Genserkins 6-Axis strange behavior

- xcp92

- Offline

- New Member

-

- Posts: 10

- Thank you received: 3

i have a 6-Axis Robot arm (Motoman K10S) running with genserkins. Kartesian movement is working good if the last joint is pointing straight down.

If the last joint points horizontal the movement in the Y-direction is off ( to long and a slight ark).

If i use a pencil to track the movement and try to make a circle in the X-Y plane, I get a circle when the robot points straight down. When the robot is facing in the X - direction (horizontal) i get approximately an ellipse. (Pictures as reference).

It seems thougt the distance of the tooltip to the last joint is neglected in the movement, but the X - coordinate is correct. Y - Movement ( if Y near to 0 +- 200mm is off by 30%. X-Movement is spot on. If i turn the robot 90° and X is near 0, Y-Movement is correct and X- Movement is off.

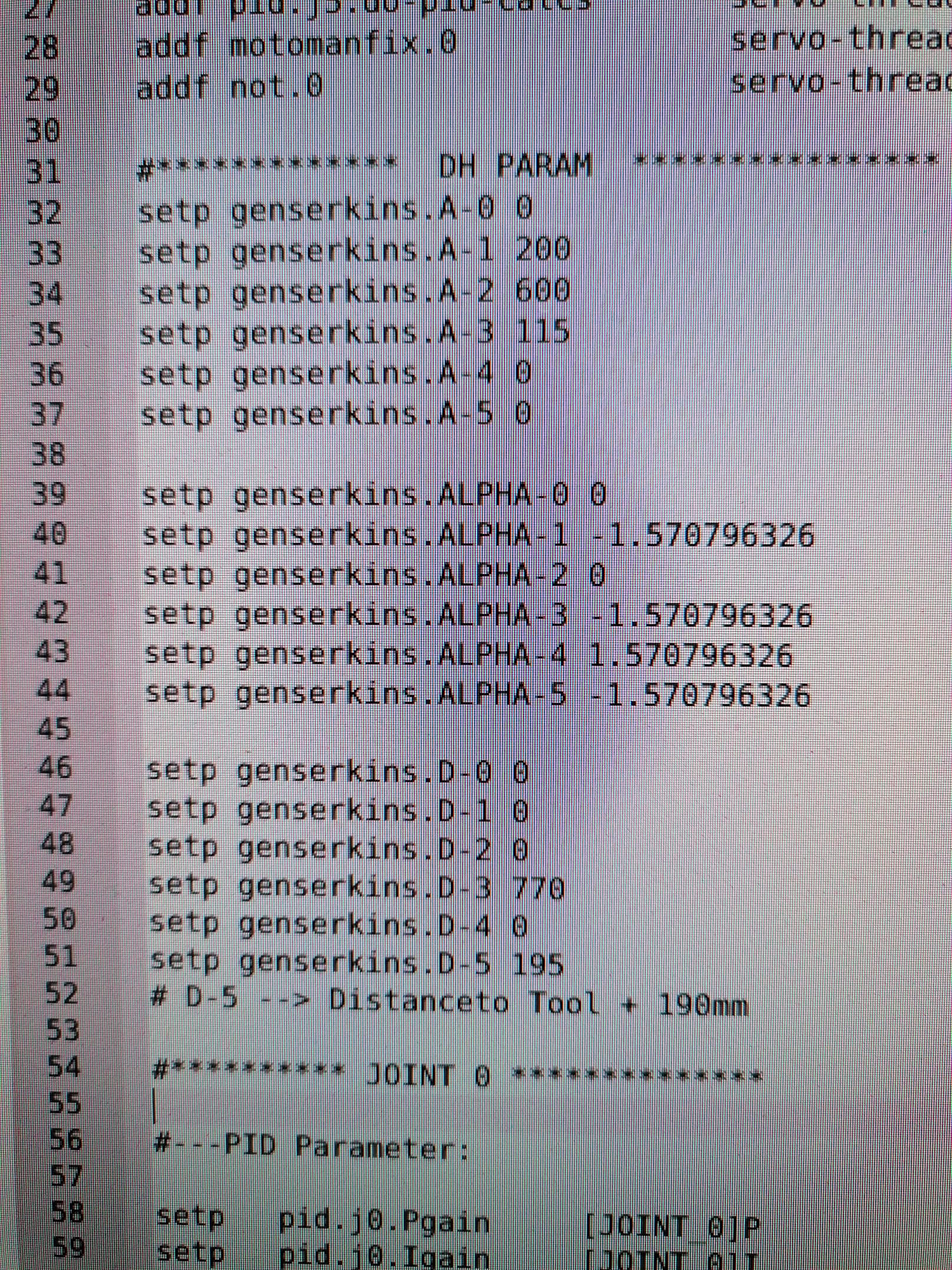

I followed the D-H Parameter tutorial and the Puma560 Demo helped a lot ( The robots are the simmilar in theconstruction and order of the joint - types, just the dimensions from joint to joint are different)

The DH-Parameter are attached.

This is strange or is this normal behavior??

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4650

- Thank you received: 2077

Are you sure your X-coordinate is correct when the wrist is horizontal as in the hand-drawn sketch on the left? If it is then D-5 parameter would seem to be correct.

Also, if you go from the horizontal to the vertical orientation does the z-coordinate value change by the value of D-5?

Looking at your parameter list (D-0 = 0), it seems that your origin is in your shoulder joint rather than on the base plate. Is that intended?

linuxcnc.org/docs/html/motion/dh-parameters.html

Note: If you are using the 'switchable kinematic' feature you should update to current master as a bug has been identified and a fix has been pushed recently.

Please Log in or Create an account to join the conversation.

- xcp92

- Offline

- New Member

-

- Posts: 10

- Thank you received: 3

If i increase the d-5 Offset to 400 or 0 not much changes.

1. Yes i tested it multiple times.Are you sure your X-coordinate is correct when the wrist is horizontal as in the hand-drawn sketch on the left? If it is then D-5 parameter would seem to be correct.

Also, if you go from the horizontal to the vertical orientation does the z-coordinate value change by the value of D-5?

2. I only measured the x - Value. I will test the z - Value and then reply.

Yes its intended, this way, the z coordinate absolute 0 is near the Workbench surface. In absolute World mode its simpler to measure z height for me.Looking at your parameter list (D-0 = 0), it seems that your origin is in your shoulder joint rather than on the base plate. Is that intended?

As far as i know i dont use switchable kinematics. What is this feature?Note: If you are using the 'switchable kinematic' feature you should update to current master as a bug has been identified and a fix has been pushed recently.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4650

- Thank you received: 2077

The 'switchable kinematics' feature let's you switch between different kinematic models in GCode. For robots it is often useful to switch between cartesian 'world' mode and trivial 'joint' mode because the mathematical modelling for the inverse kinematic fails in certain regions of the work space (singular points, gimbal lock). This is not unique to 'genserkins' but is a problem that all robot controllers have.

Please Log in or Create an account to join the conversation.

- xcp92

- Offline

- New Member

-

- Posts: 10

- Thank you received: 3

I found the problem when I turned joint 3 +90° and then joint 4 90°. The y-coordinate should be 195mm but it was -195mm.

The other directions were correct.

I switched the turning direction of joint 3 and 5. Now it works.

Sometimes you can't see the obvious and need a hint :-D

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4650

- Thank you received: 2077

Looks like you're planning to use it for welding, would be very interesting to see how that works out for you and please do post your custom component for the joint compensation.

Please Log in or Create an account to join the conversation.