Retrofitting a 1986 Maho MH400E

- D Jensen

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 16

22 Mar 2024 03:43 #296530

by D Jensen

Replied by D Jensen on topic Retrofitting a 1986 Maho MH400E

A few more things to add that may be of help for the Linux programing.I've finally got my Maho running faultlessly. The 2 final hurdles were some timing issues with the handshake between the gear-change PLC and the Heidenhain controller. I had to change some parameters on the Heidenhain controller and invoke the coded outputs for machine M calls, then change some of the strobe time durations because of the gear-change PLC was sending back function finished before the Heidenhain controller was listening for it. That must have caused years of anguish for the previous owners as for more than a decade it would have stopped machining intermittently, waiting for a "auxiliary function finished" strobe that had already been and gone. Lovely when it works, but I had to draw accurate timing graphs to be sure the various clocks step increments always overlapped. Not much interest to you guys, but just wonderful when irritating problems disappear.But the final issue may be of interest. My machine has an 18 speed gearbox, but the top 3 speeds had been inhibited by the machine parameters in the Heidenhain TNC 155 controller. So limited to 1250 rev/min maximum. 1600, 2000 and 2500 were not available. These are important when using smaller tool sizes. particularly when I've been routing wood frame members for my vintage Fiat Topolino. 10 times that would be nice.It appears the reason is that the star delta start on the spindle motor was on a simple adjustable stand alone timer originally. So only one star time available for all speeds.The gear-change PLC has plenty of spare capacity, so I added a whole section of ladder code which decides which gear has just been selected, then invokes a timer appropriate for that particular start inertia etc. At low speeds it seems the star time is roughly the same for several gear selections, probably because its mainly the motor armature inertia to be overcome. But around 1600 rev/min things change and the star time gets rapidly longer. To get to 2500 rev/min the star time needs to be 4 seconds, which is agonizingly long. I initially timed these with a stop watch, but once I had it programmed I went through and set them on the ammeter response with a bit of safety margin. I also added the to gear-change PLC an inhibition to the "auxiliary function finished" reply so that the Heidenhain doesn't start machining again until the spindle has switched to delta mode. The previous system didn't know about that and could mill down from the safety distance and start cutting before the old timer went to delta. Nasty.Another reason for inhibiting the speed could be spindle temperature. My Maho has a grinder spindle with taper roller bearings. I recently gave it it's 4000 hour disassembly and regrease. There is a run in procedure where you fit a thermocouple to the spindle and run it up one speed at a time, checking it doesn't overheat. If it does, you simply stop, let it cool down, and try again. So I needed to run in those 3 new higher speeds. If I run it for extended periods at 2500 rev/min it does exceed the recommendation a bit. But I can keep it in spec by using my shop vacuum. The spindle fan is crude as is the way the cooling air controlled around the spindle assembly casing. I'm looking a how to improve that. It's also been fairly hot this summer in Sydney and it's been operating in 28 C ambient.For those of you who are interested I'll add the ladder code from the gear-change Izumi FA-1J PLC. The code at the end is simple in case you need to do something similar in LinuxCNC. It's still a bit open loop. Monitoring the motor current might be better.BTW. I think I've seen comment asking how the cooling fan is driven. Mine seems to have bits missing and the fan was free to slip on the spindle. The section view in the manual is difficult to decipher. In my case I've added a spacer (the white piece) and a thick "O" ring that applies sufficient pressure to drive the fan. The "O" ring sits in an existing groove, but I don't know what the groove was really for. Does anyone know what is really meant to drive the fan? My "O" ring seems okay, but usually a nitrile "O" ring under tension like that gets attacked by ozone in the air and starts to crack. EPDM doesn't, but I couldn't source one. So far so good, but I think it will fail.Cheers,David

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- D Jensen

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 16

04 Sep 2024 07:40 #309341

by D Jensen

Replied by D Jensen on topic Retrofitting a 1986 Maho MH400E

I got around to doing some videos on how my Maho works. Not quite the calibre of Mark's. But there may be stuff of interest to some of you. There is stuff about the switchgear, transformers, contactors, breakers, gear change, etc that will be common. Mine has some older stuff on it. There is also a run through some G-code in the older format that Heidenhain used. It's on my Google drive here:

drive.google.com/drive/folders/1NVXGKyaN...cWKjsMfe?usp=sharing

Cheers,

David

drive.google.com/drive/folders/1NVXGKyaN...cWKjsMfe?usp=sharing

Cheers,

David

The following user(s) said Thank You: tommylight, Aciera

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

02 Dec 2024 14:07 #315789

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi Guys,

The Maho has been out of service/ limited service for a couple of months while I gave procrastination and denial a chance to solve it's problems...

Cheers,

Mark

The Maho has been out of service/ limited service for a couple of months while I gave procrastination and denial a chance to solve it's problems...

Cheers,

Mark

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

02 Dec 2024 15:23 #315798

by spumco

Replied by spumco on topic Retrofitting a 1986 Maho MH400E

Drawbar springs?

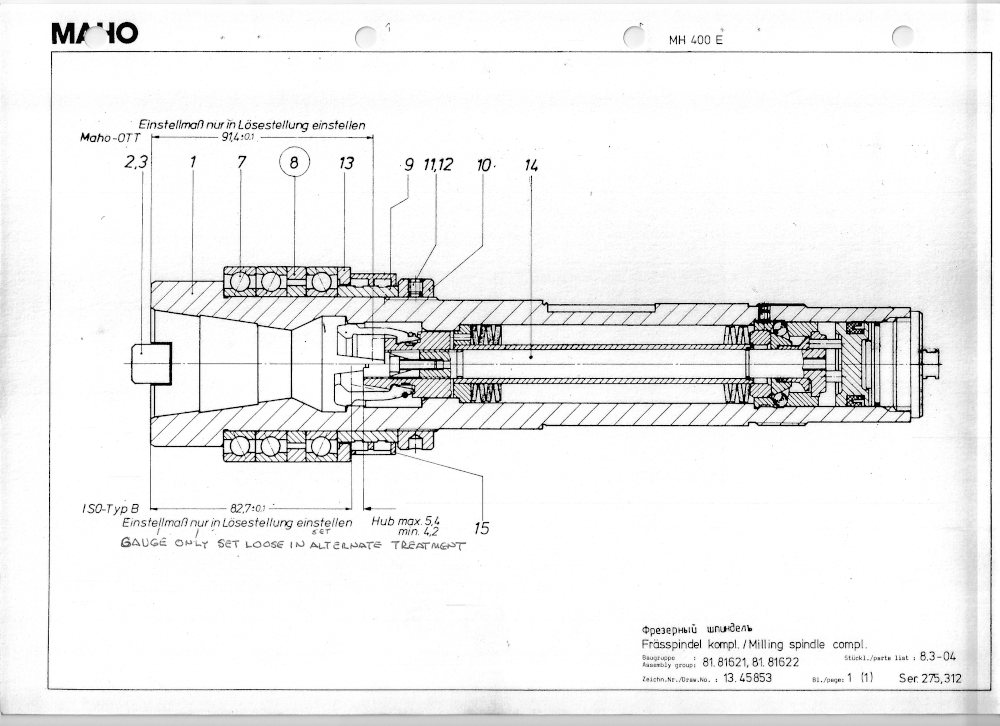

I can't tell from the diagram you had in the vid, but it looks (and sounds) like the hydraulic DB is a spring return system - I thought I only heard the pump loading up during release.

And DB springs are consumables...

Easy enough to pull the DB and have a look at the springs (if I'm right) before fully digging in to bearings.

I can't tell from the diagram you had in the vid, but it looks (and sounds) like the hydraulic DB is a spring return system - I thought I only heard the pump loading up during release.

And DB springs are consumables...

Easy enough to pull the DB and have a look at the springs (if I'm right) before fully digging in to bearings.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

02 Dec 2024 19:53 #315828

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Yeah, that is the first thing I will check. I just started trying to remove the draw bar unit. I dont have a good cut away or manual for this, so will just disassemble what I can find.

Please Log in or Create an account to join the conversation.

- D Jensen

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 16

02 Dec 2024 23:01 #315837

by D Jensen

Replied by D Jensen on topic Retrofitting a 1986 Maho MH400E

Here are the pages from my manual on how to disassemble and re-grease the spindle. Mine is NT40 so a bit bigger and with a different pull stud. But I would think much the same. I've added the page on how to adjust the claws. It's very quick and simple. The whole assembly item 2 is fitted when it's all assembled into the spindle, in my case back in the machine. It simply screws in. When the depth dimension is right ( I used the tail end on my dial calipers) you simply tighten the grub item 1. That presses the ball into the coned recess in the stud and expands the thread onto item 2. The hatched portion where item 2 points to are actually longitudinal cuts in the thread.

Your 30 size tool holder will have a different adjustment length I would think. .In the diagram you can see that as the claws are retracted they are jammed closed by the bore of the spindle. That means that it is more likely any rattle is due to damaged or worn claws I think. The claws are the finer cross hatch.

Cheers,

David

Your 30 size tool holder will have a different adjustment length I would think. .In the diagram you can see that as the claws are retracted they are jammed closed by the bore of the spindle. That means that it is more likely any rattle is due to damaged or worn claws I think. The claws are the finer cross hatch.

Cheers,

David

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- D Jensen

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 16

03 Dec 2024 00:09 #315841

by D Jensen

Replied by D Jensen on topic Retrofitting a 1986 Maho MH400E

I noted your comments on Z axis machining and thought I might stick my neck out here.

Your machine looks like it came with the old Philips controller from one of the early photos. They set the axes up differently to what I believe is the current convention. That is with the Y and Z axes swapped. So you might find your servo closing relays in the wrong physical order on the DIN C rail. The convention seems to be X side to side, Y forward and aft, and Z up and down. Certainly Heidenhain uses that on controllers from my TNC 155 up to 400 series. Early Bridgeports used the TNC 155 so they are that convention also.

Rotary axis A, B and C rotate around X, Y, and Z axes respectively. So I code my rotary axis as C, but it is possible to not use that convention by changing a parameter.

So in the your programming examples you wouldn't change the axes orientation, you simply tell the machine the cutter in in the Y axis by using G18 in the G code.

There is a program showing this in one of the links to my cloud previously. It's the one where it pretends to cut a spiral thread using a cutter in the Y axis and the C rotary table.Rather like a vertical lathe.

The next problem is that on our machines the cutter is usually attached to the Y axis, so it moves that way. The other 2 involve the table moving up and down and sideways.. On the typical Bridgeport of that era, the quill moves the cutter in the Z direction and the table moves back and forward and sideways. And yet you set up the program identically for both!

So the convention is that the DATUM is the work piece. So when you do the familiar right hand rule with your real hand, You place the back of your hand on the work piece whilst standing in front of the machine. And keep it stuck in the same place on the work piece as it moves.

Now look at where the cutter is moving relative to you hand:

If it is moving in the direction your thumb is pointing then it's moving positive X

If it is moving in the direction your index finger is pointing then it's moving positive Y

If it is moving in the direction your middle finger is pointing then it's moving positive Z

That works for all types of 3 axis machines.I have no idea how they label machines with 5 axes and seemingly infinite rotation axes.

In our case what seems counter intuitive is that for X+ the table will move left and for Z+ the table will move down.

Cheers,

David

Your machine looks like it came with the old Philips controller from one of the early photos. They set the axes up differently to what I believe is the current convention. That is with the Y and Z axes swapped. So you might find your servo closing relays in the wrong physical order on the DIN C rail. The convention seems to be X side to side, Y forward and aft, and Z up and down. Certainly Heidenhain uses that on controllers from my TNC 155 up to 400 series. Early Bridgeports used the TNC 155 so they are that convention also.

Rotary axis A, B and C rotate around X, Y, and Z axes respectively. So I code my rotary axis as C, but it is possible to not use that convention by changing a parameter.

So in the your programming examples you wouldn't change the axes orientation, you simply tell the machine the cutter in in the Y axis by using G18 in the G code.

There is a program showing this in one of the links to my cloud previously. It's the one where it pretends to cut a spiral thread using a cutter in the Y axis and the C rotary table.Rather like a vertical lathe.

The next problem is that on our machines the cutter is usually attached to the Y axis, so it moves that way. The other 2 involve the table moving up and down and sideways.. On the typical Bridgeport of that era, the quill moves the cutter in the Z direction and the table moves back and forward and sideways. And yet you set up the program identically for both!

So the convention is that the DATUM is the work piece. So when you do the familiar right hand rule with your real hand, You place the back of your hand on the work piece whilst standing in front of the machine. And keep it stuck in the same place on the work piece as it moves.

Now look at where the cutter is moving relative to you hand:

If it is moving in the direction your thumb is pointing then it's moving positive X

If it is moving in the direction your index finger is pointing then it's moving positive Y

If it is moving in the direction your middle finger is pointing then it's moving positive Z

That works for all types of 3 axis machines.I have no idea how they label machines with 5 axes and seemingly infinite rotation axes.

In our case what seems counter intuitive is that for X+ the table will move left and for Z+ the table will move down.

Cheers,

David

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

03 Dec 2024 09:28 #315871

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi David,

Thanks a lot for that. I have a bunch of questions for you...

What year is your machine?

Have you lubricated your bearings already?

Did you confirm yours has the tapered roller bearings?

What Max RPM does it have?

What alternative grease did you use, as it seems Kluber F23A is discontinued?

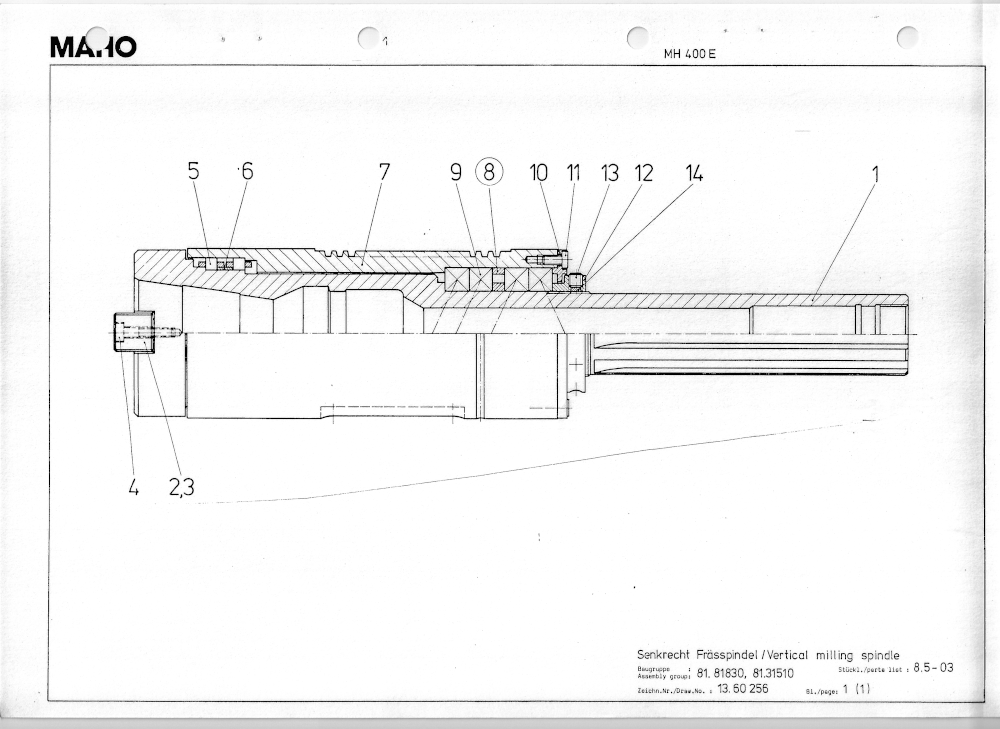

Is the instruction you uploaded for the vertical spindle or the horizontal?

Do you have any advice on removing the draw bar unit?

My understanding is that the vertical has a more complicated set up with integral bearings. My machine is also 40 taper. It's pulls studs are the ISO 7388 Type B option and my Manual covers the adjustment in 7.35 like yours.

No wonder that MAHO gave out such different manuals, as my user manual (in German) has the cover guard removal in that section 7.10, and nothing on spindle lubrication, but I guess this is tied in with them keeping reinventing the wheel, as there are also drawings of 400E with these horizontal...

...and vertical spindle bearing configurations.

I am starting to feel like Forest Gump, where a Maho spindle is like a box of chocolates

If you have the whole manual scanned, I would appreciate a copy of it please. I can send you my German language version if you are interested.

With regards to the axis swap, when I did my LinuxCNC retrofit, I configured mine as a vertical mill (Z up down) whereas Maho configured them standard as a horizontal, with an option to Axis swap. Servo closing relays? My schematic doesn't have any. 7K2 provides the muscle power to all three channels of the Indramat, and the axis enables are hard wired onto inputs from the vertical axis motor brake, and a couple of other contacts, so LinuxCNC has no control over them.

I have my PP of my CAM set up for a vertical mill as well. I have been editing my G-code files, to do the axis swap (reversing Y/Z, inverting one, replacing I, J with I, K, and Inverting it, and could easily write a macro to automate that.

I was in the middle of setting up a second LinuxCNC configuraton with the mill as horizontal (Y vertical movement), but was getting confused with the Ini edits, before I got sidetracked with my DoAll gearbox, and now with the spindle noise. I still need to complete the second config, as it makes most sense to have both, and then I can use the same PP, and code generated can be used on either configurations.

Cheers,

Mark

Thanks a lot for that. I have a bunch of questions for you...

What year is your machine?

Have you lubricated your bearings already?

Did you confirm yours has the tapered roller bearings?

What Max RPM does it have?

What alternative grease did you use, as it seems Kluber F23A is discontinued?

Is the instruction you uploaded for the vertical spindle or the horizontal?

Do you have any advice on removing the draw bar unit?

My understanding is that the vertical has a more complicated set up with integral bearings. My machine is also 40 taper. It's pulls studs are the ISO 7388 Type B option and my Manual covers the adjustment in 7.35 like yours.

No wonder that MAHO gave out such different manuals, as my user manual (in German) has the cover guard removal in that section 7.10, and nothing on spindle lubrication, but I guess this is tied in with them keeping reinventing the wheel, as there are also drawings of 400E with these horizontal...

...and vertical spindle bearing configurations.

I am starting to feel like Forest Gump, where a Maho spindle is like a box of chocolates

If you have the whole manual scanned, I would appreciate a copy of it please. I can send you my German language version if you are interested.

With regards to the axis swap, when I did my LinuxCNC retrofit, I configured mine as a vertical mill (Z up down) whereas Maho configured them standard as a horizontal, with an option to Axis swap. Servo closing relays? My schematic doesn't have any. 7K2 provides the muscle power to all three channels of the Indramat, and the axis enables are hard wired onto inputs from the vertical axis motor brake, and a couple of other contacts, so LinuxCNC has no control over them.

I have my PP of my CAM set up for a vertical mill as well. I have been editing my G-code files, to do the axis swap (reversing Y/Z, inverting one, replacing I, J with I, K, and Inverting it, and could easily write a macro to automate that.

I was in the middle of setting up a second LinuxCNC configuraton with the mill as horizontal (Y vertical movement), but was getting confused with the Ini edits, before I got sidetracked with my DoAll gearbox, and now with the spindle noise. I still need to complete the second config, as it makes most sense to have both, and then I can use the same PP, and code generated can be used on either configurations.

Cheers,

Mark

Attachments:

Please Log in or Create an account to join the conversation.

- D Jensen

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 16

03 Dec 2024 11:19 #315878

by D Jensen

Replied by D Jensen on topic Retrofitting a 1986 Maho MH400E

Wow. Lots of questions!

I have the original quote from November 1982. Some of the castings have 1979 on them as I recall.

$A 89,000 for the machine

$A 600 for the overarm

$A 15,000 for the rotary table

$A 4,000 for the tooling

$A 6,000 for the printer/reader

So about $A 114,600 all up. Looks like the sale went through in July 83.

From Eric James Industries here in Sydney.

The replacement of the Philips 6600 controller with the Heidenhain TNC 155 was done by them in 1987 for about $A 19,000 plus tax.

I've just placed the full manual here for all to read along with the series of videos there that let you know a lot about my machine:

drive.google.com/drive/folders/1NVXGKyaN...cWKjsMfe?usp=sharing

I've marked it up with the things particular to my machine. The lubricants are on page 7.06-1

I spoke to the Gulf and Western rep here and he went away to double check the data for Kluber and was satisfied their Super Blue grease was equivalent or better. It wasn't worth buying all the other greases since I have a 4 liter can of it. This is overkill for all the rest. So I fully stripped the spindle and repacked it. It is the type in the diagrams I sent. So it is typical of a precision grinder spindle. You do need to go through the run in procedure as the spindle runs hot at every speed.

The run time clock on my machine is hard wired through the spindle motor auxiliary contacts, so it runs when the spindle does.It had 4,000 hours on it so the book says repack it.

My machine is much heavier than yours so it's max speed is 2500 rev/min. But it had been limited to 1250 in the parameter list as the star delta timer needed about 3.5 seconds. they hadn't programed things properly so it was possible for the machine to start milling in star mode. I've reprogrammed the Izumi PLC that does the gear change so it stops that happening.

I haven't pulled the horizontal spindle apart. It looks to have the same quill assembly, but there is no manual hand wheel on the Y slide for it. The rack teeth are there on the quill is there but you have to take a plate off the side and undo the clamp by hand. I cant get the quill to move and haven't really tried.

I had some trouble making the photos small enough to attach today. I might try again later. On mine the trick to get the hydraulic ram off the retractor is that the thread has Loctite on it. I think they note it in the manual that you have to heat it. But that is to melt the Loctite, not to overcome some preload. i used my solder reflow hot air on it, while applying torque and it suddenly came free. you diagram is the same in essense, but the way it assembles is quite different

I think Maho has a rule that they never make 2 identical machines.

My tool holders are ISO NT40 so I have to cut a groove in the parallel part for the clamping claws. How to do it is in the manual above. So there is no pull stud.

The section on the spindle i translated from German thanks to Google. But then I translated it again into understandable English.

My machine is an orphan having the Heidenhain controller. But I think my axes orientation is the more usual. It seems simpler to me to just program the horizontal axis as G18. That is the way Heidenhain do it in their G code examples. Why would the standard have G17, G18, and G19 otherwise?

With Heidenhain they seek for index mark open loop on the encoders. That speed is preset in the parameters for a particular machine. I think that velocity is controlled by the tachos. After finding the index marks there are relays that pull in for each axis and the Heidenhain go closed loop with the encoders.

I watched your video. My miscible oil seems much higher concentration than you run. I'm using 10:1 water to oil and it looks like creamy milk. hard to tell from the video but you seem to run the cutters faster than the equation I use. I have similar problems with boring. Usually i put a pilot drill hole in first as the over center flute on a slot drill doesn't always seem to work. Heidenhain does that routinely with canned cycles for pockets etc.

More later.

Cheers,

David

I have the original quote from November 1982. Some of the castings have 1979 on them as I recall.

$A 89,000 for the machine

$A 600 for the overarm

$A 15,000 for the rotary table

$A 4,000 for the tooling

$A 6,000 for the printer/reader

So about $A 114,600 all up. Looks like the sale went through in July 83.

From Eric James Industries here in Sydney.

The replacement of the Philips 6600 controller with the Heidenhain TNC 155 was done by them in 1987 for about $A 19,000 plus tax.

I've just placed the full manual here for all to read along with the series of videos there that let you know a lot about my machine:

drive.google.com/drive/folders/1NVXGKyaN...cWKjsMfe?usp=sharing

I've marked it up with the things particular to my machine. The lubricants are on page 7.06-1

I spoke to the Gulf and Western rep here and he went away to double check the data for Kluber and was satisfied their Super Blue grease was equivalent or better. It wasn't worth buying all the other greases since I have a 4 liter can of it. This is overkill for all the rest. So I fully stripped the spindle and repacked it. It is the type in the diagrams I sent. So it is typical of a precision grinder spindle. You do need to go through the run in procedure as the spindle runs hot at every speed.

The run time clock on my machine is hard wired through the spindle motor auxiliary contacts, so it runs when the spindle does.It had 4,000 hours on it so the book says repack it.

My machine is much heavier than yours so it's max speed is 2500 rev/min. But it had been limited to 1250 in the parameter list as the star delta timer needed about 3.5 seconds. they hadn't programed things properly so it was possible for the machine to start milling in star mode. I've reprogrammed the Izumi PLC that does the gear change so it stops that happening.

I haven't pulled the horizontal spindle apart. It looks to have the same quill assembly, but there is no manual hand wheel on the Y slide for it. The rack teeth are there on the quill is there but you have to take a plate off the side and undo the clamp by hand. I cant get the quill to move and haven't really tried.

I had some trouble making the photos small enough to attach today. I might try again later. On mine the trick to get the hydraulic ram off the retractor is that the thread has Loctite on it. I think they note it in the manual that you have to heat it. But that is to melt the Loctite, not to overcome some preload. i used my solder reflow hot air on it, while applying torque and it suddenly came free. you diagram is the same in essense, but the way it assembles is quite different

I think Maho has a rule that they never make 2 identical machines.

My tool holders are ISO NT40 so I have to cut a groove in the parallel part for the clamping claws. How to do it is in the manual above. So there is no pull stud.

The section on the spindle i translated from German thanks to Google. But then I translated it again into understandable English.

My machine is an orphan having the Heidenhain controller. But I think my axes orientation is the more usual. It seems simpler to me to just program the horizontal axis as G18. That is the way Heidenhain do it in their G code examples. Why would the standard have G17, G18, and G19 otherwise?

With Heidenhain they seek for index mark open loop on the encoders. That speed is preset in the parameters for a particular machine. I think that velocity is controlled by the tachos. After finding the index marks there are relays that pull in for each axis and the Heidenhain go closed loop with the encoders.

I watched your video. My miscible oil seems much higher concentration than you run. I'm using 10:1 water to oil and it looks like creamy milk. hard to tell from the video but you seem to run the cutters faster than the equation I use. I have similar problems with boring. Usually i put a pilot drill hole in first as the over center flute on a slot drill doesn't always seem to work. Heidenhain does that routinely with canned cycles for pockets etc.

More later.

Cheers,

David

Please Log in or Create an account to join the conversation.

- D Jensen

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 16

03 Dec 2024 23:55 #315925

by D Jensen

Replied by D Jensen on topic Retrofitting a 1986 Maho MH400E

Hi again Mark,

I realized the technical manual was a bit large so I ran it through a later version of my document compositor and replaced it on the Google drive. It's about half the size at 151MB or so.

You asked about my Maho speed capability. There is a video called 13_Gearchange.mp4 at the same link that explains it in full. The video is relevant to both yours and my machine and probably other Mahos. I think your machine goes 2 gears higher and misses the lower 2. It is relevant to LinuxCNC programing on Mahos also, I think

I'm envious of a lot of the high quality kit you have. Even your metal vise looks superb. Your tool setter is wonderful. But the way you do the Z with the round bar is a bit nasty. There is a video of my Z setter in the link which I think works more elegantly. It's a real cheap one but it works really well. I could possibly replace the dial gauge in it with a micron scale one, but it seems repeatable if I put it exactly on the dial line with respect to the micrometer scale on my Heidenhain VDU.

I'm thinking that many of the things we are talking about aren't directly relevant to many LinuxCNC users, mainly Maho stuff, and this to and from is very slow. So if you want you can Skype me on david.jensen11, I can share screen and go through myriad topics and photos. Switzerland is 10 hours behind Sydney at the moment. 3 months either side of new year we are UT+11, Otherwise UT+10

Cheers,

David

I realized the technical manual was a bit large so I ran it through a later version of my document compositor and replaced it on the Google drive. It's about half the size at 151MB or so.

You asked about my Maho speed capability. There is a video called 13_Gearchange.mp4 at the same link that explains it in full. The video is relevant to both yours and my machine and probably other Mahos. I think your machine goes 2 gears higher and misses the lower 2. It is relevant to LinuxCNC programing on Mahos also, I think

I'm envious of a lot of the high quality kit you have. Even your metal vise looks superb. Your tool setter is wonderful. But the way you do the Z with the round bar is a bit nasty. There is a video of my Z setter in the link which I think works more elegantly. It's a real cheap one but it works really well. I could possibly replace the dial gauge in it with a micron scale one, but it seems repeatable if I put it exactly on the dial line with respect to the micrometer scale on my Heidenhain VDU.

I'm thinking that many of the things we are talking about aren't directly relevant to many LinuxCNC users, mainly Maho stuff, and this to and from is very slow. So if you want you can Skype me on david.jensen11, I can share screen and go through myriad topics and photos. Switzerland is 10 hours behind Sydney at the moment. 3 months either side of new year we are UT+11, Otherwise UT+10

Cheers,

David

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 1.624 seconds