Ballscrew Mapping to Having an Effect

- CNC4Life

- Offline

- Junior Member

-

Less

More

- Posts: 36

- Thank you received: 2

21 Jun 2021 18:16 - 21 Jun 2021 18:17 #212574

by CNC4Life

Ballscrew Mapping to Having an Effect was created by CNC4Life

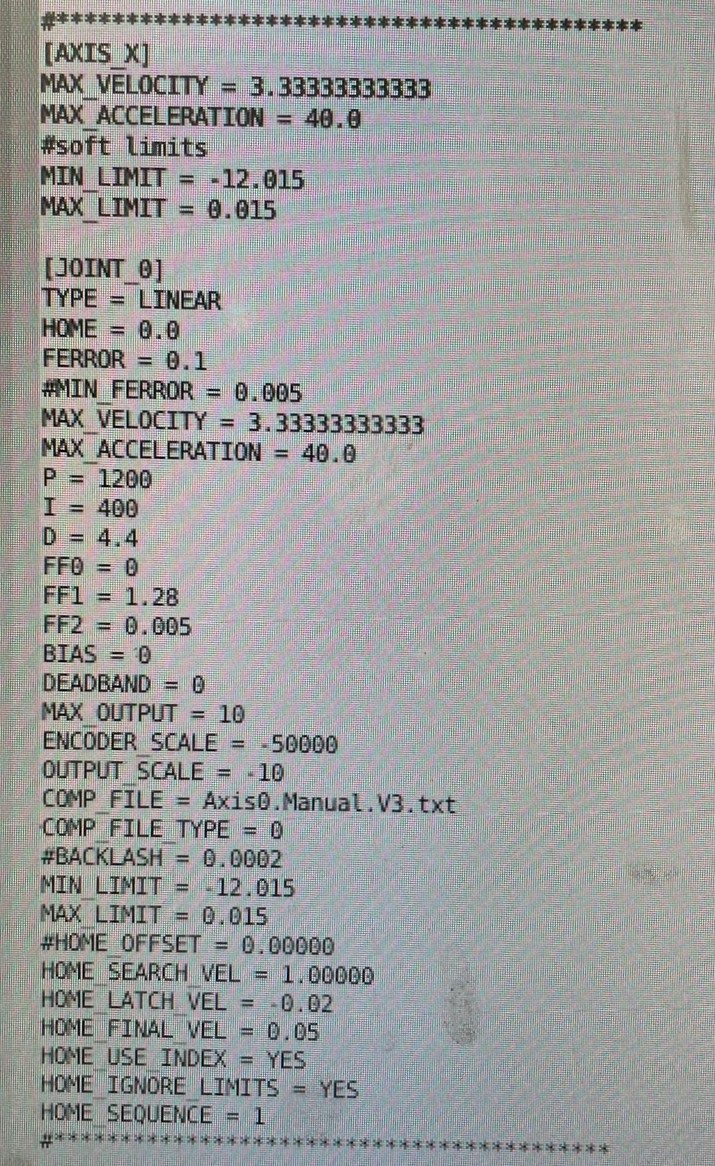

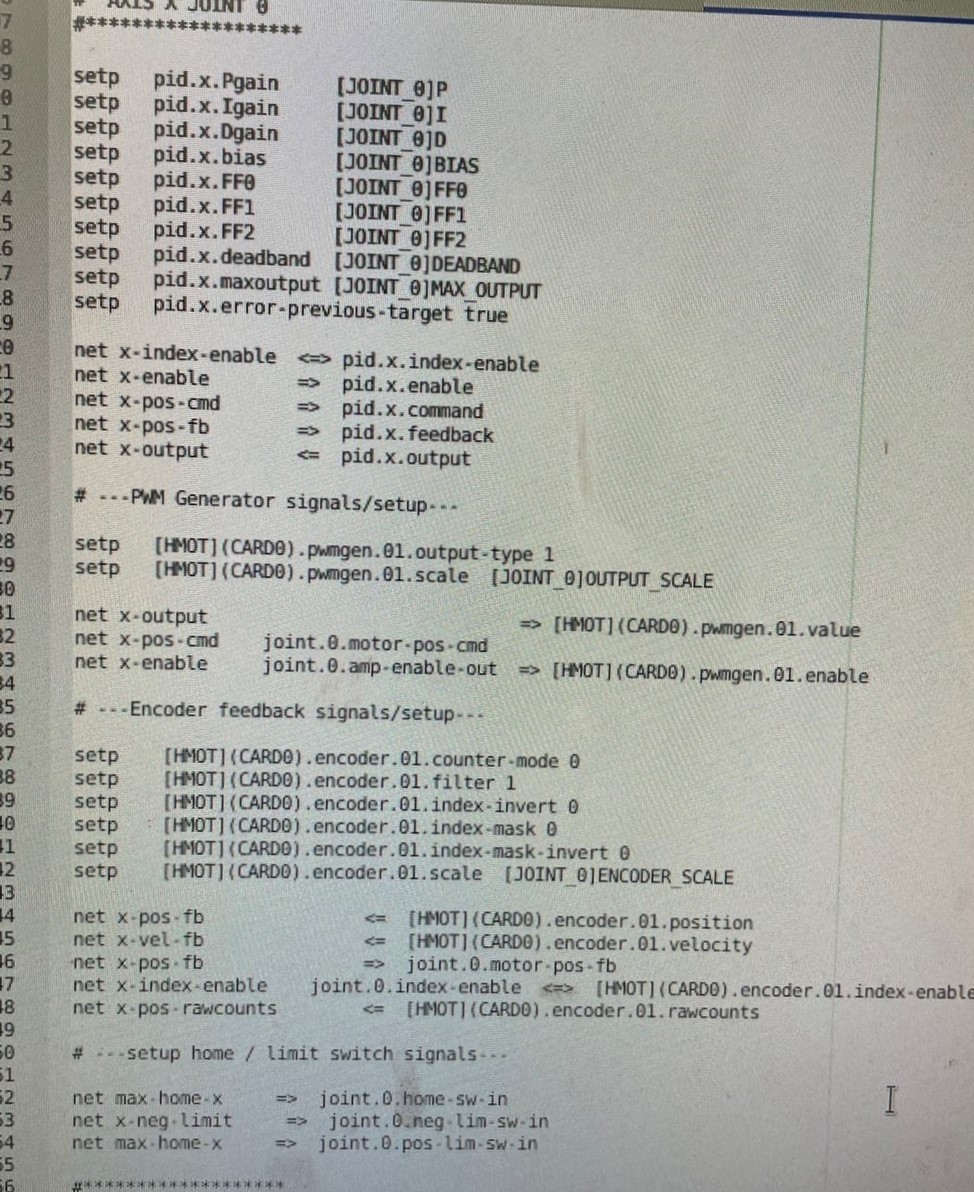

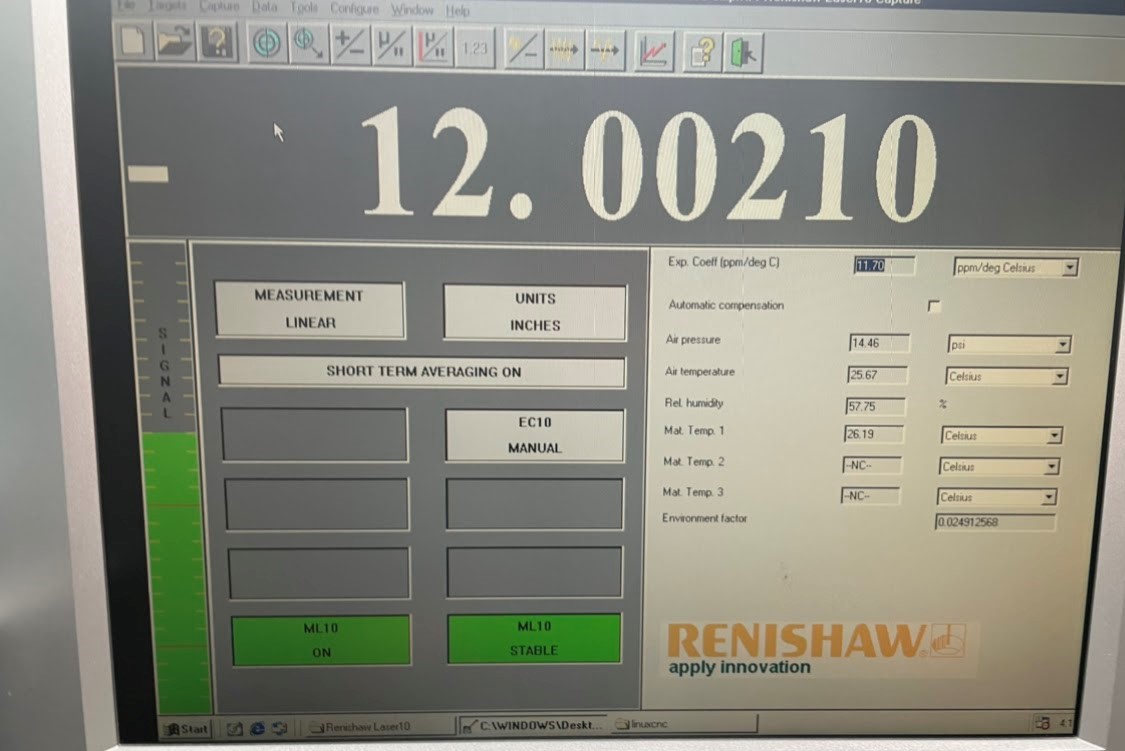

So I'm trying to laser calibrate out the error on my ballscrew and I'm not having much luck. One of the quirks of my setup is I'm trying to maintain backward compatibility with the old control so my machine can run the same programs with little to no changes.

The machine's X/Y/Z are homed to the positive limit and all axis move in the negative direction from home. I can't put negative values in the first value of the octet or LinuxCNC gives me errors. So I tried moving the machine from home/limit+ to limit- and vice versa. The change in values after compensation are almost nothing. Like on the last value where the error is .00194" I get a change of maybe .0002". The results are repeatable over multiple runs both comped and not.

I'm trying to at least match the OEM controller that could get the machine within .0002" across 12".

Any help would be greatly appreciated. I'm running 2.8.1 of LinuxCNC

The machine's X/Y/Z are homed to the positive limit and all axis move in the negative direction from home. I can't put negative values in the first value of the octet or LinuxCNC gives me errors. So I tried moving the machine from home/limit+ to limit- and vice versa. The change in values after compensation are almost nothing. Like on the last value where the error is .00194" I get a change of maybe .0002". The results are repeatable over multiple runs both comped and not.

I'm trying to at least match the OEM controller that could get the machine within .0002" across 12".

Any help would be greatly appreciated. I'm running 2.8.1 of LinuxCNC

Attachments:

Last edit: 21 Jun 2021 18:17 by CNC4Life.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

22 Jun 2021 00:10 #212623

by andypugh

Replied by andypugh on topic Ballscrew Mapping to Having an Effect

If LinuxCNC can't accept negative numbers in the screw comp file then I think that LinuxCNC is wrong.....

What is the exact error message? (Then we can search the source code for it)

What is the exact error message? (Then we can search the source code for it)

Please Log in or Create an account to join the conversation.

- CNC4Life

- Offline

- Junior Member

-

Less

More

- Posts: 36

- Thank you received: 2

22 Jun 2021 01:55 - 22 Jun 2021 01:56 #212632

by CNC4Life

Replied by CNC4Life on topic Ballscrew Mapping to Having an Effect

joint 0: compensation values must increase (X)

It created an error for each entry. Which was crazy when I had 118 entries.

Octets were

target out back

0.0 0.000 0.0002

-1.0 -1.003 -1.005

-2.0 etc.....

As soon as I made them positive LinuxCNC didn't complain.

It created an error for each entry. Which was crazy when I had 118 entries.

Octets were

target out back

0.0 0.000 0.0002

-1.0 -1.003 -1.005

-2.0 etc.....

As soon as I made them positive LinuxCNC didn't complain.

Last edit: 22 Jun 2021 01:56 by CNC4Life.

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

22 Jun 2021 18:55 #212693

by Joco

Replied by Joco on topic Ballscrew Mapping to Having an Effect

I followed this thread in going down this path at one point:

forum.linuxcnc.org/38-general-linuxcnc-q...adscrew-compensation

The compensation file that resulted worked with linuxcnc. I eventually installed my old 5um scales to create a closed loop system so as to ge better tolerance on resulting parts. But that was more due to other limitations.

Cheers - j.

forum.linuxcnc.org/38-general-linuxcnc-q...adscrew-compensation

The compensation file that resulted worked with linuxcnc. I eventually installed my old 5um scales to create a closed loop system so as to ge better tolerance on resulting parts. But that was more due to other limitations.

Cheers - j.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

23 Jun 2021 13:24 #212739

by andypugh

Ah, that is actually reasonable, as the system needs to search through them to find where it is.

But you need to start at the most-negative value and increase. So negative is OK, but the numbers need to increase monotonically.

ie:

-100 ...

-99 ...

-98 ...

Replied by andypugh on topic Ballscrew Mapping to Having an Effect

joint 0: compensation values must increase (X)

Ah, that is actually reasonable, as the system needs to search through them to find where it is.

But you need to start at the most-negative value and increase. So negative is OK, but the numbers need to increase monotonically.

ie:

-100 ...

-99 ...

-98 ...

Please Log in or Create an account to join the conversation.

- CNC4Life

- Offline

- Junior Member

-

Less

More

- Posts: 36

- Thank you received: 2

23 Jun 2021 19:59 #212762

by CNC4Life

Replied by CNC4Life on topic Ballscrew Mapping to Having an Effect

Well, I feel sheepish...

I'll try that!

I'll try that!

Please Log in or Create an account to join the conversation.

Time to create page: 0.139 seconds