two independent heads on one Y axis

- palain

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

30 Dec 2019 15:52 - 30 Dec 2019 15:54 #153553

by palain

two independent heads on one Y axis was created by palain

I have a gantry with two tool heads, they were originally meant to work in tandem on production runs.

I would like to use one head for the drill and the other for the laser.

The drill works fine on the y axis.

The laser works fine when mounted on the drill. But the 25 kg drill has a bit of inertia and enhibits the laser to move fast for engraving.

Each head can be parked out of the way so they would not be traveling together.

My question: my question is how to select a head (tool) to park the drill and make activate the laser.

and vice versa?

Also, it would be nice if the Y coordinates be used for both heads.... in other words, I wouldn't have to post process the Gcode for to change the Y axis to A . but this is a possibility.

I would like to use one head for the drill and the other for the laser.

The drill works fine on the y axis.

The laser works fine when mounted on the drill. But the 25 kg drill has a bit of inertia and enhibits the laser to move fast for engraving.

Each head can be parked out of the way so they would not be traveling together.

My question: my question is how to select a head (tool) to park the drill and make activate the laser.

and vice versa?

Also, it would be nice if the Y coordinates be used for both heads.... in other words, I wouldn't have to post process the Gcode for to change the Y axis to A . but this is a possibility.

Attachments:

Last edit: 30 Dec 2019 15:54 by palain.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21227

- Thank you received: 7249

31 Dec 2019 07:52 #153593

by tommylight

Replied by tommylight on topic two independent heads on one Y axis

There is more than one way of doing that, but the easiest would be to make separate configs and start the one you need, it works very nicely but you can not use both tools at the same time.

You can make a config with xyz and a or u or v or whatever as the second x or z, you can use both at the same time but requires a bit of gcode editing or filtering.

You can make a config with xyz and a or u or v or whatever as the second x or z, you can use both at the same time but requires a bit of gcode editing or filtering.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

31 Dec 2019 17:12 - 31 Dec 2019 17:18 #153616

by Grotius

Replied by Grotius on topic two independent heads on one Y axis

It this senario you can do this with the drive enable signal.

If using laser, enable laser y axis motor drive.

If using drill, enable drill y axis motor drive.

In this config you can enable bot'h drives with only Gcode for Y0 with fixed tool offset.

If you want to use them bot'h in the same program for different operations.

You have to use Y0 (laser) and Y1 (drill) in your axis config and use tool offsets.

Good luck, and the machine looks stable !

If using laser, enable laser y axis motor drive.

If using drill, enable drill y axis motor drive.

In this config you can enable bot'h drives with only Gcode for Y0 with fixed tool offset.

If you want to use them bot'h in the same program for different operations.

You have to use Y0 (laser) and Y1 (drill) in your axis config and use tool offsets.

Good luck, and the machine looks stable !

Last edit: 31 Dec 2019 17:18 by Grotius.

Please Log in or Create an account to join the conversation.

- palain

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

31 Dec 2019 21:23 - 31 Dec 2019 21:29 #153634

by palain

Replied by palain on topic two independent heads on one Y axis

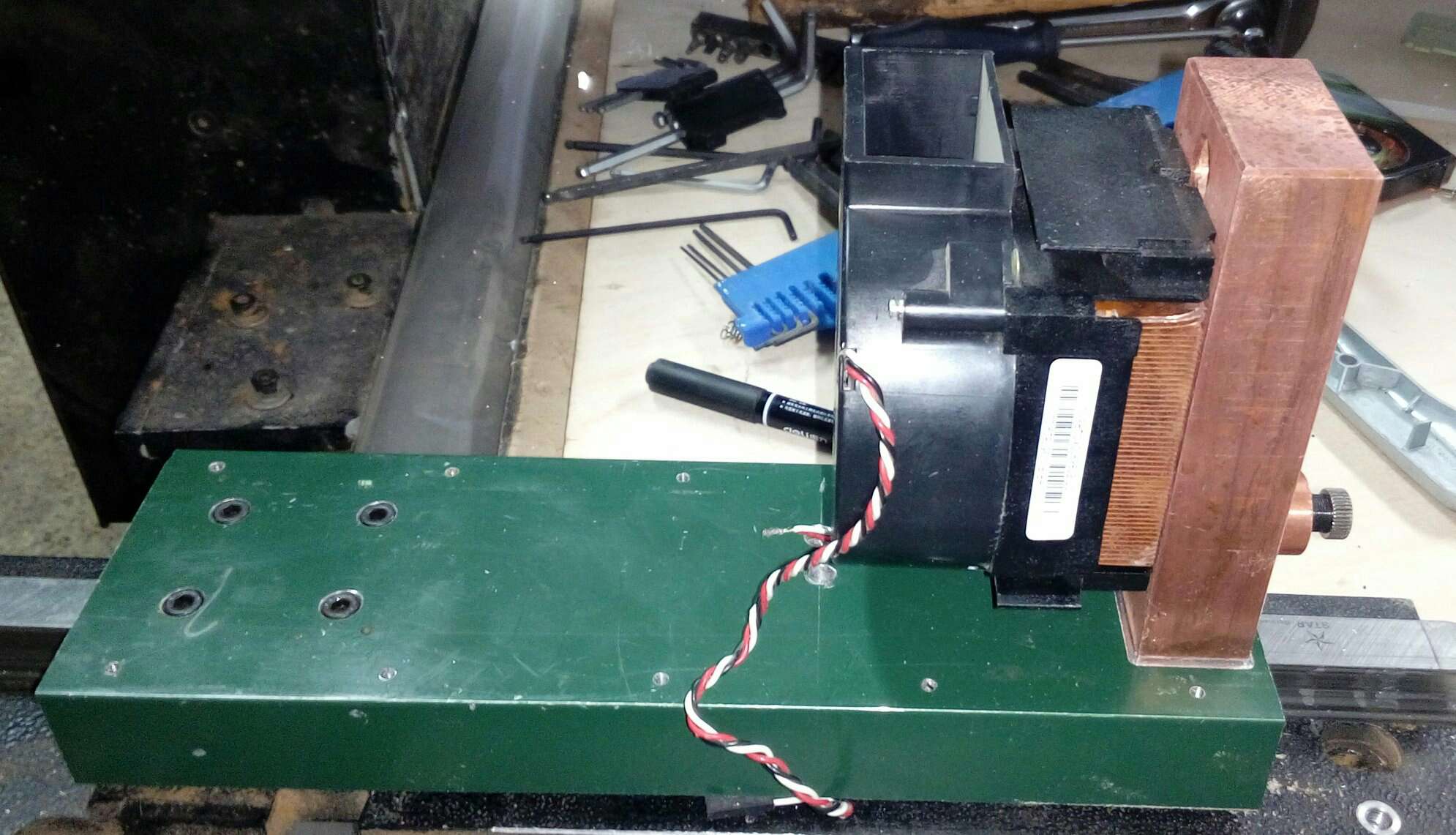

this machine was built like a bridge.

I like the motor enable solution. Just one pin controls one motor or the other. I will keep posting progress.

I am currently building the laser head - 7W Nichia with integrated PWM drive in the copper holder mounted on 2kg copper block with a copper heat sink and a 15W blower which is temperature sensitive (the hotter the air the more the blower works) all that mounted on a 8mm thick aluminium U channel which also provides heat sink.

I like the motor enable solution. Just one pin controls one motor or the other. I will keep posting progress.

I am currently building the laser head - 7W Nichia with integrated PWM drive in the copper holder mounted on 2kg copper block with a copper heat sink and a 15W blower which is temperature sensitive (the hotter the air the more the blower works) all that mounted on a 8mm thick aluminium U channel which also provides heat sink.

Last edit: 31 Dec 2019 21:29 by palain.

Please Log in or Create an account to join the conversation.

- palain

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

01 Jan 2020 00:55 #153677

by palain

Replied by palain on topic two independent heads on one Y axis

After checking the motor enable, I found it was difficult to use without getting lost in the coordinates.... homing at two different switches makes it confusing.

Since I have 4 motors, I have 4 axes.

kinematics are trivial

The V is supposed to be parallel to Y

[TRAJ]

AXES = 4

COORDINATES = X Y Z V

Since I have 4 motors, I have 4 axes.

kinematics are trivial

The V is supposed to be parallel to Y

[TRAJ]

AXES = 4

COORDINATES = X Y Z V

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

07 Jan 2020 22:39 #154271

by andypugh

Replied by andypugh on topic two independent heads on one Y axis

You might want to think about which tool needs to move fastest as the controller does much better blending and lookahead in XYZ than with other axes.

But then you can't do XV arcs at all....

But then you can't do XV arcs at all....

Please Log in or Create an account to join the conversation.

Time to create page: 0.117 seconds