Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1545

- Thank you received: 572

09 Jan 2019 18:00 #123846

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks Andy, It was a syntax error from me. I had:

...instead of :

Mark

loadrt and2.0

addf and2.0...instead of :

loadrt and2

addf and2.0Mark

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1545

- Thank you received: 572

09 Jan 2019 18:06 - 09 Jan 2019 18:08 #123847

by RotarySMP

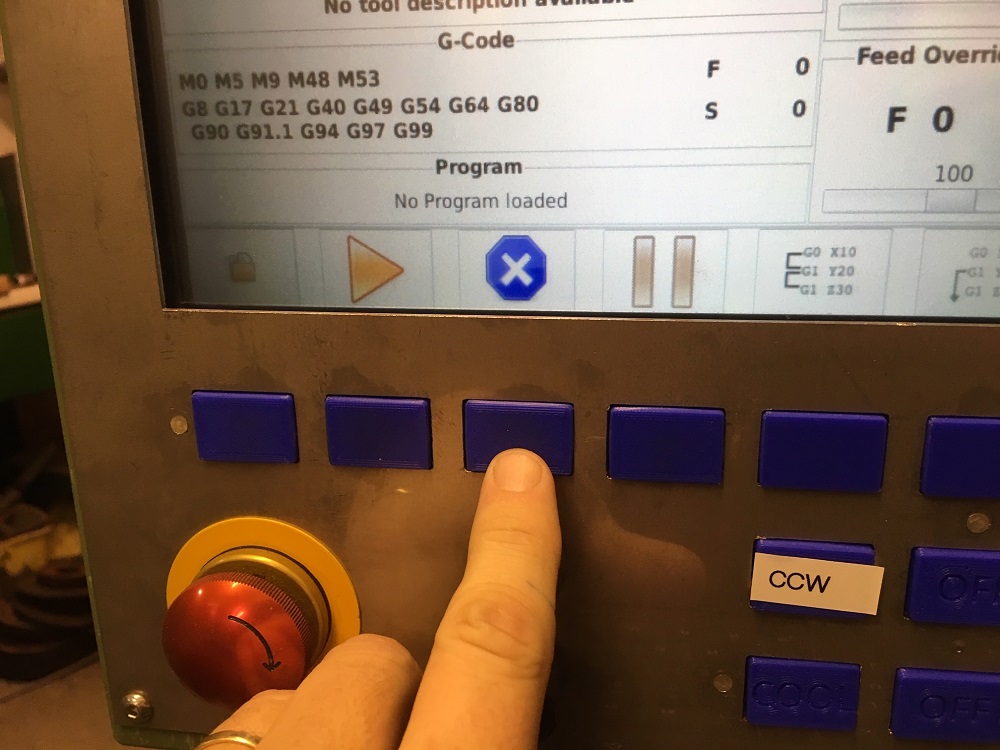

I agree about a physical button. With the touch screen, you have no tactile feedback if your stop finger moved while looking away to the work or spindle. That is what is cool about gmoccapy. When you need your physical run/pause/stop button, it is there. When you are not in mode where you are running a program, it is freed up for a different purpose.

Program run mode...

Jog mode...

Mark

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Just an opinion on physical run, pause and stop buttons. I use machines with both types of controls. One large vertical borer with retrofitted touch screen only, and another reftrofitted mill with normal screen and physical buttons. I believe having physical buttons is safer (on the machines i use) as you can always have your finger on the physical button, while you watch the machine, waiting for something unexpected to happen.........

In the end, it comes down to personal preference. Whatever your comfortable with.

Cheers

Matt

I agree about a physical button. With the touch screen, you have no tactile feedback if your stop finger moved while looking away to the work or spindle. That is what is cool about gmoccapy. When you need your physical run/pause/stop button, it is there. When you are not in mode where you are running a program, it is freed up for a different purpose.

Program run mode...

Jog mode...

Mark

Attachments:

Last edit: 09 Jan 2019 18:08 by RotarySMP.

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

11 Jan 2019 02:34 #123937

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Found the videos , my thinking is compare the brief scans of the lathe control panel to the Deckel control panel . Of note to me was the lathe control panel using also a non stainless material.

There is also some ".A" axis lust and a very brief bit on his coolant system. Wish Mr Roger M would video more on those machines --- Hint Hint Wish Wish

Keyboard Control

Coolant

Mark looking at the remains of the slotter cutting bit -- I am wondering if that was just a excuse to justify having a tool & cutter grinder ?

Bob

There is also some ".A" axis lust and a very brief bit on his coolant system. Wish Mr Roger M would video more on those machines --- Hint Hint Wish Wish

Keyboard Control

Coolant

Mark looking at the remains of the slotter cutting bit -- I am wondering if that was just a excuse to justify having a tool & cutter grinder ?

Bob

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1545

- Thank you received: 572

11 Jan 2019 09:33 - 11 Jan 2019 09:34 #123961

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Really nice set up the Mr Moore has there. Looks like he recycled a Heidenhain keyboard. Very impressive small part turning example in that first video.

madmodder.net/index.php/topic,11250.0.html

I picked up the Clarkson from a friend a couple of years ago (he upgraded to a Tos, which is a dream machine, especially now with the Haller sprial grinding attachment he scored at auction - there is a picture in the madmodder thread). Having a T&C grider was a bit of a luxury, until I started abusing end mills with the MAHO.

I finished off the anvil job using the face mill. There is a large hard spot in the middle, and I had to slow down to 80rpm, 80mm/min at 0.2 Ap to prevent it chattering.

Mark

madmodder.net/index.php/topic,11250.0.html

I picked up the Clarkson from a friend a couple of years ago (he upgraded to a Tos, which is a dream machine, especially now with the Haller sprial grinding attachment he scored at auction - there is a picture in the madmodder thread). Having a T&C grider was a bit of a luxury, until I started abusing end mills with the MAHO.

I finished off the anvil job using the face mill. There is a large hard spot in the middle, and I had to slow down to 80rpm, 80mm/min at 0.2 Ap to prevent it chattering.

Mark

Last edit: 11 Jan 2019 09:34 by RotarySMP.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

11 Jan 2019 12:40 #123969

by andypugh

It's a pity his f1-2000.co.uk web site has gone down, it had some amazing pics of the tiny parts he is making for his 1/4 scale Ferarri engine. Like this one: goo.gl/images/FknhTL

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

Wish Mr Roger M would video more on those machines

It's a pity his f1-2000.co.uk web site has gone down, it had some amazing pics of the tiny parts he is making for his 1/4 scale Ferarri engine. Like this one: goo.gl/images/FknhTL

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

11 Jan 2019 13:44 #123972

by andypugh

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

I have a better picture of Roger's lathe panel:

photos.app.goo.gl/1VCnuD7dm6LmWPsw8

He built the console from off-the-shelf sections, but searching through old emails hasn't found the link.

photos.app.goo.gl/1VCnuD7dm6LmWPsw8

He built the console from off-the-shelf sections, but searching through old emails hasn't found the link.

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1545

- Thank you received: 572

12 Jan 2019 22:09 #124052

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Today I had a play around with thread milling.

Unfortunately, this again indicated that the Y-axis creeps. I notice that the cutter was only touching at the front (-Y). After centering it better, I reoccurred.

I ran a test and such enough, there are drop outs on the B channel of the Y encoder.

It was cold in the basement so I took a break. Since I now have a single channel 602EXE on Z, and it is wired with the differential signals, I will use that to test whether it is an EMI noise issue.

Mark

Unfortunately, this again indicated that the Y-axis creeps. I notice that the cutter was only touching at the front (-Y). After centering it better, I reoccurred.

I ran a test and such enough, there are drop outs on the B channel of the Y encoder.

It was cold in the basement so I took a break. Since I now have a single channel 602EXE on Z, and it is wired with the differential signals, I will use that to test whether it is an EMI noise issue.

Mark

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

13 Jan 2019 00:30 #124057

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Mark Sorry to see the Y axis scale is still a lurking problem. I was wondering if your new 5volt switch mode powder supply might be causing EMI issues? Would it be worth rigging up a bunch of batteries ,say flash-light type for a test ? Don't remember the 5 volt range of the scales,but could use a length of small steel wire as a dropping resistor. Please don't burn out the scales bulb.

Could you recruit some old analog electronic hobbiest person/codger that has analog test gear , like a real analog scope an analog variable power supply. -- be sure to quiz them about making shop/house visits.

The cold Maho -- I have used a rigged up tent made from rigid electrical conduit frame with U clamps and plastic film type cover that used a electric heater . Takes a while to warm up the metal such that my tongue doesn't stick to the Maho..

Was useful for painting also.

Thread milling

be very careful as you might fall into that need of spindle indexing trap

Hope you find the scale issue very soon

Bob who is --- cold old analog

Could you recruit some old analog electronic hobbiest person/codger that has analog test gear , like a real analog scope an analog variable power supply. -- be sure to quiz them about making shop/house visits.

The cold Maho -- I have used a rigged up tent made from rigid electrical conduit frame with U clamps and plastic film type cover that used a electric heater . Takes a while to warm up the metal such that my tongue doesn't stick to the Maho..

Was useful for painting also.

Thread milling

be very careful as you might fall into that need of spindle indexing trap

Hope you find the scale issue very soon

Bob who is --- cold old analog

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1545

- Thank you received: 572

13 Jan 2019 10:55 - 13 Jan 2019 10:55 #124070

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi Bob,

Hanno, one of the German guys who is also converting a MAHO also identified that cheap chinese 5VDC PSU as a potential cause. He pointed out from the datasheet that the isolation at 100MOhm/500VDC is not very good.

He also suggested a metal EMI shield over the 7i77, like I put over the EXE.

Here is a my plan for trouble shooting:

1/ Switch the Y and Z axis encoders exe's. This is easy as I just switch encoder and 7i77 connectors. Z has a stand alone 602 EXE, which only takes 5V power. The three channel board mounted EXE on X and Y also has 12V supply which I pulled from the ITX MoBo PSE. Since the 602EXE also has the differential signals output from the EXE--> 7i77, I am hoping to isolate with this step whether the problem is in the EXE or the Encoder.

2/ Make up a battery PSU per your suggestion. I bought an assortment of resisters at some stage, so it will be easy enough to bodge up a battery pack, tuned for 5V output. Thanks for that suggestion. If that works, would replacing the cheap 5VDC PSU with a name brand rail mount PSU be expected to also work, or do I need to do more to solve a problem like this?

3/ According to all the EXE datasheets I have been able to find, the differential signals should be available on the three axis board. They were just not brought out to the Phillips on the output cables. If the interference is is being picked up on those last cables, I could try replacing them and and bringing out the differential signals on twisted pairs.

Mark

Hanno, one of the German guys who is also converting a MAHO also identified that cheap chinese 5VDC PSU as a potential cause. He pointed out from the datasheet that the isolation at 100MOhm/500VDC is not very good.

He also suggested a metal EMI shield over the 7i77, like I put over the EXE.

Here is a my plan for trouble shooting:

1/ Switch the Y and Z axis encoders exe's. This is easy as I just switch encoder and 7i77 connectors. Z has a stand alone 602 EXE, which only takes 5V power. The three channel board mounted EXE on X and Y also has 12V supply which I pulled from the ITX MoBo PSE. Since the 602EXE also has the differential signals output from the EXE--> 7i77, I am hoping to isolate with this step whether the problem is in the EXE or the Encoder.

2/ Make up a battery PSU per your suggestion. I bought an assortment of resisters at some stage, so it will be easy enough to bodge up a battery pack, tuned for 5V output. Thanks for that suggestion. If that works, would replacing the cheap 5VDC PSU with a name brand rail mount PSU be expected to also work, or do I need to do more to solve a problem like this?

3/ According to all the EXE datasheets I have been able to find, the differential signals should be available on the three axis board. They were just not brought out to the Phillips on the output cables. If the interference is is being picked up on those last cables, I could try replacing them and and bringing out the differential signals on twisted pairs.

Mark

Last edit: 13 Jan 2019 10:55 by RotarySMP.

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1545

- Thank you received: 572

13 Jan 2019 13:32 - 13 Jan 2019 17:09 #124080

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks to this post I got the matchbox virtual keyboard installed and working with Gmoccapy.

forum.linuxcnc.org/gmoccapy/34409-virtual-keyboard#109691

I once read a post about changing the size of the letters/keys on the Matchbox virtual keyboard, but can't find it again. If anyone could point me in the right direction I would appreciate it.

forum.linuxcnc.org/gmoccapy/34409-virtual-keyboard#109691

I once read a post about changing the size of the letters/keys on the Matchbox virtual keyboard, but can't find it again. If anyone could point me in the right direction I would appreciate it.

Last edit: 13 Jan 2019 17:09 by RotarySMP.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.286 seconds