3D touch probe + Tool setter + Z touch

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

07 Dec 2020 16:58 #191327

by alkabal

3D touch probe + Tool setter + Z touch was created by alkabal

Hi all

I have a question, how did you manage to connect safely different Probe.

My card is mesa 7i76e 24v powered.

I have ordered a vers.by toolsetter that is NC NPN. (and order a little convert NPN/PNP NO/NC)

I now plan to order a 3D touch probe and i'm unsure how to make both work safely with unconnected detection (tool setter permanently connected but 3D probe removable) (possible choice NPN/PNP NO/NC)

I also need confirmation, with these 2 unit and using macro a basic Z touch plate is useless ?

Did you see the correct way for 3D probe removed detection and keep connected the tool setter (and of course if toolsetter missing need to be detected)

If possible using only one input but i can use two different input and some hal or2 if they are no other way.

Thanks in advance

I have a question, how did you manage to connect safely different Probe.

My card is mesa 7i76e 24v powered.

I have ordered a vers.by toolsetter that is NC NPN. (and order a little convert NPN/PNP NO/NC)

I now plan to order a 3D touch probe and i'm unsure how to make both work safely with unconnected detection (tool setter permanently connected but 3D probe removable) (possible choice NPN/PNP NO/NC)

I also need confirmation, with these 2 unit and using macro a basic Z touch plate is useless ?

Did you see the correct way for 3D probe removed detection and keep connected the tool setter (and of course if toolsetter missing need to be detected)

If possible using only one input but i can use two different input and some hal or2 if they are no other way.

Thanks in advance

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

07 Dec 2020 17:01 - 07 Dec 2020 20:05 #191328

by alkabal

Replied by alkabal on topic 3D touch probe + Tool setter + Z touch

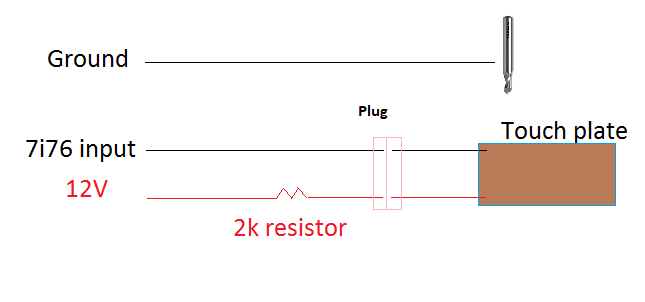

Attachments:

Last edit: 07 Dec 2020 20:05 by alkabal.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

08 Dec 2020 01:55 #191377

by JohnnyCNC

I have a touch plate wired like yours which is normally open. I just added a 3D probe (Hallmark ITTP) which electrically just a NC switch. I wired them to separate inputs which both feed into an or2 hal component. I use a macro which is started buy a button on my touch-plate when using it and the probing buttons/routines in QTDragon when using the 3D probe. Both work great.

Replied by JohnnyCNC on topic 3D touch probe + Tool setter + Z touch

Hi all

I have a question, how did you manage to connect safely different Probe.

My card is mesa 7i76e 24v powered.

I have ordered a vers.by toolsetter that is NC NPN. (and order a little convert NPN/PNP NO/NC)

I now plan to order a 3D touch probe and i'm unsure how to make both work safely with unconnected detection (tool setter permanently connected but 3D probe removable) (possible choice NPN/PNP NO/NC)

I also need confirmation, with these 2 unit and using macro a basic Z touch plate is useless ?

Did you see the correct way for 3D probe removed detection and keep connected the tool setter (and of course if toolsetter missing need to be detected)

If possible using only one input but i can use two different input and some hal or2 if they are no other way.

Thanks in advance

I have a touch plate wired like yours which is normally open. I just added a 3D probe (Hallmark ITTP) which electrically just a NC switch. I wired them to separate inputs which both feed into an or2 hal component. I use a macro which is started buy a button on my touch-plate when using it and the probing buttons/routines in QTDragon when using the 3D probe. Both work great.

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

08 Dec 2020 09:38 #191401

by alkabal

Replied by alkabal on topic 3D touch probe + Tool setter + Z touch

Hi

Thanks for confirmation using or2 component but I think they can’t detect a missing probe

Imo they are 3 situation

Detect tool setter missing for Regular tool change with autolenght (maybe detect wrong tool if tool 1 is 3D probe)

Detect 3D probe missing for touch to material.

Detect 3D probe missing or tool setter missing for autolenght for reference tool 1 (probe is tool 1 if I’m right)

Best regards

Thanks for confirmation using or2 component but I think they can’t detect a missing probe

Imo they are 3 situation

Detect tool setter missing for Regular tool change with autolenght (maybe detect wrong tool if tool 1 is 3D probe)

Detect 3D probe missing for touch to material.

Detect 3D probe missing or tool setter missing for autolenght for reference tool 1 (probe is tool 1 if I’m right)

Best regards

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

09 Dec 2020 01:47 - 09 Dec 2020 01:49 #191458

by alkabal

Replied by alkabal on topic 3D touch probe + Tool setter + Z touch

Well

I have do some basic test with vers tsm + converter, the result is imo better using NPN-NO, in this situation i can have the same behavior with basic touch plate or vers.by TSM.

Pin is low if nothing is connected (generating error if i try to use probe)

Pin is High if TSM + converter is connected or if touch plate + pullup

Pin is low if probe is triggered

If i'm right for 3D touch probe i need to order also a NPN-NO (or use convertor) for have all the same result.

This does not solve my interrogation about separating device missing detection vs used macro.

I think for someone like me that have sometimes the head in the air, better is to found a way for preventing one or other missing sensor depending on what is needed for the macro used.

The basic idea i have for now is :

2 input pin from mesa card

or2 for connect both to motion.probe-input

at the macro beginning use if HAL_PIN_VARS for detect if one or other is low or high

If you have better idea your welcome.

br

I have do some basic test with vers tsm + converter, the result is imo better using NPN-NO, in this situation i can have the same behavior with basic touch plate or vers.by TSM.

Pin is low if nothing is connected (generating error if i try to use probe)

Pin is High if TSM + converter is connected or if touch plate + pullup

Pin is low if probe is triggered

If i'm right for 3D touch probe i need to order also a NPN-NO (or use convertor) for have all the same result.

This does not solve my interrogation about separating device missing detection vs used macro.

I think for someone like me that have sometimes the head in the air, better is to found a way for preventing one or other missing sensor depending on what is needed for the macro used.

The basic idea i have for now is :

2 input pin from mesa card

or2 for connect both to motion.probe-input

at the macro beginning use if HAL_PIN_VARS for detect if one or other is low or high

If you have better idea your welcome.

br

Last edit: 09 Dec 2020 01:49 by alkabal.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

09 Dec 2020 13:33 #191494

by JohnnyCNC

Replied by JohnnyCNC on topic 3D touch probe + Tool setter + Z touch

You can always use the inverted version of a pin to get the logic state you want for a given NO or NC device.

FALSE hm2_5i25.0.7i76.0.0.input-05

TRUE hm2_5i25.0.7i76.0.0.input-05-not

FALSE hm2_5i25.0.7i76.0.0.input-05

TRUE hm2_5i25.0.7i76.0.0.input-05-not

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

09 Dec 2020 13:59 #191497

by alkabal

Replied by alkabal on topic 3D touch probe + Tool setter + Z touch

Thanks a lot, you are right i already use the not function for the probe input.

For now i hope the wire solution i have found is good for detect if probe is connected or not connected, i have do some test using NPN NC Tool setter + converter for output a NPN NO signal or with touch plate with externalized pull-up is in my opinion the best solution for my usage (detecting if probe is connected/not connected/triggered)

Now the TODO is the most important parts for me : found the best way for link safely 2 or 3 probe input before motion.probe-input and check the presence separately inside macro. (need to do the test with 2 input with or2/or3 or other hal component)

Maybe the proposed solution with HAL_PIN_VARS "hm2_5i25.0.7i76.0.0.input-0x" check inside macro can be a good solution

Thanks for interest.

For now i hope the wire solution i have found is good for detect if probe is connected or not connected, i have do some test using NPN NC Tool setter + converter for output a NPN NO signal or with touch plate with externalized pull-up is in my opinion the best solution for my usage (detecting if probe is connected/not connected/triggered)

Now the TODO is the most important parts for me : found the best way for link safely 2 or 3 probe input before motion.probe-input and check the presence separately inside macro. (need to do the test with 2 input with or2/or3 or other hal component)

Maybe the proposed solution with HAL_PIN_VARS "hm2_5i25.0.7i76.0.0.input-0x" check inside macro can be a good solution

Thanks for interest.

Please Log in or Create an account to join the conversation.

Time to create page: 0.230 seconds