gearchange

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

24 Jan 2021 22:50 #196478

by andypugh

That might actually be easier, unexpectedly enough.

Though you probably need to cycle the motor to get the gears to slide through. Wath the Rotary SMP Maho videos on Youtube for an automatically-selecting gearbox.

Replied by andypugh on topic gearchange

I am slowly getting an idea how I can build something to automatically change the manual gears

That might actually be easier, unexpectedly enough.

Though you probably need to cycle the motor to get the gears to slide through. Wath the Rotary SMP Maho videos on Youtube for an automatically-selecting gearbox.

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

25 Jan 2021 07:55 #196507

by anfänger

Replied by anfänger on topic gearchange

Yes I follow hin on you tube.

I would use two steppers with a belt drive for handle turning.

An an bunch of switches for gear detection.

But this would be to much for now. I want to have an easy solution to get started.

I would use two steppers with a belt drive for handle turning.

An an bunch of switches for gear detection.

But this would be to much for now. I want to have an easy solution to get started.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

25 Jan 2021 08:37 #196508

by andypugh

Replied by andypugh on topic gearchange

If you want to start easy, then a PyVCP box to enter the gear number in would be a good starting point.

Possibly a ComboBox to drop down the nominal speed of the selected gear, as I imagine that is how it is labelled on the machine?

Possibly a ComboBox to drop down the nominal speed of the selected gear, as I imagine that is how it is labelled on the machine?

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

25 Jan 2021 09:28 #196512

by anfänger

Replied by anfänger on topic gearchange

On the machine the gears are labelled with the nominal gear.

2240/1400

800/500

1120/710

1600/1000

560/355

200/125

280/180

400/250

140/80

50/31,5

71/45

100/63

which if those pairs I run can I change with an Mcode while spindle is running but not cutting.

Yea combox is probably the way to start

2240/1400

800/500

1120/710

1600/1000

560/355

200/125

280/180

400/250

140/80

50/31,5

71/45

100/63

which if those pairs I run can I change with an Mcode while spindle is running but not cutting.

Yea combox is probably the way to start

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

25 Jan 2021 14:02 #196527

by db1981

Replied by db1981 on topic gearchange

Hi,

in case you are talking about your NEF480.

Pay attention with using an VFD on this Motor, i already burned an NEF Motor....

This Motor is only Iso Class B (evtl. E) and not build for use with VFDs. When using with lower RPMs there will be to much thermal stress for the windings, also the electrical insulation is not enough for todays VFDs. PWM and generated "Sinus" Output will produce µs Spikes of 800V or above.

Also with low rpms the gearbox lubrication will be insufficent.

Usable range for this motor will only be between 40-50Hz (60Hz if you have trust in the gearbox bearings.)

ps "ist das die blaue NEF aus Kirchen im WW?"

in case you are talking about your NEF480.

Pay attention with using an VFD on this Motor, i already burned an NEF Motor....

This Motor is only Iso Class B (evtl. E) and not build for use with VFDs. When using with lower RPMs there will be to much thermal stress for the windings, also the electrical insulation is not enough for todays VFDs. PWM and generated "Sinus" Output will produce µs Spikes of 800V or above.

Also with low rpms the gearbox lubrication will be insufficent.

Usable range for this motor will only be between 40-50Hz (60Hz if you have trust in the gearbox bearings.)

ps "ist das die blaue NEF aus Kirchen im WW?"

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

25 Jan 2021 14:26 - 25 Jan 2021 14:27 #196528

by anfänger

Replied by anfänger on topic gearchange

HI,

Yes I am talking about my NEF480 and it is the one from Kirchen. Do you know this machine?

I thought of using it from 35hz to 50hz. I know the oil pump is directly on the main shaft. I don’t know what the Punk thinks of 60Hz (1740 instead of 1450 rpm) But 40 to 56hz usage would cover almost all speeds.

How did you solve the Gearbox or are you using the VFD just as a soft start?

Yes I am talking about my NEF480 and it is the one from Kirchen. Do you know this machine?

I thought of using it from 35hz to 50hz. I know the oil pump is directly on the main shaft. I don’t know what the Punk thinks of 60Hz (1740 instead of 1450 rpm) But 40 to 56hz usage would cover almost all speeds.

How did you solve the Gearbox or are you using the VFD just as a soft start?

Last edit: 25 Jan 2021 14:27 by anfänger.

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

25 Jan 2021 15:37 #196531

by db1981

Replied by db1981 on topic gearchange

I consider to take a look at this machine because it was only 10km away from me...

But then i made the wrong decision and got a douple pack with nef 280 and nef 480.

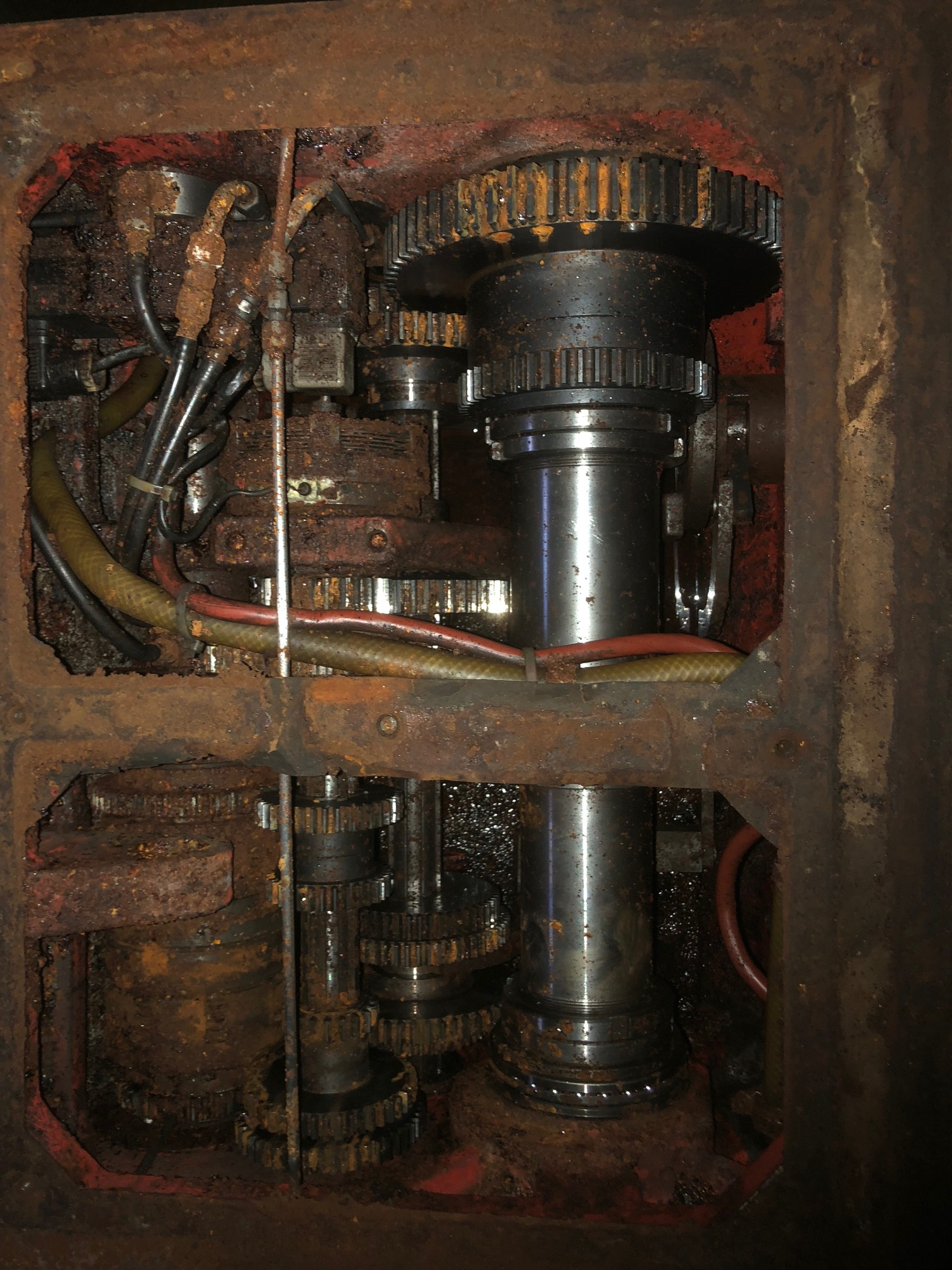

i will retrofit the 280. The 480 was ok from the bed and the rest but at home i got a shock after a deeper lock .

.

For the Gearbox and vfd i would write a specific component, like i did before for other retrofits.

But then i made the wrong decision and got a douple pack with nef 280 and nef 480.

i will retrofit the 280. The 480 was ok from the bed and the rest but at home i got a shock after a deeper lock

For the Gearbox and vfd i would write a specific component, like i did before for other retrofits.

Attachments:

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

25 Jan 2021 16:10 #196534

by anfänger

Replied by anfänger on topic gearchange

Oh that looks nasty, sorry for that.

Mine was a workhorse a bit neglected but not really mistreated. (They bypassed the limit Switches and crashed, so there are some nasty marks on the chuck and sled ). The Gearbox looks much better than yours. I negotiated a bit on the price and they drove it over to me. So far no really bad surprises.

I never programmed a comp just some small bash and python scripts to get my Chiron running.

I will start easy and maybe later get more fancy hoping the motor survives. I it dies I guess I am in trouble.

Mine was a workhorse a bit neglected but not really mistreated. (They bypassed the limit Switches and crashed, so there are some nasty marks on the chuck and sled ). The Gearbox looks much better than yours. I negotiated a bit on the price and they drove it over to me. So far no really bad surprises.

I never programmed a comp just some small bash and python scripts to get my Chiron running.

I will start easy and maybe later get more fancy hoping the motor survives. I it dies I guess I am in trouble.

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

25 Jan 2021 20:42 #196556

by anfänger

Replied by anfänger on topic gearchange

I tried think I installed the gearchange from page 1,

I added this too my hal file:

loadrt gearchange count=2 personality=12,2

addf gearchange.0 servo-thread

addf gearchange.1 servo-thread

but I think there are some pins missing like ratio and the min and max for each gear:

I added this too my hal file:

loadrt gearchange count=2 personality=12,2

addf gearchange.0 servo-thread

addf gearchange.1 servo-thread

but I think there are some pins missing like ratio and the min and max for each gear:

32 float OUT 0 gearchange.0.accel-limit

32 bit IN FALSE gearchange.0.dir-in

32 bit OUT FALSE gearchange.0.dir-out

32 bit IN FALSE gearchange.0.gear-0-sel

32 bit IN FALSE gearchange.0.gear-1-sel

32 bit IN FALSE gearchange.0.gear-10-sel

32 bit IN FALSE gearchange.0.gear-11-sel

32 bit IN FALSE gearchange.0.gear-12-sel

32 bit IN FALSE gearchange.0.gear-2-sel

32 bit IN FALSE gearchange.0.gear-3-sel

32 bit IN FALSE gearchange.0.gear-4-sel

32 bit IN FALSE gearchange.0.gear-5-sel

32 bit IN FALSE gearchange.0.gear-6-sel

32 bit IN FALSE gearchange.0.gear-7-sel

32 bit IN FALSE gearchange.0.gear-8-sel

32 bit IN FALSE gearchange.0.gear-9-sel

32 u32 IN 0x00000000 gearchange.0.gear-number

32 bit OUT FALSE gearchange.0.max-lim

32 bit OUT FALSE gearchange.0.min-lim

32 bit IN FALSE gearchange.0.sel

32 float OUT 0 gearchange.0.speed-filtered

32 float IN 0 gearchange.0.speed-in

32 float OUT 0 gearchange.0.speed-out

32 s32 OUT 0 gearchange.0.time

32 float OUT 0 gearchange.1.accel-limit

32 bit IN FALSE gearchange.1.dir-in

32 bit OUT FALSE gearchange.1.dir-out

32 bit IN FALSE gearchange.1.gear-0-sel

32 bit IN FALSE gearchange.1.gear-1-sel

32 bit IN FALSE gearchange.1.gear-2-sel

32 u32 IN 0x00000000 gearchange.1.gear-number

32 bit OUT FALSE gearchange.1.max-lim

32 bit OUT FALSE gearchange.1.min-lim

32 bit IN FALSE gearchange.1.sel

32 float OUT 0 gearchange.1.speed-filtered

32 float IN 0 gearchange.1.speed-in

32 float OUT 0 gearchange.1.speed-out

32 s32 OUT 0 gearchange.1.timePlease Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

25 Jan 2021 22:12 #196574

by db1981

Replied by db1981 on topic gearchange

The Pins you missing, are not PINs, that are PARAMETERS,

take a look in halshow, at the Parameter Section.

Usually you will set them with an INI Entry.

Example:

INI:

[BLOCK] (z.B. TRANSMISSION)

ENTRY = 120.0

HAL:

setp gearchange.0.parameterxxx [BLOCK] ENTRY

take a look in halshow, at the Parameter Section.

Usually you will set them with an INI Entry.

Example:

INI:

[BLOCK] (z.B. TRANSMISSION)

ENTRY = 120.0

HAL:

setp gearchange.0.parameterxxx [BLOCK] ENTRY

The following user(s) said Thank You: anfänger

Please Log in or Create an account to join the conversation.

Time to create page: 0.138 seconds