Challenges Tuning Servos on Brother TC-225 Retrofit

- Type_Zero_Design

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 7

02 Sep 2019 01:26 #143830

by Type_Zero_Design

Challenges Tuning Servos on Brother TC-225 Retrofit was created by Type_Zero_Design

Hello Everyone,

***In the interest of reducing confusion and making this more beneficial for anyone that may be reading this I have created a dedicated post from my questions in Tommy's Servo Tuning how to (which has been super helpful) to address my issues***

So with that being said here are the details of my current situation:

- 3 axis mill retrofit using STEP/DIR Servos and Drives with encoder feedback. Using Mesa 7i76E with 7i85 handling the encoders.

- Servos and Drives installed

- Drive Enable working

- limits and E-Stop working

- Confirmed direction of motion and encoder feedback

- Confirmed encoders reporting to DRO via manually moving screws

- Confirmed movement matches commanded movement via indicator.

- Confirmed encoders are connected to PID

- Confirmed Max error removed

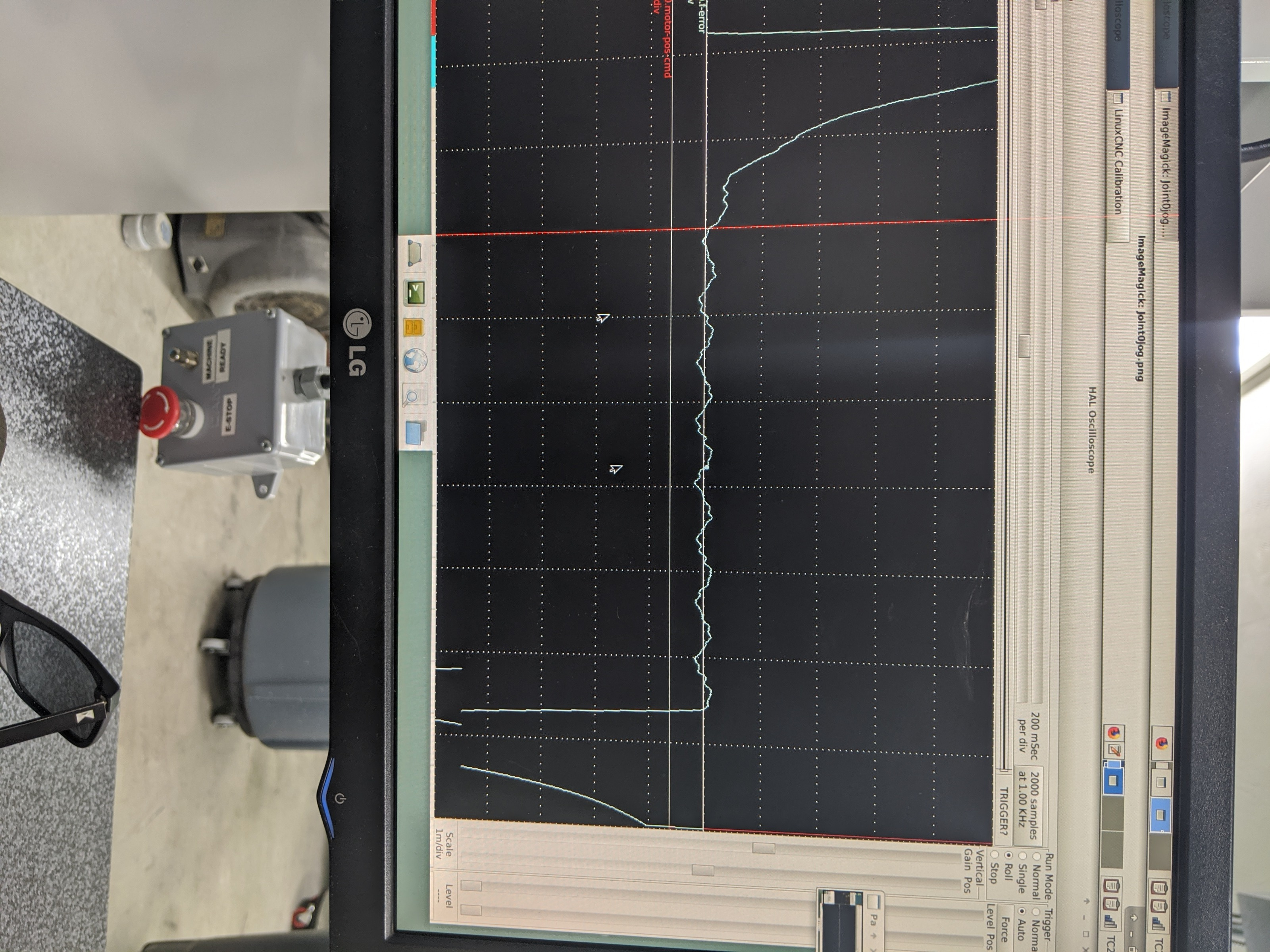

I have now followed Tommy's guide and upped my P untill oscillations occurred after a short jog, then backed off untill they cleared. At that point the joint.n.f-error would spike up relatively stabilize above the command line and after releasing the jog would drop back in line. From there I upped my FF1 untill the joint.n.f-erro would peak up for a split second and while continuing to hold the jog would the run centered on the commanded line. Now that I have accomplished this I now have an oscilattion that occurs after releasing the jog as shown in the video at this link: Current HAL Scope with oscillations

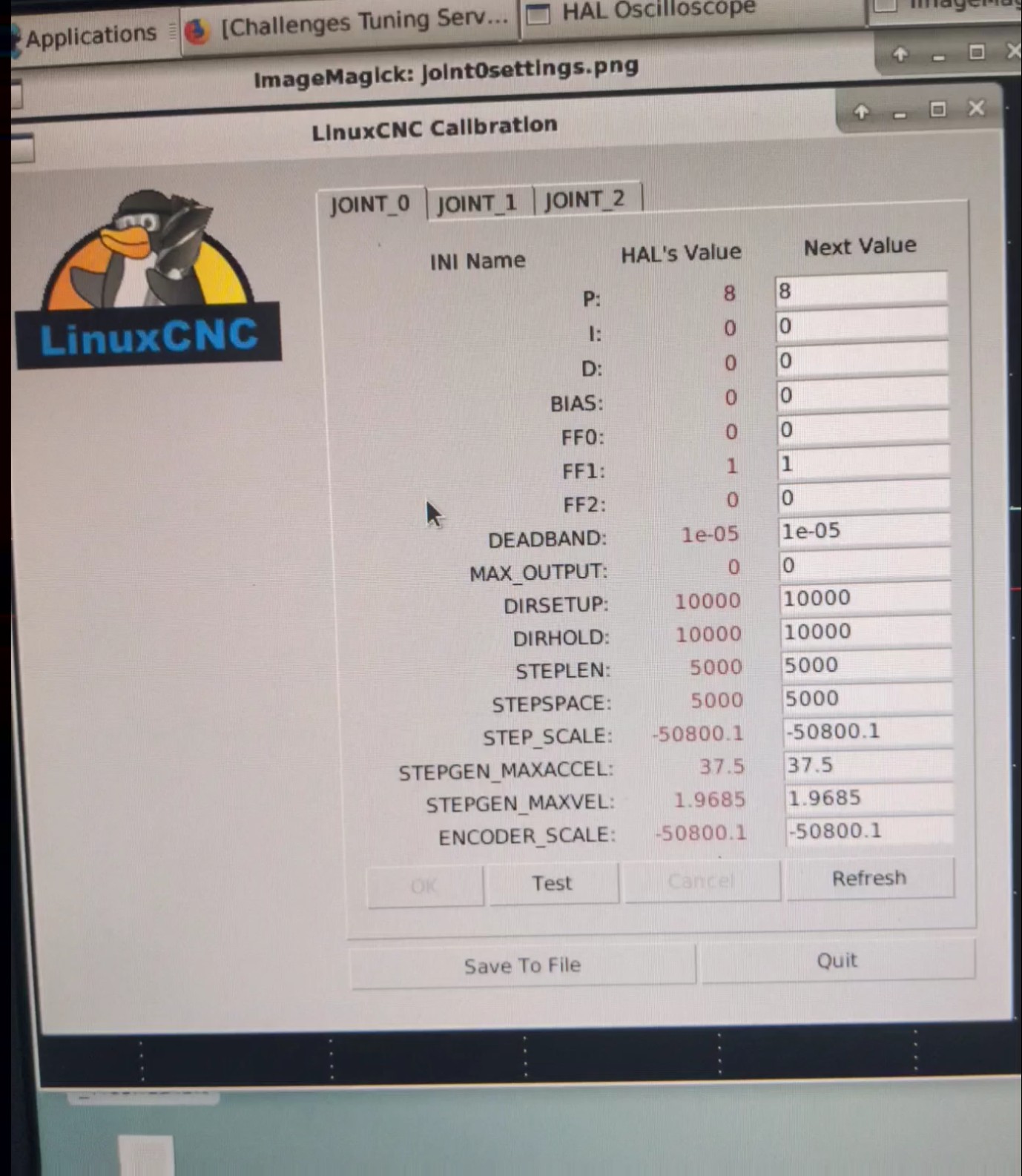

This is a photo of the settings that were running in this video and are current now:

I am trying to figure out where to go from here. If I dial back my FF1 to clear the oscillations my error goes out, and vice versa.

There is a good chance I also have some additional setting wrong that needs to be resolved to actually tune correctly.

I appreciate any help!

***In the interest of reducing confusion and making this more beneficial for anyone that may be reading this I have created a dedicated post from my questions in Tommy's Servo Tuning how to (which has been super helpful) to address my issues***

So with that being said here are the details of my current situation:

- 3 axis mill retrofit using STEP/DIR Servos and Drives with encoder feedback. Using Mesa 7i76E with 7i85 handling the encoders.

- Servos and Drives installed

- Drive Enable working

- limits and E-Stop working

- Confirmed direction of motion and encoder feedback

- Confirmed encoders reporting to DRO via manually moving screws

- Confirmed movement matches commanded movement via indicator.

- Confirmed encoders are connected to PID

- Confirmed Max error removed

I have now followed Tommy's guide and upped my P untill oscillations occurred after a short jog, then backed off untill they cleared. At that point the joint.n.f-error would spike up relatively stabilize above the command line and after releasing the jog would drop back in line. From there I upped my FF1 untill the joint.n.f-erro would peak up for a split second and while continuing to hold the jog would the run centered on the commanded line. Now that I have accomplished this I now have an oscilattion that occurs after releasing the jog as shown in the video at this link: Current HAL Scope with oscillations

This is a photo of the settings that were running in this video and are current now:

I am trying to figure out where to go from here. If I dial back my FF1 to clear the oscillations my error goes out, and vice versa.

There is a good chance I also have some additional setting wrong that needs to be resolved to actually tune correctly.

I appreciate any help!

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

02 Sep 2019 03:54 #143858

by PCW

Replied by PCW on topic Challenges Tuning Servos on Brother TC-225 Retrofit

Can you post your hal and ini files?

If this is a step/dir driven system, FF1 must =1.000, its not something you tune

If this is a step/dir driven system, FF1 must =1.000, its not something you tune

Please Log in or Create an account to join the conversation.

- Type_Zero_Design

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 7

02 Sep 2019 20:49 #143942

by Type_Zero_Design

Replied by Type_Zero_Design on topic Challenges Tuning Servos on Brother TC-225 Retrofit

PCW,

Here are my current HAL and INI files:

Here are my current HAL and INI files:

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

02 Sep 2019 21:09 #143953

by PCW

Replied by PCW on topic Challenges Tuning Servos on Brother TC-225 Retrofit

The hal ini files look OK

where is the encoder feedback coming from?

where is the encoder feedback coming from?

Please Log in or Create an account to join the conversation.

- Type_Zero_Design

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 7

03 Sep 2019 01:53 - 03 Sep 2019 01:55 #144000

by Type_Zero_Design

Replied by Type_Zero_Design on topic Challenges Tuning Servos on Brother TC-225 Retrofit

You mean physically? They are encoders mounted on the servo motors. Fed back to the 7i85 through the drives.

So basses on your statement about FF1 that would seem to explain why when I got to 1 as a part of my tuning procedure it seemed f error seemed to come in line. So where would I proceed from this point you tuning wise if FF1 isn't to be touched?

So basses on your statement about FF1 that would seem to explain why when I got to 1 as a part of my tuning procedure it seemed f error seemed to come in line. So where would I proceed from this point you tuning wise if FF1 isn't to be touched?

Last edit: 03 Sep 2019 01:55 by Type_Zero_Design.

The following user(s) said Thank You: Mike_Eitel

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

03 Sep 2019 02:27 #144003

by PCW

Replied by PCW on topic Challenges Tuning Servos on Brother TC-225 Retrofit

You might try running open loop = pid feedback from stepgen but still feeding the encoders to motions feedback pin

This will give you a measurement of how well the drive itself follows the step/dir position commands

Also you should make sure you have no smoothing filters enabled in the drive

This will give you a measurement of how well the drive itself follows the step/dir position commands

Also you should make sure you have no smoothing filters enabled in the drive

Please Log in or Create an account to join the conversation.

- Type_Zero_Design

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 7

03 Sep 2019 02:32 #144004

by Type_Zero_Design

Replied by Type_Zero_Design on topic Challenges Tuning Servos on Brother TC-225 Retrofit

Ok I will take a look at that. Waiting out to see if we are going to get wrecked by this hurricane tomorrow.

Please Log in or Create an account to join the conversation.

- Type_Zero_Design

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 7

21 Sep 2019 20:39 #145790

by Type_Zero_Design

Replied by Type_Zero_Design on topic Challenges Tuning Servos on Brother TC-225 Retrofit

PCW,

I don't see anything in my Hal or Ini files that matches up with what you were saying here:

I understand what your saying, just not 100% on what I need to change in my Ini and Hal that I posted to accomplish that.

I don't see anything in my Hal or Ini files that matches up with what you were saying here:

You might try running open loop = pid feedback from stepgen but still feeding the encoders to motions feedback pin

I understand what your saying, just not 100% on what I need to change in my Ini and Hal that I posted to accomplish that.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

21 Sep 2019 21:26 #145792

by PCW

Replied by PCW on topic Challenges Tuning Servos on Brother TC-225 Retrofit

What I am saying is the the stepgens take the joint commanded position and the PID takes the stepgen feedback position (like a non encoder stepgen setup) but you feed the encoder position back to motion

that is:

motion joint position command --> PID command

stepgen feedback position -- >PID feedback

(which is standard open loop stepgen setup)

but

motion joint position feedback <-- encoder position

rather than from stepgen position feedback

This means that any actual following error will be calculated

and can cause a fault

that is:

motion joint position command --> PID command

stepgen feedback position -- >PID feedback

(which is standard open loop stepgen setup)

but

motion joint position feedback <-- encoder position

rather than from stepgen position feedback

This means that any actual following error will be calculated

and can cause a fault

Please Log in or Create an account to join the conversation.

- Type_Zero_Design

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 7

19 Jul 2020 03:10 - 19 Jul 2020 03:22 #175099

by Type_Zero_Design

Replied by Type_Zero_Design on topic Challenges Tuning Servos on Brother TC-225 Retrofit

PCW,

Its been about a year since I have been working on this, life happens.... I spent the evening getting caught up on where i was and I wanted to pick your brain on this.

Here is a quick screen shot of the current scope im getting on joint 0.

Here is a shot of my settings for Joint 0

Based on your last post I know that you were suggesting that I change a few things in my HAL file to try to verify the tune of the actual servo drive. Unfortunately looking through my HAL file i don't find anything that quite matches what you are describing. If its possible that you could take a look at the attached HAL file and copy the lines in that I should change and what to that would be immensely helpful.

I appreciate everyone on heres support and look forward to getting my machine up and running!

Its been about a year since I have been working on this, life happens.... I spent the evening getting caught up on where i was and I wanted to pick your brain on this.

Here is a quick screen shot of the current scope im getting on joint 0.

Here is a shot of my settings for Joint 0

Based on your last post I know that you were suggesting that I change a few things in my HAL file to try to verify the tune of the actual servo drive. Unfortunately looking through my HAL file i don't find anything that quite matches what you are describing. If its possible that you could take a look at the attached HAL file and copy the lines in that I should change and what to that would be immensely helpful.

I appreciate everyone on heres support and look forward to getting my machine up and running!

Attachments:

Last edit: 19 Jul 2020 03:22 by Type_Zero_Design.

Please Log in or Create an account to join the conversation.

Time to create page: 0.267 seconds