Quill Control

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

18 Sep 2013 05:06 - 18 Sep 2013 05:07 #38963

by BigJohnT

Replied by BigJohnT on topic Quill Control

Last edit: 18 Sep 2013 05:07 by BigJohnT.

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 239

18 Sep 2013 13:54 #38974

by ArcEye

Replied by ArcEye on topic Quill Control

Hi

I too have a knee mill with a ballscrew quill.

The knee is manual and I just move the bed up and down to account for the size of the workpiece and roughly touch off to the cutter.

All the fine adjustment and cutter movement throughout the program is done via the Z axis ball screw and it is very accurate.

One method of retrofit I have seen (which is sometimes also used in purpose built machines built upon an existing manual one) is to mount the stepper and ballscrew on the side of the spindle head.

The quill is held in a heavy clamping plate, which is drawn up and down by the stepper actuated ballscrew.

Retrofitting using the existing gears acting on the rack gear cut into the back of the spindle tube was quite common for the RF40 RF30 type of manual mill, but was never very satisfactory because of the

inherant slop which was impossible to eliminate.

The biggest single difference I noticed when I moved from a RF40 manual mill to a CNC one with ballscrew Z axis, was an accuracy of depth of cut I could never previously achieve

regards

I too have a knee mill with a ballscrew quill.

The knee is manual and I just move the bed up and down to account for the size of the workpiece and roughly touch off to the cutter.

All the fine adjustment and cutter movement throughout the program is done via the Z axis ball screw and it is very accurate.

One method of retrofit I have seen (which is sometimes also used in purpose built machines built upon an existing manual one) is to mount the stepper and ballscrew on the side of the spindle head.

The quill is held in a heavy clamping plate, which is drawn up and down by the stepper actuated ballscrew.

Retrofitting using the existing gears acting on the rack gear cut into the back of the spindle tube was quite common for the RF40 RF30 type of manual mill, but was never very satisfactory because of the

inherant slop which was impossible to eliminate.

The biggest single difference I noticed when I moved from a RF40 manual mill to a CNC one with ballscrew Z axis, was an accuracy of depth of cut I could never previously achieve

regards

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 516

- Thank you received: 125

20 Sep 2013 00:45 #39034

by jmelson

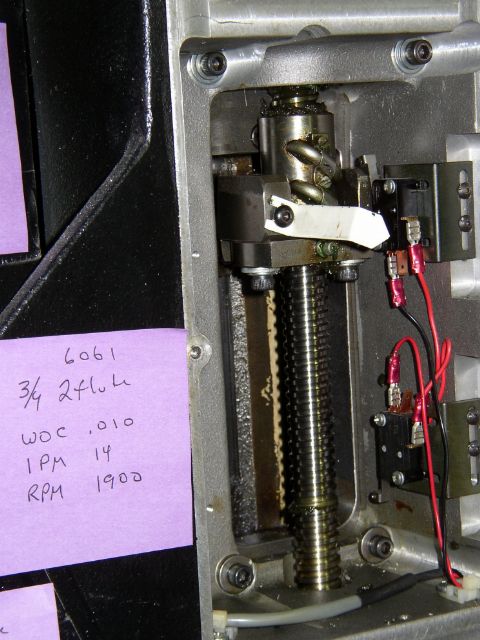

head here:

jelinux.pico-systems.com/zaxis.html

I got a ballscrew and mounted it as close to the front of the head as possible, to

minimize the moment arm of the link driving the quill up and down. I still get

.0015" of "backlash", which is actually flex of this link. This is a velocity servo

setup, so I have an encoder directly driven via helical-slit coupler from the

top of the ballscrew (red unit in pics) a dc tach driven by mini belt, and a

motor on the bottom driving the screw by belt.

I made this in 1997 or so.

Jon

Replied by jmelson on topic Quill Control

I have some pictures and text describing how I did my Z axis retrofit on my 1J BridgeportI'm working through a CNC conversion on a SuperMax manual knee mill. The control side of things is now mostly setup and I'm now working through the steel side. I have noticed that there are some companies which sell ball screw kits for the quill. I understand ball screws are a must for X and Y, but I'm lost on why these kits exist for quill control. It makes more sense to be to direct drive it or have a pulley setup. I feel like I'm missing part of the equation. What am I missing?

head here:

jelinux.pico-systems.com/zaxis.html

I got a ballscrew and mounted it as close to the front of the head as possible, to

minimize the moment arm of the link driving the quill up and down. I still get

.0015" of "backlash", which is actually flex of this link. This is a velocity servo

setup, so I have an encoder directly driven via helical-slit coupler from the

top of the ballscrew (red unit in pics) a dc tach driven by mini belt, and a

motor on the bottom driving the screw by belt.

I made this in 1997 or so.

Jon

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

20 Sep 2013 05:29 #39047

by BigJohnT

Replied by BigJohnT on topic Quill Control

My Anilam is similar and suffers from the same kind of problems with backlash. Other than that it gets the job done.

Very nice work Jon.

JT

Very nice work Jon.

JT

Please Log in or Create an account to join the conversation.

- Skullworks

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 2

28 Nov 2015 10:14 #65925

by Skullworks

Replied by Skullworks on topic Quill Control

I know I'm late to this party but if anyone else has this issue. Check out Elrod Machine in AZ. They make a complete Z axis bolt on assy for B-port type mills that is 1st rate. I made the trip down to Elrod Machine to check this option out for a company I was working for. Our machine had a Z axis issue and while apart several key parts were lost and the OEM no longer supported this machine. As it turns out the retrofit was never done as a machine dealer made a trade offer for a Bliss OBI press that our VP wanted for a project.

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 239

28 Nov 2015 10:27 #65926

by ArcEye

Replied by ArcEye on topic Quill Control

I think you are referring to this

www.elrodmachine.com/Z%20Axis%20CNC%20Quill%20kit.htm

Don't know what the price is, just powder coating is $155.

Here is one fitted to the worlds cleanest Bridgeport

regards

www.elrodmachine.com/Z%20Axis%20CNC%20Quill%20kit.htm

Don't know what the price is, just powder coating is $155.

Here is one fitted to the worlds cleanest Bridgeport

regards

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.109 seconds