How does my encoder feedback look?

- charleyann

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 10

24 Jun 2022 20:48 #245808

by charleyann

How does my encoder feedback look? was created by charleyann

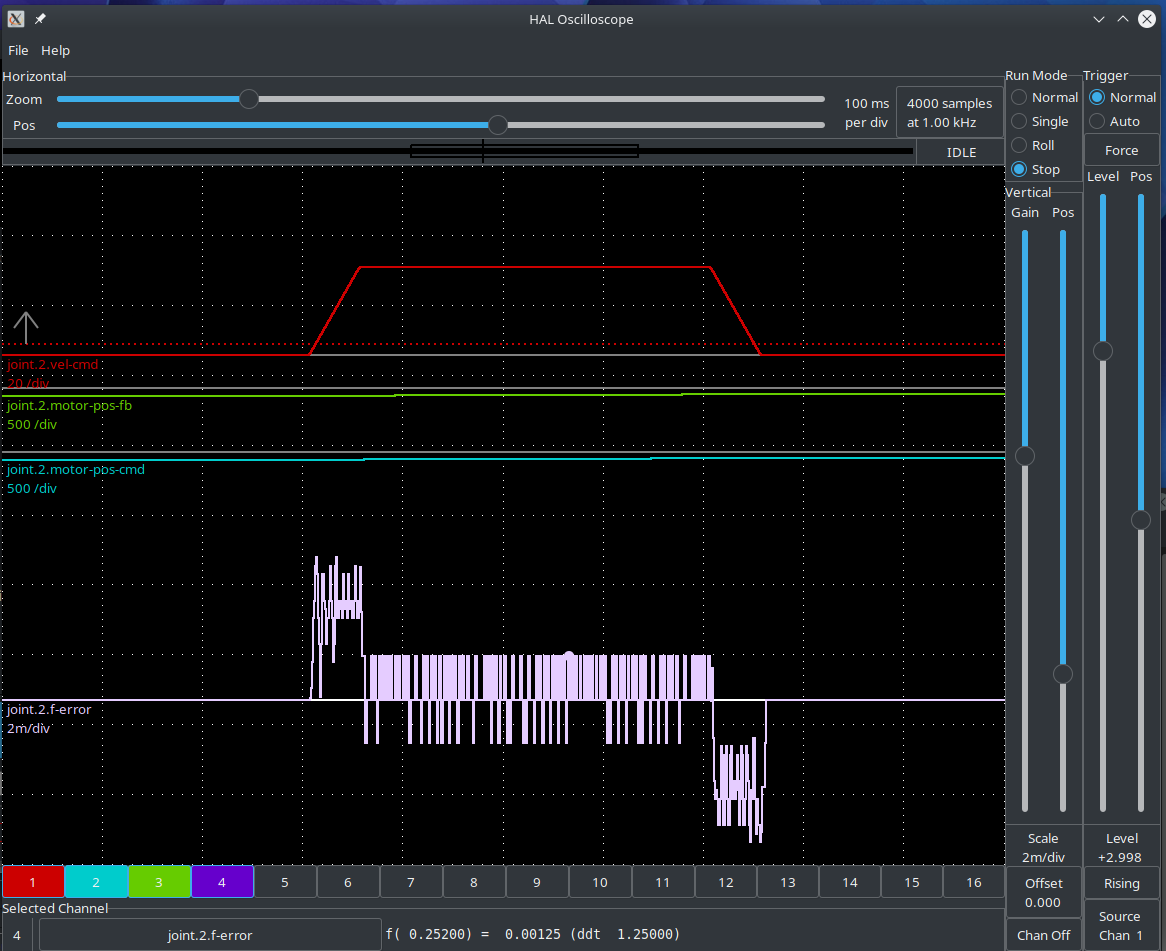

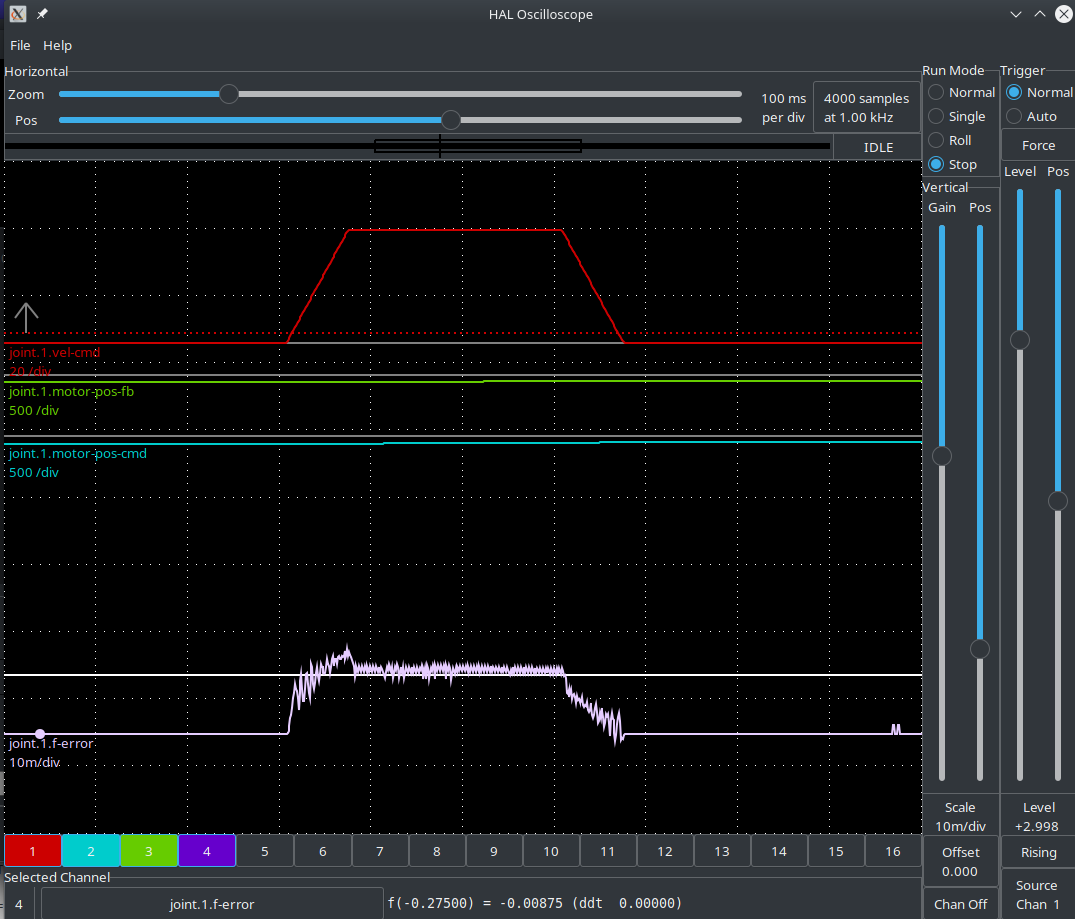

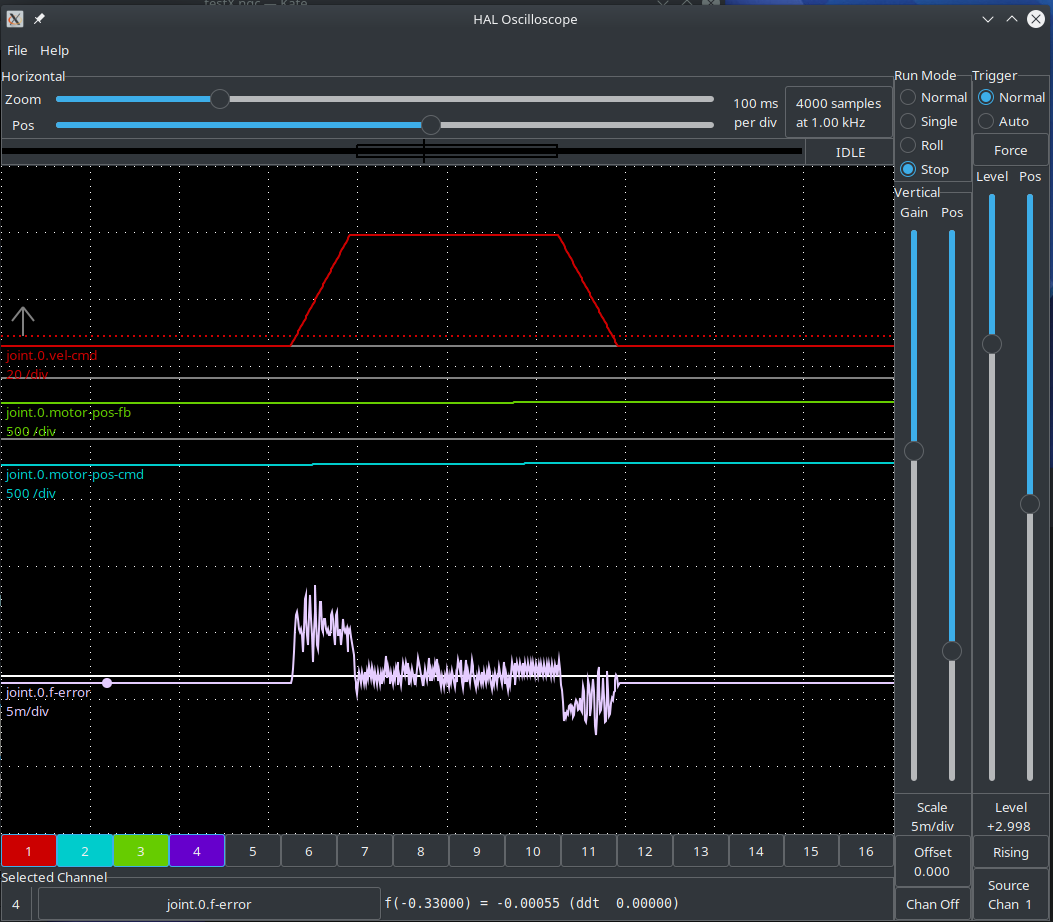

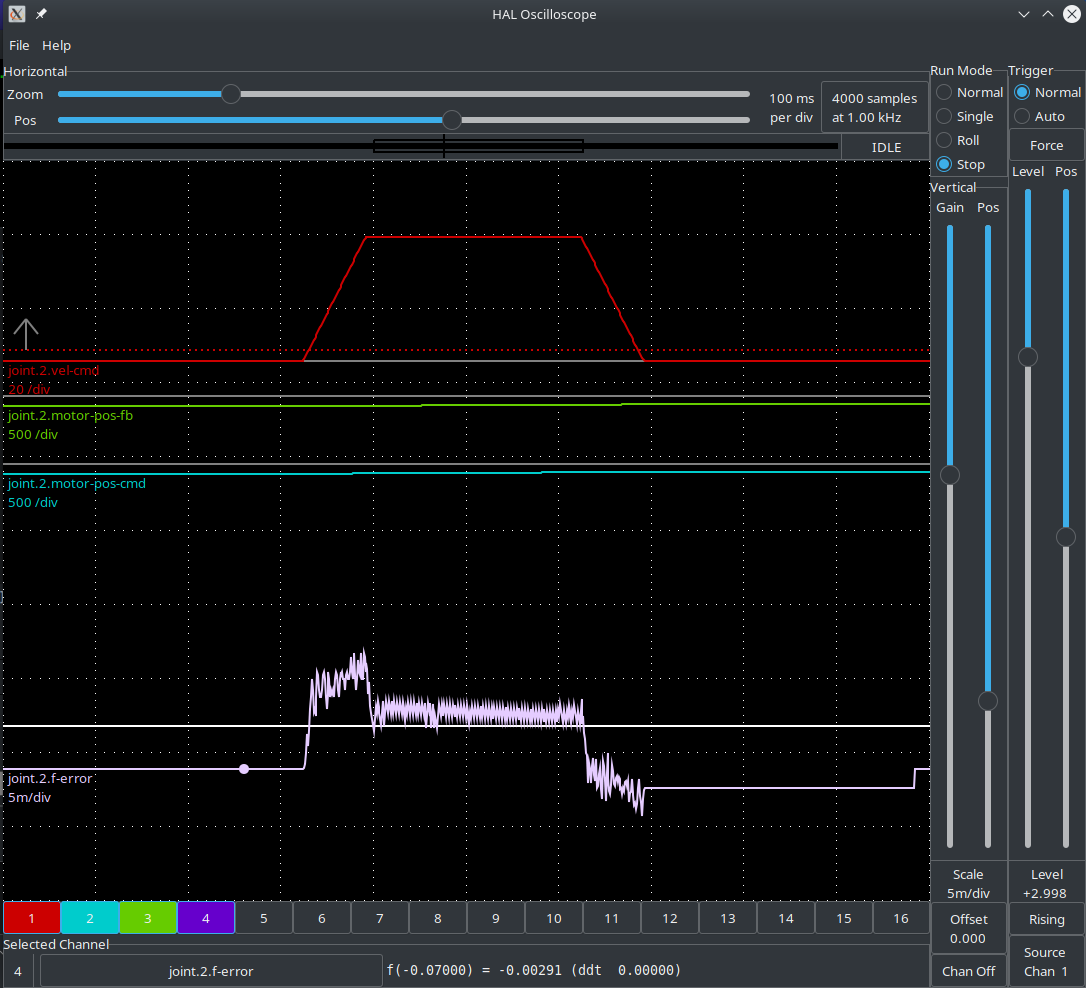

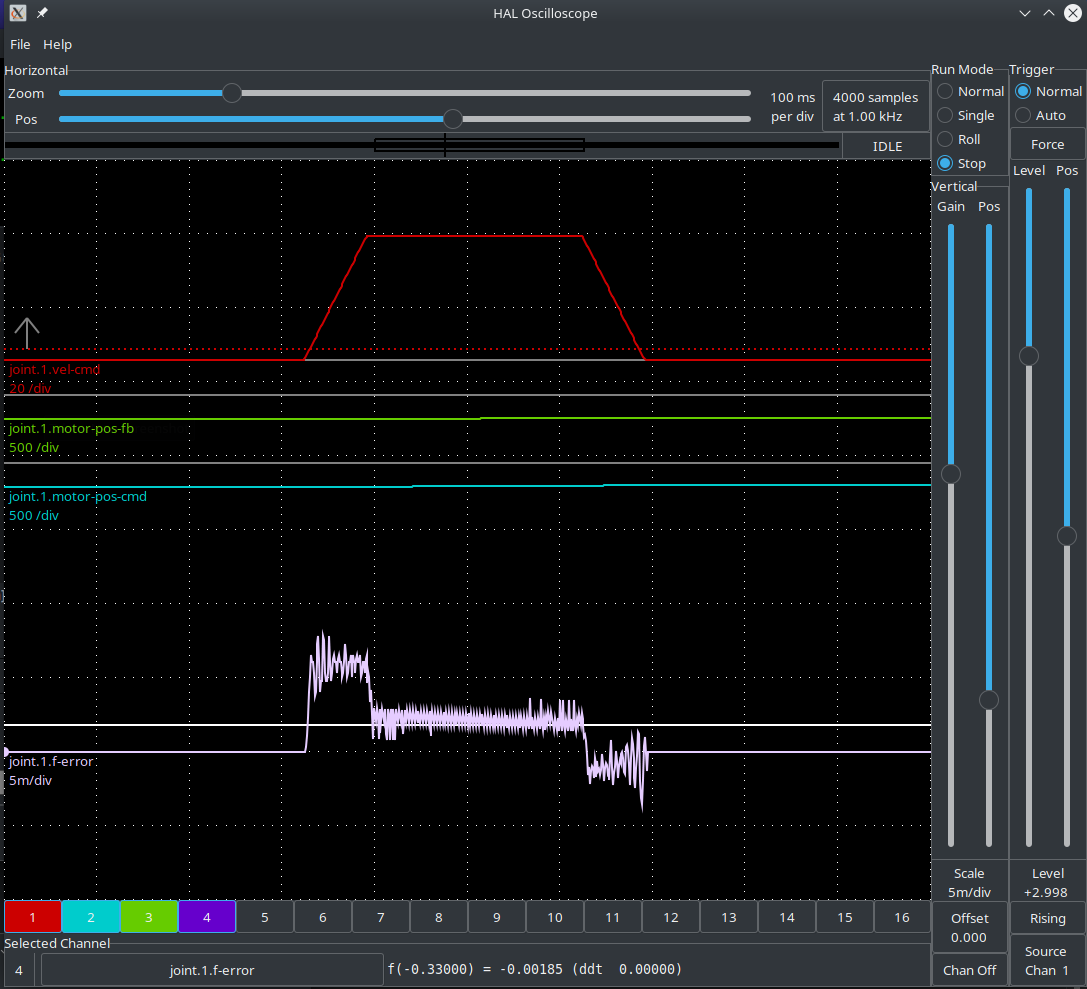

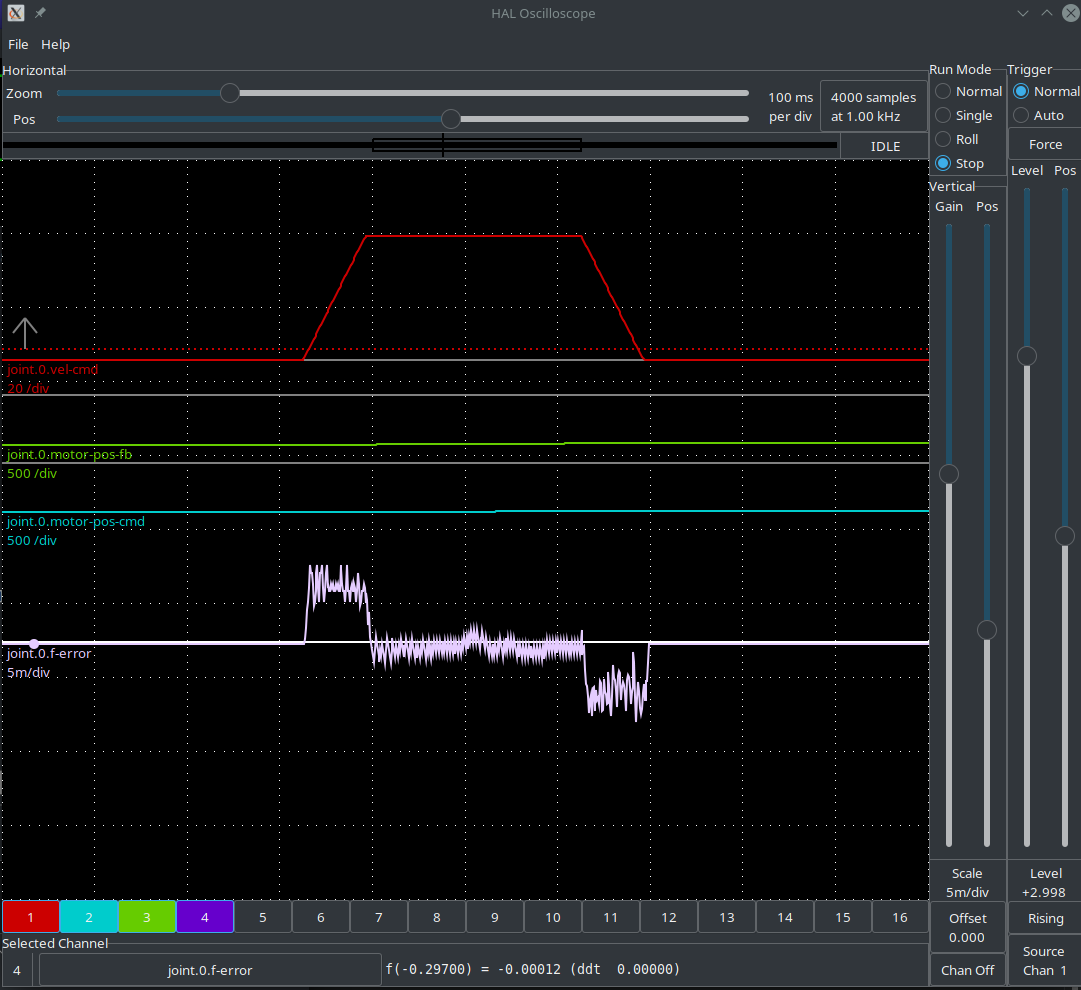

I'm tuning the steppers after adding encoders to X, Y & Z axis. I have it working and I think this is about as good as I'm going to get. This is my first time with encoder feedback. Please take a look at the halscope graphs and let me know what you think.

The machine is a home built vertical mill with nema23 steppers, mesa 7i76e with the 7i85 for the encoders.

One of my concerns is the Y and Z axis will hum when they stop moving. This only happens once in a while and the hum is not very loud and I don't see any movement visually or with halscope.

The machine is a home built vertical mill with nema23 steppers, mesa 7i76e with the 7i85 for the encoders.

One of my concerns is the Y and Z axis will hum when they stop moving. This only happens once in a while and the hum is not very loud and I don't see any movement visually or with halscope.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17685

- Thank you received: 5171

24 Jun 2022 21:33 #245810

by PCW

Replied by PCW on topic How does my encoder feedback look?

On the first and last plots, a tiny bit of FF2 may help

correct the acceleration dependent error.

On the middle plot and very small change of FF1 from 1.000

to say .999 or 1.001 may help the velocity dependent error.

correct the acceleration dependent error.

On the middle plot and very small change of FF1 from 1.000

to say .999 or 1.001 may help the velocity dependent error.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21276

- Thank you received: 7265

24 Jun 2022 21:34 #245811

by tommylight

Replied by tommylight on topic How does my encoder feedback look?

Try omitting this line for all axis/joints

setp pid.y.maxerror 0.012700

by putting a # in front of them, save, restart LinuxCNC

setp pid.y.maxerror 0.012700

by putting a # in front of them, save, restart LinuxCNC

Please Log in or Create an account to join the conversation.

- charleyann

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 10

24 Jun 2022 22:31 #245814

by charleyann

Replied by charleyann on topic How does my encoder feedback look?

Thanks guy, I tried both of the above with very minor improvements. I can center the error during the cruise part but I can't seem to improve the accel/decel.

I have been running all of my tests at rapid travel rate of 1500mm/min. Should I be happy with what I've got?

I have been running all of my tests at rapid travel rate of 1500mm/min. Should I be happy with what I've got?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

25 Jun 2022 00:14 #245822

by andypugh

My old knee mill does 45 mm/sec which is 2700mm/min so you do seem very much in the low side of normal.

Replied by andypugh on topic How does my encoder feedback look?

That depends on the machine. That seems a bit low for plasma or a router.I have been running all of my tests at rapid travel rate of 1500mm/min. Should I be happy with what I've got?

My old knee mill does 45 mm/sec which is 2700mm/min so you do seem very much in the low side of normal.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17685

- Thank you received: 5171

25 Jun 2022 00:19 - 25 Jun 2022 00:19 #245824

by PCW

Replied by PCW on topic How does my encoder feedback look?

You should be able to make the errors during accel be above or below 0

by tweaking FF2

Is P as high as it can get without oscillation?

When everything else it optimized you can try adding as much I term as is stable

(watch out for large magnitude oscillations with too much I term)

by tweaking FF2

Is P as high as it can get without oscillation?

When everything else it optimized you can try adding as much I term as is stable

(watch out for large magnitude oscillations with too much I term)

Last edit: 25 Jun 2022 00:19 by PCW.

Please Log in or Create an account to join the conversation.

- charleyann

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 10

25 Jun 2022 01:41 #245832

by charleyann

Replied by charleyann on topic How does my encoder feedback look?

You should be able to make the errors during accel be above or below 0

by tweaking FF2

Yes, I am able to move this.

Is P as high as it can get without oscillation?

No, I can increase P to 50-60 with no oscillation but it make it difficult to remove the following error.

I thought it was best to keep P as low as possible. I will play with higher numbers tomorrow.

When everything else it optimized you can try adding as much I term as is stable

(watch out for large magnitude oscillations with too much I term)

I'll try adding some I also.

Thanks

Please Log in or Create an account to join the conversation.

- charleyann

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 10

25 Jun 2022 16:35 #245867

by charleyann

Replied by charleyann on topic How does my encoder feedback look?

I have been running all of my tests at rapid travel rate of 1500mm/min. Should I be happy with what I've got?

That depends on the machine. That seems a bit low for plasma or a router.

My old knee mill does 45 mm/sec which is 2700mm/min so you do seem very much in the low side of normal.

Hi Andy, it's a small machine. 400x300x250 I cut mostly aluminum and some mild steel.

I can get 3000mm/min with no problem. I just prefer to keep it slower.

Please Log in or Create an account to join the conversation.

- charleyann

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 10

25 Jun 2022 18:13 #245872

by charleyann

Replied by charleyann on topic How does my encoder feedback look?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

28 Jun 2022 21:57 #246110

by andypugh

Replied by andypugh on topic How does my encoder feedback look?

What are the units? 5 microns of following error on accel and decel isn't terrible.

Please Log in or Create an account to join the conversation.

Time to create page: 0.223 seconds