Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

17 Jan 2019 09:41 - 17 Jan 2019 09:43 #124339

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi Bob,

I've been in discussion with Hanno for a couple of weeks per email already.

Instead of a second voltmeter, I have this little bundle of excellence...

Who designs a tiny, potable hand held device which will obviously be battery powered, but makes no provision for the battery in the housing???

I'll hook that up and see what it says about ripple voltage.

Mark

I've been in discussion with Hanno for a couple of weeks per email already.

Instead of a second voltmeter, I have this little bundle of excellence...

Who designs a tiny, potable hand held device which will obviously be battery powered, but makes no provision for the battery in the housing???

I'll hook that up and see what it says about ripple voltage.

Mark

Attachments:

Last edit: 17 Jan 2019 09:43 by RotarySMP.

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

17 Jan 2019 09:42 #124340

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Hi,

a capacitors` resistance, depending on the damage, can be down to zero,

which is short circuit. This could drive a PSU to its limit.

but...it is only a guess...it could also be a faulty voltage regulator on the EXE.

You changed the ELKOs in the 3TRM.

Did you also change the 24V (Field Power) bus ELKOs on the relay PCB ? They are +30 years old, too.

In one of your videos you already identified that the B-Channel of the encoder has drop-outs:

I would take a closer look at this section on the PCB.

Does anyone have a schematic of that MAHO EXE ?

Hanno

a capacitors` resistance, depending on the damage, can be down to zero,

which is short circuit. This could drive a PSU to its limit.

but...it is only a guess...it could also be a faulty voltage regulator on the EXE.

You changed the ELKOs in the 3TRM.

Did you also change the 24V (Field Power) bus ELKOs on the relay PCB ? They are +30 years old, too.

In one of your videos you already identified that the B-Channel of the encoder has drop-outs:

I would take a closer look at this section on the PCB.

Does anyone have a schematic of that MAHO EXE ?

Hanno

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

17 Jan 2019 10:11 #124341

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

aahhh, nice, a DIY scope.

You could watch the drop-outs in LinuxCNC while moving the axis at lowest speed,

hook up the scope and measure several Voltages at different stages like 12V, 5V, ICs, etc. on the PCB while that dropouts occur. This might be the fastest way.

You could watch the drop-outs in LinuxCNC while moving the axis at lowest speed,

hook up the scope and measure several Voltages at different stages like 12V, 5V, ICs, etc. on the PCB while that dropouts occur. This might be the fastest way.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

17 Jan 2019 11:07 #124342

by andypugh

It also makes it less likely that a stray strand will bridge adjacent terminals.

I have one of this style of very cheap ferrule crimpers and it works very nicely.

www.amazon.co.uk/Self-adjustable-Ratchet...rminal/dp/B00IR7A3ZU

Though for not a lot more you can get a set that also includes a thousand ferrules too.

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

Using barrel wire termination looks great ,to me. I think it is the small details that really pay off in long time usage.

It also makes it less likely that a stray strand will bridge adjacent terminals.

I have one of this style of very cheap ferrule crimpers and it works very nicely.

www.amazon.co.uk/Self-adjustable-Ratchet...rminal/dp/B00IR7A3ZU

Though for not a lot more you can get a set that also includes a thousand ferrules too.

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

17 Jan 2019 12:31 #124345

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

That is simply the standard for flexible wires (in Germany).

One thing about shielding the wires:

In my opinion the best is to connect both ends and additionally ground the shielding to earth potential (PE) at one point.

That is the way the original controller had the shieldings screwed on top of the chassis.

You can visualize this as an extension of the chassis around the cable.

One thing about shielding the wires:

In my opinion the best is to connect both ends and additionally ground the shielding to earth potential (PE) at one point.

That is the way the original controller had the shieldings screwed on top of the chassis.

You can visualize this as an extension of the chassis around the cable.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

17 Jan 2019 16:09 #124360

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

When splitting out the individual wires from the ribbon cable, I ended up crimp a lot of 0.1mm² ferrules. I used this style,

www.amazon.de/Transmedia-Handkrimpzange-...3%BClsen+crimpzangen

which doesn't work well at that size.

I see that the ones Andy recommended only go down to 0.25mm².

Which ones do you guys use for the little stuff?

Mark

www.amazon.de/Transmedia-Handkrimpzange-...3%BClsen+crimpzangen

which doesn't work well at that size.

I see that the ones Andy recommended only go down to 0.25mm².

Which ones do you guys use for the little stuff?

Mark

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

17 Jan 2019 16:57 #124366

by Todd Zuercher

Replied by Todd Zuercher on topic Retrofitting a 1986 Maho MH400E

I have one like Andy pointed out, and even though it says 0.25-6 it works perfectly well on the 0.14mm² ferrules (the smallest ones I have.) and I think it might also do the 0.1mm² ferrules. (They are cheap Chinese tools but handy enough that not long after I got mine, several more were ordered for others in the shop.) I think it seems to work pretty good for little stuff, but I'd be a little worried about using it for crimping a lot of things at the larger end of it's limit.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

17 Jan 2019 17:27 #124367

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks Todd. 0.14mm² was what I meant

I'll get one of those. I didn't realise cheap chinese versions were available. I borrowed a similar one from a an Avionics guy at work, one with replaceable inserts, and it was a €€€ tool!

Mark

I'll get one of those. I didn't realise cheap chinese versions were available. I borrowed a similar one from a an Avionics guy at work, one with replaceable inserts, and it was a €€€ tool!

Mark

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

17 Jan 2019 17:38 #124368

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

I have the one you can see in this picture:

forum.linuxcnc.org/media/kunena/attachme...5/klein_IMGP4263.jpg

Today was a good day;-)

I talked to a co-worker that I'm looking for a touch monitor and, guess what,

he was cleaning up a storage room and found this.

It is a former public information stand with vandalism-proof keyboard and 17" Touch Monitor.:

Some more impressions of my build.

A chopped Desktop PC with i5 Quad-Core, 16GB RAM and an 500GB SSD:

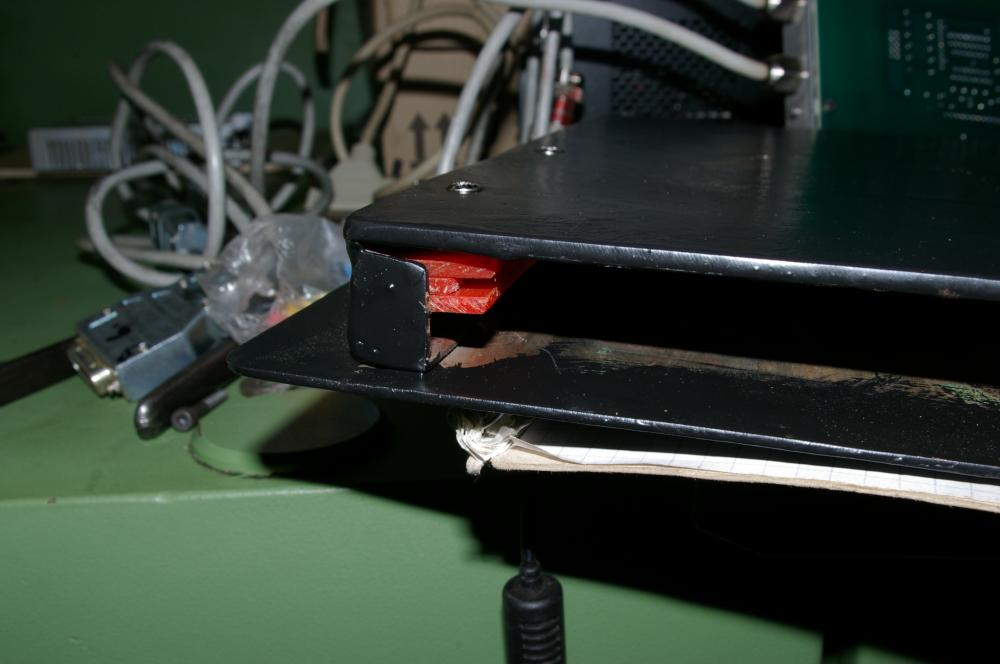

A selfmade housing for the MAHO-EXE.

It is made of 3/4/5mm junk sheet metal.

The PCB guide rails are made of rests of sheet plastic.

Not a beauty, but it works and is bullet proof :

:

The PC took a seat for the picture in its later position.

I chose this position because I need the space behind it, beside the Mesa boards, for the 4th-axis controller which I will definitely realise in the future.

As you can see, the cable of the X-Axis glass-scale is too short to mount the EXE where Mark placed his one.

I will have to exchange that cable in the long run:

forum.linuxcnc.org/media/kunena/attachme...5/klein_IMGP4263.jpg

Today was a good day;-)

I talked to a co-worker that I'm looking for a touch monitor and, guess what,

he was cleaning up a storage room and found this.

It is a former public information stand with vandalism-proof keyboard and 17" Touch Monitor.:

Some more impressions of my build.

A chopped Desktop PC with i5 Quad-Core, 16GB RAM and an 500GB SSD:

A selfmade housing for the MAHO-EXE.

It is made of 3/4/5mm junk sheet metal.

The PCB guide rails are made of rests of sheet plastic.

Not a beauty, but it works and is bullet proof

The PC took a seat for the picture in its later position.

I chose this position because I need the space behind it, beside the Mesa boards, for the 4th-axis controller which I will definitely realise in the future.

As you can see, the cable of the X-Axis glass-scale is too short to mount the EXE where Mark placed his one.

I will have to exchange that cable in the long run:

Attachments:

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

17 Jan 2019 18:16 #124371

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi Hanno,

I suspected that someone who actually knows how to do this stuff could convert a Maho in a week or two. You are proving it. Respect.

No wonder that the German machine tool industry tanked in the 80's. The cost of production planning and after market support of having ever product go out the door as a one off must have been very costly.

Mark

I suspected that someone who actually knows how to do this stuff could convert a Maho in a week or two. You are proving it. Respect.

No wonder that the German machine tool industry tanked in the 80's. The cost of production planning and after market support of having ever product go out the door as a one off must have been very costly.

Mark

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.269 seconds