Switchkins Master possible malfunction/bug.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 492

- Thank you received: 297

22 Oct 2021 02:02 #223868

by dgarrett

Replied by dgarrett on topic Switchkins Master possible malfunction/bug.

i think you you can download the deb from the linked dir and install:

$ wget buildbot.linuxcnc.org/dists/buster/scrat...~7e7a1c756_armhf.deb

$ sudo dpkg -i linuxcnc-uspace_2.9.0~pre0~dgarr.stest~7e7a1c756_armhf.deb

I plan to update the stest branch so that the sim config is more like OP's

config in ini settings and force push that branch this weekend.

The deb name includes the top commit: 7e7a1c756

(Scratch debs are available for a limited time.)

$ wget buildbot.linuxcnc.org/dists/buster/scrat...~7e7a1c756_armhf.deb

$ sudo dpkg -i linuxcnc-uspace_2.9.0~pre0~dgarr.stest~7e7a1c756_armhf.deb

I plan to update the stest branch so that the sim config is more like OP's

config in ini settings and force push that branch this weekend.

The deb name includes the top commit: 7e7a1c756

(Scratch debs are available for a limited time.)

Please Log in or Create an account to join the conversation.

- NoJo

- Offline

- Elite Member

-

Less

More

- Posts: 180

- Thank you received: 43

22 Oct 2021 07:15 #223884

by NoJo

Replied by NoJo on topic Switchkins Master possible malfunction/bug.

Thanks for the guidance - I lack experienced with this so battle a bit.

I think the Pi4 is a bit of a waste of time - After doing as you proposed I end up with broken packages in Synaptic - linuxcnc-uspace-dbgsym and linuxcnc-uspace-dev

and with linuxcnc-uspace (1.2.9.0~pre0~dgarr.stest~7e7a1c756) starred for 'upgrade'

Linuxcnc then obviously has no Stest in the config picker..

When I ran sudo dpkg there was a warning - downgrading linuxcnc-uspace from ....pre.4830.gfaab5f10e to ....dgarr.stest.7e7a1c756, but the dpkg ran and completed ok.

I don't want to waste your time with this and the Pi - resolving the odd axis behaviour is the aim!

We have some ideas wrt modifying the mill-turn sim itself to simulate the same problem - probably the quickest route now.

In parallel I am procuring an amd64 pc - the only other pc's around are old 32bit machines - one has Lcnc/wheezy/stretch on it, but I think we will mess around with the same issues on that - I am reluctant to use the pc on the lathe for this since I fear breaking that one as well!

Any comments of the capture using Task_Issue ( with the missing feedrate in the linear move)?

I think the Pi4 is a bit of a waste of time - After doing as you proposed I end up with broken packages in Synaptic - linuxcnc-uspace-dbgsym and linuxcnc-uspace-dev

and with linuxcnc-uspace (1.2.9.0~pre0~dgarr.stest~7e7a1c756) starred for 'upgrade'

Linuxcnc then obviously has no Stest in the config picker..

When I ran sudo dpkg there was a warning - downgrading linuxcnc-uspace from ....pre.4830.gfaab5f10e to ....dgarr.stest.7e7a1c756, but the dpkg ran and completed ok.

I don't want to waste your time with this and the Pi - resolving the odd axis behaviour is the aim!

We have some ideas wrt modifying the mill-turn sim itself to simulate the same problem - probably the quickest route now.

In parallel I am procuring an amd64 pc - the only other pc's around are old 32bit machines - one has Lcnc/wheezy/stretch on it, but I think we will mess around with the same issues on that - I am reluctant to use the pc on the lathe for this since I fear breaking that one as well!

Any comments of the capture using Task_Issue ( with the missing feedrate in the linear move)?

Please Log in or Create an account to join the conversation.

- NoJo

- Offline

- Elite Member

-

Less

More

- Posts: 180

- Thank you received: 43

23 Oct 2021 06:05 #223975

by NoJo

Replied by NoJo on topic Switchkins Master possible malfunction/bug.

Attesting to my linux inexperience..I redid the master install on the Pi4, and achieved a successful install of the stest branch - all running on the Pi.

I will let you know how it goes.

I will let you know how it goes.

Please Log in or Create an account to join the conversation.

- NoJo

- Offline

- Elite Member

-

Less

More

- Posts: 180

- Thank you received: 43

23 Oct 2021 13:33 #223986

by NoJo

Replied by NoJo on topic Switchkins Master possible malfunction/bug.

We have tried to reproduce the problem in the stest simulation - without success. On the Simulation, the first C axis move after the switch is generated correctly, whereas with the same ini file settings on the actual lathe, it is always incorrect.

The problem seems to be related to what occurs as a result of the M66 command after the M68 command. What we have noticed is that there is

a repeatable difference in the motion.program_line log.

The ngc file is as follows

G7

G18

G01 X40 F800

G0 C0

G12.1

G01 X40 C20 F800

G01 X-40 C20 F800

G01 X-40 C-20 F800

G01 X40 C-20 F800

G01 X40 C0 F800

G13.1

M30

%

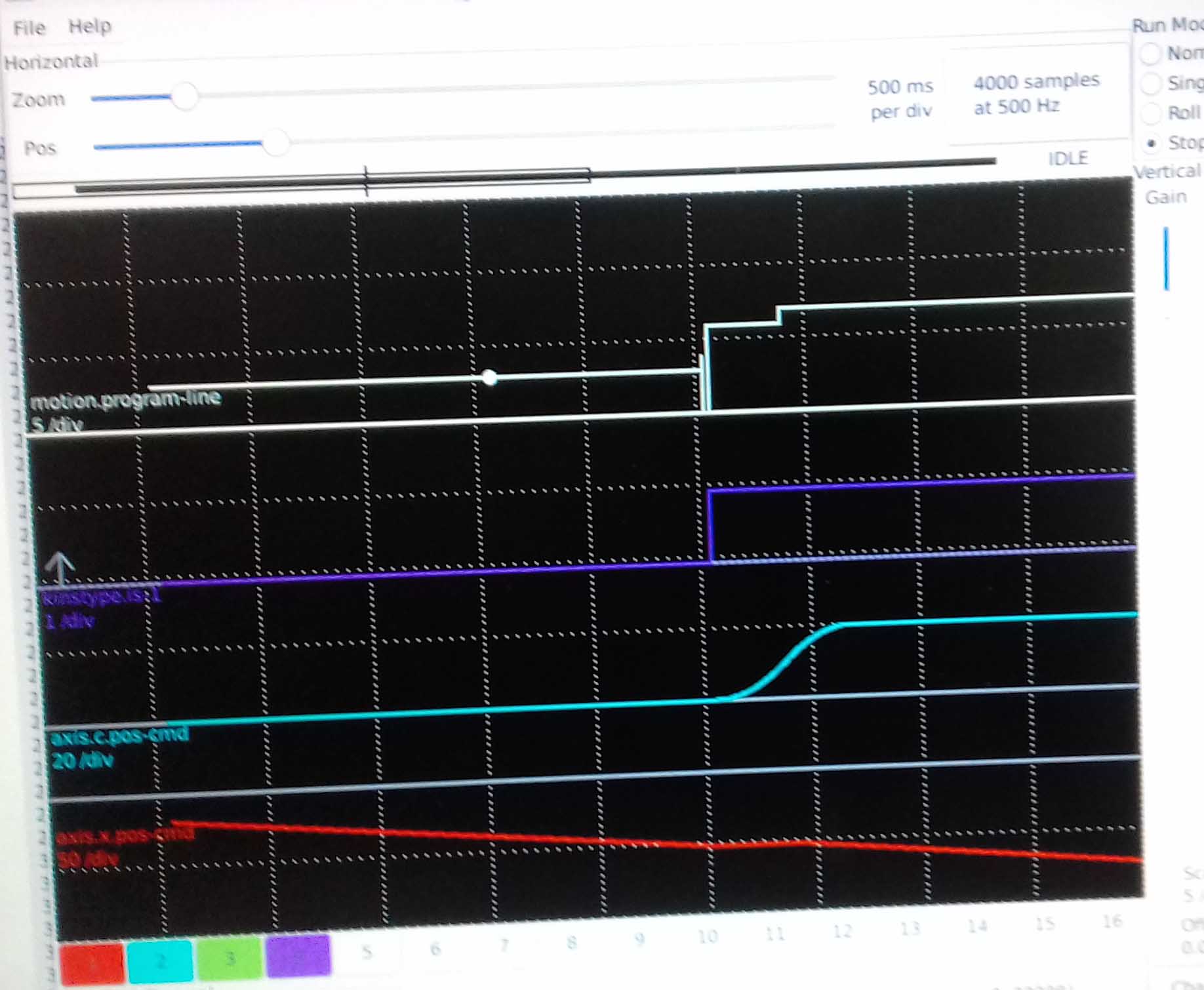

In the simulation, the log is line 3 --> 0 --> line6 (See plot of motion.program-line below)

Whereas in the real machine, the log is line 3 --> line 4 --> 0 --> line6 (See plot below of motion.program-line below)

We are not sufficiently clued as to what the significance of this is - but maybe it may aid those endeavouring to assist us with this issue to home in on the problem

The problem seems to be related to what occurs as a result of the M66 command after the M68 command. What we have noticed is that there is

a repeatable difference in the motion.program_line log.

The ngc file is as follows

G7

G18

G01 X40 F800

G0 C0

G12.1

G01 X40 C20 F800

G01 X-40 C20 F800

G01 X-40 C-20 F800

G01 X40 C-20 F800

G01 X40 C0 F800

G13.1

M30

%

In the simulation, the log is line 3 --> 0 --> line6 (See plot of motion.program-line below)

Whereas in the real machine, the log is line 3 --> line 4 --> 0 --> line6 (See plot below of motion.program-line below)

We are not sufficiently clued as to what the significance of this is - but maybe it may aid those endeavouring to assist us with this issue to home in on the problem

Attachments:

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 492

- Thank you received: 297

23 Oct 2021 17:46 #224005

by dgarrett

Replied by dgarrett on topic Switchkins Master possible malfunction/bug.

Updated branch dgarr/stest 23oct21:

0) rebased to master (@be96bf6d6)

and force push dgarr/stest = commit 8c6a400f4

1) adds some debugging prints to supplement debug

TaskIssue messages

2) stest.comp provision for stest.fakeoffset pin

sim_pin stest.fakeoffset to activate in sim

3) uses [DISPlAY]OPEN_FILE=stest_square.ngc

with provisions to to add dwell command and

detect/exit for unexpected c,j2 values

If using deb: fetch and reinstall updated scratch deb

reqd, then use linuxcnc config picker to make an

updated stest sim config

Adding timing dwell(s) and test provisions akin to those in

stest_square.ngc might provide some clues on hardware

testing too.

github.com/LinuxCNC/linuxcnc/blob/dgarr/...est/stest_square.ngc

> Any comments of the capture using Task_Issue ( with

> the missing feedrate in the linear move)?

The debug print:

> Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-52.250000,0.0,0.0,0.0,0.0,20.0,0.0,0.0,0.0, +2,0.0,0.0,0.0, +0, -1,)

i have not reproduced and have not yet found a scenario that can

reset ini_maxvel to 0.

The added debug prints in dgarr/stest may provide clues --

requires running the scratch branch (8c6a400f4) on the

hardware under test

Please post output from the command 'linuxcnc_info' for the

hardware under test.

You could experiment with the sequencing of the 'addf

caxis.0 servo-thread' to see how placing it last or first

changes the observed behavior.

0) rebased to master (@be96bf6d6)

and force push dgarr/stest = commit 8c6a400f4

1) adds some debugging prints to supplement debug

TaskIssue messages

2) stest.comp provision for stest.fakeoffset pin

sim_pin stest.fakeoffset to activate in sim

3) uses [DISPlAY]OPEN_FILE=stest_square.ngc

with provisions to to add dwell command and

detect/exit for unexpected c,j2 values

If using deb: fetch and reinstall updated scratch deb

reqd, then use linuxcnc config picker to make an

updated stest sim config

Adding timing dwell(s) and test provisions akin to those in

stest_square.ngc might provide some clues on hardware

testing too.

github.com/LinuxCNC/linuxcnc/blob/dgarr/...est/stest_square.ngc

> Any comments of the capture using Task_Issue ( with

> the missing feedrate in the linear move)?

The debug print:

> Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-52.250000,0.0,0.0,0.0,0.0,20.0,0.0,0.0,0.0, +2,0.0,0.0,0.0, +0, -1,)

i have not reproduced and have not yet found a scenario that can

reset ini_maxvel to 0.

The added debug prints in dgarr/stest may provide clues --

requires running the scratch branch (8c6a400f4) on the

hardware under test

Please post output from the command 'linuxcnc_info' for the

hardware under test.

You could experiment with the sequencing of the 'addf

caxis.0 servo-thread' to see how placing it last or first

changes the observed behavior.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- NoJo

- Offline

- Elite Member

-

Less

More

- Posts: 180

- Thank you received: 43

24 Oct 2021 16:35 - 24 Oct 2021 19:53 #224104

by NoJo

Replied by NoJo on topic Switchkins Master possible malfunction/bug.

We have performed the tests as requested. Results as follows:

(1) Playing with sequence of addf caxis.0 servo-thread makes no difference

(2) The outputs from the debug prints are as follows:

Dwell_______ 0.000

aBEFORE SWITCH OK j2=0.0

bBEFORE SWITCH OK j2=0.0

AFTER SWITCH OK j2=0.0

(3) linuxcnc_info for hardware is attached

Regardless of whatever changes we make to settings related to accelerations and velocities in the ini file, the problem remains unchanged with the problem line : (ie vel and ini_maxvel set tro zero)

EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-52.250000,0.0,0.0,0.0,0.0,20.0,0.0,0.0,0.0, +2,0.0,0.0,0.0, +0, -1,)

We have hence searched the source code to trace the path of code executed as a result of the M66 command.

This command will result in function 'flush_segments' being executed.With reference to the lines

if (canon.cartesian_move && !canon.angular_move) {

if (vel > canon.linearFeedRate) {

vel = canon.linearFeedRate;

}

} else if (!canon.cartesian_move && canon.angular_move) {

if (vel > canon.angularFeedRate) {

vel = canon.angularFeedRate;

}

} else if (canon.cartesian_move && canon.angular_move) {

if (vel > canon.linearFeedRate) {

vel = canon.linearFeedRate;

}

}

the second case is applicable for our problem move (ie an angular move only). If for some reason, the value of canon.angularFeedRate is zero, this would explain why the values of vel and ini_maxvel are zero. Could this be the source of the problem?

Is there a pin by which we can gain further insight into these values?

(1) Playing with sequence of addf caxis.0 servo-thread makes no difference

(2) The outputs from the debug prints are as follows:

Dwell_______ 0.000

aBEFORE SWITCH OK j2=0.0

bBEFORE SWITCH OK j2=0.0

AFTER SWITCH OK j2=0.0

(3) linuxcnc_info for hardware is attached

Regardless of whatever changes we make to settings related to accelerations and velocities in the ini file, the problem remains unchanged with the problem line : (ie vel and ini_maxvel set tro zero)

EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-52.250000,0.0,0.0,0.0,0.0,20.0,0.0,0.0,0.0, +2,0.0,0.0,0.0, +0, -1,)

We have hence searched the source code to trace the path of code executed as a result of the M66 command.

This command will result in function 'flush_segments' being executed.With reference to the lines

if (canon.cartesian_move && !canon.angular_move) {

if (vel > canon.linearFeedRate) {

vel = canon.linearFeedRate;

}

} else if (!canon.cartesian_move && canon.angular_move) {

if (vel > canon.angularFeedRate) {

vel = canon.angularFeedRate;

}

} else if (canon.cartesian_move && canon.angular_move) {

if (vel > canon.linearFeedRate) {

vel = canon.linearFeedRate;

}

}

the second case is applicable for our problem move (ie an angular move only). If for some reason, the value of canon.angularFeedRate is zero, this would explain why the values of vel and ini_maxvel are zero. Could this be the source of the problem?

Is there a pin by which we can gain further insight into these values?

Attachments:

Last edit: 24 Oct 2021 19:53 by NoJo. Reason: Attachment

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 492

- Thank you received: 297

25 Oct 2021 18:28 #224287

by dgarrett

Replied by dgarrett on topic Switchkins Master possible malfunction/bug.

> (2) The outputs from the debug prints are as follows:

> Dwell_______ 0.000 ...

testing for nonzero values (3sec) of Dwell would be

welcome too.

>> The added debug prints in dgarr/stest may provide

>> clues -- requires running the scratch branch

>> (8c6a400f4) on the realmachine under test.

To clarify, the debug prints referred to for

dgarr/stest include added prints to stderr (e.g., you

must: 1) run linuxcnc from the command line, 2) enable

debug for TaskIsuue, and 3) view/capture terminal

output).

> This command will result in function 'flush_segments'

> being executed.With reference to the lines ...

The branch dgarr/stest (8c6a400f4) committed 23oct

includes added prints in emccanon.c in flush_segments()

(and other places):

github.com/LinuxCNC/linuxcnc/blob/dgarr/...ask/emccanon.cc#L935

> the second case is applicable for our problem move (ie

> an angular move only). If for some reason, the value of

> canon.angularFeedRate is zero, this would explain why

> the values of vel and ini_maxvel are zero. Could this

> be the source of the problem?

Possibly -- I have not found a way to do that

in a sim config. If you find a way, let us know.

> Is there a pin by which we can gain further insight

> into these values?

You should load the test branch deb on the hardware

buster/amd64 machine to see, record, and post output

from the added prints (to stderr) in the test branch

e.g.; (for buster/amd64) replace the reported package

(master deb of 12oct21):

> ii linuxcnc-uspace 1:2.9.0~pre0.4760.gc4345283f

with the scratch deb (buster/amd64):

buildbot.linuxcnc.org/dists/buster/scrat...~8c6a400f4_amd64.deb

Using the scratch deb on the real machine: 1) start

linuxcnc from a terminal, 2) run the square.ngc and 3)

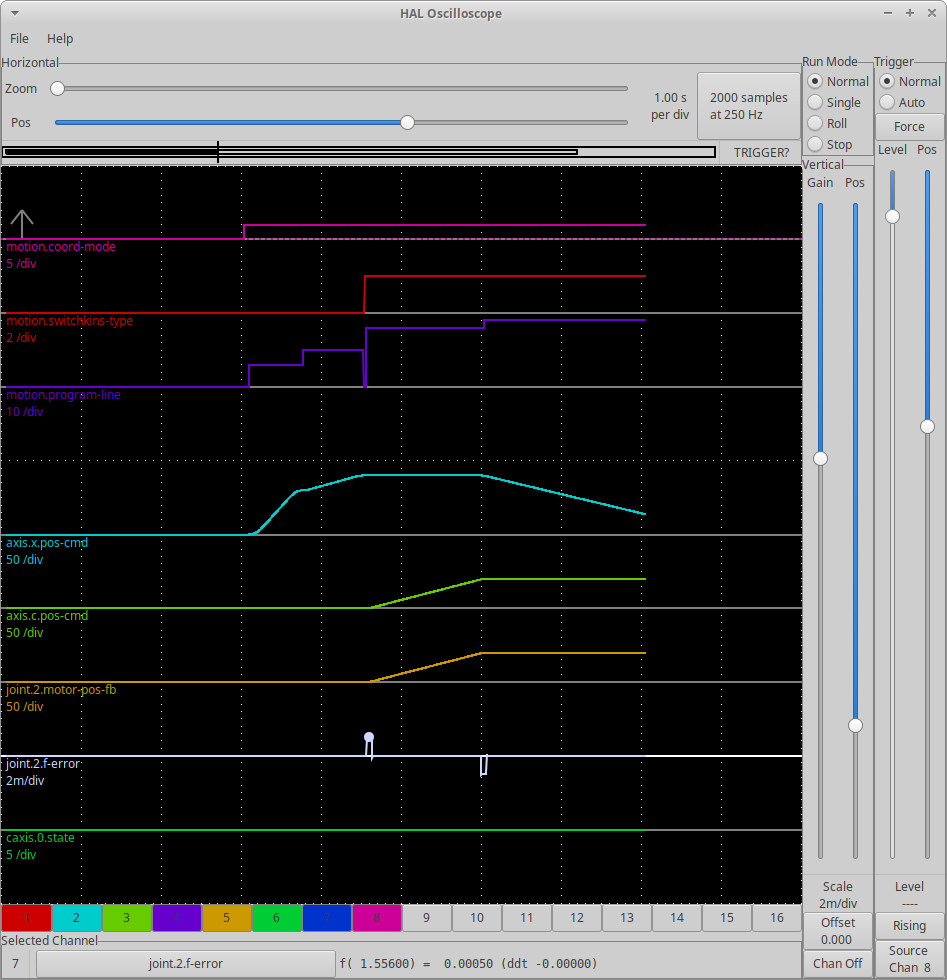

post a file of the terminal output and a snapshot of

the unexpected x,c motions, motion.switchkins-type,

motion.program-line.

> Dwell_______ 0.000 ...

testing for nonzero values (3sec) of Dwell would be

welcome too.

>> The added debug prints in dgarr/stest may provide

>> clues -- requires running the scratch branch

>> (8c6a400f4) on the realmachine under test.

To clarify, the debug prints referred to for

dgarr/stest include added prints to stderr (e.g., you

must: 1) run linuxcnc from the command line, 2) enable

debug for TaskIsuue, and 3) view/capture terminal

output).

> This command will result in function 'flush_segments'

> being executed.With reference to the lines ...

The branch dgarr/stest (8c6a400f4) committed 23oct

includes added prints in emccanon.c in flush_segments()

(and other places):

github.com/LinuxCNC/linuxcnc/blob/dgarr/...ask/emccanon.cc#L935

> the second case is applicable for our problem move (ie

> an angular move only). If for some reason, the value of

> canon.angularFeedRate is zero, this would explain why

> the values of vel and ini_maxvel are zero. Could this

> be the source of the problem?

Possibly -- I have not found a way to do that

in a sim config. If you find a way, let us know.

> Is there a pin by which we can gain further insight

> into these values?

You should load the test branch deb on the hardware

buster/amd64 machine to see, record, and post output

from the added prints (to stderr) in the test branch

e.g.; (for buster/amd64) replace the reported package

(master deb of 12oct21):

> ii linuxcnc-uspace 1:2.9.0~pre0.4760.gc4345283f

with the scratch deb (buster/amd64):

buildbot.linuxcnc.org/dists/buster/scrat...~8c6a400f4_amd64.deb

Using the scratch deb on the real machine: 1) start

linuxcnc from a terminal, 2) run the square.ngc and 3)

post a file of the terminal output and a snapshot of

the unexpected x,c motions, motion.switchkins-type,

motion.program-line.

Please Log in or Create an account to join the conversation.

- NoJo

- Offline

- Elite Member

-

Less

More

- Posts: 180

- Thank you received: 43

26 Oct 2021 13:54 - 26 Oct 2021 14:43 #224398

by NoJo

Replied by NoJo on topic Switchkins Master possible malfunction/bug.

We have upgraded to your latest version and run the tests as requested. Attached are screen shots and terminal outputs for cases with Dwell = 0 and Dwell = 3. Hoping the debug prints shed some light...

I examined the terminal output / prints done by your updated code.

Based on the values of axis velocity and accel I could link the prints in function flush_segments to the EMC_TRAJ_LINEAR_MOVE information.

This clearly shows that the last 4 moves are generated correctly.

However, the print in flush segments for the first move after the G12.1 (BOLD) shows a problem in that the values of linearMoveMsg.vel, linearMoveMsg.ini_maxvel and linearMoveMsg.acc are all zero!

In addition, one would have expected the print related to the angular move only to have occurred (as we are moving from X40, C0 to X40, C20), but this print is not there.

So something is amiss after the call to handle_kinematicsSwitch()?

=== SET_FEED_RATE feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 566

=== getStraightVelocity feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 876

=== flush_segments type=2 vel= 0.000 ini_maxvel= 0.000 acc= 0.000 emc/task/emccanon.cc 980 this is X40 C20 First move after G12.1

=== SET_FEED_RATE feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 566

=== SET_FEED_RATE feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 566

=== getStraightVelocity feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 876

=== flush_segments type=2 vel= 13.333 ini_maxvel= 60.000 acc= 350.000 emc/task/emccanon.cc 980 this is X-40 C20 (based on 60,350)

=== getStraightVelocity feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 876

=== flush_segments vel= 13.333 (using canon.angularFeedRate)emc/task/emccanon.cc 939

=== flush_segments type=2 vel= 13.333 ini_maxvel= 500.000 acc= 750.000 emc/task/emccanon.cc 980 this is X-40 C-20 (based on 500,750), and is angular only

=== SET_FEED_RATE feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 566

=== SET_FEED_RATE feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 566

=== getStraightVelocity feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 876

=== flush_segments type=2 vel= 13.333 ini_maxvel= 60.000 acc= 350.000 emc/task/emccanon.cc 980 this is X40 C-20 (based on 60,350)

=== getStraightVelocity feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 876

=== flush_segments vel= 13.333 (using canon.angularFeedRate)emc/task/emccanon.cc 939

=== flush_segments type=2 vel= 13.333 ini_maxvel= 500.000 acc= 750.000 emc/task/emccanon.cc 980 this is X40 C0 (based on 500,750), and is angular only

Issuing EMC_OPERATOR_DISPLAY -- ( +13,+280, +0, +0,AFTER\032SWITCH\032OK\032j2=0.000000,)

Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-32.250000,0.000000,-5.000000,0.000000,0.000000,20.000000,0.000000,0.000000,0.000000, +2,0.000000,0.000000,0.000000, +0, -1,)

Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-112.250000,0.000000,-5.000000,0.000000,0.000000,20.000000,0.000000,0.000000,0.000000, +2,13.333333,60.000000,350.000000, +0, -1,)

Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-112.250000,0.000000,-5.000000,0.000000,0.000000,-20.000000,0.000000,0.000000,0.000000, +2,13.333333,500.000000,750.000000, +0, -1,)

Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-32.250000,0.000000,-5.000000,0.000000,0.000000,-20.000000,0.000000,0.000000,0.000000, +2,13.333333,60.000000,350.000000, +0, -1,)

Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-32.250000,0.000000,-5.000000,0.000000,0.000000,0.000000,0.000000,0.000000,0.000000, +2,13.333333,500.000000,750.000000, +0, -1,)

I examined the terminal output / prints done by your updated code.

Based on the values of axis velocity and accel I could link the prints in function flush_segments to the EMC_TRAJ_LINEAR_MOVE information.

This clearly shows that the last 4 moves are generated correctly.

However, the print in flush segments for the first move after the G12.1 (BOLD) shows a problem in that the values of linearMoveMsg.vel, linearMoveMsg.ini_maxvel and linearMoveMsg.acc are all zero!

In addition, one would have expected the print related to the angular move only to have occurred (as we are moving from X40, C0 to X40, C20), but this print is not there.

So something is amiss after the call to handle_kinematicsSwitch()?

=== SET_FEED_RATE feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 566

=== getStraightVelocity feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 876

=== flush_segments type=2 vel= 0.000 ini_maxvel= 0.000 acc= 0.000 emc/task/emccanon.cc 980 this is X40 C20 First move after G12.1

=== SET_FEED_RATE feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 566

=== SET_FEED_RATE feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 566

=== getStraightVelocity feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 876

=== flush_segments type=2 vel= 13.333 ini_maxvel= 60.000 acc= 350.000 emc/task/emccanon.cc 980 this is X-40 C20 (based on 60,350)

=== getStraightVelocity feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 876

=== flush_segments vel= 13.333 (using canon.angularFeedRate)emc/task/emccanon.cc 939

=== flush_segments type=2 vel= 13.333 ini_maxvel= 500.000 acc= 750.000 emc/task/emccanon.cc 980 this is X-40 C-20 (based on 500,750), and is angular only

=== SET_FEED_RATE feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 566

=== SET_FEED_RATE feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 566

=== getStraightVelocity feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 876

=== flush_segments type=2 vel= 13.333 ini_maxvel= 60.000 acc= 350.000 emc/task/emccanon.cc 980 this is X40 C-20 (based on 60,350)

=== getStraightVelocity feed_mode=0 linFRate= 13.333 angFRate= 13.333 emc/task/emccanon.cc 876

=== flush_segments vel= 13.333 (using canon.angularFeedRate)emc/task/emccanon.cc 939

=== flush_segments type=2 vel= 13.333 ini_maxvel= 500.000 acc= 750.000 emc/task/emccanon.cc 980 this is X40 C0 (based on 500,750), and is angular only

Issuing EMC_OPERATOR_DISPLAY -- ( +13,+280, +0, +0,AFTER\032SWITCH\032OK\032j2=0.000000,)

Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-32.250000,0.000000,-5.000000,0.000000,0.000000,20.000000,0.000000,0.000000,0.000000, +2,0.000000,0.000000,0.000000, +0, -1,)

Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-112.250000,0.000000,-5.000000,0.000000,0.000000,20.000000,0.000000,0.000000,0.000000, +2,13.333333,60.000000,350.000000, +0, -1,)

Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-112.250000,0.000000,-5.000000,0.000000,0.000000,-20.000000,0.000000,0.000000,0.000000, +2,13.333333,500.000000,750.000000, +0, -1,)

Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-32.250000,0.000000,-5.000000,0.000000,0.000000,-20.000000,0.000000,0.000000,0.000000, +2,13.333333,60.000000,350.000000, +0, -1,)

Issuing EMC_TRAJ_LINEAR_MOVE -- ( +220,+208, +0,-32.250000,0.000000,-5.000000,0.000000,0.000000,0.000000,0.000000,0.000000,0.000000, +2,13.333333,500.000000,750.000000, +0, -1,)

Last edit: 26 Oct 2021 14:43 by NoJo. Reason: Additional analysis

Please Log in or Create an account to join the conversation.

- NoJo

- Offline

- Elite Member

-

Less

More

- Posts: 180

- Thank you received: 43

29 Oct 2021 09:12 #224635

by NoJo

Replied by NoJo on topic Switchkins Master possible malfunction/bug.

This is a follow up on our previous post. Please could you respond as to comments on what the debug prints show, and what further tests we can assist with.

Just a reminder that the problem does not occur if the first move after the switch is a cartesian move only, or a combined angular/cartesian move. The problem is there only if it is an angular move only

Just a reminder that the problem does not occur if the first move after the switch is a cartesian move only, or a combined angular/cartesian move. The problem is there only if it is an angular move only

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 492

- Thank you received: 297

01 Nov 2021 16:19 - 01 Nov 2021 16:19 #224891

by dgarrett

Replied by dgarrett on topic Switchkins Master possible malfunction/bug.

Attached is a new sim config (stest2) that adopts

caxis.comp (renamed as stest2_caxis.comp) and implements

joint2 (c coordinate) using the in-tree sim_spindle

component configured with a velocity-based pid.

Instead of making a test branch, all files are included

in the attached tar file so it can be tested with the

master branch (or any branch based on recent master).

(The stest2*.comp hal components must be

halcompiled/installed).

Example:

$ wget stest2.tar ;# use link for attached file

$ tar xf stest2.tar ;# extract contents

$ cd stest2

$ # Note: sudo reqd for deb installs (not needed if RIP)

$ sudo halcompile --install stest2.comp

$ sudo halcompile --install stest2_caxis.comp

$ linuxcnc stest2.ini ;# run the stest2 sim config

In axis gui:

F1 # Estop off

F2 # Machine-on

Ctrl-Home # HomeAll

R # Run OPEN_FILE=stest2_square.ngc

==========================================================

A definitive test for checking the compatibility of a

machine's hal components/connections that manage

joint.N.motor-pos-fb values is to 'short circuit' the

joint's motor-pos-cmd to its motor-pos-fb. Such a test

will disable actual joint motion but ensure LinuxCNC's

expectations that joint.N.motor-pos-cmd and

joint.N.motor-pos-fb are *always* the same (to within

the limits enforced by inifile settings for

[JOINT_N]MIN_FERROR and [JOINT_N]FERROR).

The tar file includes an additional inifile

(stest2_shortcircuit.ini) that demonstrates this test

by adding a [HAL]HALFILE=shortcircuit.hal that removes

(unlinkp) prior joint.2.motor-pos-cmd, motor-pos-fb

connections and then makes the short circuit

connections.

When a configuration works as expected with

shortcircuit connections but fails with halfile

specified connections, something unexpected is

happening.

A similar test on real hardware would be useful.

One method is to copy the realmachine inifile to a

new 'test.ini' file and add an appropriate

[HAL]HALFILE=shortcircuit.hal.

==========================================================

The setting in CNC_Lathe.ini (zip file from post

223654) for [JOINT_2]MIN_FERROR=1000,FERROR=1000 are so

big they will likely mask unexpected following errors.

Large ferror settings may be useful while tuning but

should be set to realistic values for operation. Using

appropriate inifile ferror limits and plotting the

joint.2.f-error could be instructive.

==========================================================

Refs:

linuxcnc.org/docs/devel/html/man/man9/sim_spindle.9.html

linuxcnc.org/docs/devel/html/config/ini-...t__lt_num_gt_section

forum.linuxcnc.org/10-advanced-configura...n-bug?start=0#223654

caxis.comp (renamed as stest2_caxis.comp) and implements

joint2 (c coordinate) using the in-tree sim_spindle

component configured with a velocity-based pid.

Instead of making a test branch, all files are included

in the attached tar file so it can be tested with the

master branch (or any branch based on recent master).

(The stest2*.comp hal components must be

halcompiled/installed).

Example:

$ wget stest2.tar ;# use link for attached file

$ tar xf stest2.tar ;# extract contents

$ cd stest2

$ # Note: sudo reqd for deb installs (not needed if RIP)

$ sudo halcompile --install stest2.comp

$ sudo halcompile --install stest2_caxis.comp

$ linuxcnc stest2.ini ;# run the stest2 sim config

In axis gui:

F1 # Estop off

F2 # Machine-on

Ctrl-Home # HomeAll

R # Run OPEN_FILE=stest2_square.ngc

==========================================================

A definitive test for checking the compatibility of a

machine's hal components/connections that manage

joint.N.motor-pos-fb values is to 'short circuit' the

joint's motor-pos-cmd to its motor-pos-fb. Such a test

will disable actual joint motion but ensure LinuxCNC's

expectations that joint.N.motor-pos-cmd and

joint.N.motor-pos-fb are *always* the same (to within

the limits enforced by inifile settings for

[JOINT_N]MIN_FERROR and [JOINT_N]FERROR).

The tar file includes an additional inifile

(stest2_shortcircuit.ini) that demonstrates this test

by adding a [HAL]HALFILE=shortcircuit.hal that removes

(unlinkp) prior joint.2.motor-pos-cmd, motor-pos-fb

connections and then makes the short circuit

connections.

When a configuration works as expected with

shortcircuit connections but fails with halfile

specified connections, something unexpected is

happening.

A similar test on real hardware would be useful.

One method is to copy the realmachine inifile to a

new 'test.ini' file and add an appropriate

[HAL]HALFILE=shortcircuit.hal.

==========================================================

The setting in CNC_Lathe.ini (zip file from post

223654) for [JOINT_2]MIN_FERROR=1000,FERROR=1000 are so

big they will likely mask unexpected following errors.

Large ferror settings may be useful while tuning but

should be set to realistic values for operation. Using

appropriate inifile ferror limits and plotting the

joint.2.f-error could be instructive.

==========================================================

Refs:

linuxcnc.org/docs/devel/html/man/man9/sim_spindle.9.html

linuxcnc.org/docs/devel/html/config/ini-...t__lt_num_gt_section

forum.linuxcnc.org/10-advanced-configura...n-bug?start=0#223654

Last edit: 01 Nov 2021 16:19 by dgarrett.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.141 seconds