Wohlhaupter UPA-4 push button issues

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

06 Feb 2018 15:10 #105494

by tecno

Wohlhaupter UPA-4 push button issues was created by tecno

I have one UPA-4 that has been in storage for a while and now I have issues with the 12 push buttons that will not release.

These buttons have been pushed in and been so for some years (I have never used this head yet!)

Have been following manual but I get no response at all, does anybody here have a UPA-4 that might have tips and tricks for the boring head?

Grateful for any assistance I can get.

Cheers

Bengt

These buttons have been pushed in and been so for some years (I have never used this head yet!)

Have been following manual but I get no response at all, does anybody here have a UPA-4 that might have tips and tricks for the boring head?

Grateful for any assistance I can get.

Cheers

Bengt

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4698

- Thank you received: 1441

06 Feb 2018 15:57 #105496

by Todd Zuercher

Replied by Todd Zuercher on topic Wohlhaupter UPA-4 push button issues

Have you tried giving it a good cleaning and soaking it in penetrating oil?

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

06 Feb 2018 16:09 #105497

by tecno

Replied by tecno on topic Wohlhaupter UPA-4 push button issues

Ongoing soaking, was a bit *stiff* but all parts moving except the release ring for the buttons.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

06 Feb 2018 18:24 - 06 Feb 2018 18:25 #105500

by tecno

Replied by tecno on topic Wohlhaupter UPA-4 push button issues

Last edit: 06 Feb 2018 18:25 by tecno.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

08 Feb 2018 13:15 #105566

by tecno

Replied by tecno on topic Wohlhaupter UPA-4 push button issues

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19798

- Thank you received: 4608

08 Feb 2018 13:31 #105567

by andypugh

Replied by andypugh on topic Wohlhaupter UPA-4 push button issues

I have a slightly different UPA4. It is the most beautifully-made thing I have ever handled.

Mine has pairs of pins with their axis along the spindle axis. The pairs are coupled with tiny gears, so that when you push one down the other pops up.

I also have a UPA3 which I use extensively.

I even have a _CNC_ UPA3:

Mine has pairs of pins with their axis along the spindle axis. The pairs are coupled with tiny gears, so that when you push one down the other pops up.

I also have a UPA3 which I use extensively.

I even have a _CNC_ UPA3:

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

08 Feb 2018 13:36 #105569

by tecno

Replied by tecno on topic Wohlhaupter UPA-4 push button issues

Wow,that is interesting. Something you have made your self?

I also have a modern 236 set with ISO40 taper = I like it very much.

I also have a modern 236 set with ISO40 taper = I like it very much.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19798

- Thank you received: 4608

08 Feb 2018 13:45 #105571

by andypugh

Replied by andypugh on topic Wohlhaupter UPA-4 push button issues

The CNC adaptor was an experiment. (It should fit any changeable-shank UPA3) but wasn't 100% successful.

I should try it again using the STMBL drive instead of the 7i33.

The main problem with it was the internal home-made encoders. But also the design of the hand-wound 100% custom motor could probably be improved.

I should try it again using the STMBL drive instead of the 7i33.

The main problem with it was the internal home-made encoders. But also the design of the hand-wound 100% custom motor could probably be improved.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

08 Feb 2018 13:57 #105573

by tecno

Replied by tecno on topic Wohlhaupter UPA-4 push button issues

I am intrigued of such engineering. Have no need for such tooling now but who knows what i might need in the future.

So, keep up the good work!

So, keep up the good work!

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

10 Feb 2018 11:51 #105698

by tecno

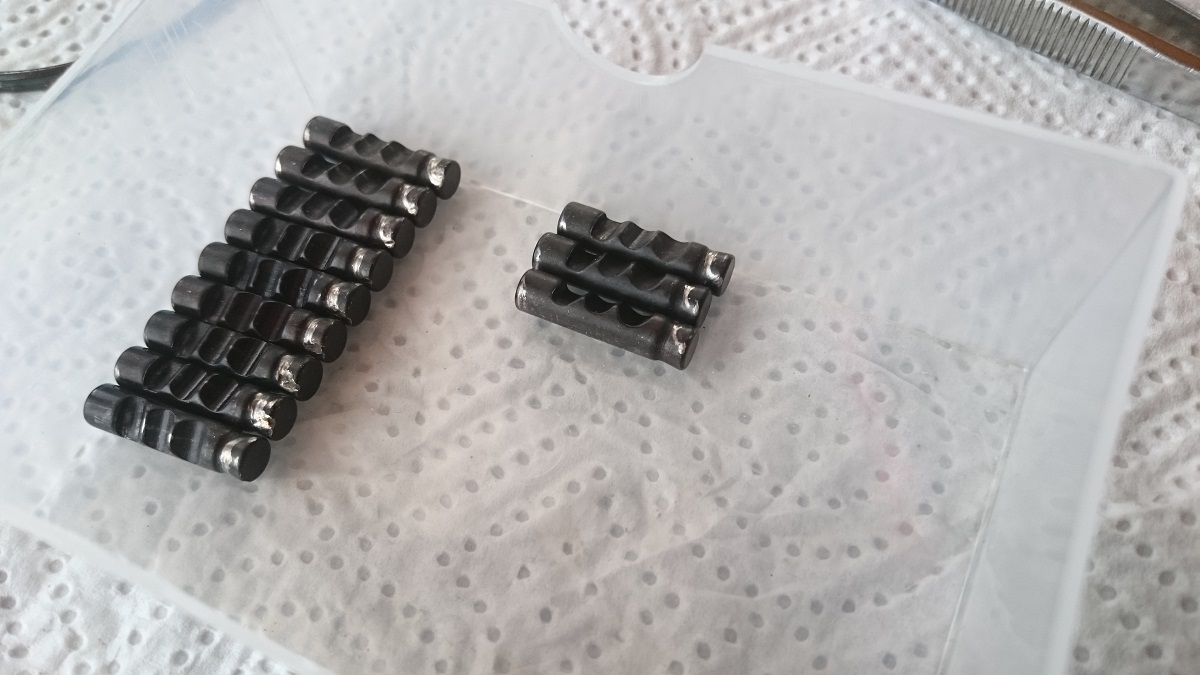

Here are the pins, they are badly worn in the end that connects to the star wheel.

Have contacted Wohlhaupter in Germany to hear if they have spare parts to reasonable price.

3-4 out of 12 are OK.

Now all parts cleaned and greased/oiled awaiting final assembly with new pins.

As I see it the main reason to the faulty behavior is lack of grease and oil.

Replied by tecno on topic Wohlhaupter UPA-4 push button issues

Here are the pins, they are badly worn in the end that connects to the star wheel.

Have contacted Wohlhaupter in Germany to hear if they have spare parts to reasonable price.

3-4 out of 12 are OK.

Now all parts cleaned and greased/oiled awaiting final assembly with new pins.

As I see it the main reason to the faulty behavior is lack of grease and oil.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.181 seconds