Can a component know the diameter of an arc its cutting

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

28 Feb 2019 13:52 - 28 Feb 2019 13:53 #127323

by andypugh

Replied by andypugh on topic Can a component know the diameter of an arc its cutting

You should probably use the same dx and dy to calculate velocity.

v = sqrt(dx^2 + dy^2) / fperiod

(Or, at least, see if that number differs from the current_vel)

(You can probably actually remove fperiod from both calculations)

v = sqrt(dx^2 + dy^2) / fperiod

(Or, at least, see if that number differs from the current_vel)

(You can probably actually remove fperiod from both calculations)

Last edit: 28 Feb 2019 13:53 by andypugh.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11690

- Thank you received: 3940

28 Feb 2019 21:57 #127364

by rodw

Replied by rodw on topic Can a component know the diameter of an arc its cutting

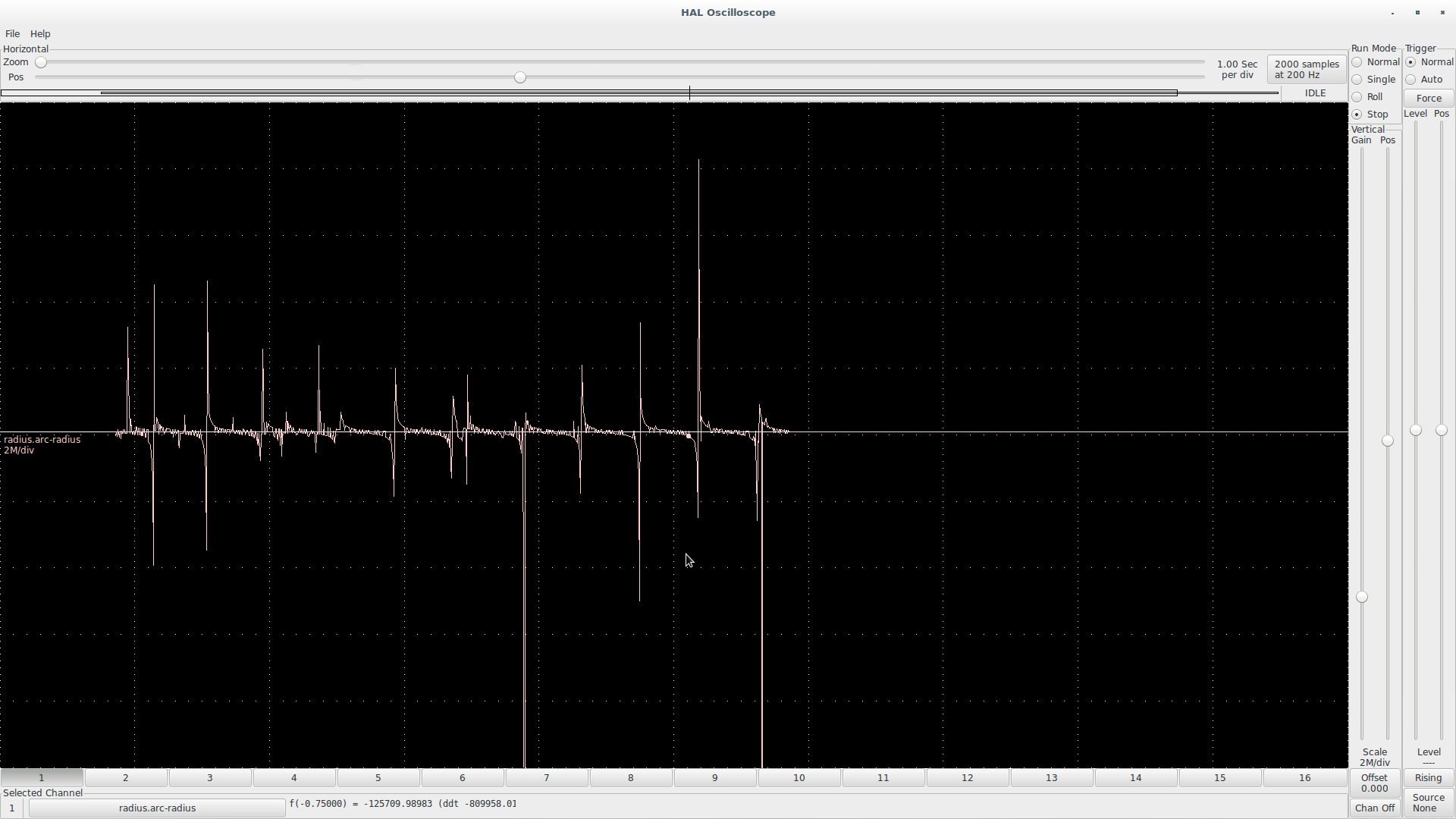

ANdy thanks. The calculated velocity agrees pretty much with motion.current-vel which remains constant (variance about +- 0.1mm/sec)

I started to play with Halscope but ran out of time.

Looks like we need to revisit the formulas somewhere or filter out the spikes somehow.

I think I have a logic error calculating the change in heading so I'll dig in hal scope a bit further

I started to play with Halscope but ran out of time.

Looks like we need to revisit the formulas somewhere or filter out the spikes somehow.

I think I have a logic error calculating the change in heading so I'll dig in hal scope a bit further

Attachments:

The following user(s) said Thank You: tommylight, Grotius

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

28 Feb 2019 22:15 - 28 Feb 2019 22:41 #127366

by Grotius

Replied by Grotius on topic Can a component know the diameter of an arc its cutting

Wow Rod,

This looks like a signal from an other planet. It could be of of Mars. Wow man.

I have looked at the I and J tonight again in my c comment's therefor. But Andy is right about the radius formula.

Diameter formula is radius *2. V can be vertical or a far planet like Vertunius of the V of velocity. So for me it's a quess.

I like Andy because he is one of the few who solves problem's of newby's and further experienced linuxcnc users.

So i have a good feeling about Andy. He has private youtube video's where he made a piece of a product, amazing.

Andy is becoming very clever i see in the past 2 years. So keep on going Andy, and take your time. You know a lot on linuxcnc !!!

So in gcode Dxfdecode processing i made a course you know. There was a post before here in this thread that explained the raw process good with a streaming process. But Mach3 is looking 20 lines behead. Is linux doing that not? No it's not so it's not calculating the circle before it get's there. Or am i wrong?

Can a component know the diameter of an arc its cutting Yes it can.

The I and J in gcode is x and y center point of the circle or arc. You can calcutate it back to radius with cos and sin.

But in fact why would you do this? The G-code language is the most clean logic drawing language on earth. If i must make a cad

program, i will start with g-code output as standard. So Autodesk Dxf has hard logic. If you add a line in the drawing, logic is to append this line. Add this line add the end of file without adding it into the contour. So Autodesk is quilty to void logic operations about the past 20 years or so. I can say this after a deep investegation. But Autodesk is on of the richest company's of the world today.

The reason that Draftsight is for free, is to prevent upgrowing marktets of other product's.

But i don't care. If you have skill's to make a cad system. If you look at Sascha. He is a Ethercat legend. So i must make a point if i have the skill's. Provide a free cad cam software. I have time.

This looks like a signal from an other planet. It could be of of Mars. Wow man.

I have looked at the I and J tonight again in my c comment's therefor. But Andy is right about the radius formula.

Diameter formula is radius *2. V can be vertical or a far planet like Vertunius of the V of velocity. So for me it's a quess.

I like Andy because he is one of the few who solves problem's of newby's and further experienced linuxcnc users.

So i have a good feeling about Andy. He has private youtube video's where he made a piece of a product, amazing.

Andy is becoming very clever i see in the past 2 years. So keep on going Andy, and take your time. You know a lot on linuxcnc !!!

So in gcode Dxfdecode processing i made a course you know. There was a post before here in this thread that explained the raw process good with a streaming process. But Mach3 is looking 20 lines behead. Is linux doing that not? No it's not so it's not calculating the circle before it get's there. Or am i wrong?

Can a component know the diameter of an arc its cutting Yes it can.

The I and J in gcode is x and y center point of the circle or arc. You can calcutate it back to radius with cos and sin.

But in fact why would you do this? The G-code language is the most clean logic drawing language on earth. If i must make a cad

program, i will start with g-code output as standard. So Autodesk Dxf has hard logic. If you add a line in the drawing, logic is to append this line. Add this line add the end of file without adding it into the contour. So Autodesk is quilty to void logic operations about the past 20 years or so. I can say this after a deep investegation. But Autodesk is on of the richest company's of the world today.

The reason that Draftsight is for free, is to prevent upgrowing marktets of other product's.

But i don't care. If you have skill's to make a cad system. If you look at Sascha. He is a Ethercat legend. So i must make a point if i have the skill's. Provide a free cad cam software. I have time.

Last edit: 28 Feb 2019 22:41 by Grotius.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11690

- Thank you received: 3940

28 Feb 2019 23:59 #127370

by rodw

Replied by rodw on topic Can a component know the diameter of an arc its cutting

Yeh, I think there is an error in the way I calculate the difference between the heading rate of change but I've not found it yet as I ran out of time util tonight. All of Andy's other maths is working as it should I think so there is only one other factor to debug.

The idea I had was for LinuxCNC to apply something like Sheetcam's cutting rules automatically to manage hole and radius cutting as I have not had that much luck using the cutting rules. If the algoritihm had say material and thickness data available, it could become quite sophisticated in its approach. A linuxcnc version of truehole technology without resorting to a Hypertherm CAM system.

Anyway, it will be cool if it works!

And yes, Andy's engineering background and his intimate knowledge of LinuxCNC allowed him to come up with a valid mathematical approach to solve the problem. I just had to put the pieces together. Thanks for that again Andy!

The idea I had was for LinuxCNC to apply something like Sheetcam's cutting rules automatically to manage hole and radius cutting as I have not had that much luck using the cutting rules. If the algoritihm had say material and thickness data available, it could become quite sophisticated in its approach. A linuxcnc version of truehole technology without resorting to a Hypertherm CAM system.

Anyway, it will be cool if it works!

And yes, Andy's engineering background and his intimate knowledge of LinuxCNC allowed him to come up with a valid mathematical approach to solve the problem. I just had to put the pieces together. Thanks for that again Andy!

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

01 Mar 2019 00:32 - 01 Mar 2019 00:58 #127374

by Grotius

Replied by Grotius on topic Can a component know the diameter of an arc its cutting

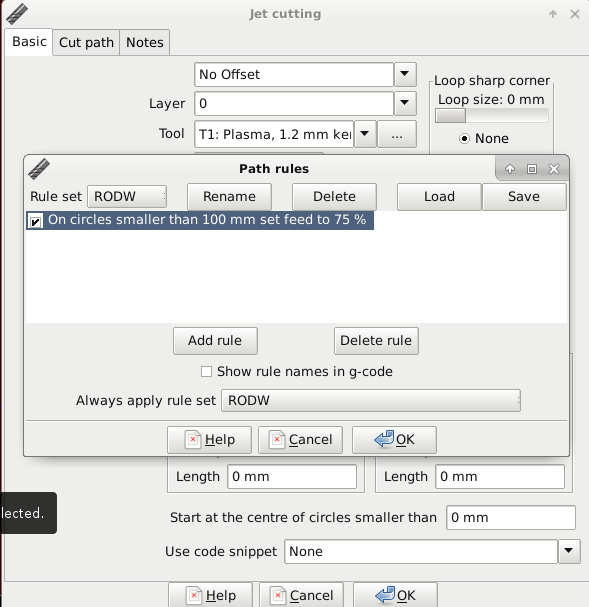

I have not had that much luck using the cutting rules

Okey apply them.

And check this one for applying them global

And finally after some trail and error you get this out, arc compensation by Grotius in 2017....

Good luck Rodw !!

A linuxcnc version of truehole technology without resorting to a Hypertherm CAM system.

Hypertherm is losing power. Do you use a Thermal Dynamics 120 amps at the moment instead of a Powermax 125 or 105?

Today Hypertherm lost a customer in Letland. It was a Hypertherm distributor for 6-7 years.

If you want to read some news paper : hypertherm.email/2019/02/07/legal-action...counterfeit-product/

Okey apply them.

And check this one for applying them global

And finally after some trail and error you get this out, arc compensation by Grotius in 2017....

Good luck Rodw !!

A linuxcnc version of truehole technology without resorting to a Hypertherm CAM system.

Hypertherm is losing power. Do you use a Thermal Dynamics 120 amps at the moment instead of a Powermax 125 or 105?

Today Hypertherm lost a customer in Letland. It was a Hypertherm distributor for 6-7 years.

If you want to read some news paper : hypertherm.email/2019/02/07/legal-action...counterfeit-product/

Attachments:

Last edit: 01 Mar 2019 00:58 by Grotius.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11690

- Thank you received: 3940

01 Mar 2019 01:36 #127380

by rodw

Replied by rodw on topic Can a component know the diameter of an arc its cutting

But when you want to do something like this to avoid some pierces

and you add a fillet on the entrance to the slot, you are dealing with arcs, not holes, I don't want to slow down on the entrance but I do on the arc for the hole. (Hole is cleaned out with a drill). And yes to be able to prototype on 16mm steel with the Thermal Dynamics 120 amp machine.

I was unable to get Sheetcam to exclude the fillet from the cutting rule. I could edit the Sheetcam POST but this is an interesting way forward.

and you add a fillet on the entrance to the slot, you are dealing with arcs, not holes, I don't want to slow down on the entrance but I do on the arc for the hole. (Hole is cleaned out with a drill). And yes to be able to prototype on 16mm steel with the Thermal Dynamics 120 amp machine.

I was unable to get Sheetcam to exclude the fillet from the cutting rule. I could edit the Sheetcam POST but this is an interesting way forward.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

01 Mar 2019 01:47 - 01 Mar 2019 01:52 #127382

by Grotius

Replied by Grotius on topic Can a component know the diameter of an arc its cutting

Row if you cut this at 120 amps 700mm/min you are master kenobi but only with water table to avoid to much heat in the product what will be negative for accuracy. Will result in 1 to 5 mm material stretch at your product in worst case and will form dirty toxic smoke flue gasses for serrounding guys if no exheast blower is mounted inside the factory.

What you can do is make a liitle water table of sheet metal 70mm water height. Plate bottom into the water. Cut the same parts you shown. You will be amazed if you use my specs.

What you can do is make a liitle water table of sheet metal 70mm water height. Plate bottom into the water. Cut the same parts you shown. You will be amazed if you use my specs.

Last edit: 01 Mar 2019 01:52 by Grotius.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11690

- Thank you received: 3940

01 Mar 2019 02:26 #127384

by rodw

Replied by rodw on topic Can a component know the diameter of an arc its cutting

I think we ran a lot faster than 700 mm/min! Yes, nothing on my table for fume control yet so its very dirty around here!. I need to wire in an Ohmic sensor so I can cut thin material. My old plasma could not do ohmic. Hopefully, I will get that done this weekend. Need to fit a larger drag chain to get all the cables there as part of that and fit a separate isolated power supply so its a bit of work...

16mm is not something I want to make a habit of cutting as the material handling is a bit of a problem for me on a half sized table so once the prototype is cut from flat bar, its easier to just get the parts laser cut. But I might revisit that as I get a bit further. down the track.

My original design concept was to be able to drop in a water table or downdraft hopper but I've built neither yet....

16mm is not something I want to make a habit of cutting as the material handling is a bit of a problem for me on a half sized table so once the prototype is cut from flat bar, its easier to just get the parts laser cut. But I might revisit that as I get a bit further. down the track.

My original design concept was to be able to drop in a water table or downdraft hopper but I've built neither yet....

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

01 Mar 2019 02:38 - 01 Mar 2019 02:39 #127385

by Grotius

Replied by Grotius on topic Can a component know the diameter of an arc its cutting

Yeahh. Cutting charts are always fast i know. Just take off 30% speed. 20mm is coockie for your plasma. 16mm is peanuts. Jou can get very good results with 120 amps. 16mm is also good at 100 amps 1400mm/min. You can do a short water test with a temponary object you put on your table. If you cut inox you have the best toxic level. Just a joke.  to keep on smiling.

to keep on smiling.

Last edit: 01 Mar 2019 02:39 by Grotius.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

01 Mar 2019 10:25 #127394

by andypugh

It might be better to treat this as a geometry problem rather than circular motion.

The needs three points, but we are already considering three points anyway to get heading rate of change.

stackoverflow.com/questions/22791951/alg...ngles-given-3-points

And a rather interesting version:

math.stackexchange.com/questions/133638/...points-actually-work

Replied by andypugh on topic Can a component know the diameter of an arc its cutting

Yeh, I think there is an error in the way I calculate the difference between the heading rate of change but I've not found it yet as I ran out of time util tonight

It might be better to treat this as a geometry problem rather than circular motion.

The needs three points, but we are already considering three points anyway to get heading rate of change.

stackoverflow.com/questions/22791951/alg...ngles-given-3-points

And a rather interesting version:

math.stackexchange.com/questions/133638/...points-actually-work

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.518 seconds