- Configuring LinuxCNC

- Advanced Configuration

- How do I control the speed and acceleration of the analog output of the 7i77 ?

How do I control the speed and acceleration of the analog output of the 7i77 ?

- programador

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 5

15 Jan 2025 14:17 #319026

by programador

How do I control the speed and acceleration of the analog output of the 7i77 ? was created by programador

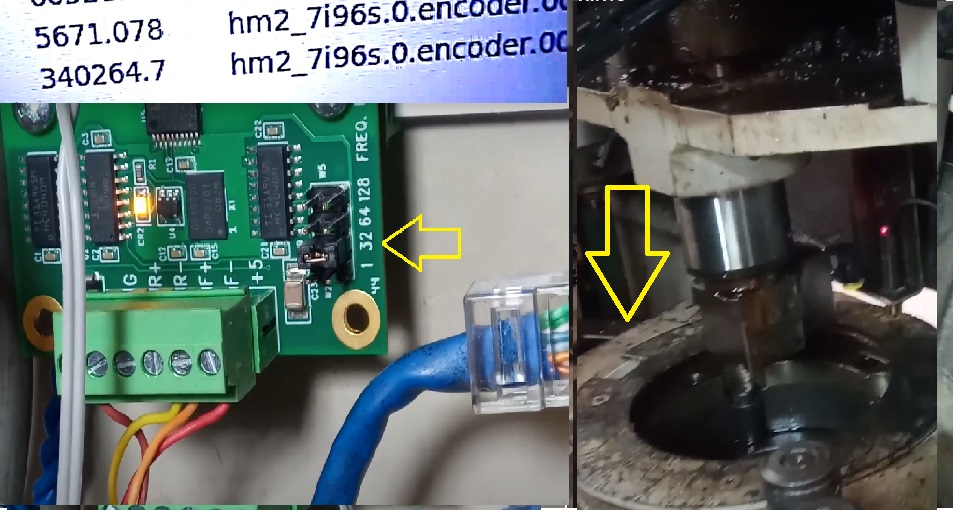

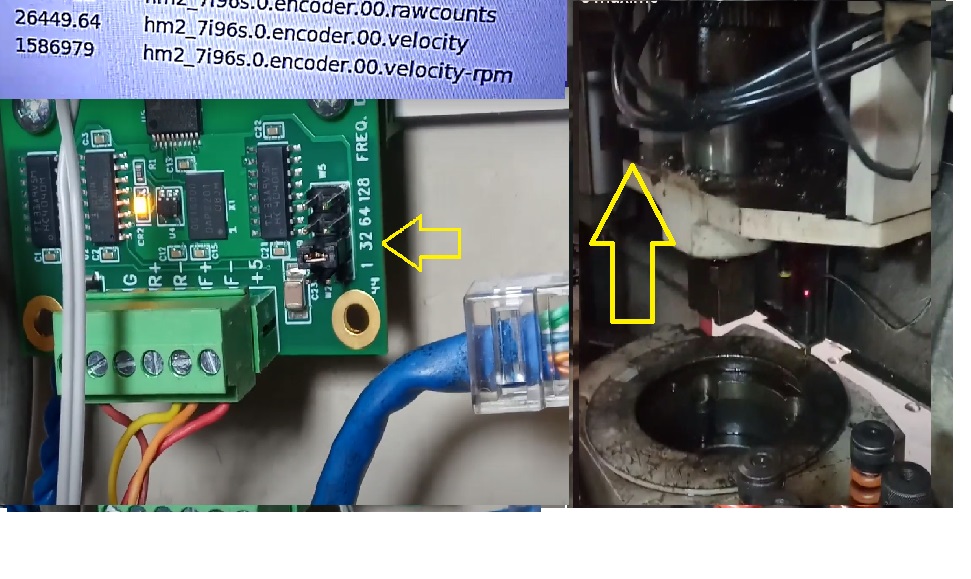

I can't find a suitable configuration so that the analog output can control the correct movement of the punching machine's piston. How do I solve this?Summary of what I'm trying to control:The piston that hits the punches is hydraulic, but it has an actuator that controls its descent and ascent by applying analog voltage of -10 volts and +10 volts, where +10 volts goes up and -10 volts goes down. However, unlike a motor, when there is no voltage at all, the piston descends gradually. To keep it high, a voltage above 2 volts positive will always be necessary.Hardware information: the sensor that detects the movement of the piston hitting the punches is magnetic and provides an analog output voltage, being 0 volts when it descends completely and 8 volts when it rises completely. This position voltage is connected to the THCAD2 electronic board that converts it into frequency. This frequency is used in channel 0 of the 7i77 electronic board's encoder, which is configured asThis reading is being shown on the display after the following modificationI'm worried that the problem is becausewas disconnected since it is being used to report the position, will the 7i77 electronic board work without net z-vel-fb?

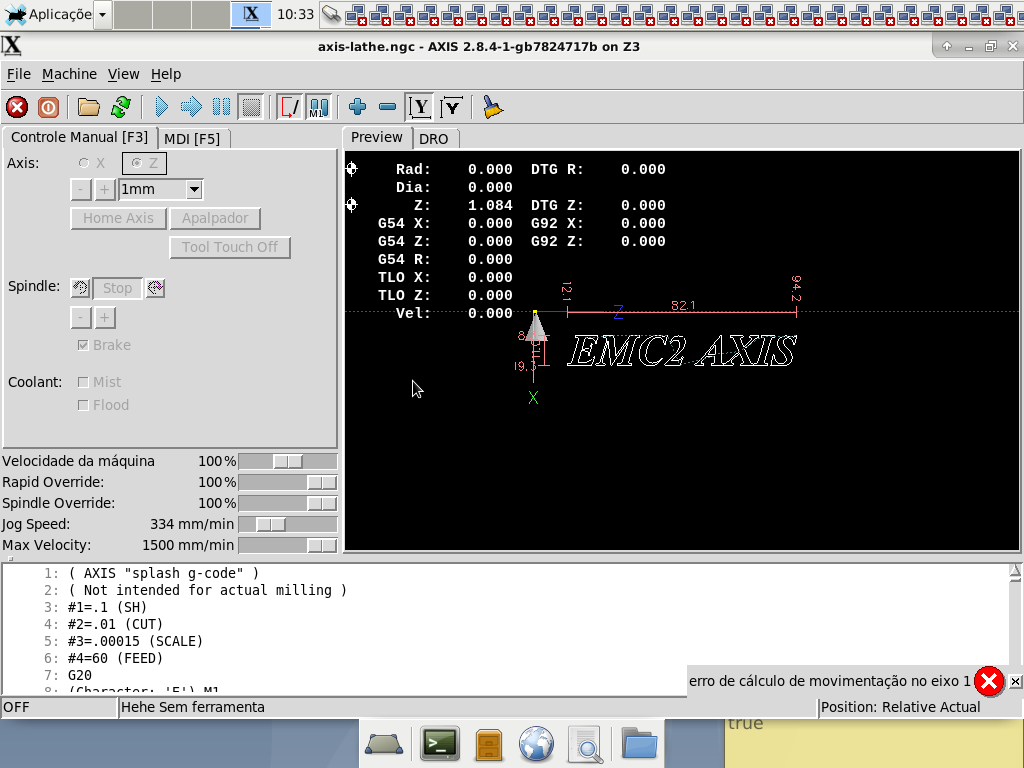

Below is information that may helpWhen I manually jog the Z axis to 1mm or 5mm, it makes no difference in the actual movement of the piston, it always moves the same and the Z axis calculation error appearsWhen I manually jog the Z axis to 1mm

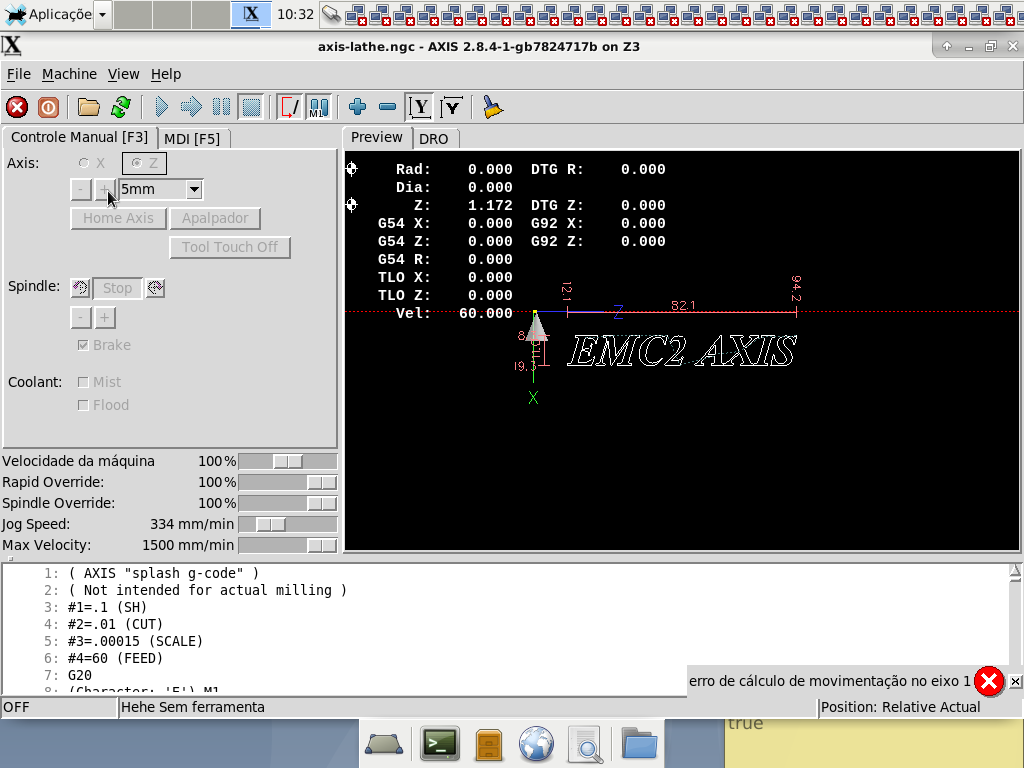

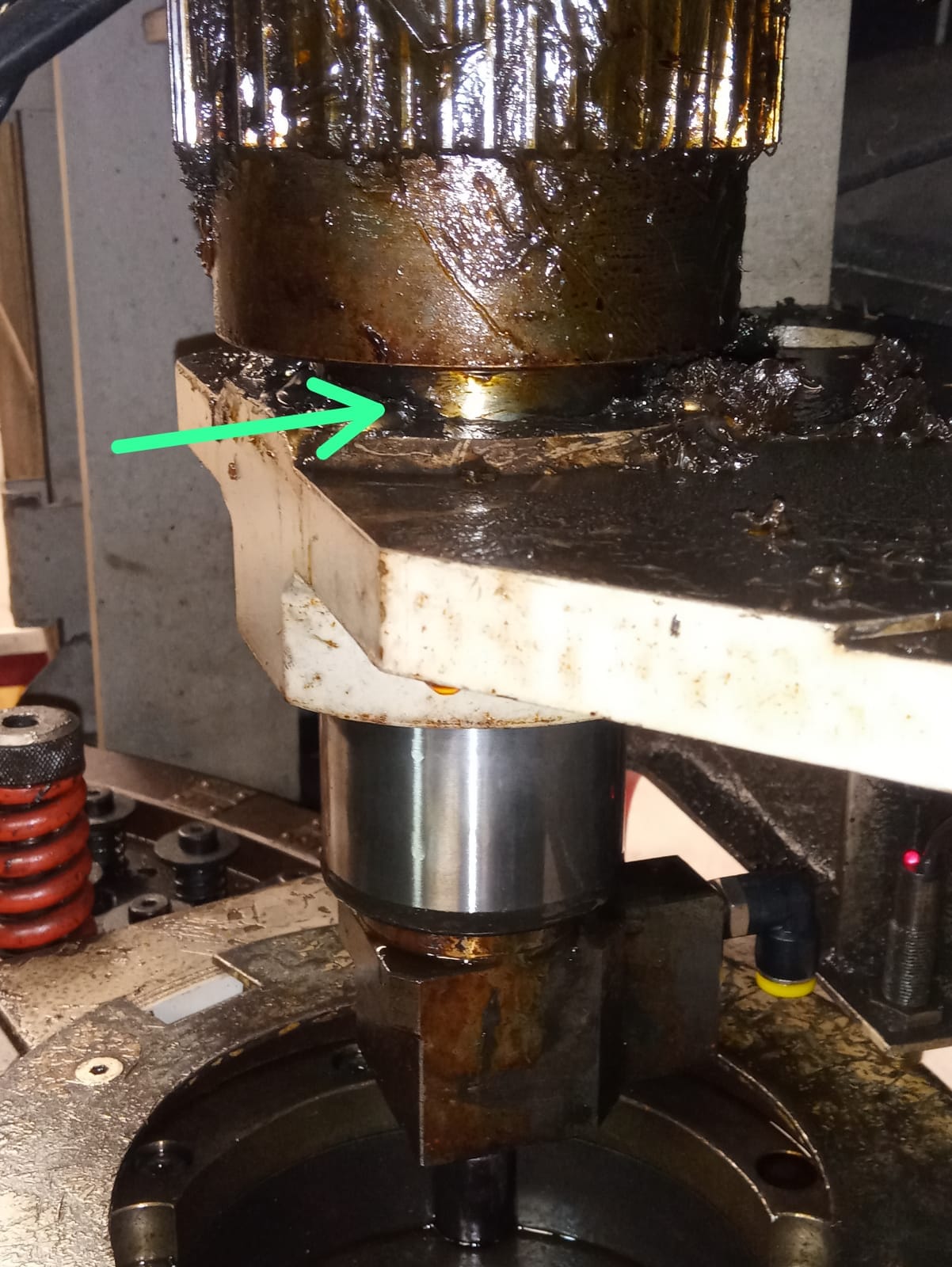

When I manually jog the Z axis to 5mm Piston hitting the punches in the zero position

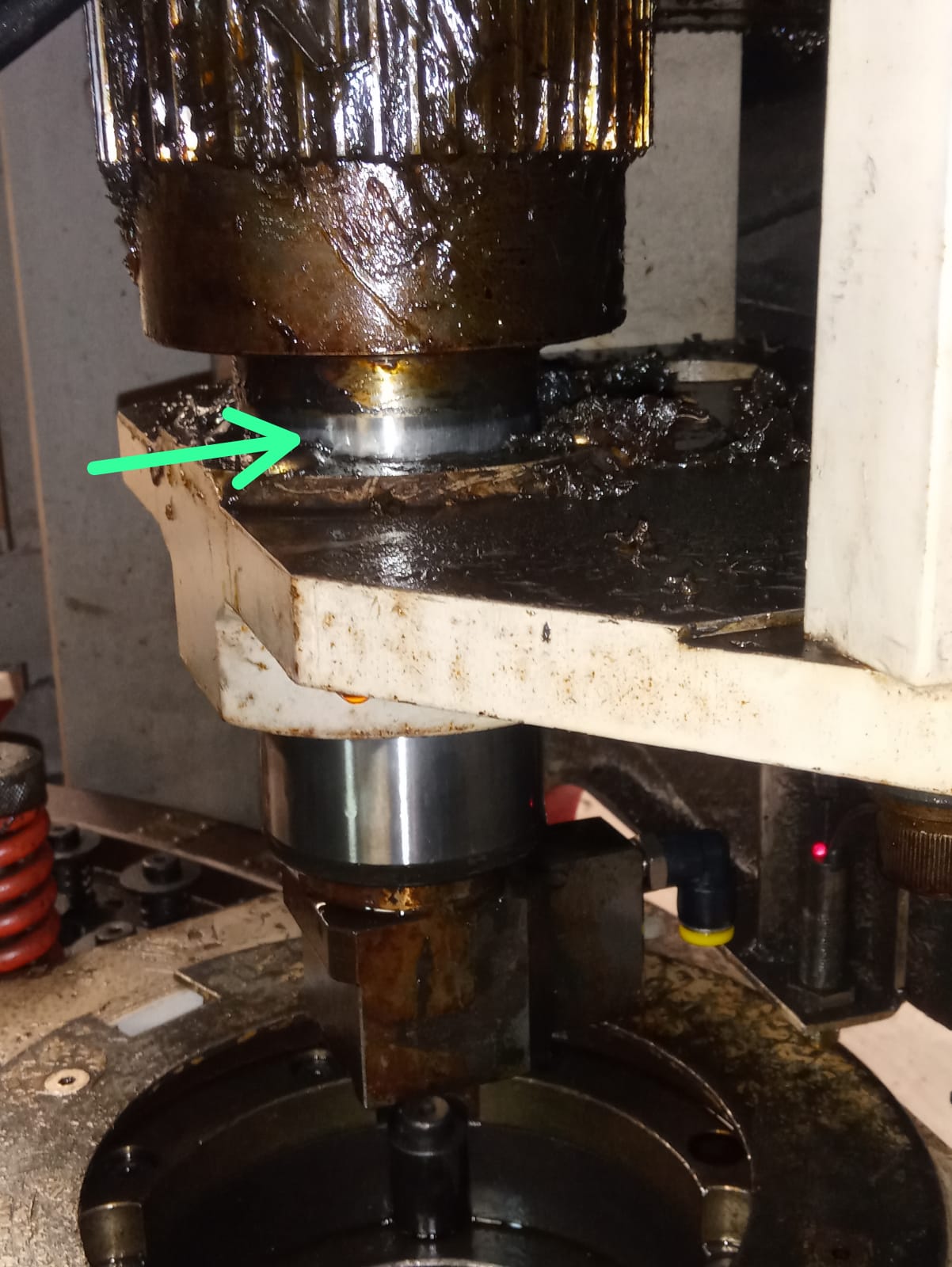

Piston hitting the punches in the position after a 1mm jog

Piston hitting the punches in the position after a 5mm jog I have been working on this machine retrofit for over 2 years, unfortunately here in Brazil I have not found qualified labor to perform this service. If I cannot resolve this step I will have to give up on LinuxCNC. I am willing to pay if someone resolves this situation. Even so, I thank all the contributions from the Forum and Mr. Peter.

setp hm2_7i96s.0.encoder.00.counter-mode 1#net z-pos-fb <= hm2_7i96s.0.encoder.00.position # Disabled Linenet z-pos-fb <= hm2_7i96s.0.encoder.00.velocity #New Linenet z-pos-fb => joint.1.motor-pos-fb#net z-vel-fb <= hm2_7i96s.0.encoder.00.velocity # Disabled Linenet z-pos-fb => joint.1.motor-pos-fbnet z-index-enable joint.1.index-enable <=> hm2_7i96s.0.encoder.00.index-enablenet z-pos-rawcounts <= hm2_7i96s.0.encoder.00.rawcountsnet z-vel-fbBelow is information that may helpWhen I manually jog the Z axis to 1mm or 5mm, it makes no difference in the actual movement of the piston, it always moves the same and the Z axis calculation error appearsWhen I manually jog the Z axis to 1mm

When I manually jog the Z axis to 5mm Piston hitting the punches in the zero position

Piston hitting the punches in the position after a 1mm jog

Piston hitting the punches in the position after a 5mm jog I have been working on this machine retrofit for over 2 years, unfortunately here in Brazil I have not found qualified labor to perform this service. If I cannot resolve this step I will have to give up on LinuxCNC. I am willing to pay if someone resolves this situation. Even so, I thank all the contributions from the Forum and Mr. Peter.

Attachments:

Please Log in or Create an account to join the conversation.

- programador

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 5

15 Jan 2025 14:19 - 15 Jan 2025 14:22 #319027

by programador

Replied by programador on topic How do I control the speed and acceleration of the analog output of the 7i77 ?

This reading is being shown on the display after the following modification

#net z-pos-fb <= hm2_7i96s.0.encoder.00.position # Disabled Line

net z-pos-fb <= hm2_7i96s.0.encoder.00.velocity #New Line

net z-pos-fb => joint.1.motor-pos-fb

#net z-vel-fb <= hm2_7i96s.0.encoder.00.velocity # Disabled Line

net z-pos-fb => joint.1.motor-pos-fb

net z-index-enable joint.1.index-enable <=> hm2_7i96s.0.encoder.00.index-enable

net z-pos-rawcounts <= hm2_7i96s.0.encoder.00.rawcountsAttachments:

Last edit: 15 Jan 2025 14:22 by programador.

Please Log in or Create an account to join the conversation.

- programador

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 5

15 Jan 2025 14:22 #319028

by programador

Replied by programador on topic How do I control the speed and acceleration of the analog output of the 7i77 ?

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17724

- Thank you received: 5186

15 Jan 2025 15:13 - 15 Jan 2025 15:46 #319032

by PCW

Replied by PCW on topic How do I control the speed and acceleration of the analog output of the 7i77 ?

One thing I see is that the Z encoder scale is off by orders of magnitude.

If you are using the ~100 to 900 KHz range of the THCAD2, I would expect

and encoder scale to be roughly 800,000 / Z_motion_range.

What is the Z motion range for 0 to 10V out from your sensor?

It addition the scale may need to be negative. This is the first thing to get setup correctly

Also as I mentioned, you may need to feed the encoder velocity signal through LinuxCNCs

offset component to remove the offset at 0V

If you are using the ~100 to 900 KHz range of the THCAD2, I would expect

and encoder scale to be roughly 800,000 / Z_motion_range.

What is the Z motion range for 0 to 10V out from your sensor?

It addition the scale may need to be negative. This is the first thing to get setup correctly

Also as I mentioned, you may need to feed the encoder velocity signal through LinuxCNCs

offset component to remove the offset at 0V

Last edit: 15 Jan 2025 15:46 by PCW.

Please Log in or Create an account to join the conversation.

- programador

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 5

15 Jan 2025 18:07 #319042

by programador

Replied by programador on topic How do I control the speed and acceleration of the analog output of the 7i77 ?

What is the Z motion range for 0 to 10V out from your sensor?

Response:

ranger 10364.831 hm2_7i96s.00.enconder.00.velocity

ranger 621866.8 hm2_7i96s.00.velocity-rpm

I am testing with jump 64 on the THCAD2 board.

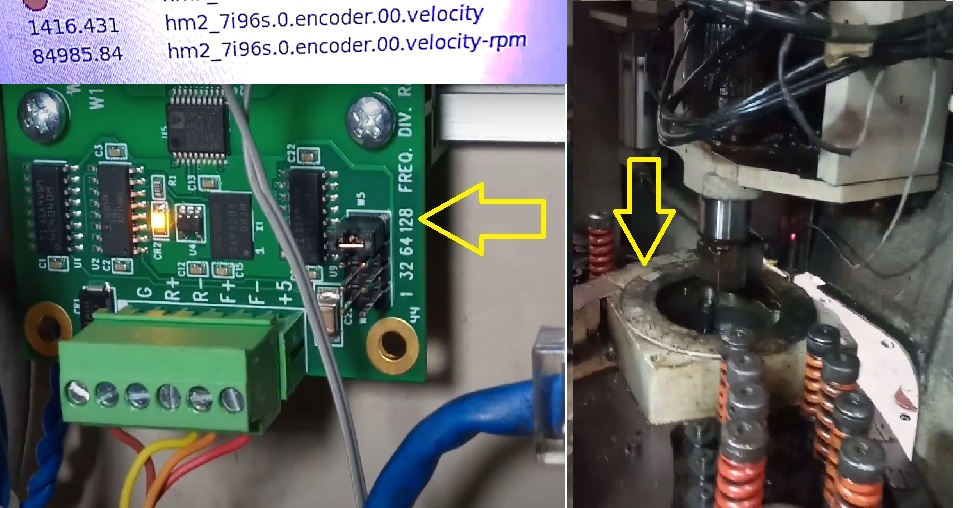

Simulations with other jumpers:

advanced hydraulic cylinder THCAD2 jump128

1416.431 hm2_7i96s.00.enconder.00.velocity

84985.84 hm2_7i96s.00.velocity-rpm

recessed hydraulic cylinder THCAD2 jump128

6616.257 hm2_7i96s.00.enconder.00.velocity

396875.4 hm2_7i96s.00.velocity-rpm

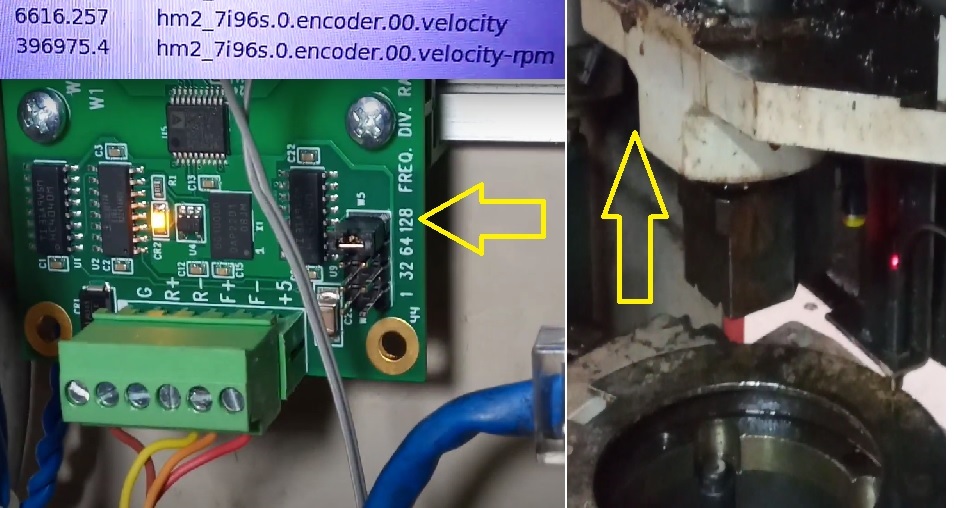

advanced hydraulic cylinder THCAD2 jump64

2868.069 hm2_7i96s.00.enconder.00.velocity

172084.1 hm2_7i96s.00.velocity-rpm

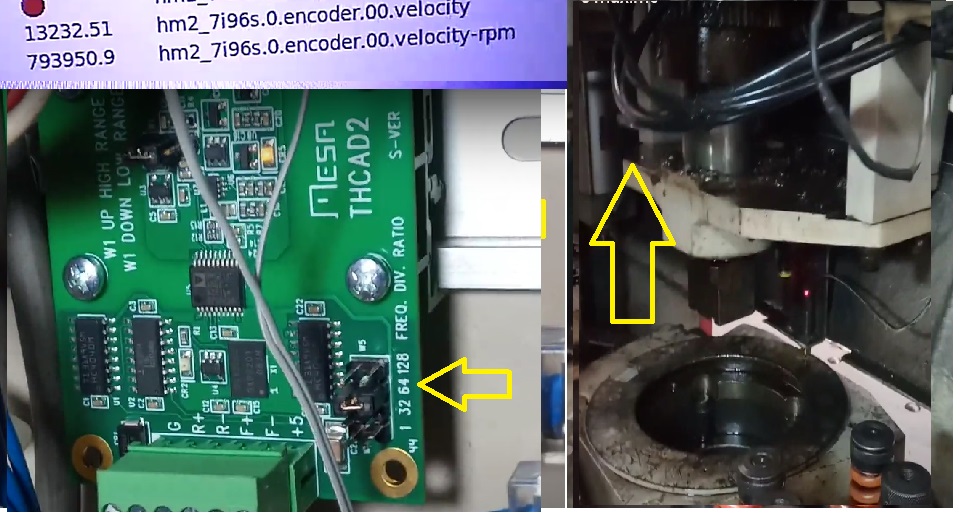

recessed hydraulic cylinder THCAD2 jump64

13232.51 hm2_7i96s.00.enconder.00.velocity

793950.9 hm2_7i96s.00.velocity-rpm

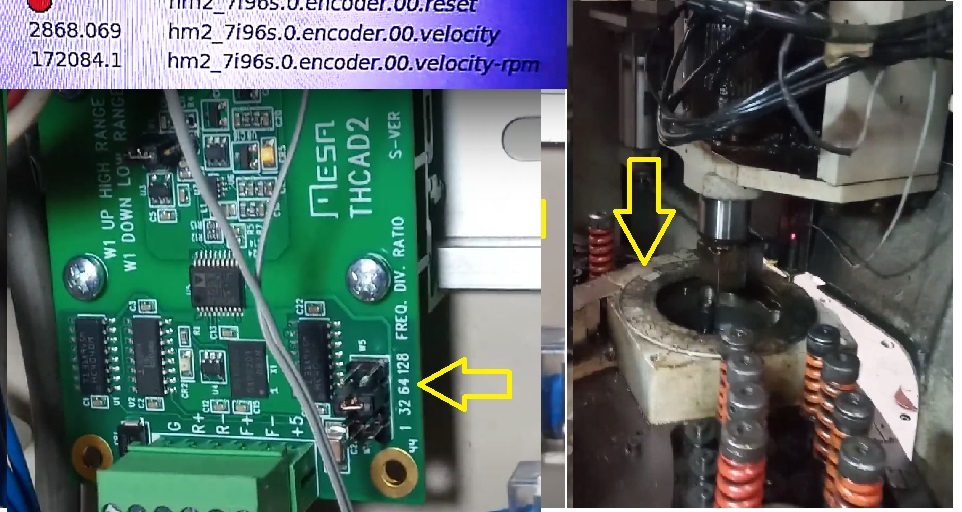

advanced hydraulic cylinder THCAD2 jump32

5671.078 hm2_7i96s.00.enconder.00.velocity

340264.7 hm2_7i96s.00.velocity-rpm

recessed hydraulic cylinder THCAD2 jump32

26449.64 hm2_7i96s.00.enconder.00.velocity

1586979 hm2_7i96s.00.velocity-rpm

I put the value 800 in the scale encoder, but it continues to display a calculation error message on the axis, but the axis moves a little, below is the video showing the result

Regarding another question, sorry for my lack of knowledge, do you have any example of how to: feed the encoder velocity signal through LinuxCNCs

offset component to remove the offset at 0V ?

Response:

ranger 10364.831 hm2_7i96s.00.enconder.00.velocity

ranger 621866.8 hm2_7i96s.00.velocity-rpm

I am testing with jump 64 on the THCAD2 board.

Simulations with other jumpers:

advanced hydraulic cylinder THCAD2 jump128

1416.431 hm2_7i96s.00.enconder.00.velocity

84985.84 hm2_7i96s.00.velocity-rpm

recessed hydraulic cylinder THCAD2 jump128

6616.257 hm2_7i96s.00.enconder.00.velocity

396875.4 hm2_7i96s.00.velocity-rpm

advanced hydraulic cylinder THCAD2 jump64

2868.069 hm2_7i96s.00.enconder.00.velocity

172084.1 hm2_7i96s.00.velocity-rpm

recessed hydraulic cylinder THCAD2 jump64

13232.51 hm2_7i96s.00.enconder.00.velocity

793950.9 hm2_7i96s.00.velocity-rpm

advanced hydraulic cylinder THCAD2 jump32

5671.078 hm2_7i96s.00.enconder.00.velocity

340264.7 hm2_7i96s.00.velocity-rpm

recessed hydraulic cylinder THCAD2 jump32

26449.64 hm2_7i96s.00.enconder.00.velocity

1586979 hm2_7i96s.00.velocity-rpm

I put the value 800 in the scale encoder, but it continues to display a calculation error message on the axis, but the axis moves a little, below is the video showing the result

Regarding another question, sorry for my lack of knowledge, do you have any example of how to: feed the encoder velocity signal through LinuxCNCs

offset component to remove the offset at 0V ?

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17724

- Thank you received: 5186

15 Jan 2025 19:19 #319047

by PCW

Replied by PCW on topic How do I control the speed and acceleration of the analog output of the 7i77 ?

You still did not answer what the Z motion range was

Anyway say its 50 mm and using the /32 tap that's

a encoder scale of ~415

When tuning you need to loosen the following error limits

and have some reasonable output scale value:TYPE = LINEAR

HOME = 0.0

FERROR = 50

MIN_FERROR = 50

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = 415 # estimate with THCAD /32 and 50 mm full motion

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

#MIN_LIMIT = -100.0

#MAX_LIMIT = 0.01

MIN_LIMIT = -15000.0 # these should be some reasonable numbers one you get the encoder scale correct

MAX_LIMIT = 15000.0

HOME_OFFSET = 0.0

loadrt offset

addf offset.0.update-feedback servo-thread

addf offset.0.update-output servo-thread

setp offset.0.offset -5671.078 # for /32net z-pos-fb_with_offset <= hm2_7i96s.0.encoder.00.velocity #New Line

net z-pos-fb_with_offset => offset.0.in

net z-pos-fb <= offset.0.out

net z-pos-fb => joint.1.motor-pos-fb

net z-index-enable joint.1.index-enable <=> hm2_7i96s.0.encoder.00.index-enable

net z-pos-rawcounts <= hm2_7i96s.0.encoder.00.rawcounts

Anyway say its 50 mm and using the /32 tap that's

a encoder scale of ~415

When tuning you need to loosen the following error limits

and have some reasonable output scale value:TYPE = LINEAR

HOME = 0.0

FERROR = 50

MIN_FERROR = 50

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = 415 # estimate with THCAD /32 and 50 mm full motion

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

#MIN_LIMIT = -100.0

#MAX_LIMIT = 0.01

MIN_LIMIT = -15000.0 # these should be some reasonable numbers one you get the encoder scale correct

MAX_LIMIT = 15000.0

HOME_OFFSET = 0.0

loadrt offset

addf offset.0.update-feedback servo-thread

addf offset.0.update-output servo-thread

setp offset.0.offset -5671.078 # for /32net z-pos-fb_with_offset <= hm2_7i96s.0.encoder.00.velocity #New Line

net z-pos-fb_with_offset => offset.0.in

net z-pos-fb <= offset.0.out

net z-pos-fb => joint.1.motor-pos-fb

net z-index-enable joint.1.index-enable <=> hm2_7i96s.0.encoder.00.index-enable

net z-pos-rawcounts <= hm2_7i96s.0.encoder.00.rawcounts

The following user(s) said Thank You: programador

Please Log in or Create an account to join the conversation.

- programador

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 5

15 Jan 2025 20:18 #319048

by programador

Replied by programador on topic How do I control the speed and acceleration of the analog output of the 7i77 ?

Attachments:

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- How do I control the speed and acceleration of the analog output of the 7i77 ?

Time to create page: 0.306 seconds