Retrofitting a 1986 Maho MH400E

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

13 Mar 2019 15:46 - 13 Mar 2019 15:46 #128532

by andypugh

The extra port on the 5i25 is DIL26. This needs a DIL26 to DB25 adaptor, then a DB25 cable to connect to a 7i74.

www.amazon.co.uk/Female-Motherboard-Brac...s-show/dp/B07M64X6LS

(Or you could make your own DI26 to DB25 connector.)

The 7i44 connects to the _50_ pin cards (such as the 5i20 or 5i24)

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

Doesn't he need that DB25 connection on the 5i25 for the 7i77? The 5i25 has a second DIL26 pinhead, for connecting a 7i44.

The extra port on the 5i25 is DIL26. This needs a DIL26 to DB25 adaptor, then a DB25 cable to connect to a 7i74.

www.amazon.co.uk/Female-Motherboard-Brac...s-show/dp/B07M64X6LS

(Or you could make your own DI26 to DB25 connector.)

The 7i44 connects to the _50_ pin cards (such as the 5i20 or 5i24)

Last edit: 13 Mar 2019 15:46 by andypugh. Reason: Got 7i74 / 7i44 mixed up

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

13 Mar 2019 15:48 #128533

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Oh. Thanks for picking that up.

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

13 Mar 2019 16:13 #128535

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Thanks a lot for all the info guys, I will definitely work on becoming a bit less clueless when I get some time to read all the manuals. In the meantime it's great to know what cables and accessories are needed, I can order them online to have everything ready. Will it be possible to connect both the Maho's main spindle drive and my small VFD auxiliary spindle using the cards I got?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

14 Mar 2019 01:56 #128555

by tommylight

Replied by tommylight on topic Retrofitting a 1986 Maho MH400E

I do think it is possible, granted you do not need all 5 servo outputs from the 7i77. You can use any of the +-10V outputs and corresponding encoder input to have a closed loop VFD spindle control, but most probably you will need to use the ABS component and wire an output for the VFD in HAL to have it reverse the spindle, as the VFD does not like the negative voltages that 7i77 outputs for servo drives when reversing..Will it be possible to connect both the Maho's main spindle drive and my small VFD auxiliary spindle using the cards I got?

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

14 Mar 2019 07:10 - 14 Mar 2019 07:15 #128558

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Is your MAHO an E model or an E2? If it is an E model, then the spindle control it just the pins which switch the various gearbox and on off relays, and the comp which works out when to switch them.

Does your HF spindle have a tool changer, or at least tool release, or is it just one of the ER collet spindles? To completely integrate both spindles under inuxCNC control will require you to write a comp, and provide LinuxCNC with feedback as which spindle is fitted. However if it is an ER collet HF Spindle, where tool changing is slow anyway, you could simple switch it on and off manually and use tool paths which dont include splindle control.

Mark

Does your HF spindle have a tool changer, or at least tool release, or is it just one of the ER collet spindles? To completely integrate both spindles under inuxCNC control will require you to write a comp, and provide LinuxCNC with feedback as which spindle is fitted. However if it is an ER collet HF Spindle, where tool changing is slow anyway, you could simple switch it on and off manually and use tool paths which dont include splindle control.

Mark

Last edit: 14 Mar 2019 07:15 by RotarySMP.

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

14 Mar 2019 08:31 #128564

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

My Maho is an E model just like yours. The HF spindle is the ER collet type. I was curious about the possibility of setting it up in LinuxCNC because switching it on and off manually is a drag, and setting the frequency using the knob on the VFD sometimes gives poor results.

For exmaple, I cut acrylic at 244 Hz to match the spindle with the maximum feed of the Maho (1500), but the knob seems to "click" at uneven numbers and getting it to stay at 244 instead of intermittently oscillating between 244 and 243/245 is tricky to say the least. It would seem that shouldn't be a big deal, but it sometimes has the effect of getting extruded acrylic to stick to the cutter.

The VFD goes from 120-300 Hz and the spindle goes from 6000-18000 rpm. So 1 Hz is a difference of 66,6 rpm. Cast acrylic doesn't seem to care, but the extruded variety is very sensitive to temperature and you need the feeds and speeds to be just right or you risk breaking the tool (plastic builds up on the cutter and forms a solid blob which eventually causes the carbide to break when the tool enters the workpiece; this can happen very quickly when you're not paying attention, which I usually don't since I work while the machine is on).

For exmaple, I cut acrylic at 244 Hz to match the spindle with the maximum feed of the Maho (1500), but the knob seems to "click" at uneven numbers and getting it to stay at 244 instead of intermittently oscillating between 244 and 243/245 is tricky to say the least. It would seem that shouldn't be a big deal, but it sometimes has the effect of getting extruded acrylic to stick to the cutter.

The VFD goes from 120-300 Hz and the spindle goes from 6000-18000 rpm. So 1 Hz is a difference of 66,6 rpm. Cast acrylic doesn't seem to care, but the extruded variety is very sensitive to temperature and you need the feeds and speeds to be just right or you risk breaking the tool (plastic builds up on the cutter and forms a solid blob which eventually causes the carbide to break when the tool enters the workpiece; this can happen very quickly when you're not paying attention, which I usually don't since I work while the machine is on).

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

16 Mar 2019 08:27 - 16 Mar 2019 08:29 #128714

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

LinuxCNC can definitely do what you want, it can do basically anything  Does the MAHO vertical spindle remain installed, and the HF spindle attach next to it, with both usable, or do you remove one and install the other? Does the HF Spindle mount with the same axis center as the MAHO (could simplify the need to have different tool offset tables)?

Does the MAHO vertical spindle remain installed, and the HF spindle attach next to it, with both usable, or do you remove one and install the other? Does the HF Spindle mount with the same axis center as the MAHO (could simplify the need to have different tool offset tables)?

In hardware, assuming you remove the MAHO spindle to attach the HF one, you will have two parallel systems, sharing no components. You will have a set of I/O pins dedicated to the VFD on/off/direction/speed feedback etc, just as you have pins dedicated to the MAHO on/off/direction/and gearbox control/spindle at speed etc.

In software, there is a comp for controlling a VFD, and a comp for controlling the MAHO gearbox. What you will need is a software widget to choose which one is currently active, and therefore which one gets to parse S words, and spindle commands , which input pins are read, and which output pins are written.

If you look at the schematic of how Sergey's gearbox.comp is controlling speed..

github.com/jin-eld/mh400e-linuxcnc/blob/...e%20flow%20chart.odg

... you need to start above that with a first question, "which spindle is currently fitted", and if it is the VFD, branch off into a parallel flow of VFD control decisions.

Ideally you could fit a switch, which automatically closes when the HF spindle is installed, and that switch feeds the spindle selection widget. So if the MAHO head is fitted, that pin is read and, the maho gearbox.comp parses the S words. If the HF head is fitted, then you have your S word parsed by the VFD.comp.

I am not enough of a software guy to know whether it is best, or even possible to have three comp's (A spindle selector widget, the gearbox comp, and the VFD.comp), or whether you will need to merge those three into one new comp. The advantage is that this is open source stuff, so you shouldn't need to recreate all code.

Having the VFD speed command generated by LinuxCNC digitally, rather than trying to set a specific frequency from a Pot should meean you hit that exact frequency every time.

Mark

In hardware, assuming you remove the MAHO spindle to attach the HF one, you will have two parallel systems, sharing no components. You will have a set of I/O pins dedicated to the VFD on/off/direction/speed feedback etc, just as you have pins dedicated to the MAHO on/off/direction/and gearbox control/spindle at speed etc.

In software, there is a comp for controlling a VFD, and a comp for controlling the MAHO gearbox. What you will need is a software widget to choose which one is currently active, and therefore which one gets to parse S words, and spindle commands , which input pins are read, and which output pins are written.

If you look at the schematic of how Sergey's gearbox.comp is controlling speed..

github.com/jin-eld/mh400e-linuxcnc/blob/...e%20flow%20chart.odg

... you need to start above that with a first question, "which spindle is currently fitted", and if it is the VFD, branch off into a parallel flow of VFD control decisions.

Ideally you could fit a switch, which automatically closes when the HF spindle is installed, and that switch feeds the spindle selection widget. So if the MAHO head is fitted, that pin is read and, the maho gearbox.comp parses the S words. If the HF head is fitted, then you have your S word parsed by the VFD.comp.

I am not enough of a software guy to know whether it is best, or even possible to have three comp's (A spindle selector widget, the gearbox comp, and the VFD.comp), or whether you will need to merge those three into one new comp. The advantage is that this is open source stuff, so you shouldn't need to recreate all code.

Having the VFD speed command generated by LinuxCNC digitally, rather than trying to set a specific frequency from a Pot should meean you hit that exact frequency every time.

Mark

Last edit: 16 Mar 2019 08:29 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

16 Mar 2019 19:36 - 16 Mar 2019 19:45 #128761

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I had another play with thread milling today.

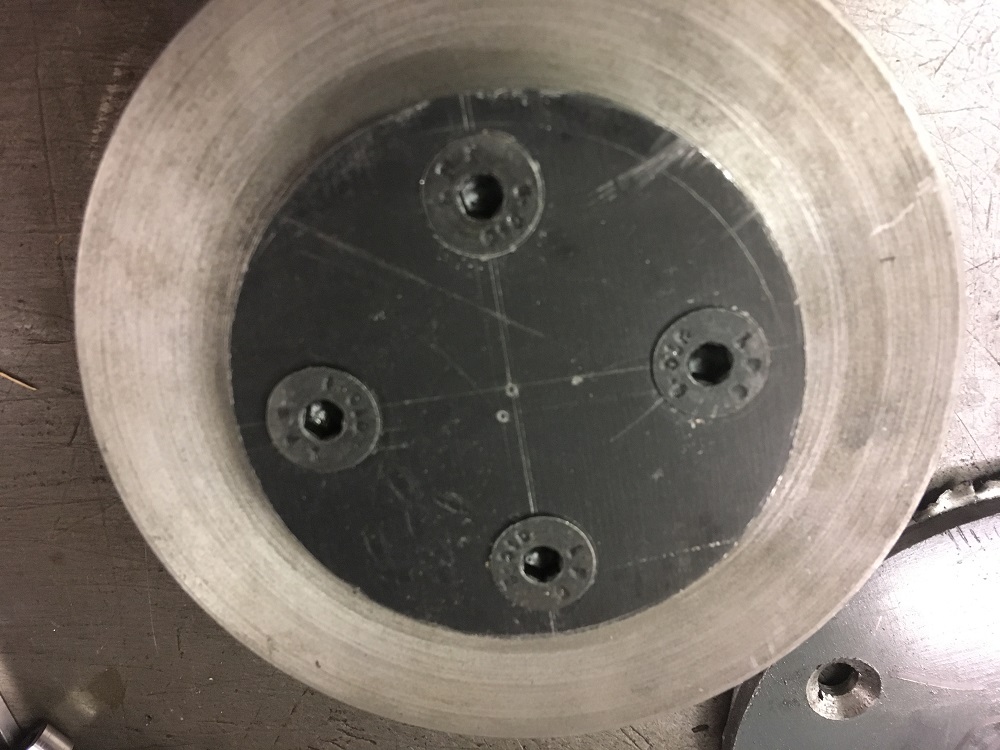

Also needed a couple of round pieces of 6mm mild steel plate.These are the end plates for the wheel of my sand muller. The Maho made pretty quick work of chopping out the circles. At least least it seemed faster while cutting at 700mm/min, and required no effort from me other than chopping out the last half mm with a cold chisel before turning the back side.

Mark

Also needed a couple of round pieces of 6mm mild steel plate.These are the end plates for the wheel of my sand muller. The Maho made pretty quick work of chopping out the circles. At least least it seemed faster while cutting at 700mm/min, and required no effort from me other than chopping out the last half mm with a cold chisel before turning the back side.

Mark

Attachments:

Last edit: 16 Mar 2019 19:45 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

16 Mar 2019 19:52 - 16 Mar 2019 19:55 #128762

by drimaropoylos

You can use three different configurations one configuration with the vertical maho head, one for the horizontal spindle (with the axis y and z swapped so the z is always in line with the spindle) and one configuration for the hi speed head.

Depending what head you are going to use, you have to start the right configuration.

You can also add a b axis in the first configuration (the rotating head), and add a stop wen b axis make a move, rotate the head manually and continue with the program.

John

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

My Maho is an E model just like yours. The HF spindle is the ER collet type. I was curious about the possibility of setting it up in LinuxCNC because switching it on and off manually is a drag, and setting the frequency using the knob on the VFD sometimes gives poor results.

You can use three different configurations one configuration with the vertical maho head, one for the horizontal spindle (with the axis y and z swapped so the z is always in line with the spindle) and one configuration for the hi speed head.

Depending what head you are going to use, you have to start the right configuration.

You can also add a b axis in the first configuration (the rotating head), and add a stop wen b axis make a move, rotate the head manually and continue with the program.

John

Last edit: 16 Mar 2019 19:55 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

16 Mar 2019 19:54 #128764

by andypugh

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

Nice that it worked, but I am slightly confused why you thread-milled it when you already had it set up on the lathe?

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.408 seconds