7i96 Splindle Encoder setup.

- Wonkyaxis

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

23 Jun 2024 09:37 #303628

by Wonkyaxis

7i96 Splindle Encoder setup. was created by Wonkyaxis

Hi, Im retrofitting a ZX7045. Im trying to get a encoder setup on my spindle.

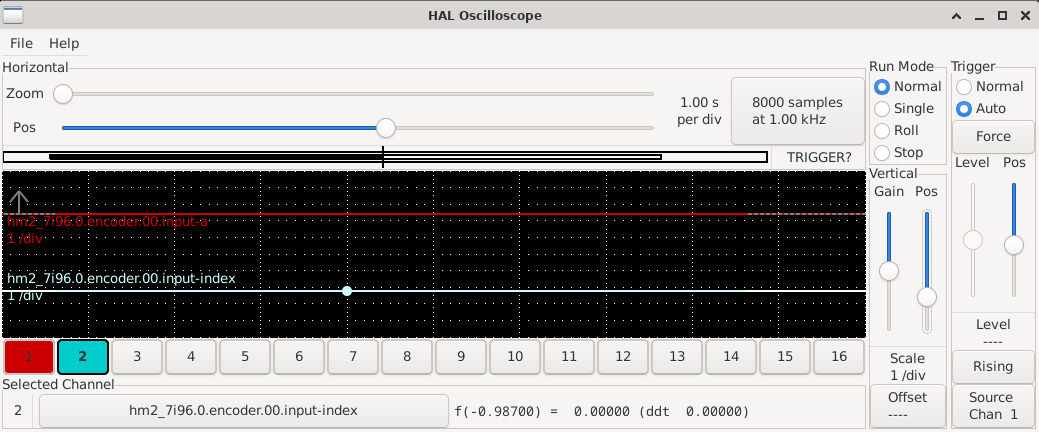

I used pncconfig to setup the spindle encoder, but when I run the spindle i get no feedback on linuxcnc.

I tried using hal.scope but im seeing no activity. Same goes for hal show.

I have a oscilloscope connected between the encoder A and ground and I can see the signal there.

This is my first advance linuxcnc build, so I'm still figuring out how to edit .HAL and .INI directly.

I suspect my encoder is not configured correctly. I have attached my INI and HAL files.

Can someone see if I did something wrong in my configuration?

Some extra info:

Mesa 7i96 (7i96d_1pwm.bit firmware)

1.5kw spindle on vfd with Pwm to 10V analog converter for speed control.

Encoder : Omron E6B2-CWZ3E-1024

Connection

A => TB2.Pin7

B => TB2.Pin10

Z => TB2.Pin13

GND => TB2.Pin9

5V => TB2.Pin12

Gear ratio between encoder and spindle: 1 turn spindle = 3 turns encoder. (i will fix this in the future to be 1:1)

Goal: tapping cycles and speed/torque control.

Speed/torque control through something like this:

I want linux cnc to run the spindle at 100%pwm first, then check the actual speed.

If the desired speed achievable with pwm between 70 and 100%. Set pwm to required value.

If not achievable in pwm range, Stop and tell me to shift gear up or down.

Repeat speed set in new gear.

I used pncconfig to setup the spindle encoder, but when I run the spindle i get no feedback on linuxcnc.

I tried using hal.scope but im seeing no activity. Same goes for hal show.

I have a oscilloscope connected between the encoder A and ground and I can see the signal there.

This is my first advance linuxcnc build, so I'm still figuring out how to edit .HAL and .INI directly.

I suspect my encoder is not configured correctly. I have attached my INI and HAL files.

Can someone see if I did something wrong in my configuration?

Some extra info:

Mesa 7i96 (7i96d_1pwm.bit firmware)

1.5kw spindle on vfd with Pwm to 10V analog converter for speed control.

Encoder : Omron E6B2-CWZ3E-1024

Connection

A => TB2.Pin7

B => TB2.Pin10

Z => TB2.Pin13

GND => TB2.Pin9

5V => TB2.Pin12

Gear ratio between encoder and spindle: 1 turn spindle = 3 turns encoder. (i will fix this in the future to be 1:1)

Goal: tapping cycles and speed/torque control.

Speed/torque control through something like this:

I want linux cnc to run the spindle at 100%pwm first, then check the actual speed.

If the desired speed achievable with pwm between 70 and 100%. Set pwm to required value.

If not achievable in pwm range, Stop and tell me to shift gear up or down.

Repeat speed set in new gear.

Attachments:

Please Log in or Create an account to join the conversation.

- Dave2024

-

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 10

23 Jun 2024 10:31 #303631

by Dave2024

Replied by Dave2024 on topic 7i96 Splindle Encoder setup.

Im not qualified to be the one to answer this but if I could attempt it would be perhaps your encoder is single ended and your board is configured for differential input. If you wanted you could try moving the jumpers on W1, W2 , and W3 over to the left pins and try check if you get any data.

In Pncconf on the Spindle page if you also have the encoder correctly connected to the encoder port A,B,Z and GND then click the 'Open Loop Test' button it should display encoder feedback

But otherwise theres some pros on here look for PCW and Tommylight they will get you setup

In Pncconf on the Spindle page if you also have the encoder correctly connected to the encoder port A,B,Z and GND then click the 'Open Loop Test' button it should display encoder feedback

But otherwise theres some pros on here look for PCW and Tommylight they will get you setup

The following user(s) said Thank You: Wonkyaxis

Please Log in or Create an account to join the conversation.

- Wonkyaxis

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

23 Jun 2024 11:18 #303637

by Wonkyaxis

Replied by Wonkyaxis on topic 7i96 Splindle Encoder setup.

Thank you, Yes, it works now. I can see rpm.

I thought it going to be something this stupid.

Jumper position, I did not think of jumper position.

Now I can move on to figuring out how to program my Speed/torque control.

Thank you. I have been banging my head against the wall for two weeks now trying to solve this. First thought it was EMI, so got a bunch of filter, shielded wire and earthed every thing on the machine. I even installed a second earthing rod in my house.

Lol all because a jumper position.

I thought it going to be something this stupid.

Jumper position, I did not think of jumper position.

Now I can move on to figuring out how to program my Speed/torque control.

Thank you. I have been banging my head against the wall for two weeks now trying to solve this. First thought it was EMI, so got a bunch of filter, shielded wire and earthed every thing on the machine. I even installed a second earthing rod in my house.

Lol all because a jumper position.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21276

- Thank you received: 7265

23 Jun 2024 11:23 #303639

by tommylight

After checking that we can move on to other stuff, if any.

Replied by tommylight on topic 7i96 Splindle Encoder setup.

That would be the best answer right now, thank you.Im not qualified to be the one to answer this but if I could attempt it would be perhaps your encoder is single ended and your board is configured for differential input. If you wanted you could try moving the jumpers on W1, W2 , and W3 over to the left pins and try check if you get any data.

After checking that we can move on to other stuff, if any.

Please Log in or Create an account to join the conversation.

Time to create page: 0.077 seconds