2 |

# -------------- -------------- -------------- --------------

#-----1ere ligne-----------------------------------------------

reset = halui.estop.activate

stop = halui.mode.manual

#-----2eme ligne-----------------------------------------------

goto-zero = ""

goto-zero-x = halui.joint.0.home

goto-zero-y = halui.joint.1.home

goto-zero-z = halui.joint.2.home

start-pause = std_start_pause

rewind = halui.program.step

probe-z = halui.program.stop

#-----3eme ligne-----------------------------------------------

spindle = halui.spindle.start

half = halui.mdi-command-03

zero = halui.mdi-command-04

safe-z = halui.mdi-command-05

#-----4eme ligne-----------------------------------------------

home = halui.spindle.stop

macro-1 = halui.mdi-command-00

macro-2 = halui.mdi-command-01

macro-3 = halui.mdi-command-02

#-----5eme ligne-----------------------------------------------

step = xhc-hb04.stepsize-up

mode = xhc-hb04.stepsize-down

macro-6 = halui.mdi-command-06

macro-7 = halui.mdi-command-07

[HALUI]

MDI_COMMAND=G0 X0 (00)

MDI_COMMAND=G0 Y0 (01)

MDI_COMMAND=G0 Z20 (02)

MDI_COMMAND=G0 X500 (03)

MDI_COMMAND=G0 Y300 (04)

MDI_COMMAND=G0 Z100 (05)

MDI_COMMAND=G0 X0 Y0 Z50 (06)

MDI_COMMAND=G0 X0 Y300 Z50 (07)

#*********************************************************************************************************************Please Log in or Create an account to join the conversation.

- Blumax

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

20 Nov 2018 16:17 #121067

by Blumax

Replied by Blumax on topic Gantry homing witch XHC_HB04 HandWheel enabled.

I find a solution.

I do not know for that reason but it is enough to remove all the lines mentionanat "spindle" of the file xhc-hb04.tcl and the homing is done correctly!

I do not know for that reason but it is enough to remove all the lines mentionanat "spindle" of the file xhc-hb04.tcl and the homing is done correctly!

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 492

- Thank you received: 297

20 Nov 2018 20:23 - 20 Nov 2018 20:39 #121084

by dgarrett

Replied by dgarrett on topic Gantry homing witch XHC_HB04 HandWheel enabled.

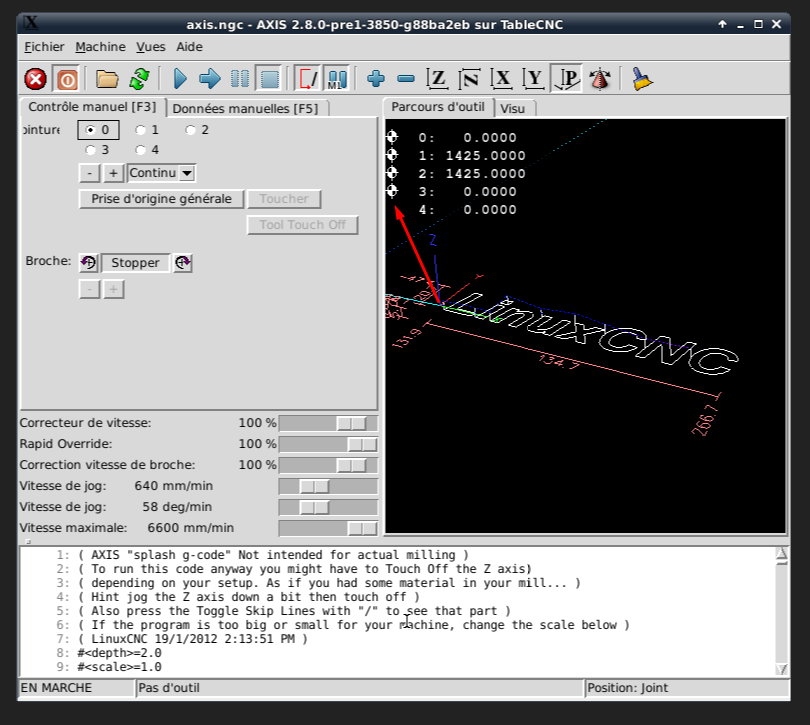

Your photo showsindicating buildbot build number 3850 at commit 88ba2eb.

This commit was made on Sep 6.

Prior to this date, a number of commits were made to incorporate multispindle

functionality begining with commit e3caa92e1

Ref: github.com/LinuxCNC/linuxcnc/commit/e3caa92e1

This commit was followed by a number of updates and bug fixes:

So, the problem you observed may have been fixed by commits made

after your buildbot deb update.

For example, the commit: "5e6943032 Wed Oct 3 07:20:14 2018 -0700 ..."

made changes to the library file xhc-hb04.tcl that could affect your

configuration.

Ref: github.com/LinuxCNC/linuxcnc/commit/5e69...db73e96919e946a389c0

Users of buildbot debs for the master branch may encounter some instability.

It is a good idea to update with consideration of commits made since your

last update especially when substantial changes are made to the master

branch. Commits for the master branch are listed (in order) on github

at:

github.com/LinuxCNC/linuxcnc/commits/master

2.8.0-pre1-3850-g88ba2ebThis commit was made on Sep 6.

$ git show -s 88ba2eb25|grep Date:

Date: Thu Sep 6 15:15:37 2018 +0200Prior to this date, a number of commits were made to incorporate multispindle

functionality begining with commit e3caa92e1

Ref: github.com/LinuxCNC/linuxcnc/commit/e3caa92e1

This commit was followed by a number of updates and bug fixes:

$ git log --oneline --pretty=format:"%h %ad %s"|cut -b -70|grep -i multispindle

3291d5725 Thu Nov 8 07:37:55 2018 -0700 multispindle: linuxcnctop upda

a2b06c4dc Thu Nov 1 23:32:01 2018 +0000 Multispindle: Remove some debu

58624aab3 Sun Oct 21 13:37:49 2018 +0100 Multispindle: Fix the F9 / F1

2e8f4d3c8 Thu Oct 18 19:13:18 2018 +0100 Multispindle: Further docs up

13434870f Wed Oct 17 23:53:45 2018 +0100 Multispindle: Docs Update

826232c9f Wed Oct 17 23:44:09 2018 +0100 Multispindle: CLean up some c

9b5e9dc3a Wed Oct 17 21:50:03 2018 +0100 Multispindle: add EMCMOT_NUM_

d42d9b097 Tue Oct 16 01:41:52 2018 +0100 Multispindle: Remove debug me

7fb914d19 Tue Oct 16 01:30:24 2018 +0100 Multispindle: Make S commands

5b477ad7e Sun Oct 14 22:36:10 2018 +0100 Multispindle: Make interp_che

bedc7e501 Sun Oct 14 22:36:10 2018 +0100 Multispindle: Make interp_che

5e98296f4 Thu Oct 11 22:58:19 2018 +0100 Multispindle: Fix some wierd

458436175 Tue Oct 9 21:12:57 2018 +0100 Multispindle: Guard against at

eb8d43fad Mon Oct 8 22:27:09 2018 +0100 Multispindle: Fix a bug with s

db55cea24 Thu Oct 4 15:03:58 2018 -0700 Multispindle: update some brok

5e6943032 Wed Oct 3 07:20:14 2018 -0700 Multispindle: update xhc-hb04.

04d8d1d30 Sun Sep 30 10:36:32 2018 +0100 Multispindle: Revert base sim

1fc06379d Sat Sep 29 22:00:13 2018 +0100 Multispindle: Elide some extr

b948dba1a Sat Sep 29 12:14:35 2018 +0100 Multispindle: Change generate

ebb709fc2 Sat Sep 15 14:17:15 2018 +0100 Multispindle: Correct the spi

ac154e06d Fri Sep 28 23:20:52 2018 +0100 Multispindle: Update sample

aa4d20b92 Tue Sep 25 00:35:37 2018 +0100 Multispindle: Modify runtests

5f3c097e5 Mon Sep 24 02:14:05 2018 +0100 multispindle: Update the upda

6431a525b Sun Sep 23 22:10:34 2018 +0100 multispindle: Modify user-int

7d5ccc7b6 Sun Sep 23 22:09:56 2018 +0100 multispindle: Make required c

3f7fdc047 Sun Sep 16 14:37:11 2018 +0100 Multispindle: Switch to usingSo, the problem you observed may have been fixed by commits made

after your buildbot deb update.

For example, the commit: "5e6943032 Wed Oct 3 07:20:14 2018 -0700 ..."

made changes to the library file xhc-hb04.tcl that could affect your

configuration.

Ref: github.com/LinuxCNC/linuxcnc/commit/5e69...db73e96919e946a389c0

Users of buildbot debs for the master branch may encounter some instability.

It is a good idea to update with consideration of commits made since your

last update especially when substantial changes are made to the master

branch. Commits for the master branch are listed (in order) on github

at:

github.com/LinuxCNC/linuxcnc/commits/master

Last edit: 20 Nov 2018 20:39 by dgarrett.

Please Log in or Create an account to join the conversation.

Time to create page: 0.132 seconds