Deckel-Maho DMU 50T

- Str8jacket

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 6

02 Sep 2024 10:00 #309202

by Str8jacket

Deckel-Maho DMU 50T was created by Str8jacket

Hi guys as the title says I am planning on retro-fit to my 1997 Deckel-Maho DMU 50T. It is a 3 axis machine with 2 manual axis’s on the table. 16pos ATC.

I was about to pull the trigger on a Centroid Oak system, but it appears they don't support my drives, so I got to more searching and found / re-found linuxcnc. So here I am, after searching this forum and watching some (many) youtube vids I think I am better off here. Below is copy pasted from my post over there.

My machine currently has the following controls and drives.

* Heidenhain TNC 426 cnc controller

* Siemens 611 drives fitted with a Heidenhain interface control card / board.

* Siemens Servo motors – 1FK6 series with 1Vpp encoders feed back direct to the TNC

* Siemens spindle motor - 1PH6 series with 1Vpp encoder fed back direct to the TNC

* Heidenhain LS486 linear scales on the X, Y, Z. +-5um accuracy ( I think, still looking for exact specs on these)

*Manual axis’s have Heidenhain ROD280 encoders on them both.

I have only just unloaded it from the truck, I have not yet had it powered up but it had been inspected and running before I bought it. I would like to change to a more modern system, hopefully the sale of all the TNC hardware will help too. It is in very good condition.

I have come up with the following solutions to the conversion requirements if you could please have a look and see if I am in the right direction.

1. I will need to remove the Heidenhain interface controls from the 611 and replace with a SIMODRIVE 611 HR universal controller 6SN1118-0NH01-0AA1, I am going to need 3 of these. From reading the Siemens functional manual on the 611 it appears I can wire the 1Vpp encoders to this control board and program a pass through for these signal which converts to TTL format which i can use with a Mesa board.

2. I “think” I can then control the 611 in velocity mode via analog signals +-10v

3. I have found an Aikron signal converter which can convert the scales and manual axis encoders to TTL to connect to the OAK via and expansion board www.aikrondro.com/product/signa ... a-and-ttl/ it would be good to see if these work as I have a total of 5 1Vpp encoders to read not including the ones on the servos. I have looked a the exe601? heidenhain ones and they appear to be pricey second hand.

A few things I am unsure of, it appears this machine uses the scale feed back as the hard limits not proximity switches, I cant see any other way it would do it with the hardware fitted. Can I do this with linuxcnc?

The 611 controls I am looking at have Nset ( which I have deciphered to mean analog control) and Positioning mode. It appears it can do position via digital inputs, but I would lose the encoder pass through option as they use those pins. It also has Positioning via Profibus DP.... can of worms Im sure.

Further to this, how does the controller control the spindle? Is it the same analog format? As it is the same control board in the 611.

How would the manual axis's integrate? Can this be utilised in conjunction with the servo encoder feed back / closed loop or is it just a DRO style output.

I have only begun looking at the mesa options, I am pretty sure I would go for the ethernet version 7197T as a start but I am still working through these options. I am going to sit down and fully map the IO on the mill so I can get a good picture of what I require. I have full schematics and manuals so I am very lucky in that regard. I have scanned both if any one has need of them.

There is probably more but this will get me started. More photos to come. Thanks Str8

I was about to pull the trigger on a Centroid Oak system, but it appears they don't support my drives, so I got to more searching and found / re-found linuxcnc. So here I am, after searching this forum and watching some (many) youtube vids I think I am better off here. Below is copy pasted from my post over there.

My machine currently has the following controls and drives.

* Heidenhain TNC 426 cnc controller

* Siemens 611 drives fitted with a Heidenhain interface control card / board.

* Siemens Servo motors – 1FK6 series with 1Vpp encoders feed back direct to the TNC

* Siemens spindle motor - 1PH6 series with 1Vpp encoder fed back direct to the TNC

* Heidenhain LS486 linear scales on the X, Y, Z. +-5um accuracy ( I think, still looking for exact specs on these)

*Manual axis’s have Heidenhain ROD280 encoders on them both.

I have only just unloaded it from the truck, I have not yet had it powered up but it had been inspected and running before I bought it. I would like to change to a more modern system, hopefully the sale of all the TNC hardware will help too. It is in very good condition.

I have come up with the following solutions to the conversion requirements if you could please have a look and see if I am in the right direction.

1. I will need to remove the Heidenhain interface controls from the 611 and replace with a SIMODRIVE 611 HR universal controller 6SN1118-0NH01-0AA1, I am going to need 3 of these. From reading the Siemens functional manual on the 611 it appears I can wire the 1Vpp encoders to this control board and program a pass through for these signal which converts to TTL format which i can use with a Mesa board.

2. I “think” I can then control the 611 in velocity mode via analog signals +-10v

3. I have found an Aikron signal converter which can convert the scales and manual axis encoders to TTL to connect to the OAK via and expansion board www.aikrondro.com/product/signa ... a-and-ttl/ it would be good to see if these work as I have a total of 5 1Vpp encoders to read not including the ones on the servos. I have looked a the exe601? heidenhain ones and they appear to be pricey second hand.

A few things I am unsure of, it appears this machine uses the scale feed back as the hard limits not proximity switches, I cant see any other way it would do it with the hardware fitted. Can I do this with linuxcnc?

The 611 controls I am looking at have Nset ( which I have deciphered to mean analog control) and Positioning mode. It appears it can do position via digital inputs, but I would lose the encoder pass through option as they use those pins. It also has Positioning via Profibus DP.... can of worms Im sure.

Further to this, how does the controller control the spindle? Is it the same analog format? As it is the same control board in the 611.

How would the manual axis's integrate? Can this be utilised in conjunction with the servo encoder feed back / closed loop or is it just a DRO style output.

I have only begun looking at the mesa options, I am pretty sure I would go for the ethernet version 7197T as a start but I am still working through these options. I am going to sit down and fully map the IO on the mill so I can get a good picture of what I require. I have full schematics and manuals so I am very lucky in that regard. I have scanned both if any one has need of them.

There is probably more but this will get me started. More photos to come. Thanks Str8

Attachments:

The following user(s) said Thank You: pommen, besriworld, Masiwood123, Unlogic

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

03 Sep 2024 13:07 #309287

by andypugh

With LinuxCNC I think this would be the normal soft-limit behaviour. But I am not clear how they are doing it?

Is there a separate limit track on the scale? Or are they absolute scales?

If neither of these are true, I can't see how it would work.

Replied by andypugh on topic Deckel-Maho DMU 50T

A few things I am unsure of, it appears this machine uses the scale feed back as the hard limits not proximity switches, I cant see any other way it would do it with the hardware fitted. Can I do this with linuxcnc?]

With LinuxCNC I think this would be the normal soft-limit behaviour. But I am not clear how they are doing it?

Is there a separate limit track on the scale? Or are they absolute scales?

If neither of these are true, I can't see how it would work.

The following user(s) said Thank You: Str8jacket

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

03 Sep 2024 18:11 #309298

by chris@cnc

Replied by chris@cnc on topic Deckel-Maho DMU 50T

The DMU 50 was very simple made. They had incremental scales and if you forgot to zero return or the scale was broken you could drive to the hard end. Usually works this fine, but if you want sure, you could set a limit switch at the end and wire these in e-stop chain.

Here the heidenhain reference.

product.heidenhain.de/JPBC/image/HWP.EN/...029-93_ls_703(c).pdf

product.heidenhain.de/JPBC/image/HWP.DE/...nr.318813-93_ls_703c).pdf

About Spindlecontrol i have no information.

And the manual axis could you set up very simple in the DRO. Link the encoder.X.position feedback to joint.X.motor-pos-fb and you should see it in DRO

Good luck. Very nice project

Here the heidenhain reference.

product.heidenhain.de/JPBC/image/HWP.EN/...029-93_ls_703(c).pdf

product.heidenhain.de/JPBC/image/HWP.DE/...nr.318813-93_ls_703c).pdf

About Spindlecontrol i have no information.

And the manual axis could you set up very simple in the DRO. Link the encoder.X.position feedback to joint.X.motor-pos-fb and you should see it in DRO

Good luck. Very nice project

The following user(s) said Thank You: Str8jacket

Please Log in or Create an account to join the conversation.

- Str8jacket

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 6

04 Sep 2024 10:56 #309346

by Str8jacket

Replied by Str8jacket on topic Deckel-Maho DMU 50T

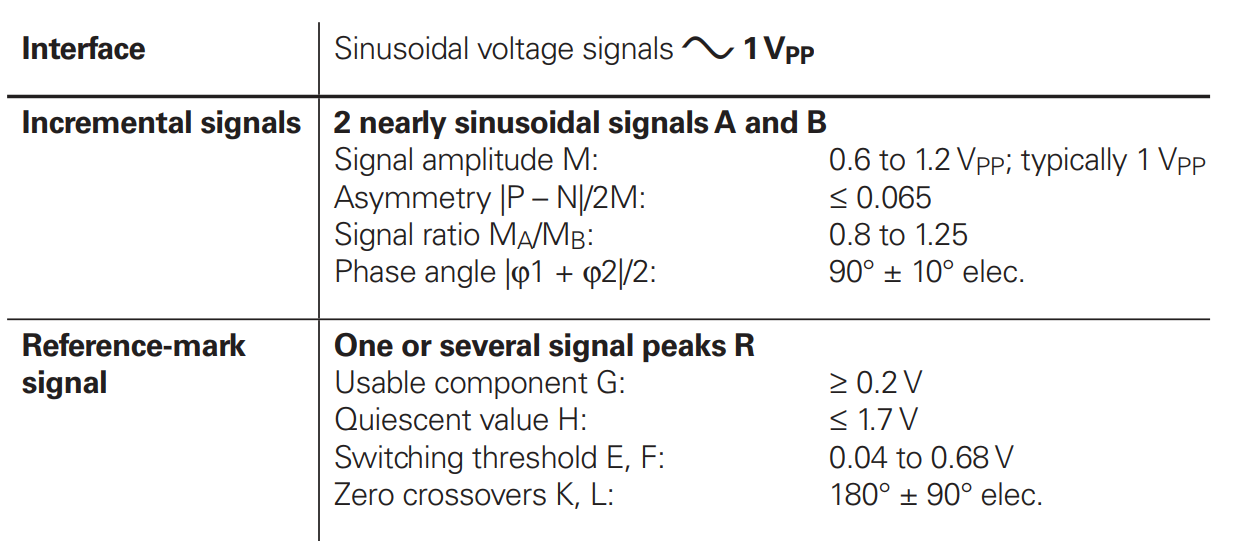

Well I have been researching the scales. It appears these scales LS486 are incremental scales 1Vpp output with a separate "R" output for reference position. It looks as though there is a reference pulse at each end 35mm from the full measuring length on one side and 70mm ish on the other, due to the reader position.

Someone here has already tackled these scales so i will post over on that thread and see how he went with them. linuxcnc scales index ref marks

This is the pin out on the schematic. I also found a pdf of the specs so that has helped. Not sure these can be a hard limits but can be used to home to set zero. It couldn't be to hard to add some hard wired limit proximity switches in as a safety?

The pulse on these sine/cos scales ref mark looks like it is only 0.5V, I am sure one of the input IO mesa boards said that the digital inputs could be set to something like 8bits resolution? hope I have the terminology right. So I should be able to program that pin to look for a set voltage difference to indicate zero etc? have I got that correct?

Thats enough for one post. Cheers Str8

Someone here has already tackled these scales so i will post over on that thread and see how he went with them. linuxcnc scales index ref marks

This is the pin out on the schematic. I also found a pdf of the specs so that has helped. Not sure these can be a hard limits but can be used to home to set zero. It couldn't be to hard to add some hard wired limit proximity switches in as a safety?

The pulse on these sine/cos scales ref mark looks like it is only 0.5V, I am sure one of the input IO mesa boards said that the digital inputs could be set to something like 8bits resolution? hope I have the terminology right. So I should be able to program that pin to look for a set voltage difference to indicate zero etc? have I got that correct?

Thats enough for one post. Cheers Str8

Please Log in or Create an account to join the conversation.

- Str8jacket

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 6

03 Oct 2024 09:27 #311217

by Str8jacket

Replied by Str8jacket on topic Deckel-Maho DMU 50T

Updating. I have purchased and received the 3 drive control modules for the Siemens 611 drives to convert from the Heidenhain interface to one that can do Analog inputs. I am assuming velocity control is the preffered method?

I have also tracked down a company in the US that makes a 1Vpp to TTL signal converter that can handle the linear scales input and also the 2 rotary encoders used for the table pivot and tilt feedback. Cost more than I would have liked but is much cheaper than new encoders. Realistically I think I may have been able to just run with out them and used the encoder feed back via the drives / servos. But they are there and may as well be utilised. The supplier sent this when I enquired.

"=11.0ptThe HEIDENHAIN LS 486C has a 20µm resolution glass which, as you correctly calculated, will produce a 10Khz signal at 12m/min. I have attached a data sheet showing the federate limits of each interpolation version for your reference. You can choose any interpolation option from 0.5x to 5x. The 5x interpolation model (SA 1872) will provide you with a 1µm TTL output signal. "

So that is the drive and encoder interface issues solved (yet to be implemented )

With the increasing global madness ongoing I am escalating my MESA purchases and any other overseas needs so I don't end up missing out. With that in mind I am at a loss for where to start. I have been reading the manuals on the MESA boards but like most newbies I have researched, I am still confused. My machine needs

I have also tracked down a company in the US that makes a 1Vpp to TTL signal converter that can handle the linear scales input and also the 2 rotary encoders used for the table pivot and tilt feedback. Cost more than I would have liked but is much cheaper than new encoders. Realistically I think I may have been able to just run with out them and used the encoder feed back via the drives / servos. But they are there and may as well be utilised. The supplier sent this when I enquired.

"=11.0ptThe HEIDENHAIN LS 486C has a 20µm resolution glass which, as you correctly calculated, will produce a 10Khz signal at 12m/min. I have attached a data sheet showing the federate limits of each interpolation version for your reference. You can choose any interpolation option from 0.5x to 5x. The 5x interpolation model (SA 1872) will provide you with a 1µm TTL output signal. "

So that is the drive and encoder interface issues solved (yet to be implemented )

With the increasing global madness ongoing I am escalating my MESA purchases and any other overseas needs so I don't end up missing out. With that in mind I am at a loss for where to start. I have been reading the manuals on the MESA boards but like most newbies I have researched, I am still confused. My machine needs

- Analog servo control x5 .... for 3 axis, maybe a 4th down the track and spindle

- 9 TTL encoder inputs, maybe 10 if the 4th axis gets added.

- OEM inputs currently 28

- OEM outputs currently 22

- Automatic tool changer control

- MPG / keyboard control station.

- 7I97T ethernet and motion control- 6 axis analog and encoders

- 7I85 serial interface x5 and encoder interface x 4

- 7I70, 7I71 input and output cards and a 7I73 pendant

- 7I94T instead of the 7I97T

- 7I83 analog servo interface

- 7I53 12 channel encoder board

- 7I70, 7I71 input and output cards and a 7I73 pendant

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

03 Oct 2024 13:40 #311230

by PCW

Replied by PCW on topic Deckel-Maho DMU 50T

Note that the 7I53 will not work with the 7I94T (its a 50 pin Daughtercard)

A 7I89 will but that only gives you 8 encoders

You might consider 2x 7I84 rather than 7i70+7I71 if you don't need

so much I/O (2x 7i84 would give you 64 inputs and 32 outputs)

A 7I89 will but that only gives you 8 encoders

You might consider 2x 7I84 rather than 7i70+7I71 if you don't need

so much I/O (2x 7i84 would give you 64 inputs and 32 outputs)

The following user(s) said Thank You: Str8jacket

Please Log in or Create an account to join the conversation.

- Str8jacket

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 6

03 Oct 2024 18:03 #311243

by Str8jacket

Replied by Str8jacket on topic Deckel-Maho DMU 50T

If there are no disadvantages to using the 7I97T I will just go that way. I will look at the different IO boards you've suggested. Thanks

Please Log in or Create an account to join the conversation.

- Str8jacket

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 6

05 Oct 2024 02:59 #311314

by Str8jacket

Replied by Str8jacket on topic Deckel-Maho DMU 50T

Am I correct in my selection in regard to the 7I85 being required with the 7I97T so I can have enough serial ports to connect the other IO cards? Ready to order otherwise.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

05 Oct 2024 03:31 #311315

by PCW

Replied by PCW on topic Deckel-Maho DMU 50T

Yes, a 7I85 will add 5 SSerial ports and 4 encoders to a 7I97T

The following user(s) said Thank You: Str8jacket

Please Log in or Create an account to join the conversation.

- JB-Motoring

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 0

19 Feb 2025 15:35 #321993

by JB-Motoring

Replied by JB-Motoring on topic Deckel-Maho DMU 50T

Hey mate,

how is the build going?

Did you manage to get the linear scales working?

BR

how is the build going?

Did you manage to get the linear scales working?

BR

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.195 seconds