auto tool measurement working

- j.clark91

- Offline

- New Member

-

- Posts: 5

- Thank you received: 2

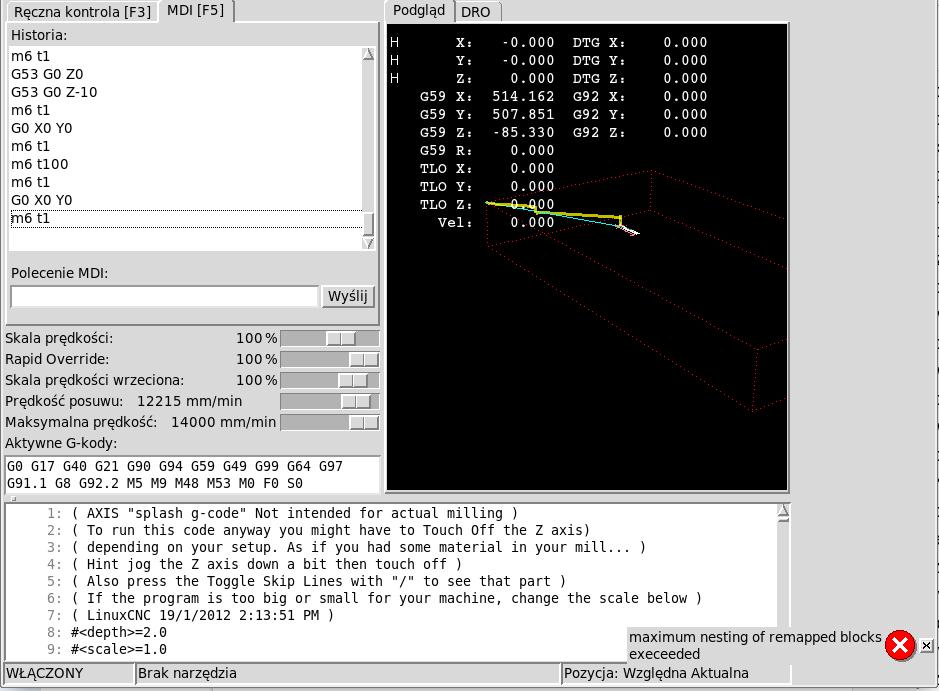

Running linuxcnc-2.7.14-wheezy.iso off the live cd downloaded from the website

i am posting this to help people who are trying to get the machine to auto measure there tool after manual tool change, after many hours of searching and reading the wiki pages i found a post on a different site that i based my program on i cant find it again but ill post the link when i do.

my set up means i cant have tool holders as it is a cheap machine from ebay so no tool is the same height.

I am going to change the file slightly as when i type T0 M6 into mdi it still goes to measure which will update later on here once done but it still works just minor inconvenience for now.

onto the tool changer

i have set my tool probe in the G59 datum in X,Y and Z so it can be easily moved around the table as needed depending on setup, to set the z i tool the nut off the spindle and jogged down until the probe pin turned true and set it from there.

I have done this because it is a constant and won't change with the nut on or tool in the spindle it will always change the z location of the tool probe.

when you call the tool with the M6 command the spindle will rise upto the top home location (safe place) and wait for you to change tool, once okay pressed it will move over to the G59 location and begin to measure the tool fast from that location. Then come up and measure again slowly to get a more accurate reading. The height in the tool table will be a plus number, this means you can use multiple work offsets in the program with each tool.

The ngc program DOES NOT change the machine back to G90 or to the datum used before tool change because the way i program

G0 G90 G53 Z0. (SAFE HIGHT)

T1 M6 (CALL TOOL)

M00 (STOP TO TURN SPINDLE ON MANUALY)

G0 G90 G54 X0. Y0. S1000 M3 (SAFE LINE, RESET TO G90 TURN SPINDLE ON AND MOVE TO LOCATION)

G43 H1 Z10. (TOOL COMP ON SAFE PLACE ABOVE WORK)

Z5.

(G CODE HERE)

G0 G90 Z10. M5 (UP TO SAFE LOCATION ABOVE WORK, SPINDLE OFF)

G0 G90 G53 Z0. (SAFE HIGHT)

M01 (OPTIONAL STOP)

this way the program will always use the write datum and mode relevant to what you are going todo.

when setting the work datum i will use a wobbler to find the x and y location and set these in the work offset as required. when setting the z i will load up a tool (usually the 1st tool i am going to use) and measure it in mdi by calling up the tool number and m6, then once set and g43 active ill touch the tool on top of each workpiece as required by the setup.

with the G43 active it will be relevant to the G59 work offset z location, so when the next tool is measured it will return to the same location on the workpiece.

the code

this is the relevant code in the .ini file

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

SUBROUTINE_PATH = macros

REMAP=M6 modalgroup=6 ngc=tool-change

i have seen a lot of posts that seam to over complicate this with inputs and options that i don't really think is very necessary.

in the .hal file this is the relevant part

loadusr -W hal_manualtoolchange

net tool-change iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-changed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-preparednow for the ngc file, i am going to change this so it is a lot more simple and easier to follow but for now it works,

i am planning on creating one big else if statement so it don't try and measure a tool that's not there.

O<tool-change> SUB

( Filename: tool-change.ngc )

(------------------------------- CONFIGURATION PARAMETERS ----------------------------------------------)

#<_ProbeRetract> = 2.0 ( small distance to retract before approaching switch/touch-off plate second time )

#<_ProbeFeed1> = 500 ( feed rate for touching switch/touch-off plate first time )

#<_ProbeFeed2> = 10.0 ( feed rate for touching switch/touch-off plate second time )

#<_ProbeMinZ> = -500. ( max distance in z for probe routine. shortest tool should trip before this)

#<_ProbeRetract> = 1 ( distance to retract before starting slow probe )

#<_tool> = #<_selected_tool>

#<_Ztravel> = 82.067 ( distance between machine zero and touch off sensor )

#<_previous_tool> = #<_current_tool> ( sets previous tool variable )

(-------------------------------------------------------------------------------------------------------)

O100 if [#<_task> EQ 0] ( only run the subroutine in milltask interpreter. **Critical** keep )

(debug, Task ist Null)

O100 return [999]

O100 endif

G53 G0 G90 Z0. ( move to high z position )

o200 IF [ #<_tool> EQ 0 ] ( check if tool zero selected and end routine )

(MSG, No Tool Selected )

o200 ENDIF

G49 ( turn off tool compensation )

G94 ( units per minute feed rate )

G40 ( turn off cutter compensation )

G90 ( use absolute mode )

G59

M6 ( run normal M6 operation )

O300 IF [ #<_tool> EQ #<_previous_tool> ]

(debug, Tool in spindle no change required)

O300 return [999]

O300 ELSE

G59 G0 G90 X0. Y0.

G91 G0

G38.2 Z[#<_ProbeMinZ>] F[#<_ProbeFeed1>]

G0 G91 Z2.0

G38.2 Z-2.5 F[#<_ProbeFeed2>]

G90

#<_ToolZRef> = #5063

#<_ToolConv> = [#<_ToolZRef>*-1]

#<_ToolOffset> = [#<_ZTravel> - #<_ToolConv>]

G10 L1 P#<_tool> Z#<_ToolOffset>

G53 G0 Z0

o300 ENDIF

#<_previous_tool> = #<_tool>

G43

O<tool-change> ENDSUB

M2i hope you followed that okay i've tried to keep it simple as possible so everyone can follow.

please let me know if i can rephrase it so its easier to understand

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

- Posts: 1872

- Thank you received: 358

some may find it good

others may need different

in general a good example

Please Log in or Create an account to join the conversation.

- REX299

-

- Visitor

-

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

Please Log in or Create an account to join the conversation.

- szatri

- Offline

- Junior Member

-

- Posts: 29

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

Please Log in or Create an account to join the conversation.

- szatri

- Offline

- Junior Member

-

- Posts: 29

- Thank you received: 1

PARAMETER_FILE = linuxcnc.var

SUBROUTINE_PATH = ./ngc

FEATURES = 12

REMAP=M6 modalgroup=6 ngc=tool-change

REMAP=M06 modalgroup=6 ngc=tool-change

doubling this entry is probably not necessary

Please Log in or Create an account to join the conversation.