KRV2000 CNC Conversion

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

03 Jan 2021 20:14 #193982

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Thanks Benb for the encouragement and continued input.

Ok. So I’ve spent a while familiarising myself with Halscope and have used it to monitor:

axis.x.jog-enable ,whb.halui.axis.x.select (on channels 1 and 2 respectively, which both synchronously give a signal when the axis select rotary switch on the MPG is turned to X)

At the same time:

pdnt.axis.x.jog-counts is monitored on channel 3 to monitor for pulses from the MPG jog wheel. None are ever recorded by halscope.

I have also hashed out the net axis-select-x halui.axis.x.select in Matilda001.hal file (including the corresponding ones for the other axes. Still the encoder wheel on the MPG does not work.

The MPG pendant tells me that it is sending a signal from the encoder wheel because it displays the "send" black dot matrix box icon next to the battery icon when the wheel is turned.

The hardware therefore appears to work as it should which leads me to conclude that there may be an issue with the driver. However, this does not explain why axis.sim configuration can respond to the MPG encoder wheel, unless of course, there is some way that axis.sim has a workaround.

This is as far as I have got so far, further comments and suggestions are very welcome.

Ok. So I’ve spent a while familiarising myself with Halscope and have used it to monitor:

axis.x.jog-enable ,whb.halui.axis.x.select (on channels 1 and 2 respectively, which both synchronously give a signal when the axis select rotary switch on the MPG is turned to X)

At the same time:

pdnt.axis.x.jog-counts is monitored on channel 3 to monitor for pulses from the MPG jog wheel. None are ever recorded by halscope.

I have also hashed out the net axis-select-x halui.axis.x.select in Matilda001.hal file (including the corresponding ones for the other axes. Still the encoder wheel on the MPG does not work.

The MPG pendant tells me that it is sending a signal from the encoder wheel because it displays the "send" black dot matrix box icon next to the battery icon when the wheel is turned.

The hardware therefore appears to work as it should which leads me to conclude that there may be an issue with the driver. However, this does not explain why axis.sim configuration can respond to the MPG encoder wheel, unless of course, there is some way that axis.sim has a workaround.

This is as far as I have got so far, further comments and suggestions are very welcome.

Please Log in or Create an account to join the conversation.

- Benb

-

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 60

04 Jan 2021 01:44 #194002

by Benb

Replied by Benb on topic KRV2000 CNC Conversion

pdnt.axis.jog-counts is connected to the raw pulse coming of the driver pin if you’re not getting any activity at that pin then I would think you have loaded the wrong driver or the hal program / the ini file is missing something. If you look at the 2.8 docs it shows 3 drivers for similar pendant (xhc-hb04-accels, xhc-hb04, xhc-whb04b-6) the developer of the 3rd driver is indicating that his driver was only tested with the 18 keys pendant and he is not sure about the 16 keys. I think your pendant looks similar to the xhc-whb04b-6, so make sure that you are loading the proper driver.

Question about your milling machine, does it have ball screws? if not, are you planning to install ballscrews? I have similar machine (Bridgeport clone) I was looking at ground ball screw on eBay, but the cost is more than I paid for the machine. So, I am looking at Chinese rolled ballscrews, but I am not sure how good they are. Do you have solution for the Z axis motor mount …?

Question about your milling machine, does it have ball screws? if not, are you planning to install ballscrews? I have similar machine (Bridgeport clone) I was looking at ground ball screw on eBay, but the cost is more than I paid for the machine. So, I am looking at Chinese rolled ballscrews, but I am not sure how good they are. Do you have solution for the Z axis motor mount …?

Please Log in or Create an account to join the conversation.

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

04 Jan 2021 12:55 #194031

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Thanks, Benb for your support. The pendant is the xhc-whb04b-6. At this point I think I am going to reinstall the driver, failing that there is always the sledgehammer method used by plenty of others on this forum for such occasions – the fresh install. If that doesn’t work, I am in deep trouble!

As for the mill, I have ordered some Taiwanese Gten C5 3205 ballscrews and FDID double ballnuts for the conversion from Motion Control Products here in the UK for the X and Y axes along with some FK/FF25 support bearings I have already got from a supplier in the Netherlands. The mounting plates will be made once I get the machine back together (it’s still in pieces at the moment for cleaning and inspection). I will do the end machining on the ballscrews myself. The Z axis will be a variation on the methods used by two CNC Zone forum members BMSTech and Muzzer who used a 1605 ballscrew mounted where the old quill trip screw was to reduce the flex found in some of the commercial designs where the ballscrew is mounted out away from the quill (www.cnczone.com/forums/knee-vertical-mills/105668-cnc-6.html). I already have a C5 1605 ballscrew left over from a previous project. It’s only a single 5/8” fine thread bolt IIRC mounting the ballscrew yoke to the quill in any case. This was an issue that we weren’t happy about from the start, but there is just not enough room in our workshop for a “small” bed mill (eg XYZ SMX2500, Southwestern Industries RX2 etc) and it would have needed to be disassembled (column removed) to get it in, otherwise we would have gone that route instead.

I’ll be posting more updates on here as the conversion progresses and I also started a thread on CNC Zone for the conversion with all the detailed mechanical non-Linux stuff (www.cnczone.com/forums/knee-vertical-mil...gineering-forum.html). I will continue to report back here on progress with the driver issues etc.

As for the mill, I have ordered some Taiwanese Gten C5 3205 ballscrews and FDID double ballnuts for the conversion from Motion Control Products here in the UK for the X and Y axes along with some FK/FF25 support bearings I have already got from a supplier in the Netherlands. The mounting plates will be made once I get the machine back together (it’s still in pieces at the moment for cleaning and inspection). I will do the end machining on the ballscrews myself. The Z axis will be a variation on the methods used by two CNC Zone forum members BMSTech and Muzzer who used a 1605 ballscrew mounted where the old quill trip screw was to reduce the flex found in some of the commercial designs where the ballscrew is mounted out away from the quill (www.cnczone.com/forums/knee-vertical-mills/105668-cnc-6.html). I already have a C5 1605 ballscrew left over from a previous project. It’s only a single 5/8” fine thread bolt IIRC mounting the ballscrew yoke to the quill in any case. This was an issue that we weren’t happy about from the start, but there is just not enough room in our workshop for a “small” bed mill (eg XYZ SMX2500, Southwestern Industries RX2 etc) and it would have needed to be disassembled (column removed) to get it in, otherwise we would have gone that route instead.

I’ll be posting more updates on here as the conversion progresses and I also started a thread on CNC Zone for the conversion with all the detailed mechanical non-Linux stuff (www.cnczone.com/forums/knee-vertical-mil...gineering-forum.html). I will continue to report back here on progress with the driver issues etc.

Please Log in or Create an account to join the conversation.

- Benb

-

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 60

05 Jan 2021 23:36 #194177

by Benb

Replied by Benb on topic KRV2000 CNC Conversion

Good news, some linuxcnc user got the same pendant as yours to work properly. MarcoGaspar with the help of Akabal got his pendant to work.

www.forum.linuxcnc.org/38-general-linuxc...king?start=90#164811

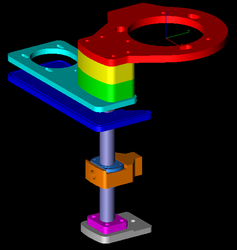

As far as the z axis I was planning to use 79TigerPilot member of the cnczone Quill assembly mount design. I have a copy of 79TigerPilot drawings and gcode files. He came out with a nifty design for the z axis; the red plate is sandwiched between top of the head and the body right below speed changer.

I did have chance to briefly look at the quill design from the link you sent me, seems achievable I will have look at that design once I get to that part of the project. Right now, planning to do the x and y axis to help me machine the parts for the z axis.

www.forum.linuxcnc.org/38-general-linuxc...king?start=90#164811

As far as the z axis I was planning to use 79TigerPilot member of the cnczone Quill assembly mount design. I have a copy of 79TigerPilot drawings and gcode files. He came out with a nifty design for the z axis; the red plate is sandwiched between top of the head and the body right below speed changer.

I did have chance to briefly look at the quill design from the link you sent me, seems achievable I will have look at that design once I get to that part of the project. Right now, planning to do the x and y axis to help me machine the parts for the z axis.

Attachments:

Please Log in or Create an account to join the conversation.

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

07 Jan 2021 12:33 #194355

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Thanks for the link, I had read through that thread for info, but it can get a bit confusing. I am going to try a couple of things in the next few days with the MPG to see if I can get it working. Otherwise I will do a fresh install.

I did see that design of quill you referenced when I looked into the conversion of the KRV first of all, but it was quite some time ago, so I will take another look at it. The knee conversion he did was also quite interesting. I have designed my own version of the quill to lessen the obstruction of the motor to the head tilt bolts and currently prototyping with some 3D printed parts. I will post the details on the build thread in due course.

I did see that design of quill you referenced when I looked into the conversion of the KRV first of all, but it was quite some time ago, so I will take another look at it. The knee conversion he did was also quite interesting. I have designed my own version of the quill to lessen the obstruction of the motor to the head tilt bolts and currently prototyping with some 3D printed parts. I will post the details on the build thread in due course.

Please Log in or Create an account to join the conversation.

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

07 Jan 2021 12:50 #194357

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Another interesting take on the quill conversion is www.hobby-machinist.com/threads/z-axis-cnc-conversion.21060/

A bit involved, but still interesting.

A bit involved, but still interesting.

Please Log in or Create an account to join the conversation.

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

07 Jan 2021 22:16 #194424

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Ok, I’m now getting a little weary of this.

I have done a fresh install of linuxcnc from the bootable usb. The original version was 2.7.14 on the usb stick so I used the buildbot repository to upgrade to 2.8. I now have 2.8.1 running happily and yet I am still getting exactly the same problem. No jog counts are ever registered except when:

1. I use a modified version of sim.axis with the pendant hal file in the configuration folder. This displays a happily running encoder wheel that moves the position on screen and DRO to wherever I choose. The pulses register on halscope and in whb section of pins.

2. I run loadusr xhc-whb04b-6 -ue from the terminal. This displays a list of “stuff” (responses) whenever I turn the encoder wheel, or indeed turn any rotary switch or push buttons on the MPG.

This doesn’t make sense. The driver, I understand, is already integrated with this version of linuxcnc, the hardware registers the fact that the pulses are being transmitted and according to the terminal command and the modified sim.axis configuration it works. The buttons always work but the encoder wheel doesn’t, except in the two above cases.

What am I missing?

I have done a fresh install of linuxcnc from the bootable usb. The original version was 2.7.14 on the usb stick so I used the buildbot repository to upgrade to 2.8. I now have 2.8.1 running happily and yet I am still getting exactly the same problem. No jog counts are ever registered except when:

1. I use a modified version of sim.axis with the pendant hal file in the configuration folder. This displays a happily running encoder wheel that moves the position on screen and DRO to wherever I choose. The pulses register on halscope and in whb section of pins.

2. I run loadusr xhc-whb04b-6 -ue from the terminal. This displays a list of “stuff” (responses) whenever I turn the encoder wheel, or indeed turn any rotary switch or push buttons on the MPG.

This doesn’t make sense. The driver, I understand, is already integrated with this version of linuxcnc, the hardware registers the fact that the pulses are being transmitted and according to the terminal command and the modified sim.axis configuration it works. The buttons always work but the encoder wheel doesn’t, except in the two above cases.

What am I missing?

Please Log in or Create an account to join the conversation.

- Benb

-

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 60

10 Jan 2021 00:57 #194661

by Benb

Replied by Benb on topic KRV2000 CNC Conversion

In matilda001.hal file at line 414 titled "HALUI SIGNALS" comment out all the signals from: LINE "net axis-select-x halui.axis.x.select" to LINE "net MDI-mode halui.mode.is-mdi". These signals are repeated in the pendant HAL file with different names. This change of signal names will cause interference with those signals.

If this does not work, try another configuration that use similar hardware to yours. see my previous memo for an example the user claims his configuration worked.

I would also suggest you open new topic in HAL section title to reflect your current problem. You might get better help from others in that section.

If this does not work, try another configuration that use similar hardware to yours. see my previous memo for an example the user claims his configuration worked.

I would also suggest you open new topic in HAL section title to reflect your current problem. You might get better help from others in that section.

Please Log in or Create an account to join the conversation.

- ChrissyAG

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 6

10 Jan 2021 01:19 #194665

by ChrissyAG

Replied by ChrissyAG on topic KRV2000 CNC Conversion

Thanks Benb, I really appreciate your response - it's gone 1:00am here in the UK and I have been trying different things to resolve this all day so I'm now heading for sleep. I will try what you have suggested tommorrow and let you know how I get on. If I cant resolve it with what you suggested, I will start a new thread in the HAL section.

Please Log in or Create an account to join the conversation.

- Benb

-

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 60

10 Jan 2021 05:44 - 10 Jan 2021 05:48 #194683

by Benb

Replied by Benb on topic KRV2000 CNC Conversion

Attached is a file showing the lines that need to be commented out in your matelda001.hal. The green highlighted lines are not configured in your xhc_whb04b_6.hal if you are planning to control the A axis from the pendant you may need to configure this part in matelda001.hal. For know focus on the count pins problem.

I had a look at couple of previous posts about the pendant, looks like you are not the only one pulling hair. The previous model had different pin configuration plus you have the 18 buttons and 16 buttons models and since we are dealing with user space USB driver there might be timing problem that will show up sporadically. Don’t feel bad you are dealing with a pandora box.

I had a look at couple of previous posts about the pendant, looks like you are not the only one pulling hair. The previous model had different pin configuration plus you have the 18 buttons and 16 buttons models and since we are dealing with user space USB driver there might be timing problem that will show up sporadically. Don’t feel bad you are dealing with a pandora box.

Last edit: 10 Jan 2021 05:48 by Benb.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.090 seconds