Retrofitting a 1986 Maho MH400E

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

16 Oct 2018 21:50 #118907

by andypugh

It might work if the sensors are fast enough. There are specific devices for gear tooth detection, for example Avago ATS667LSGTN-T

But.. Is that gear running 1:1 with the vertical spindle?

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

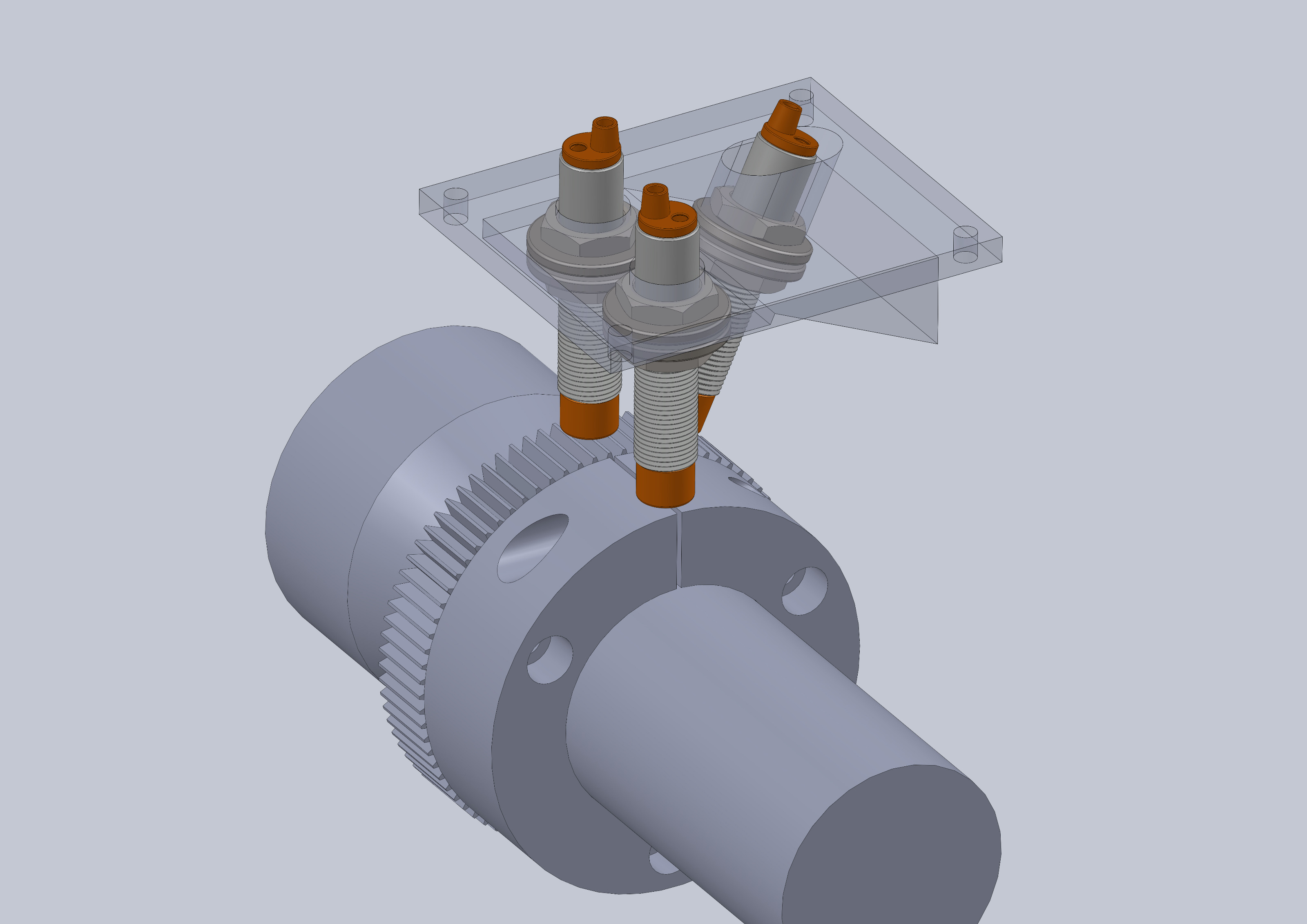

Hi to all, is this a good idea for spindle encoder on mahos?

It might work if the sensors are fast enough. There are specific devices for gear tooth detection, for example Avago ATS667LSGTN-T

But.. Is that gear running 1:1 with the vertical spindle?

The following user(s) said Thank You: drimaropoylos

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

17 Oct 2018 05:03 #118924

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Thank you, the shaft rotates 1:1 with the vertical and horizontal spindle but in reverse. 4000 revolution per minute equals 67 rotates the second, the gear has 80 teeth so 67X80 is 5360 tics per second or 5,5 KHz. I was thinking one of these sensors, they claim 10 KHz or more, down to zero speed some off them.

www.newark.com/zf-cherry/gs100502/gear-t...ct-sensor/dp/05M6388

www.aliexpress.com/item/proximity-switch...1.0.0.48034c4dellgur

www.rammeter.com/jaquet-f12s-hall-effect-zero-speed-sensor.php

sensing.honeywell.com/LCZ260-hall-effect-digital-speed-sensors

www.newark.com/zf-cherry/gs100502/gear-t...ct-sensor/dp/05M6388

www.aliexpress.com/item/proximity-switch...1.0.0.48034c4dellgur

www.rammeter.com/jaquet-f12s-hall-effect-zero-speed-sensor.php

sensing.honeywell.com/LCZ260-hall-effect-digital-speed-sensors

The following user(s) said Thank You: gernoff

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

17 Oct 2018 06:09 #118928

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi John, that is a good idea. I take it you are planning for rigid tapping. On the 400E, that gearbox cover is one peice across the whole head, so you would have to remove the motor, and the vertical head swinging arm at the least to get it off. Is this cover smaller and easier to work with on the 600E?

Mark

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

17 Oct 2018 17:16 #118945

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

18 Oct 2018 22:20 #119030

by andypugh

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

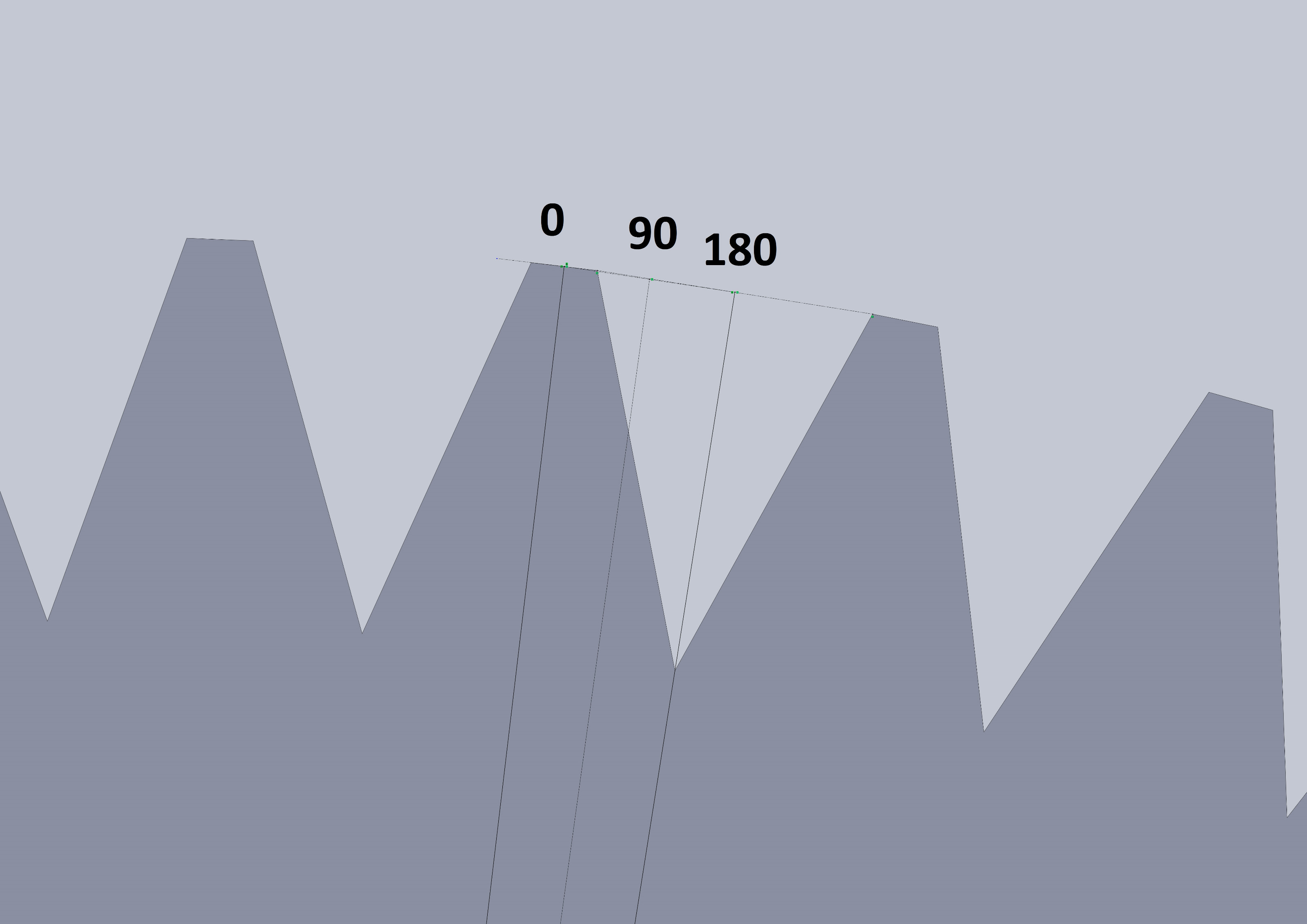

Make sure that the AB sensors are 90 degrees out of phase, not 180.

(Don't ask me how I know that's a possible mistake to make)

When one sensor sees a gap, the other needs to be at the tooth edge, not tip.

(Don't ask me how I know that's a possible mistake to make)

When one sensor sees a gap, the other needs to be at the tooth edge, not tip.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

19 Oct 2018 05:17 #119056

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

19 Oct 2018 09:31 #119063

by andypugh

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

It's good that you can learn from my mistake

The following user(s) said Thank You: drimaropoylos, Surmetall

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

20 Oct 2018 20:34 - 21 Oct 2018 12:23 #119137

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

The problem with my Y axis encoder was low voltage. I adjusted the supply up from 4.75V to 5.1, and now it is working reliably.

Z has been cleaned and reinstalled, but I haven't got it working yet.

Mark.

Z has been cleaned and reinstalled, but I haven't got it working yet.

Mark.

Last edit: 21 Oct 2018 12:23 by RotarySMP.

Please Log in or Create an account to join the conversation.

- akb1212

- Away

- Senior Member

-

Less

More

- Posts: 74

- Thank you received: 12

22 Oct 2018 18:01 #119213

by akb1212

Replied by akb1212 on topic Retrofitting a 1986 Maho MH400E

I can confirm that this will be a good way to put the encoder for rigid tapping. It is in fact similar to what is originally done on my 600E (1990 vintage).

What is done on that is that there is a shaft that is rigidly connected to the shaft going from the gearbox and forward. This shaft goes all the way through the gearbox, and is sticking out in the back. And on that shaft there is attached a 1024 (I think.....) lines/rev encoder with index.

This index is also needed when orienting the spindle for tool change (mine has that too:-)).

For this to work out correctly one have to adjust a parameter in the setup to make sure the orientation is correct. And this will need to be adjusted after the head have been disassembled (like I have done). Tha allignment will be off when you reassemble since you will most likely engage the angeled toothed gears differently when you assemble it back together.

But you can rest assured you are going about this the same way as Maho is doing it on later model mills, so you should be quite safe.

Althoug I would suggest having a higher frequency response in your readers. Remember you are reading the phase relationship continously. And that means you need more than 1/2 frequency margin. I'm not saying it won't work, but I'd be more comfortable with a higher margin than what you have now.

Anders

What is done on that is that there is a shaft that is rigidly connected to the shaft going from the gearbox and forward. This shaft goes all the way through the gearbox, and is sticking out in the back. And on that shaft there is attached a 1024 (I think.....) lines/rev encoder with index.

This index is also needed when orienting the spindle for tool change (mine has that too:-)).

For this to work out correctly one have to adjust a parameter in the setup to make sure the orientation is correct. And this will need to be adjusted after the head have been disassembled (like I have done). Tha allignment will be off when you reassemble since you will most likely engage the angeled toothed gears differently when you assemble it back together.

But you can rest assured you are going about this the same way as Maho is doing it on later model mills, so you should be quite safe.

Althoug I would suggest having a higher frequency response in your readers. Remember you are reading the phase relationship continously. And that means you need more than 1/2 frequency margin. I'm not saying it won't work, but I'd be more comfortable with a higher margin than what you have now.

Anders

The following user(s) said Thank You: drimaropoylos

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

22 Oct 2018 20:59 #119222

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I spent some more time swapping around EXE and encoders this evening. It is no so easy to cheap the wave patterns on the HAL oscilloscope when either X or Y has no encoder connected, as they both move off a a moderate speed. Z is very stable even without feedback, and only creeps up slowly.

The good news is that the Z encoder is working fine ( at least A dn B channels, I'll need it tuned to look for the index. I isolated the problem to the third axis of Exe. Ordered a 602 D stand alone EXE off Ebay this evening. The seller is even in Austria. Fro €64 including postage, I hope to have this issue closed next week.

Mark

The good news is that the Z encoder is working fine ( at least A dn B channels, I'll need it tuned to look for the index. I isolated the problem to the third axis of Exe. Ordered a 602 D stand alone EXE off Ebay this evening. The seller is even in Austria. Fro €64 including postage, I hope to have this issue closed next week.

Mark

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.206 seconds