KRV2000 CNC Conversion

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

23 Dec 2020 18:31 #192997

by ChrissyAG

KRV2000 CNC Conversion was created by ChrissyAG

This is my first post on the forum, so I thought I’d share our (mis)adventures with our current project(s).

We shut down our engineering business 3 years ago following my partners illness and we both now want to dabble with machine tools again, so are keen to CNC retrofit a milling machine for disabled use.

Earlier this year we purchased a new (to us) 1996 KRV2000 mill to replace our RF45 clone (Chester Superlux) we had from new in 2012. The RF45 clone was great, but after much consideration we chose not to go with converting the RF45 because it just didn’t have enough travel and was not rigid enough for what we wanted. We did consider a “small” bed mill like a SMX2500, but it would have needed to be disassembled to get it in the new workshop, and would have been too big anyway.

The plan is to do a CNC conversion on it with linuxcnc 7i76e/7i85 combination. The machine was tested and then stripped for cleaning and maintenance. Apart from new brake shoes and a single spindle bearing it was in pretty good shape.

We have called her Matilda and she was filthy. In a backlash to this we decided on a ‘force you to clean it’ white paint job!

The entry door on the column was modified to take an enclosure for the two vfds (one for spindle one for coolant motor). The coolant system has now been relocated externally after the incredibly unpleasant task of cleaning the sump – which we have vowed never to repeat – ever!

A new controller box has been made from an old van vault which has been resized and welded to bolt onto the side of the column to replace the original and give plenty of space for the controller, PC, servos and contactors etc. An overhead arm is currently being made to take the monitor, mouse and keyboard, along with an emergency stop and eventually a pushbutton power drawbar as an additional project.

Our lathe had a drip feed system that worked very well which has recently been upgraded to use the original single phase coolant pump and reservoir supplied when we bought the lathe new in 2014 (which drowned everything and then didn’t drain) with a SCR chopper circuit to control the flowrate. It now works pretty well for what we want, so we decided to use something similar for the mill.

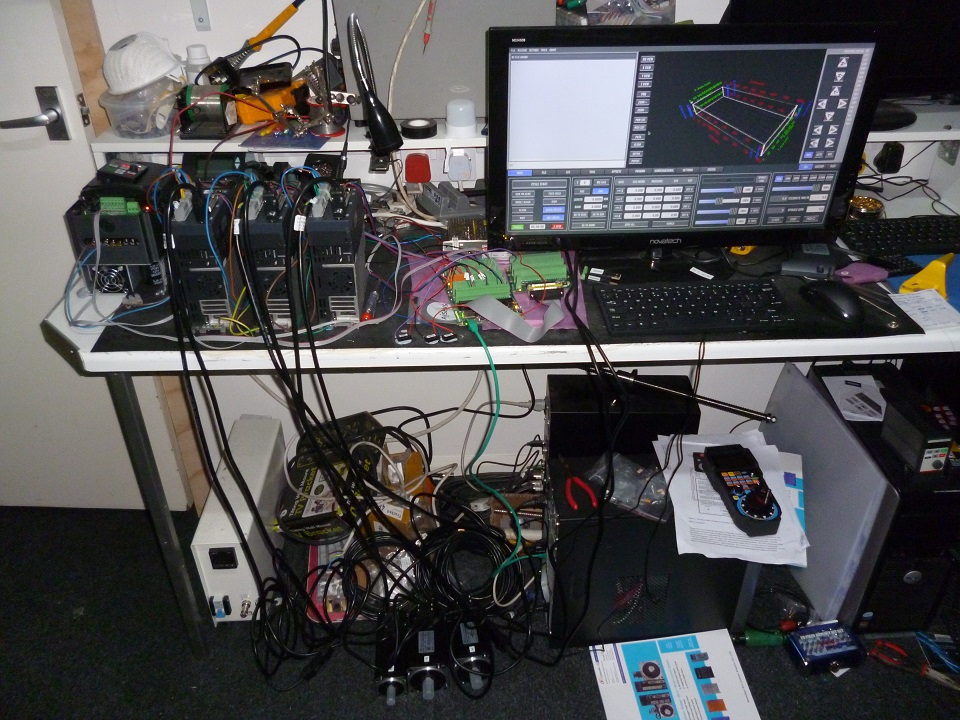

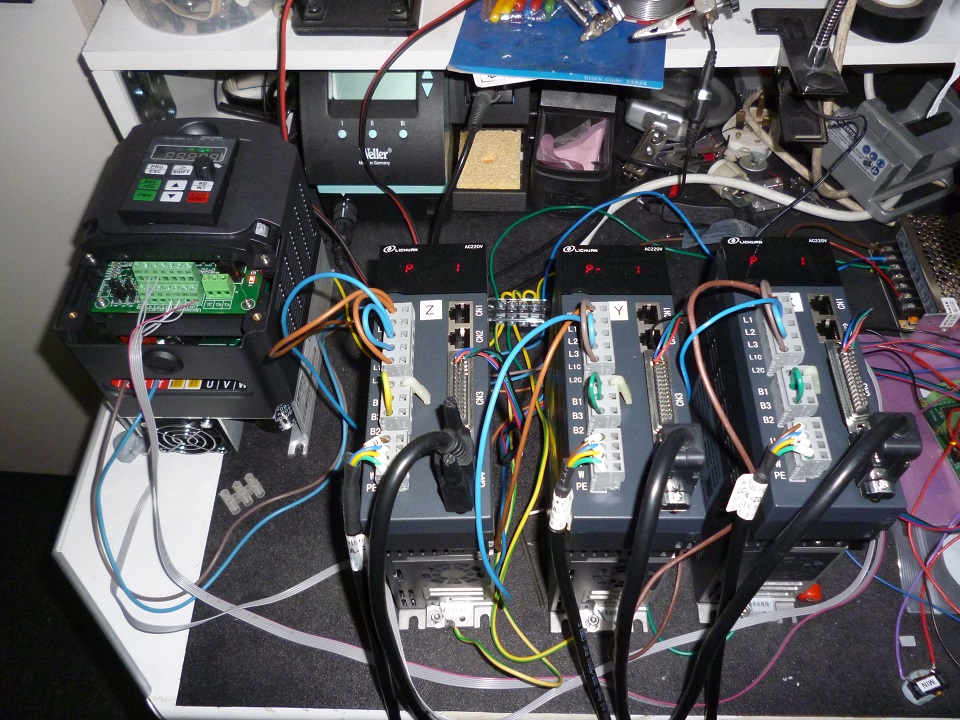

The electronics are currently on the test bench. We went with Lichuan servos purchased on AliExpress from the manufacturers shop and have replaced the original Huangyang vfd that we used for the conversion to single phase with a Nflixin 9100 that outputs 380v 3 phase which is now being used on the test bench while the HY is used to get the mill up and running again manually so we can machine parts for the CNC conversion. We are running Debian 9 with linuxcnc 2.8.0-95, and have had quite a bit of success with the controller which is currently controlling spindle vfd, servo motors and limit switches etc successfully, and have got familiar with probe basic GUI and have been impressed so far.

We shut down our engineering business 3 years ago following my partners illness and we both now want to dabble with machine tools again, so are keen to CNC retrofit a milling machine for disabled use.

Earlier this year we purchased a new (to us) 1996 KRV2000 mill to replace our RF45 clone (Chester Superlux) we had from new in 2012. The RF45 clone was great, but after much consideration we chose not to go with converting the RF45 because it just didn’t have enough travel and was not rigid enough for what we wanted. We did consider a “small” bed mill like a SMX2500, but it would have needed to be disassembled to get it in the new workshop, and would have been too big anyway.

The plan is to do a CNC conversion on it with linuxcnc 7i76e/7i85 combination. The machine was tested and then stripped for cleaning and maintenance. Apart from new brake shoes and a single spindle bearing it was in pretty good shape.

We have called her Matilda and she was filthy. In a backlash to this we decided on a ‘force you to clean it’ white paint job!

The entry door on the column was modified to take an enclosure for the two vfds (one for spindle one for coolant motor). The coolant system has now been relocated externally after the incredibly unpleasant task of cleaning the sump – which we have vowed never to repeat – ever!

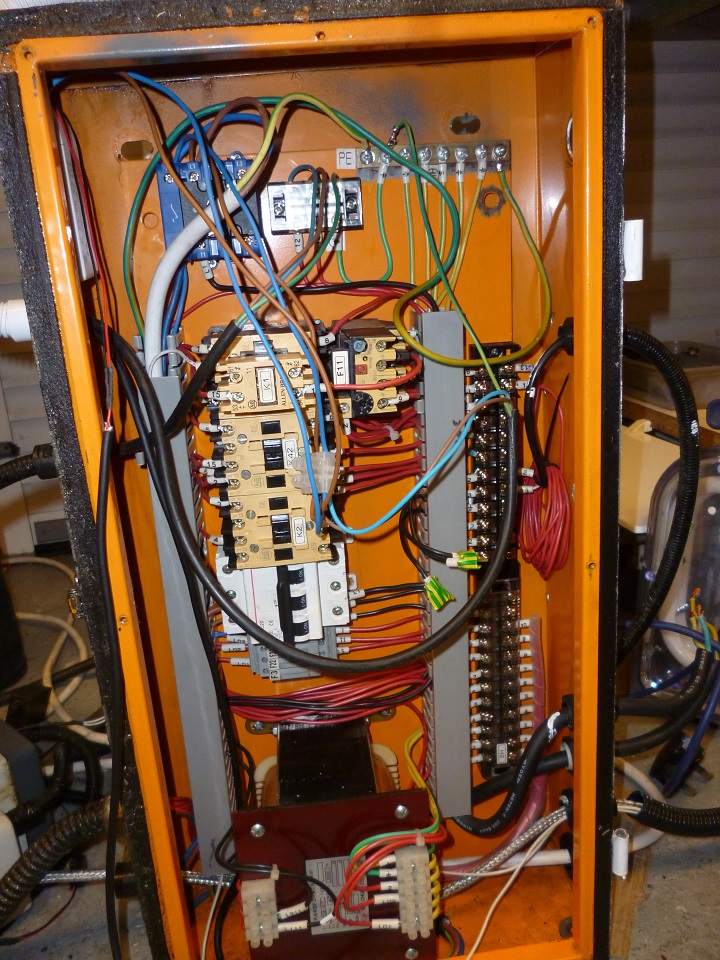

A new controller box has been made from an old van vault which has been resized and welded to bolt onto the side of the column to replace the original and give plenty of space for the controller, PC, servos and contactors etc. An overhead arm is currently being made to take the monitor, mouse and keyboard, along with an emergency stop and eventually a pushbutton power drawbar as an additional project.

Our lathe had a drip feed system that worked very well which has recently been upgraded to use the original single phase coolant pump and reservoir supplied when we bought the lathe new in 2014 (which drowned everything and then didn’t drain) with a SCR chopper circuit to control the flowrate. It now works pretty well for what we want, so we decided to use something similar for the mill.

The electronics are currently on the test bench. We went with Lichuan servos purchased on AliExpress from the manufacturers shop and have replaced the original Huangyang vfd that we used for the conversion to single phase with a Nflixin 9100 that outputs 380v 3 phase which is now being used on the test bench while the HY is used to get the mill up and running again manually so we can machine parts for the CNC conversion. We are running Debian 9 with linuxcnc 2.8.0-95, and have had quite a bit of success with the controller which is currently controlling spindle vfd, servo motors and limit switches etc successfully, and have got familiar with probe basic GUI and have been impressed so far.

The following user(s) said Thank You: tommylight, Sadmeatball

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

23 Dec 2020 18:58 #193004

by tommylight

Replied by tommylight on topic KRV2000 CNC Conversion

Just sweep those electronic under the table and be done with it !

Very nice, indeed, thank you for sharing.

Very nice, indeed, thank you for sharing.

Please Log in or Create an account to join the conversation.

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

24 Dec 2020 13:09 #193106

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Thanks tommylight

This is our first adventure with Linuxcnc, having only had experience with Mach3 and others on other machines we have built in the past, so get the popcorn, this may be tricky!

This is our first adventure with Linuxcnc, having only had experience with Mach3 and others on other machines we have built in the past, so get the popcorn, this may be tricky!

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

24 Dec 2020 13:32 #193109

by tommylight

Replied by tommylight on topic KRV2000 CNC Conversion

Mental note to self: check if there's enough popcorn in the cupboard above the microwave !

Thanks for reminding me, last i checked was 3 nights ago.

Thanks for reminding me, last i checked was 3 nights ago.

Please Log in or Create an account to join the conversation.

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

24 Dec 2020 20:15 #193144

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Few pics from earlier this afternoon, its a bit cold out in the workshop. Progress on the boom arm for the monitor, keyboard etc which is currently tack welded for mocking up prior to being welded permanently. The boom arm at the front of the mill sits lower than the lowest part of the ram to maintain the original machines flexibility with the turret. The idea is to thread the wiring for the keyboard, monitor etc through the box section to keep everything neat. The original electrical panel will be mounted on standoffs welded into the new control box along with a long thin panel to mount the servo drivers, Mesa boards and 24VDC PSU, and a cut down old PC case that serves as a carrier of the PC motherboard and PSU. Further updates in a few days.

We will probably be spending the cold snap with festivities and in mortal kombat with a pesky MPG!

Merry Xmas to all at Linuxcnc forum!

We will probably be spending the cold snap with festivities and in mortal kombat with a pesky MPG!

Merry Xmas to all at Linuxcnc forum!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

27 Dec 2020 23:57 #193323

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Despite this being our first time using Linux for anything, we have managed to get most of the control system working. However, we recently purchased a xhc whb04-6 pendant and have been trying to integrate it into the rest of the setup. This has been a bit of a nightmare – and I think we might need some help here.

We followed the instructions by talla83 as per LinuxCNC 2.8.0 & XHC-WHB04B-4 - Inbetriebnahme wireless handwheel -https://www.youtube.com/watch?v=e2DjkzCq7R4.

Run in command line:

halrun

loadusr xhc-whb04b-6 -ue

and all buttons work including the handwheel encoder.

As per alkabal’s suggestion I also run 2 terminal windows:

One with:

halrun

loadusr -W xhc-whb04b-6 -Hsf

Another with:

watch -n0.4 halcmd show pin whb

This shows that the buttons (although not all are listed), the scale and axis selection work but curiously the jog counts always stay at zero. Is this normal? As the previous method by talla83 shows the encoder wheel works.

Using axis sim and inserting the whb04b-6.hal file into it’s folder and adding the HALFILE in the axis.ini, the mpg also works fine as far as linuxcnc software can see it and shows movement on screen.

Whenever I try to use it with my configuration, the buttons work fine but the encoder wheel doesn’t work. Reading the pins in hal configuration, the encoder scale, axis selection also work fine but the encoder counts never register. As there isn’t a conventional hal file for axis sim, we are finding it difficult to see the difference so we can compare it with and debug our configuration.

After running several experiments, it seem that 3 lines of code about axis-select-<n> already being linked to halui.axis.select.<n> always cause a problem. I have tried hashing them out in the MPG hal file so that Linuxcnc starts up but the encoder wheel is disabled. I have tried numerous modifications to these lines in an attempt to make the encoder wheel work and have dedicated many hours of trying and have exhausted everything I can think of including suggestions on this forum.

I am wondering whether this can actually work for a real setup that isn’t a simulation, that the software driver for the pendant doesn’t fully work for whatever reason (I was short quite a few dependencies initially which now appears to be solved), or that I’m missing something so obvious it borders on dumbassery.

This is kind of a deal breaker on this project, as it is meant to be a key part of a cnc conversion. We don’t want to use a different MPG as this one has loads of functions that we can later program to do subroutines eg a toolsetter, probe etc, and a hardwired one would take up loads of inputs on the 7i76e, and also compromises some safety aspects of the build, despite introducing some latency which is manageable.

This is where you guys come in – I am now out of my depth here. Is there anyone out there who knows how to make this work and is willing to help me?

This is not the first cnc conversion we have done, but it is the first with linuxcnc. We are using Debian 9 and Linuxcnc 2.8.0-95 and probe basic as the GUI.

I have attached my ini, hal and mpg hal files for you to check and give comments, which hopefully will get me back on track.

Any help or suggestions would be greatly appreciated.

We followed the instructions by talla83 as per LinuxCNC 2.8.0 & XHC-WHB04B-4 - Inbetriebnahme wireless handwheel -https://www.youtube.com/watch?v=e2DjkzCq7R4.

Run in command line:

halrun

loadusr xhc-whb04b-6 -ue

and all buttons work including the handwheel encoder.

As per alkabal’s suggestion I also run 2 terminal windows:

One with:

halrun

loadusr -W xhc-whb04b-6 -Hsf

Another with:

watch -n0.4 halcmd show pin whb

This shows that the buttons (although not all are listed), the scale and axis selection work but curiously the jog counts always stay at zero. Is this normal? As the previous method by talla83 shows the encoder wheel works.

Using axis sim and inserting the whb04b-6.hal file into it’s folder and adding the HALFILE in the axis.ini, the mpg also works fine as far as linuxcnc software can see it and shows movement on screen.

Whenever I try to use it with my configuration, the buttons work fine but the encoder wheel doesn’t work. Reading the pins in hal configuration, the encoder scale, axis selection also work fine but the encoder counts never register. As there isn’t a conventional hal file for axis sim, we are finding it difficult to see the difference so we can compare it with and debug our configuration.

After running several experiments, it seem that 3 lines of code about axis-select-<n> already being linked to halui.axis.select.<n> always cause a problem. I have tried hashing them out in the MPG hal file so that Linuxcnc starts up but the encoder wheel is disabled. I have tried numerous modifications to these lines in an attempt to make the encoder wheel work and have dedicated many hours of trying and have exhausted everything I can think of including suggestions on this forum.

I am wondering whether this can actually work for a real setup that isn’t a simulation, that the software driver for the pendant doesn’t fully work for whatever reason (I was short quite a few dependencies initially which now appears to be solved), or that I’m missing something so obvious it borders on dumbassery.

This is kind of a deal breaker on this project, as it is meant to be a key part of a cnc conversion. We don’t want to use a different MPG as this one has loads of functions that we can later program to do subroutines eg a toolsetter, probe etc, and a hardwired one would take up loads of inputs on the 7i76e, and also compromises some safety aspects of the build, despite introducing some latency which is manageable.

This is where you guys come in – I am now out of my depth here. Is there anyone out there who knows how to make this work and is willing to help me?

This is not the first cnc conversion we have done, but it is the first with linuxcnc. We are using Debian 9 and Linuxcnc 2.8.0-95 and probe basic as the GUI.

I have attached my ini, hal and mpg hal files for you to check and give comments, which hopefully will get me back on track.

Any help or suggestions would be greatly appreciated.

Please Log in or Create an account to join the conversation.

- Benb

-

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 60

02 Jan 2021 02:51 #193791

by Benb

Replied by Benb on topic KRV2000 CNC Conversion

You gave the same signal two different names. I believe that is not allowed.

net axis-select-x halui.axis.x.select (in 1st file).

net pdnt.axis.x.select whb.halui.axis.x.select halui.axis.x.select (in 2nd file).

Either use axis-select-x or pdnt.axis.x.select but not both for the same signal.

net axis-select-x halui.axis.x.select (in 1st file).

net pdnt.axis.x.select whb.halui.axis.x.select halui.axis.x.select (in 2nd file).

Either use axis-select-x or pdnt.axis.x.select but not both for the same signal.

Please Log in or Create an account to join the conversation.

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

02 Jan 2021 11:52 #193832

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Thanks Benb, I will try that today and report back

Please Log in or Create an account to join the conversation.

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

02 Jan 2021 12:50 #193837

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Ok, assuming I have understood what you have suggested, I have tried the following:

1. Tried changing in Matilda001.hal

net axis-select-x halui.axis.x.select

to

net pdnt.axis.x.select halui.axis.x.select

result is that the mpg encoder wheel still doesnt work

2. Tried in Matilda001.hal hashing out

net axis-select-x halui.axis.x.select

result is still no joy with encoder wheel

When I have tried modifications to the hal files, I have opened the hal configuration window to watch for jog counts.

pdnt.axis.x.jog-counts

in signals section never displays any counts despite

pdnt.axis.x.jog-enable

and

pdnt.axis.x.jog-scale

functioning correctly.

I cant help feeling that I am being totally stupid and missing something obvious.

1. Tried changing in Matilda001.hal

net axis-select-x halui.axis.x.select

to

net pdnt.axis.x.select halui.axis.x.select

result is that the mpg encoder wheel still doesnt work

2. Tried in Matilda001.hal hashing out

net axis-select-x halui.axis.x.select

result is still no joy with encoder wheel

When I have tried modifications to the hal files, I have opened the hal configuration window to watch for jog counts.

pdnt.axis.x.jog-counts

in signals section never displays any counts despite

pdnt.axis.x.jog-enable

and

pdnt.axis.x.jog-scale

functioning correctly.

I cant help feeling that I am being totally stupid and missing something obvious.

Please Log in or Create an account to join the conversation.

- Benb

-

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 60

03 Jan 2021 00:02 #193905

by Benb

Replied by Benb on topic KRV2000 CNC Conversion

Don’t feel bad the pendants interface is a tough one. If you search the forum you will discover that you are not the only one having problems with pendants.

Now back to the problem you are having.

Comment out in matilda01.hal #net axis-select-x halui.axis.x.select

net pdnt.axis.x.jog-counts whb.axis.x.jog-counts axis.x.jog-counts

This part is correctly configured, and you should see activity if driver and hardware are working ok.

Are you using halscope? if not try it, its much better at monitoring pulse trains.

Now back to the problem you are having.

Comment out in matilda01.hal #net axis-select-x halui.axis.x.select

net pdnt.axis.x.jog-counts whb.axis.x.jog-counts axis.x.jog-counts

This part is correctly configured, and you should see activity if driver and hardware are working ok.

Are you using halscope? if not try it, its much better at monitoring pulse trains.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.329 seconds