PID tuning step & dir servos?

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

03 Dec 2023 04:17 #287065

by spumco

PID tuning step & dir servos? was created by spumco

Could use some guidance from the community. First time using linear scale feedback and tuning LCNC's PID.

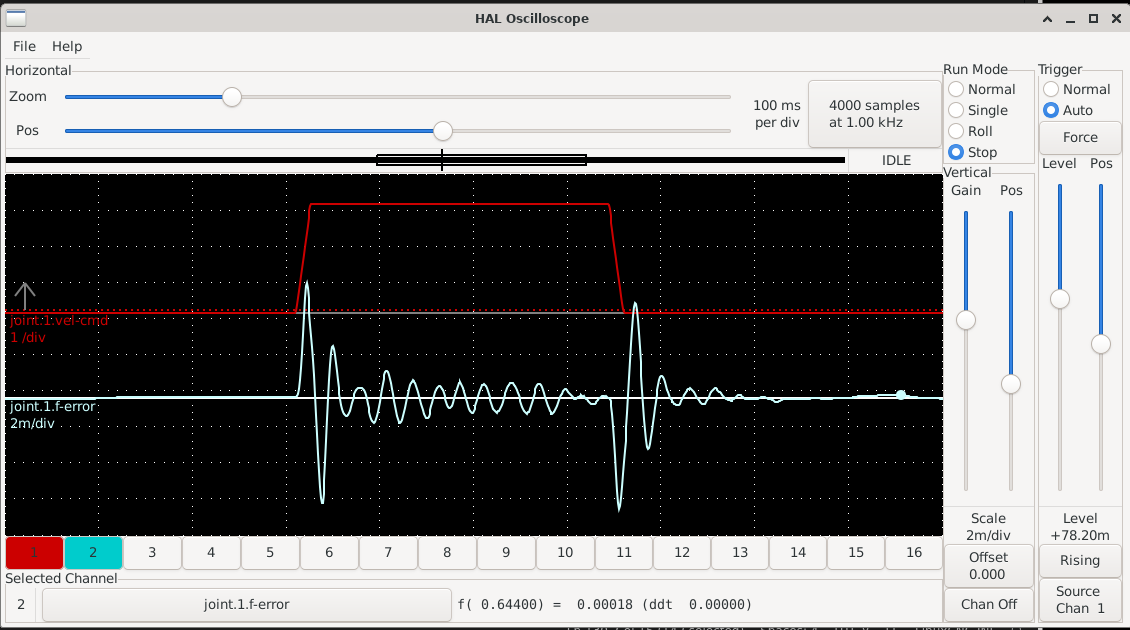

Manually adjusting and watching halscope here's where I am:

P=125

I=200

D=0.3

FF0=0

FF1=1

FF2=0.006

FF3=0

deadband=0.0005 to stop a little dither

Attached is a 1" move at 200ipm.

What is the "f(-0.18200) = -0.00001 (ddt 0.00000)" value in halscope? When I hover over the trace, the maximum value of the largest peak is 0.00628.

Does that mean 0.00628" of error at that point?

Am I on the right track?

Any suggestions on tightening up the f-error?

- 1kw S&D servos

- drives set/tuned internally to be as stiff as possible without noise/vibration

- 1um glass scales

- scale FB sent to PID FB (loop is closed)

- Lathe Z-axis

- ~75lbs of mass

- 5mm ballscrews

- MAX_ACCEL = 400 in INI and for stepgen

Manually adjusting and watching halscope here's where I am:

P=125

I=200

D=0.3

FF0=0

FF1=1

FF2=0.006

FF3=0

deadband=0.0005 to stop a little dither

Attached is a 1" move at 200ipm.

What is the "f(-0.18200) = -0.00001 (ddt 0.00000)" value in halscope? When I hover over the trace, the maximum value of the largest peak is 0.00628.

Does that mean 0.00628" of error at that point?

Am I on the right track?

Any suggestions on tightening up the f-error?

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

03 Dec 2023 12:07 #287087

by tommylight

Replied by tommylight on topic PID tuning step & dir servos?

Just to be on the safe side, is all set and working properly without feedback to LinuxCNC?

I seems way to high, start from 0, same for D and FF2

FF1 will most probably not be 1, except if you have the output scaling done based on max velocity of servos/motors.

Use a wee bit of FF2 only if you still have spikes at start/end of move after testing the above.

I seems way to high, start from 0, same for D and FF2

FF1 will most probably not be 1, except if you have the output scaling done based on max velocity of servos/motors.

Use a wee bit of FF2 only if you still have spikes at start/end of move after testing the above.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

03 Dec 2023 15:02 #287101

by spumco

Replied by spumco on topic PID tuning step & dir servos?

@Tommy,

- Yes, it's working reasonably well open loop.

- For I, the auto-tune came up with a silly 3000.0 or so. I dialed it way back, and also found a comment from PCW regarding a similar S&D configuration:

Also I would not expect the I terms to do

much of anything if less than 1000 or so- FF1 - Steps/inch is 50810, and INPUT_SCALE = 25398, so I'm guessing I need to drop it from 1.0 to 0.5 to start?

- FF2 and FF3 both seem to help with the initial spikes, but I'll work on the above first.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

04 Dec 2023 21:48 - 04 Dec 2023 21:54 #287219

by spumco

Replied by spumco on topic PID tuning step & dir servos?

Best I can do so far at F50 (ipm). X-axis is a bit better.

Is the "0.00299" in halscope (the start peak) 0.0029 inches? Or some other value?

Also wondering if the wobble during steady state is the internal drive tuning and there's nothing I can do about that in LCNC.

I and D didn't seem to make anything better. Tried really low number up to I >4000.

Any sugestions?

EDIT- added X-scope for comparison

Is the "0.00299" in halscope (the start peak) 0.0029 inches? Or some other value?

Also wondering if the wobble during steady state is the internal drive tuning and there's nothing I can do about that in LCNC.

I and D didn't seem to make anything better. Tried really low number up to I >4000.

Any sugestions?

EDIT- added X-scope for comparison

Last edit: 04 Dec 2023 21:54 by spumco. Reason: Added X

Please Log in or Create an account to join the conversation.

- PCW

-

- Online

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

04 Dec 2023 22:18 - 04 Dec 2023 22:19 #287223

by PCW

Replied by PCW on topic PID tuning step & dir servos?

I suspect error spike is because of the delay from command to motion

in the drives. Unless that is something you can improve in the drive tuning,

the only other options I can think of are:

1. Reduce the acceleration. I would expect the peak error to be roughly

proportional to acceleration.

2. Use open loop (and assume the drive delays are the same

for both axis)

3. Encourage the people working on a jerk limited TP

in the drives. Unless that is something you can improve in the drive tuning,

the only other options I can think of are:

1. Reduce the acceleration. I would expect the peak error to be roughly

proportional to acceleration.

2. Use open loop (and assume the drive delays are the same

for both axis)

3. Encourage the people working on a jerk limited TP

Last edit: 04 Dec 2023 22:19 by PCW.

The following user(s) said Thank You: rodw, spumco

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

05 Dec 2023 01:17 #287231

by spumco

I did notice improvement when I cut down the accel. But I'm greedy and want a fast machine.

I've got garbage ballscrews, and no hope of hitting decent tolerance without the scales.

I'm running out of 'thumbs-up' in the couple of jerkTP threads.

I'll fiddle with the drive internal settings, thanks.

Replied by spumco on topic PID tuning step & dir servos?

1. Reduce the acceleration. I would expect the peak error to be roughly

proportional to acceleration.2. Use open loop (and assume the drive delays are the same

for both axis)3. Encourage the people working on a jerk limited TPI'll fiddle with the drive internal settings, thanks.

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

05 Dec 2023 01:27 #287233

by tommylight

Replied by tommylight on topic PID tuning step & dir servos?

Are the ball screws that bad to cause all the wavy feedback between spikes?

If not, fix that first, then chase spikes. Feedback should track pretty flat during motion at constant speed.

If not, fix that first, then chase spikes. Feedback should track pretty flat during motion at constant speed.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

05 Dec 2023 03:38 #287237

by spumco

No Tommy, they're not that bad. I was exaggerating - they're remarkably good for Amazon. About +/-5um along 300mm according to the encoders.

I think the waves are from the drive; it's got a 'real-time' auto tuning feature I left enabled.

After taking PCW's advice and fidding with the drive's settings I knocked the f-error in half for both axes. They sound nice, no dithering, pretty stiff.

I'll wait to get tools installed and take some cuts before circling back to see if it needs improvement.

Replied by spumco on topic PID tuning step & dir servos?

Are the ball screws that bad to cause all the wavy feedback between spikes?

If not, fix that first, then chase spikes. Feedback should track pretty flat during motion at constant speed.

No Tommy, they're not that bad. I was exaggerating - they're remarkably good for Amazon. About +/-5um along 300mm according to the encoders.

I think the waves are from the drive; it's got a 'real-time' auto tuning feature I left enabled.

After taking PCW's advice and fidding with the drive's settings I knocked the f-error in half for both axes. They sound nice, no dithering, pretty stiff.

I'll wait to get tools installed and take some cuts before circling back to see if it needs improvement.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.089 seconds