Pin for manual command is running

- HiSH

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 1

01 Feb 2023 09:31 #263427

by HiSH

Pin for manual command is running was created by HiSH

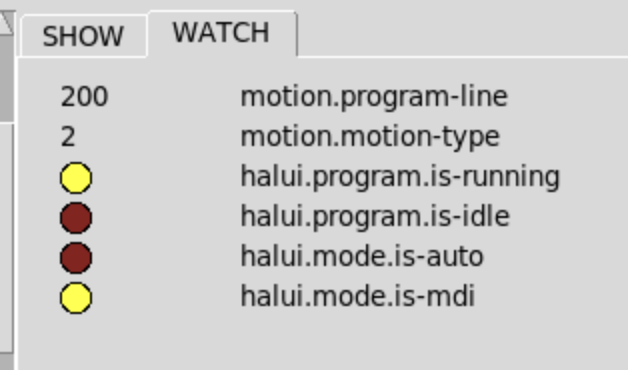

While a gcode-command is running, it is signed at the pin halui.programm.is-running.

Is there a pin, which shows a manual command from the ui is running?

Is there a pin, which shows a manual command from the ui is running?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

01 Feb 2023 18:34 #263455

by andypugh

Replied by andypugh on topic Pin for manual command is running

Attachments:

Please Log in or Create an account to join the conversation.

- HiSH

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 1

02 Feb 2023 07:53 #263500

by HiSH

Replied by HiSH on topic Pin for manual command is running

Thank you for your answer. Sorry, but i didn't mean a manual mdi-command.

I mean the buttons on the first tab in "axes". (see attachment)

I mean the buttons on the first tab in "axes". (see attachment)

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

04 Feb 2023 10:50 #263654

by andypugh

Replied by andypugh on topic Pin for manual command is running

In that case, no. Only the GUI knows that you have pressed those.

What is the use case? The buttons only do a very limited number of things, most of which directly set a HAL pin (spindle on, flood on etc)

What is the use case? The buttons only do a very limited number of things, most of which directly set a HAL pin (spindle on, flood on etc)

Please Log in or Create an account to join the conversation.

- HiSH

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 1

06 Feb 2023 08:53 #263807

by HiSH

Replied by HiSH on topic Pin for manual command is running

May be, i am using the wrong way, but for switching the spindle-gear on my cnc, i remap the s-code and set an motion.analog-out-00 pin as speed-cmd. So, if the user press for example "+"-button on the manual page for the increasing spindle-speed, i need this info for using an other speed-cmd pin as setpoint for the new spindle-speed and for switching the gear.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

06 Feb 2023 10:44 #263811

by andypugh

Replied by andypugh on topic Pin for manual command is running

For this particular situation you can create a HAL pin that changes state when the spindle buttons are operated, but I am not sure how you will then use that pin to call your remap.

Use a "ddt" component monitoring spindle speed command, and then a "wcomp" to set a bit when the ddt is non-zero.

Use a "ddt" component monitoring spindle speed command, and then a "wcomp" to set a bit when the ddt is non-zero.

Please Log in or Create an account to join the conversation.

- HiSH

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 1

07 Feb 2023 07:34 #263902

by HiSH

Replied by HiSH on topic Pin for manual command is running

Thank you! I think this may work. I could use halui.spindle.0.is-on with halui.program.is-running to decide, whether the correct speed source is.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

07 Feb 2023 10:25 #263911

by andypugh

Replied by andypugh on topic Pin for manual command is running

A better answer might be a custom HAL component that sits between the spindle pins and the controller.

I have something like this on my lathe.

The component takes spindle speed command and spindle-on as input (plus the state of the auto / manual and brake enable/disable switches) and outputs a motor speed command to the VFD along with gear change commands. And, also, spindle-at-sped so that motion does not continue until the spindle is in the new gear and up to speed.

It also considers the current motion-mode and only does a gear change when the system is doing a G0 or is not moving.

It attempts to synch the input and output shaft speeds so that it can change gear without stopping the spindle, too. but that is of a lot more relevance to a lathe than a mill as on a lathe in CSS mode the spindle speed varies a lot more than with a mill (where, typically, spindle speed only changes due to a tool change)

I have something like this on my lathe.

The component takes spindle speed command and spindle-on as input (plus the state of the auto / manual and brake enable/disable switches) and outputs a motor speed command to the VFD along with gear change commands. And, also, spindle-at-sped so that motion does not continue until the spindle is in the new gear and up to speed.

It also considers the current motion-mode and only does a gear change when the system is doing a G0 or is not moving.

It attempts to synch the input and output shaft speeds so that it can change gear without stopping the spindle, too. but that is of a lot more relevance to a lathe than a mill as on a lathe in CSS mode the spindle speed varies a lot more than with a mill (where, typically, spindle speed only changes due to a tool change)

Please Log in or Create an account to join the conversation.

- HiSH

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 1

07 Feb 2023 12:19 #263920

by HiSH

Replied by HiSH on topic Pin for manual command is running

>>A better answer might be a custom HAL component that sits between the spindle pins and the controller.

I am already using a custom HAL component for switching the gears.

>>The component takes spindle speed command and spindle-on as input (plus the state of the auto / manual and brake enable/disable switches) >>and outputs a motor speed command to the VFD along with gear change commands. And, also, spindle-at-sped so that motion does not >>continue until the spindle is in the new gear and up to speed.

Yes, i do it in my component similar as you, but my problem is, to understand which pins of which components should be served by which other component pins. Is there anywhere a schema or a plan, which shows the context between the components?

For example, there is the component "spindle" and i thought, the setpoint of the speed of the "spindle" should be the "speed-in"-pin, but this pin seams internaly connected with the "halui"-component and when i press the "+"-button on the "Manual control [F3]" tab, the "speed-in"-pin will increased. So I use

"spindle.0.speed-out" as input one und motion.analog-out--00 as input two in my user component. But, when the component "spindle" represents the issues of a spindle, both manual actions on the "Manual control" tab and g-codes like "S1000" should control the "spindle.0.speed-in". That meas for switching a gear, my user component should get the setpoints vom the ui and from the g-codes and control the "spindle.0.speed-in".

>>It attempts to synch the input and output shaft speeds so that it can change gear without stopping the spindle, too. but that is of a lot more >>relevance to a lathe than a mill as on a lathe in CSS mode the spindle speed varies a lot more than with a mill (where, typically, spindle speed >>only changes due to a tool change)

Ok, i have a mill, which makes it easier.

I still have the problems, between mdi-commands and manual inputs in the manual tab. Sometimes when chosinging the manual tab while a gcode like S1000 is running, the pin halui.program.is-running remains in true for ever and i didn't know why. Only a estop can help.

I am already using a custom HAL component for switching the gears.

>>The component takes spindle speed command and spindle-on as input (plus the state of the auto / manual and brake enable/disable switches) >>and outputs a motor speed command to the VFD along with gear change commands. And, also, spindle-at-sped so that motion does not >>continue until the spindle is in the new gear and up to speed.

Yes, i do it in my component similar as you, but my problem is, to understand which pins of which components should be served by which other component pins. Is there anywhere a schema or a plan, which shows the context between the components?

For example, there is the component "spindle" and i thought, the setpoint of the speed of the "spindle" should be the "speed-in"-pin, but this pin seams internaly connected with the "halui"-component and when i press the "+"-button on the "Manual control [F3]" tab, the "speed-in"-pin will increased. So I use

"spindle.0.speed-out" as input one und motion.analog-out--00 as input two in my user component. But, when the component "spindle" represents the issues of a spindle, both manual actions on the "Manual control" tab and g-codes like "S1000" should control the "spindle.0.speed-in". That meas for switching a gear, my user component should get the setpoints vom the ui and from the g-codes and control the "spindle.0.speed-in".

>>It attempts to synch the input and output shaft speeds so that it can change gear without stopping the spindle, too. but that is of a lot more >>relevance to a lathe than a mill as on a lathe in CSS mode the spindle speed varies a lot more than with a mill (where, typically, spindle speed >>only changes due to a tool change)

Ok, i have a mill, which makes it easier.

I still have the problems, between mdi-commands and manual inputs in the manual tab. Sometimes when chosinging the manual tab while a gcode like S1000 is running, the pin halui.program.is-running remains in true for ever and i didn't know why. Only a estop can help.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

07 Feb 2023 13:06 - 07 Feb 2023 13:07 #263925

by andypugh

Replied by andypugh on topic Pin for manual command is running

Does your HAL component need to know _why_ the spindle speed has changed? Mine doesn't care, if spindle.0.speed-out changes then the component calculates a new VFD frequency and (if necessary) shifts gear.

It doesn't matter what the cause of the speed change is.

linuxcnc.org/docs/stable/html/man/man9/m....html#SPINDLE%20PINS

It doesn't matter what the cause of the speed change is.

linuxcnc.org/docs/stable/html/man/man9/m....html#SPINDLE%20PINS

Last edit: 07 Feb 2023 13:07 by andypugh.

Please Log in or Create an account to join the conversation.

Time to create page: 0.128 seconds