Retrofitting a 1986 Maho 400E

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 39

03 Mar 2019 16:49 - 03 Mar 2019 16:50 #127607

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

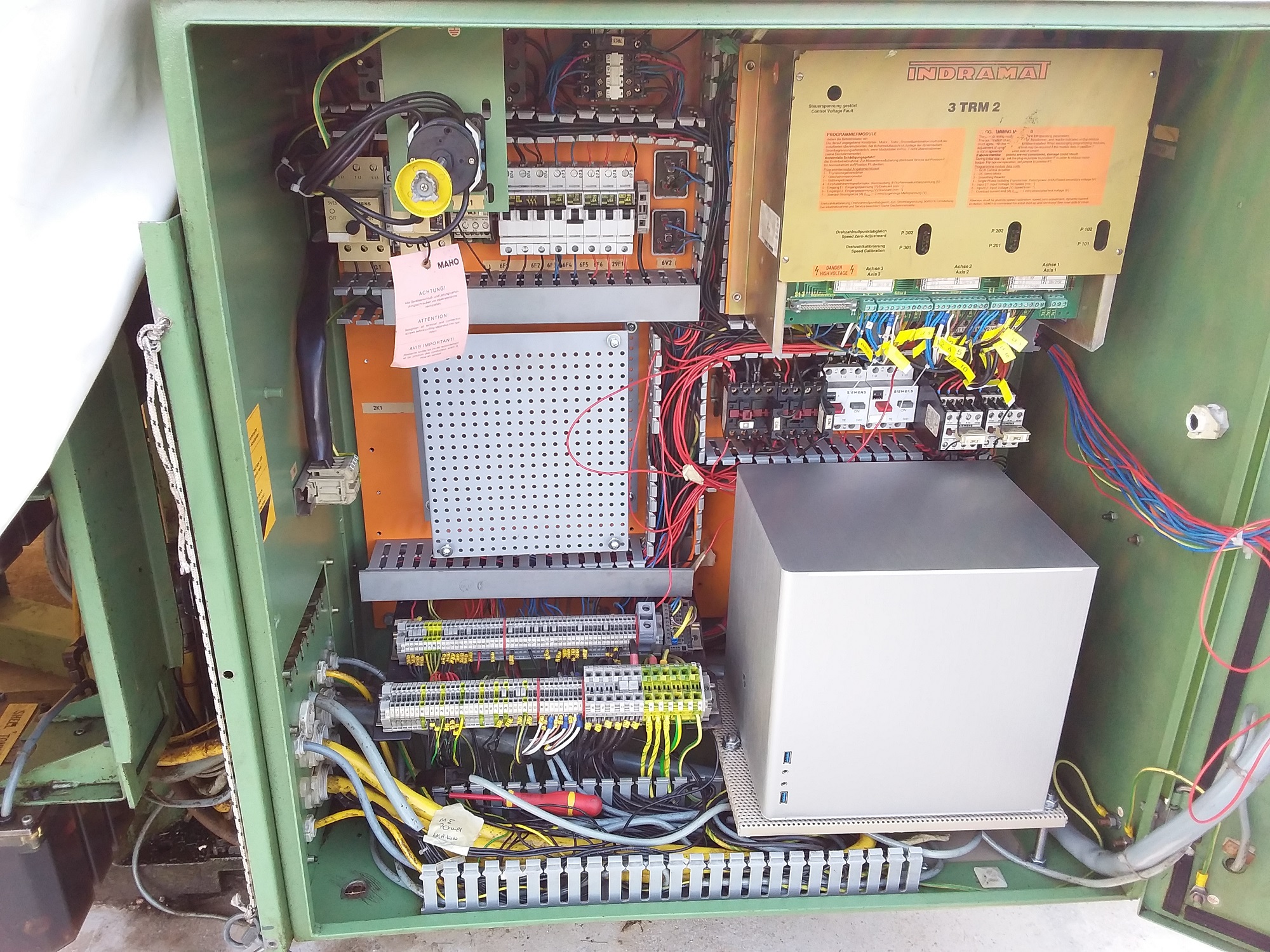

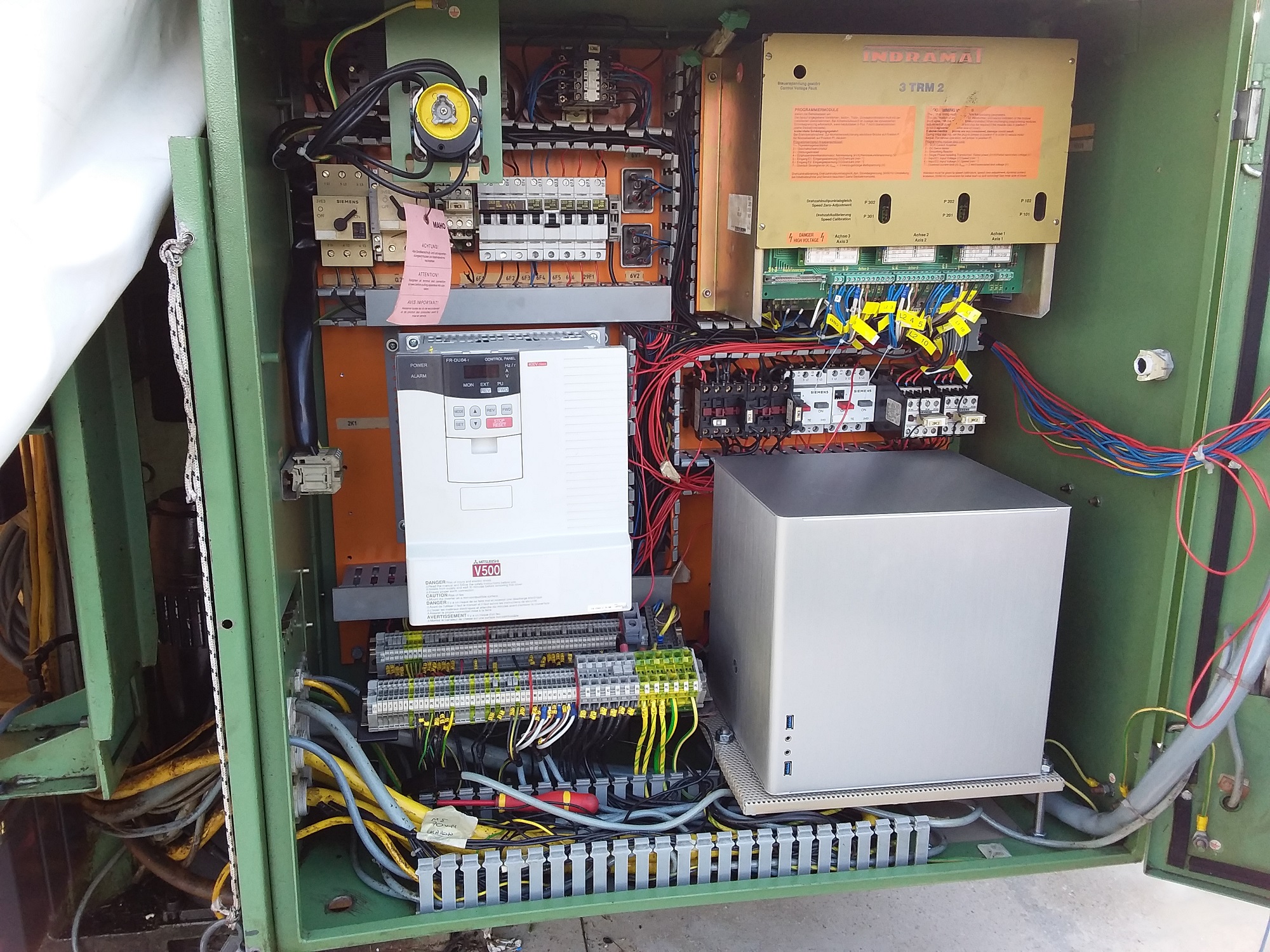

Hi to all, this is one way to fit a pc case and a VFD in the Maho cabinet.

www.google.com/search?q=Coolcube+Maxi&cl...igB&biw=1366&bih=654

www.google.com/search?q=Coolcube+Maxi&cl...igB&biw=1366&bih=654

Last edit: 03 Mar 2019 16:50 by drimaropoylos.

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

03 Mar 2019 19:34 #127626

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Good job on rearranging all those components! That's a nice case as well, what type of motherboard does it take?

The following user(s) said Thank You: drimaropoylos

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 39

03 Mar 2019 20:01 #127627

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Micro atx

John

John

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 39

03 Mar 2019 20:04 #127628

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1523

- Thank you received: 561

04 Mar 2019 10:25 - 04 Mar 2019 16:35 #127675

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Yesterday I wired up the 602/1-F EXE I got off ebay into the Y axis. Turns out Heidenhains EXE's models seem to have the same wiring color codes on the six output signals. It was only the power supply wiring which was different on this one.

This one has been wired into the Mesa 7i77 with the differential signals like the 602D.

I could'nt find any info on this 602/1-F model on the internet, and it turns out the difference to the 602D model is the lack of 5x interpolation, so this drops the axis resolution from µm, to 5µm. I got it super cheap, so maybe I'll look for another 602D and replace it. Actually, since I am now only using one channel of the original MAHO EXE board, I might get two more 602D EXEs and and remove the large MAHO board completely.

So did it fix the axis drift problem? Yes it seems to. I ran my clover leaf test for an hour and it looked fine (not an accurate test). Then spent two hours thread milling our my lathe spindle nose protector. Since this involved picking up a nearly finished 40x3.5mm thread, I had to keep running the code, sneaking up on the size in 0.1mm steps. Any drift would have been apparent.

I'll never know whether the y axis drfit was an EMI interference issue solved by the use of differential signals, or a heat sensitive component on the old EXE board, but am pretty happy to have the Maho now moving reliably.

Mark

This one has been wired into the Mesa 7i77 with the differential signals like the 602D.

I could'nt find any info on this 602/1-F model on the internet, and it turns out the difference to the 602D model is the lack of 5x interpolation, so this drops the axis resolution from µm, to 5µm. I got it super cheap, so maybe I'll look for another 602D and replace it. Actually, since I am now only using one channel of the original MAHO EXE board, I might get two more 602D EXEs and and remove the large MAHO board completely.

So did it fix the axis drift problem? Yes it seems to. I ran my clover leaf test for an hour and it looked fine (not an accurate test). Then spent two hours thread milling our my lathe spindle nose protector. Since this involved picking up a nearly finished 40x3.5mm thread, I had to keep running the code, sneaking up on the size in 0.1mm steps. Any drift would have been apparent.

I'll never know whether the y axis drfit was an EMI interference issue solved by the use of differential signals, or a heat sensitive component on the old EXE board, but am pretty happy to have the Maho now moving reliably.

Mark

Attachments:

Last edit: 04 Mar 2019 16:35 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1523

- Thank you received: 561

04 Mar 2019 14:07 #127696

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi John,

Did you have to relocate that row of contactors which is now above the PC, or was it already there? It is looking very neat and tidy.

Mark

Did you have to relocate that row of contactors which is now above the PC, or was it already there? It is looking very neat and tidy.

Mark

The following user(s) said Thank You: drimaropoylos

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 39

04 Mar 2019 19:39 #127721

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

04 Mar 2019 21:57 #127735

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Hi Mark,

the EXE-story seems to be neverending

John,

as you have the cooling unit in the cabinet door the location of the components (VFD, PC) should not make a big difference as it constantly circulates the air. Your second attempt looks really nice and well organized.

the EXE-story seems to be neverending

John,

as you have the cooling unit in the cabinet door the location of the components (VFD, PC) should not make a big difference as it constantly circulates the air. Your second attempt looks really nice and well organized.

The following user(s) said Thank You: drimaropoylos

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1523

- Thank you received: 561

05 Mar 2019 07:30 #127756

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi Hanno, how is your retrofit progressing?

It doesn't really bother me that the current Y Axis EXE has only 5µm resolution. I am such a beginner at milling that this is not limiting. I am mostly pleased to have the motion stable and predictable.

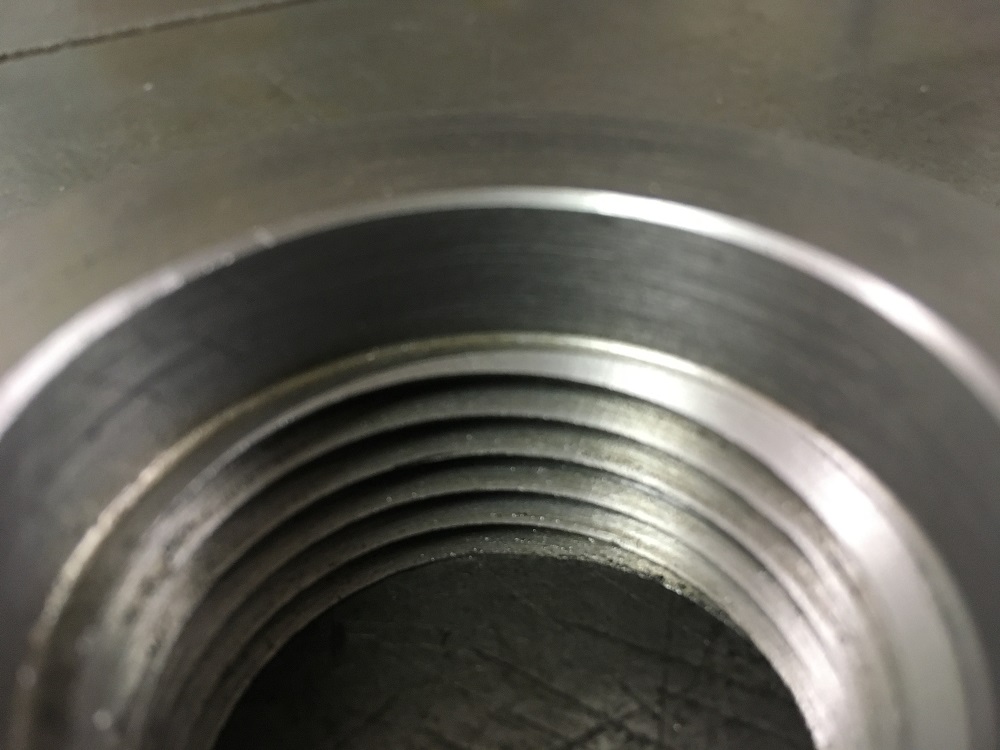

This is the nose protector for the Boley 4LV, for use with collets. I made a few back plates for the Boley, and this was the test peice for the 40x3.5x55° nose thread. It rotated in the chuck before reaching full depth, so threadmilling on the MAHO was used to finish it.

Mark

It doesn't really bother me that the current Y Axis EXE has only 5µm resolution. I am such a beginner at milling that this is not limiting. I am mostly pleased to have the motion stable and predictable.

This is the nose protector for the Boley 4LV, for use with collets. I made a few back plates for the Boley, and this was the test peice for the 40x3.5x55° nose thread. It rotated in the chuck before reaching full depth, so threadmilling on the MAHO was used to finish it.

Mark

Attachments:

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

05 Mar 2019 07:39 #127758

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Hi Mark

Glad you survived the journey to that land way down under . How are things there? weather, politics, bathroom signage etc. invitations for old style Maori dinner parties?

Since using the two 602EXE have you noticed any noise change in the servo motors at machine idle? My thinking is the differential signals for scale input are a good thing . Glad that it is looking as if the LS scales are not the problem !

Be interested in your thoughts of what is next for the Maho conversion .

Hanmon

What is the latest on your Maho conversion?

Glad you survived the journey to that land way down under . How are things there? weather, politics, bathroom signage etc. invitations for old style Maori dinner parties?

Since using the two 602EXE have you noticed any noise change in the servo motors at machine idle? My thinking is the differential signals for scale input are a good thing . Glad that it is looking as if the LS scales are not the problem !

Be interested in your thoughts of what is next for the Maho conversion .

Hanmon

What is the latest on your Maho conversion?

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.295 seconds