Retrofitting HURCO BMC30

- rasmus

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 3

26 Feb 2024 18:28 - 26 Feb 2024 18:29 #294541

by rasmus

Retrofitting HURCO BMC30 was created by rasmus

Hello, I got a Hurco BMC30 from my job for free so i could not say no...

It does work sporadically an locks up more often than not, but mechanically seems to be in good condition.

So my idea now is to simply retrofit it with Linux CNC.

Since I come from a automation background and works with engineering in general (mechanics, electronics and some coding on day to day basics) I have started to do new schematics an IO lists before i rip the old control system out which is a Ultimax 4 system.

The servos i got is Siemens servos, have not seen any other here on the forum that have Siemens system but anyway the machine will be better off with a new control system.

I have some initial questions about the way to go though.

I am planning to use MESA cards but have no clue what is the best choice is it best to use PCI cards like (6i25 or 5i25) or use ethernet based cards? I am aiming to use 7i77 and probably another IO card. Do not think there is enough IO:s on only the 7i77.

What is the best way to go?

It does work sporadically an locks up more often than not, but mechanically seems to be in good condition.

So my idea now is to simply retrofit it with Linux CNC.

Since I come from a automation background and works with engineering in general (mechanics, electronics and some coding on day to day basics) I have started to do new schematics an IO lists before i rip the old control system out which is a Ultimax 4 system.

The servos i got is Siemens servos, have not seen any other here on the forum that have Siemens system but anyway the machine will be better off with a new control system.

I have some initial questions about the way to go though.

I am planning to use MESA cards but have no clue what is the best choice is it best to use PCI cards like (6i25 or 5i25) or use ethernet based cards? I am aiming to use 7i77 and probably another IO card. Do not think there is enough IO:s on only the 7i77.

What is the best way to go?

Last edit: 26 Feb 2024 18:29 by rasmus.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

26 Feb 2024 21:35 #294547

by PCW

Replied by PCW on topic Retrofitting HURCO BMC30

The advantage of the PCI/PCIE cards is mainly simpler setup.

The PCI/PCIE cards also can typically run the servo loop faster

than the default 1 KHz, up to 4 KHz and above. This is

mainly an advantage if you have torque mode drives.

For the more common velocity mode drives, a 1 KHz

servo thread and Ethernet connected FPGA cards are fine.

Some advantages of Ethernet connected cards are

galvanic isolation of the PC from the machine and

the ability to use mini PCs and RPIs as the controller

since no PCI/PCIE slot is required.

The PCI/PCIE cards also can typically run the servo loop faster

than the default 1 KHz, up to 4 KHz and above. This is

mainly an advantage if you have torque mode drives.

For the more common velocity mode drives, a 1 KHz

servo thread and Ethernet connected FPGA cards are fine.

Some advantages of Ethernet connected cards are

galvanic isolation of the PC from the machine and

the ability to use mini PCs and RPIs as the controller

since no PCI/PCIE slot is required.

The following user(s) said Thank You: rasmus

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21364

- Thank you received: 7287

27 Feb 2024 00:02 #294558

by tommylight

Replied by tommylight on topic Retrofitting HURCO BMC30

forum.linuxcnc.org/30-cnc-machines/33529-hurco-bmc-20p-retrofit

Should be close enough, and you will need the ethernet version as the console is very far from the control box.

Configuration files included and some info on not removing the toolchanger board.

Should be close enough, and you will need the ethernet version as the console is very far from the control box.

Configuration files included and some info on not removing the toolchanger board.

The following user(s) said Thank You: rasmus

Please Log in or Create an account to join the conversation.

- rasmus

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 3

27 Feb 2024 19:31 - 27 Feb 2024 19:34 #294628

by rasmus

Replied by rasmus on topic Retrofitting HURCO BMC30

Thank you for the reply.

As you say the console is far away from the cabinet so having the computer close to the console would certainly solve a lot of problems. Was thinking of having a touch display as well which the touch is operated over USB. A solution could be using a repeater cable but this should then be tested before installing it in the machine.

I have seen your thread before and am a little confused.

I do not think my machine has a tool changer board, it has a relay board that I am currently trying to decide if it is going to be exchanged for DIN mounted relays the toolchanger should not be connected to that.

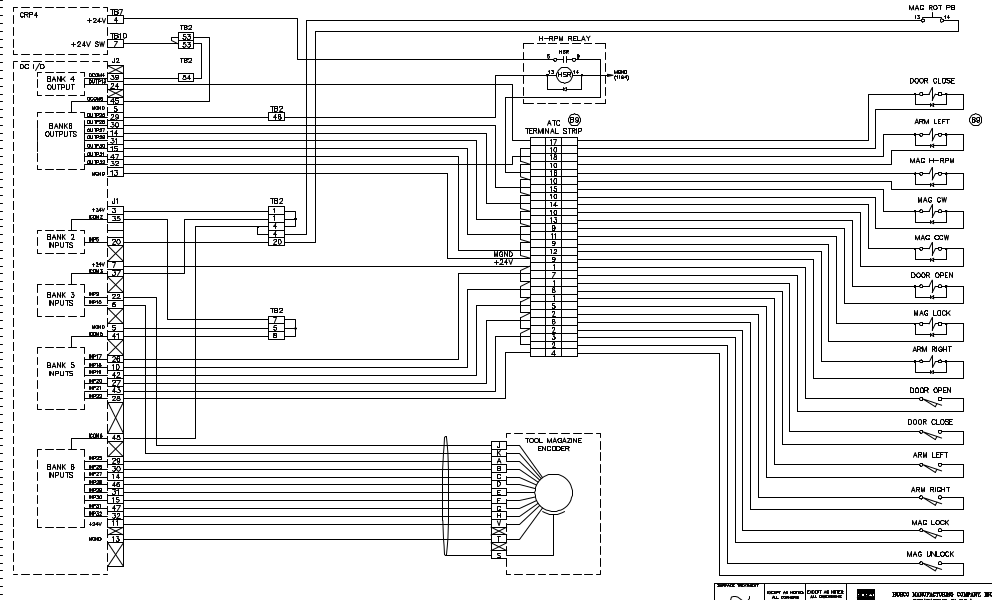

The toolchanger schematics for my machine looks like in the attachment, so it should just IOs i guess.

The ATC terminal strip I am currently not aware of where it is placed. Think it is on top of the machine on the toolchanger itself but could be wrong. Have not had the machine for that long so have not inspected it that close yet.

Will post the progress as it comes along, and will probably have more questions along the way.

As you say the console is far away from the cabinet so having the computer close to the console would certainly solve a lot of problems. Was thinking of having a touch display as well which the touch is operated over USB. A solution could be using a repeater cable but this should then be tested before installing it in the machine.

I have seen your thread before and am a little confused.

I do not think my machine has a tool changer board, it has a relay board that I am currently trying to decide if it is going to be exchanged for DIN mounted relays the toolchanger should not be connected to that.

The toolchanger schematics for my machine looks like in the attachment, so it should just IOs i guess.

The ATC terminal strip I am currently not aware of where it is placed. Think it is on top of the machine on the toolchanger itself but could be wrong. Have not had the machine for that long so have not inspected it that close yet.

Will post the progress as it comes along, and will probably have more questions along the way.

Attachments:

Last edit: 27 Feb 2024 19:34 by rasmus.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21364

- Thank you received: 7287

27 Feb 2024 19:56 #294635

by tommylight

Replied by tommylight on topic Retrofitting HURCO BMC30

I have the PC in the console, well a motherboard with no case, so everything regarding the PC is on the console and connects to the control cabinet by a single lan cable ( compared to hundreds of wires the original control used).

There is also a power cable for powering the PC and monitor.

There is also a power cable for powering the PC and monitor.

Please Log in or Create an account to join the conversation.

- Wieser

-

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 1

27 Feb 2024 21:00 #294643

by Wieser

Replied by Wieser on topic Retrofitting HURCO BMC30

I have a machine with Siemes Simudrives and servo motors. I also have the manuals for them, you can see pictures of it in the first page of this thread:

forum.linuxcnc.org/10-advanced-configura...error-spikes?start=0

If yours are similar I can send you some information.

forum.linuxcnc.org/10-advanced-configura...error-spikes?start=0

If yours are similar I can send you some information.

Please Log in or Create an account to join the conversation.

- rasmus

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 3

28 Feb 2024 19:19 #294716

by rasmus

Replied by rasmus on topic Retrofitting HURCO BMC30

Thank you for the advice, it certainly has it´s pros with this setup will have to consider this approach.

Please Log in or Create an account to join the conversation.

- rasmus

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 3

28 Feb 2024 19:37 #294719

by rasmus

Replied by rasmus on topic Retrofitting HURCO BMC30

@Wieser,

Yes my machine also has simodrive 611:s. Seems to be a littlebit diffrent setup though. The BMC has the encoder feedback hooked up to the controller, only the spindle feedback is hooked up directly to the drive.

I do not know is this is bennifitial, time will tell .

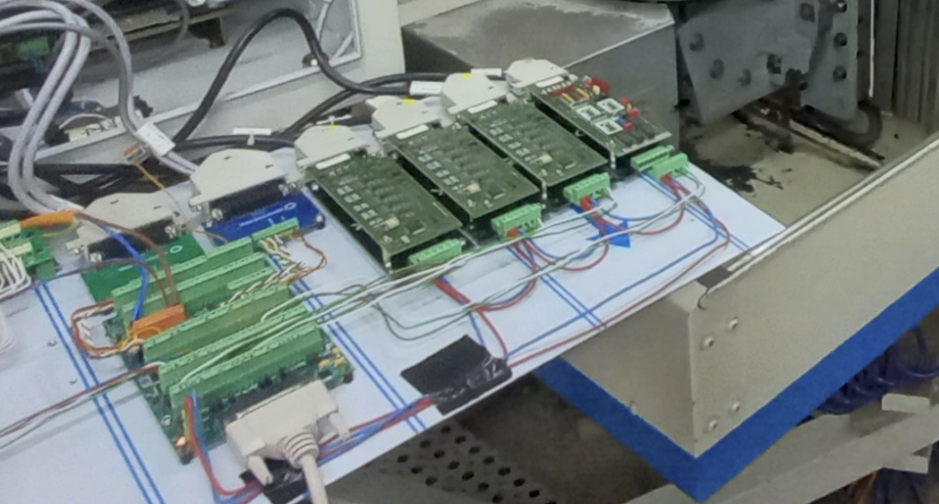

I saw a detail in your thread that i wounder a little about, specially in this these screen dump:

What are the boards to the right? Are these original from your machine or is it some special cards to hook up the cables for the drives?

Yes my machine also has simodrive 611:s. Seems to be a littlebit diffrent setup though. The BMC has the encoder feedback hooked up to the controller, only the spindle feedback is hooked up directly to the drive.

I do not know is this is bennifitial, time will tell .

I saw a detail in your thread that i wounder a little about, specially in this these screen dump:

What are the boards to the right? Are these original from your machine or is it some special cards to hook up the cables for the drives?

Attachments:

Please Log in or Create an account to join the conversation.

- Wieser

-

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 1

28 Feb 2024 21:14 - 28 Feb 2024 21:15 #294725

by Wieser

Replied by Wieser on topic Retrofitting HURCO BMC30

Those on top are the original Siemens Sinusoidal to TTL "EXEs". They were mounted inside the Siemens 820M Control.

I built simple PCB adapter cards with the correct DB-connector to interface the encoder scales to those in my setup and added a screw terminal for 5V power supply of the encoders and A, B and Index output.

In my case all axes including the spindle have a tacho feedback directly into the Simudrive and all the encoders were connected to the controller. If your encoders are similar (DB15 and same pinout), I have four of them left.

PS. if anyone sees that EXE at the right, that is for a rotating axis and it needs 15V on a specific pin to function correctly, that was a pain to find out.

PSS. If somebody has datasheets for those, they still would be highly appreciated since they have more pins to send a fault/hardware missing signal to the controller and I don’t have them incorporated yet.

I built simple PCB adapter cards with the correct DB-connector to interface the encoder scales to those in my setup and added a screw terminal for 5V power supply of the encoders and A, B and Index output.

In my case all axes including the spindle have a tacho feedback directly into the Simudrive and all the encoders were connected to the controller. If your encoders are similar (DB15 and same pinout), I have four of them left.

PS. if anyone sees that EXE at the right, that is for a rotating axis and it needs 15V on a specific pin to function correctly, that was a pain to find out.

PSS. If somebody has datasheets for those, they still would be highly appreciated since they have more pins to send a fault/hardware missing signal to the controller and I don’t have them incorporated yet.

Last edit: 28 Feb 2024 21:15 by Wieser.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rasmus

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 3

28 Apr 2024 17:54 #299263

by rasmus

Replied by rasmus on topic Retrofitting HURCO BMC30

Update of the Hurco retrofiting.

Did run it today with the old controller. It i runs but have issues with UI freezes up and going in to sleep in middle of programming.

So the new controller solution is needed before could use it to any serious jobs.

Regarding this ordered the mesa boards the other day but EU-Surplus did not have the 7i80 in stock, neither does Mesa them selves.

So the question is now should i wait for a 7i80 card or would it be possible to issue the like of two 7i92 instead?

I have read somewhere here on the forum that the real time UDP controller cards should be directly connected to the PC and not through any switch.

So with a setup of two 7i92 instead of a 7i80 then I need to use a switch in between. Would this work and is there risk to use such a setup instead?

I really have no real urgency in getting the machine ready so waiting a couple of months is okay as it is right now.

Did run it today with the old controller. It i runs but have issues with UI freezes up and going in to sleep in middle of programming.

So the new controller solution is needed before could use it to any serious jobs.

Regarding this ordered the mesa boards the other day but EU-Surplus did not have the 7i80 in stock, neither does Mesa them selves.

So the question is now should i wait for a 7i80 card or would it be possible to issue the like of two 7i92 instead?

I have read somewhere here on the forum that the real time UDP controller cards should be directly connected to the PC and not through any switch.

So with a setup of two 7i92 instead of a 7i80 then I need to use a switch in between. Would this work and is there risk to use such a setup instead?

I really have no real urgency in getting the machine ready so waiting a couple of months is okay as it is right now.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.360 seconds