PID loop tuning (ringing at destination)

- slowpoke

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 28

26 Mar 2024 18:18 - 26 Mar 2024 18:24 #296826

by slowpoke

PID loop tuning (ringing at destination) was created by slowpoke

I thought it best to start a new thread specific to this PID tuning issue.

System: ac servo driving ballscrew with linear scale feedback to Mesa 7i95t. I'm using the Axis interface

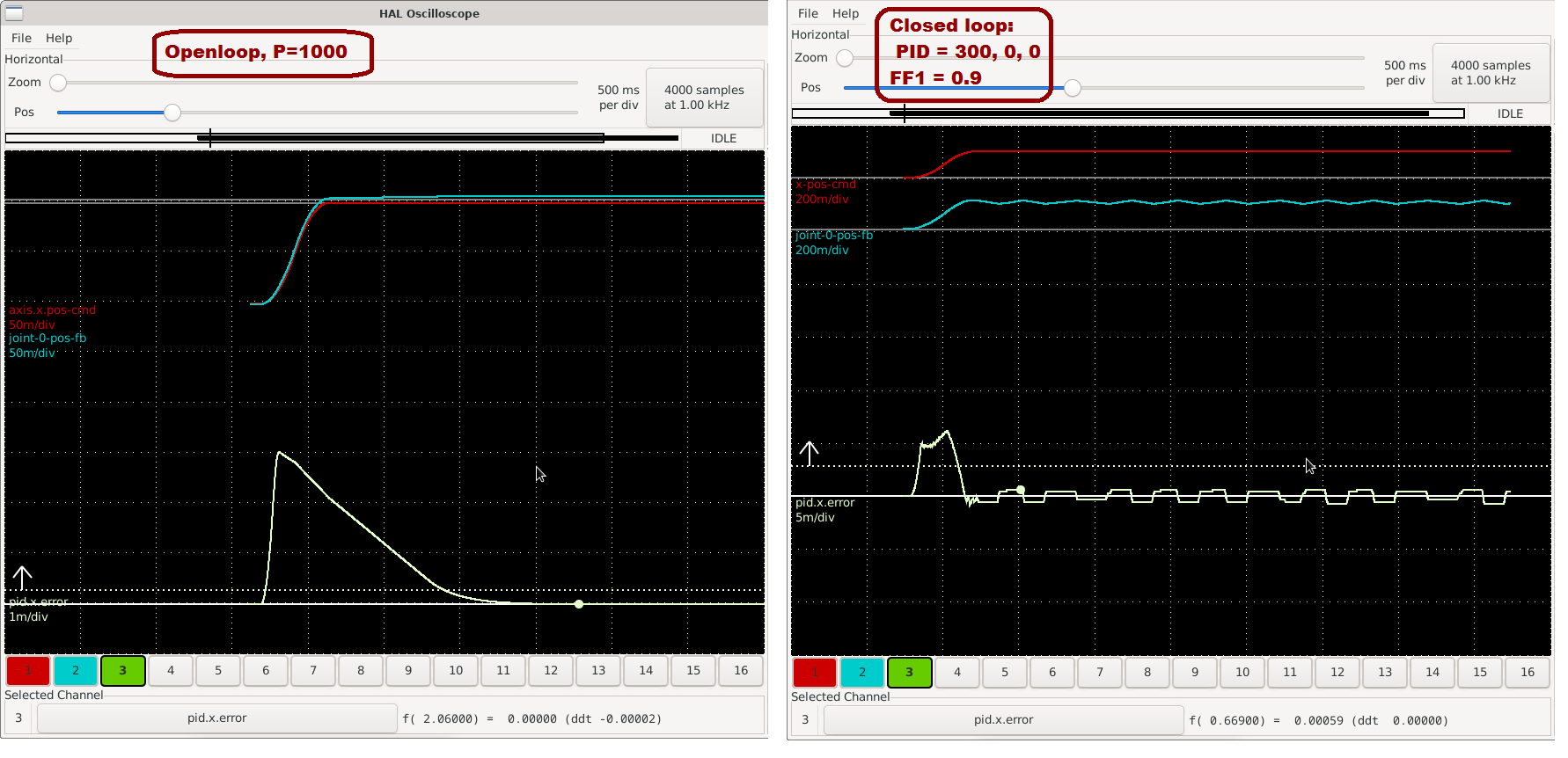

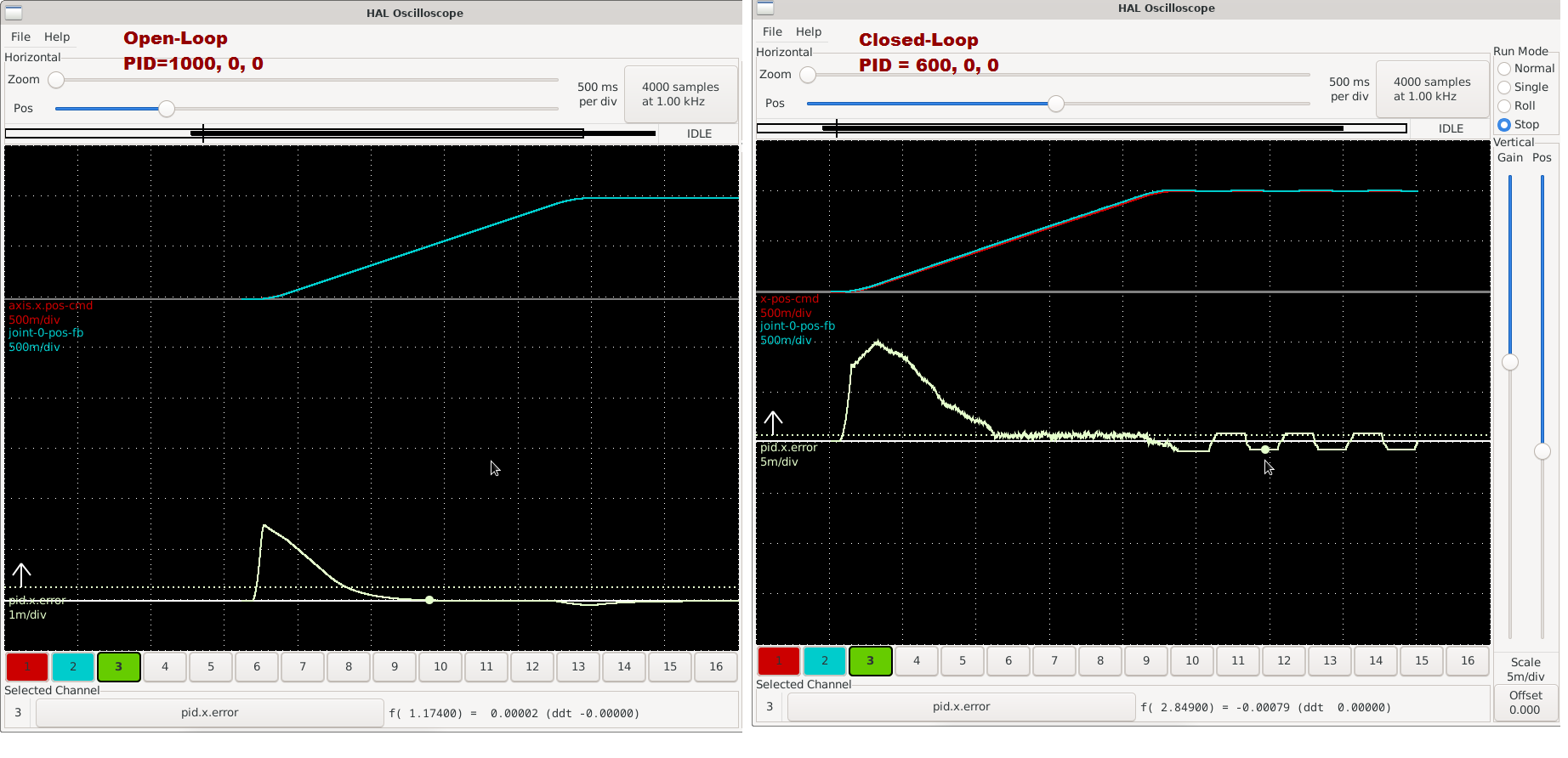

I have played with the PID tuning parameters a fair bit and have the table moves operating quite well except for small displacement ringing at the destination. I'm wondering if anyone has any suggestions. I have included a couple of HalScope plots that show the issue. I have made two configurations (one open loop and one closed loop).

System: ac servo driving ballscrew with linear scale feedback to Mesa 7i95t. I'm using the Axis interface

I have played with the PID tuning parameters a fair bit and have the table moves operating quite well except for small displacement ringing at the destination. I'm wondering if anyone has any suggestions. I have included a couple of HalScope plots that show the issue. I have made two configurations (one open loop and one closed loop).

- The open loop configuration without backlash compensation works well except an error of ~0.005" occurs when changing directions.

- The open loop configuration with backlash compensation works better error is typically ~0.001" occurs when changing directions.

- The closed loop configuration with low gain P<=200 is accurate, however slow especially towards the destination

- The closed loop configuration with higher gain P=600 is accurate and fast, however upon reaching the destination point the servo slowly oscillates and continues to oscillate typically +/- 0.001". If I disable and then re-enable the servo at the destination it stops hunting.

Note: for the P=600 case (deadband=0.0004" and maxerror=0.0005"), if I set deadband > max error, the hunting at destination stops however the error can be quite large in the 0.004-0.005" range.

Attachments:

Last edit: 26 Mar 2024 18:24 by slowpoke.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

26 Mar 2024 21:00 #296838

by Todd Zuercher

Replied by Todd Zuercher on topic PID loop tuning (ringing at destination)

It is impossible to say for sure if it is backlash or response delays of your position mode servos that is the root cause. But the end result is the same, a delay in response of the motor to changes in the command from Linuxcnc.

Halscope plots of the commanded velocity and and velocity feedback, might be a little more telling, and maybe give us some clue which is the bigger source of the delay. But as long as there is a delay in response, you will never get it much better.

Halscope plots of the commanded velocity and and velocity feedback, might be a little more telling, and maybe give us some clue which is the bigger source of the delay. But as long as there is a delay in response, you will never get it much better.

The following user(s) said Thank You: slowpoke

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17754

- Thank you received: 5191

26 Mar 2024 21:15 #296839

by PCW

Replied by PCW on topic PID loop tuning (ringing at destination)

Any backlash will cause likely hunting of the approximate size of the backlash.

This is not something you can fix with simple PID tuning.

If the instability is because of slow response of the drive (and not backlash),

you can lower the P term and use more integral term.

This is not something you can fix with simple PID tuning.

If the instability is because of slow response of the drive (and not backlash),

you can lower the P term and use more integral term.

Please Log in or Create an account to join the conversation.

- slowpoke

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 28

26 Mar 2024 21:22 - 26 Mar 2024 21:39 #296840

by slowpoke

Replied by slowpoke on topic PID loop tuning (ringing at destination)

Todd, PCW,

Thanks, that's very helpful, I'm going to swap out the regular bearings for angular contact bearings tomorrow and see where that takes me, but before I do that I want to see what happens with the less P more I approach. Wild guess for I values?

P I

600 ?

300 ?

200 ?

Thanks, that's very helpful, I'm going to swap out the regular bearings for angular contact bearings tomorrow and see where that takes me, but before I do that I want to see what happens with the less P more I approach. Wild guess for I values?

P I

600 ?

300 ?

200 ?

Last edit: 26 Mar 2024 21:39 by slowpoke.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

27 Mar 2024 00:16 #296853

by andypugh

Replied by andypugh on topic PID loop tuning (ringing at destination)

I would start with an I of 0.001, then 0.01 and so on until something seems to change.

The following user(s) said Thank You: slowpoke

Please Log in or Create an account to join the conversation.

Time to create page: 0.378 seconds