Configuration for a 3+2 Axis XYZAB machine

- geostein8888

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 0

27 Sep 2022 13:48 #252857

by geostein8888

Configuration for a 3+2 Axis XYZAB machine was created by geostein8888

Hello,

i finally got my respi4 running linuxcnc with 5 axis. Now the next problem is coming. I created in Deskproto (test version) a nc file where i machine 5 sides of a bust. In Deskproto all the tool path looks correct, but when i open the nc file in linuxcnc, the rotations are not done, means i have the 5 jobs (for each side) beside each other - overlapping. No a and no b rotition is done. In the gcode i can see in linuxcnc that the rotations are in.

Does anybody have a ini/hal configuration where i can see what might be wrong with mine?

Georg

here the nc code

Configuration

i finally got my respi4 running linuxcnc with 5 axis. Now the next problem is coming. I created in Deskproto (test version) a nc file where i machine 5 sides of a bust. In Deskproto all the tool path looks correct, but when i open the nc file in linuxcnc, the rotations are not done, means i have the 5 jobs (for each side) beside each other - overlapping. No a and no b rotition is done. In the gcode i can see in linuxcnc that the rotations are in.

Does anybody have a ini/hal configuration where i can see what might be wrong with mine?

Georg

here the nc code

Configuration

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4648

- Thank you received: 2068

27 Sep 2022 14:32 #252860

by Aciera

Replied by Aciera on topic Configuration for a 3+2 Axis XYZAB machine

I think you might just be confused by the limitations of the tool path preview. The X,Y and Z coordinate system in the preview is static. Rotations around A, B or C will not rotate the toolpath but only the toolcone.

Please Log in or Create an account to join the conversation.

- geostein8888

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 0

28 Sep 2022 08:29 #252919

by geostein8888

Replied by geostein8888 on topic Configuration for a 3+2 Axis XYZAB machine

The problem is then, that linuxcnc tries to make a Z step what is greater then my z-axis, because this step normally should be done in x or y direction (because its not turned)

i made now a simpler test wit only a die to follow this

Georg

i made now a simpler test wit only a die to follow this

Georg

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4648

- Thank you received: 2068

28 Sep 2022 09:04 #252920

by Aciera

There isn't much LinuxCNC can do except execute the gcode it gets and it will do just that regardless of the limitations of the tool path preview. In trivial kinematics a gcode move in any axis will always be the same on the machine regardless of the position of any rotary axis.

Multiside operations often require shifting the work offsets after a rotation of the work piece unless you set the origin in the center of rotation. If your actual work surface does not correspond to the work origin after a turn of the a axis then you need to address that in the CAM.

Replied by Aciera on topic Configuration for a 3+2 Axis XYZAB machine

Are you actually getting an error or is that your interpretation of what it shows you in the preview?The problem is then, that linuxcnc tries to make a Z step what is greater then my z-axis

There isn't much LinuxCNC can do except execute the gcode it gets and it will do just that regardless of the limitations of the tool path preview. In trivial kinematics a gcode move in any axis will always be the same on the machine regardless of the position of any rotary axis.

Multiside operations often require shifting the work offsets after a rotation of the work piece unless you set the origin in the center of rotation. If your actual work surface does not correspond to the work origin after a turn of the a axis then you need to address that in the CAM.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

28 Sep 2022 13:57 #252938

by andypugh

GEOMETRY = XYZAB

to

GEOMETRY = ABXYZ

(Or maybe BAXYZ, see which works better)

Replied by andypugh on topic Configuration for a 3+2 Axis XYZAB machine

In the INI file changewhen i open the nc file in linuxcnc, the rotations are not done, means i have the 5 jobs (for each side) beside each other - overlapping. No a and no b rotition is done.

GEOMETRY = XYZAB

to

GEOMETRY = ABXYZ

(Or maybe BAXYZ, see which works better)

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4648

- Thank you received: 2068

28 Sep 2022 15:38 #252954

by Aciera

Replied by Aciera on topic Configuration for a 3+2 Axis XYZAB machine

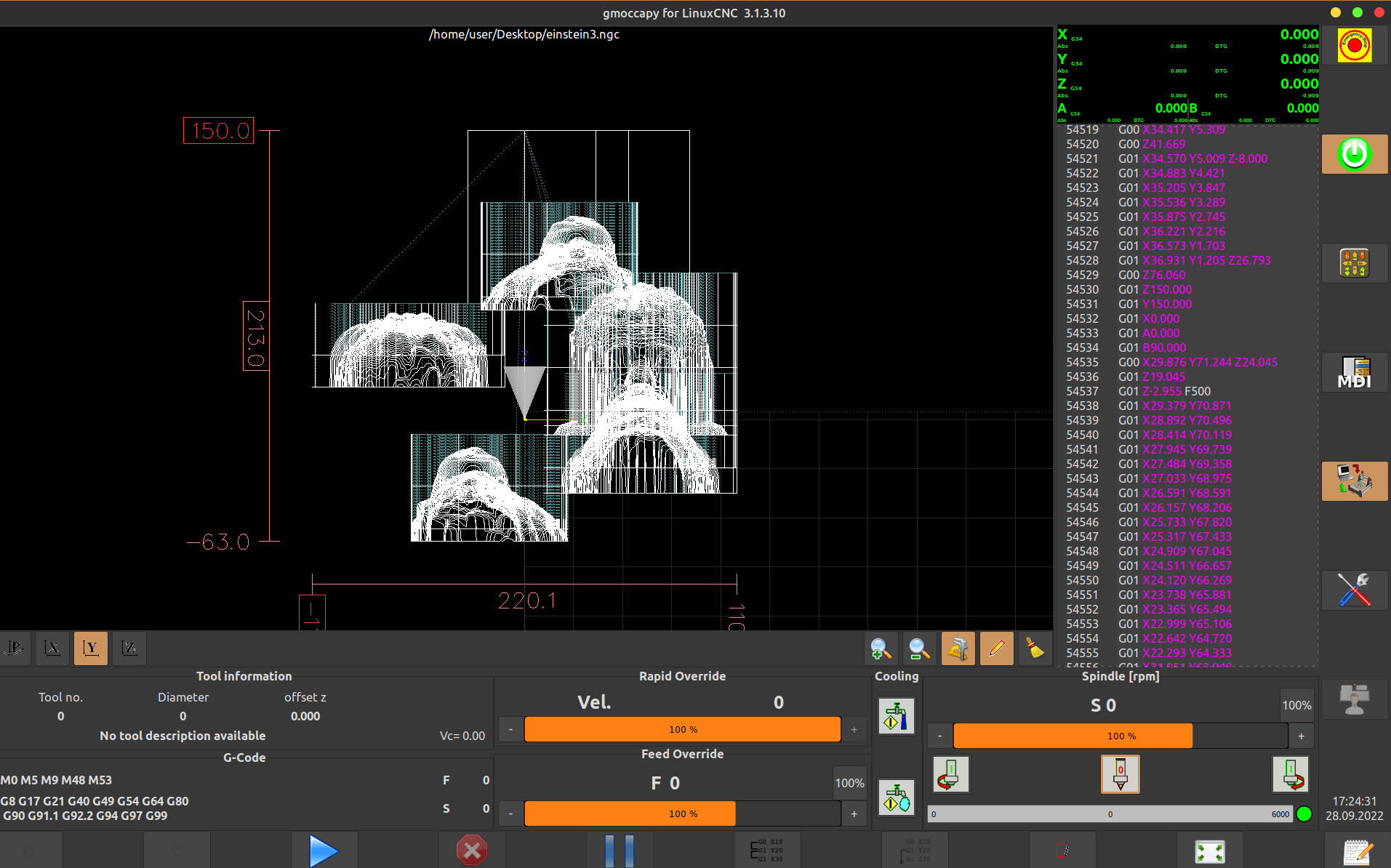

Just had a look at your code in the toolpath preview and I presume this is the orientation that shows the problem with your CAM output the best:

As you can see your code rotates upright around the work offset this is due to the fact that the preview in LinuxCNC does not actually show the toolpath rotating around the B axis but has a static xyz orientation. However it shows exactly how the tool moves in relation to the set work offset as commanded by the gcode coming from your CAM. The key here is to carefully set the work offset either in the center of rotation or reset the offset after each rotation, all of this needs to happen in the CAM.

As you can see your code rotates upright around the work offset this is due to the fact that the preview in LinuxCNC does not actually show the toolpath rotating around the B axis but has a static xyz orientation. However it shows exactly how the tool moves in relation to the set work offset as commanded by the gcode coming from your CAM. The key here is to carefully set the work offset either in the center of rotation or reset the offset after each rotation, all of this needs to happen in the CAM.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.634 seconds