- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

×

Forum Header

Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

- big wave

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

16 May 2017 14:36 #93262

by big wave

Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper was created by big wave

Hi everybody. Bit of a noob here.

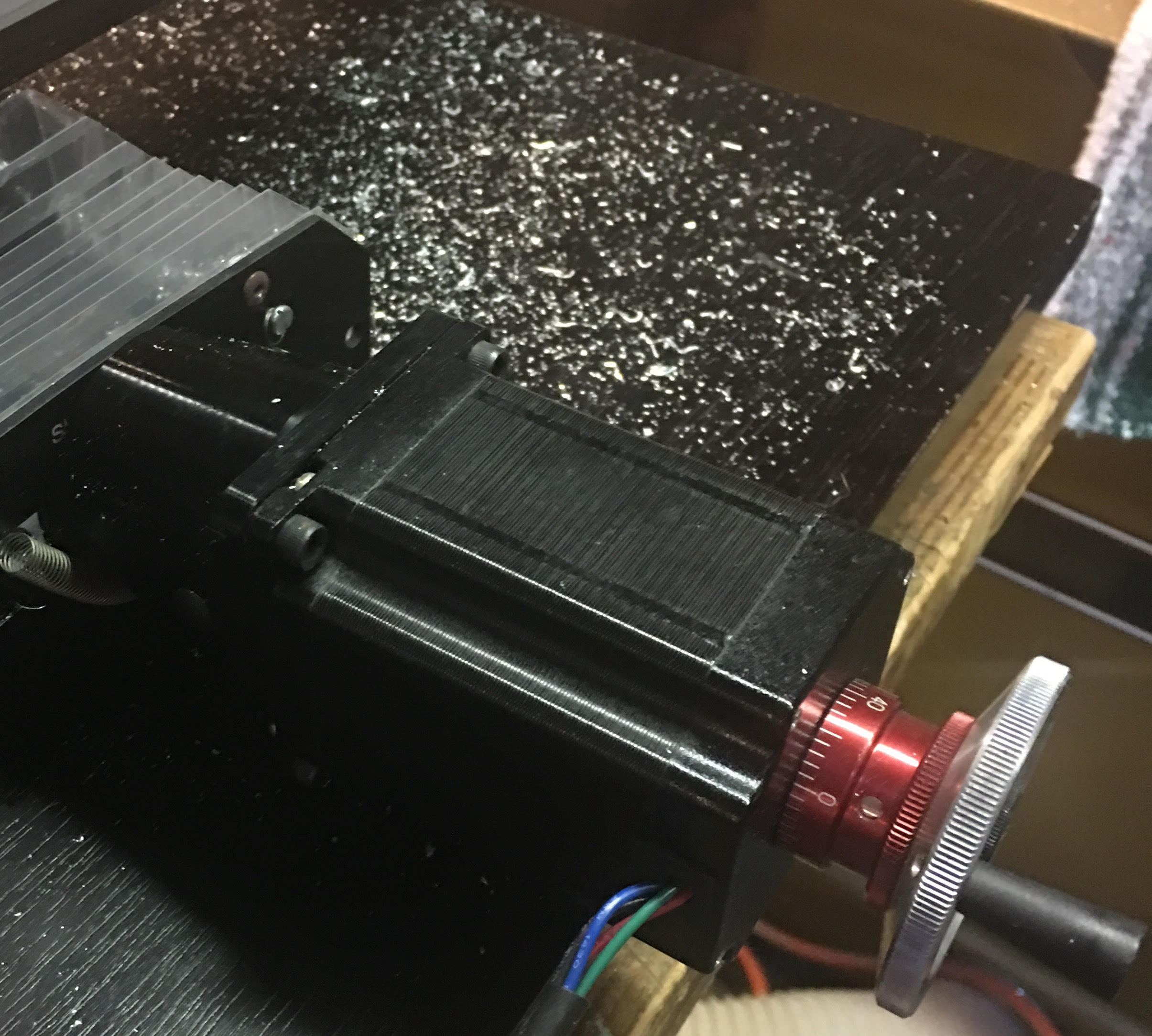

I got a second-hand Sherline 5400 mill with a Xylotex XS-3525/8S-4 controller and unmarked stepper motors. The calibration is off by about 50% [test travel for 1" only goes .5"]. The setup in Stepconf is using 200 Steps/Revolution, and 2 microsteps on each axis. I verified the lead screw thread pitch on the Sherline at 20 tpi with a direct 1:1 connection.

When I try testing the motor at 400 Steps/Rev and 2-Microsteps the Z-Axis works but X-stalls and generally complains. It seems like it's not going a full 1" but that may be an error in my observation while the axis is in motion- I'll do a more accurate measurement tomorrow.

I'm using the "Other" settings for the controller type and have set the timing to 1000, 1000, 200, 200 for Step Time, Step Space Direction Hold and Direction Setup, respectively. That seems to match the data on this site and the datasheet.

A few questions to the community:

Should the number of micro steps change the number of radians/degrees traversed if the steps per revolution is constant [e.g. 200 steps/rev set with (2, 4, or 8 micro steps) should be the same degrees traversed]? - I think not since micro steps should be incremental between a full step -- again, i 'm a bit of a noob wrt Steppers in general so please forgive my ignorance.

Also, how do you jog in single-step increments to test movement in absolute steps? -- I set the TPI on the Z-Axis to one and used the "Test this axis" GUI to "Run" with a "Test Area" of +-1" thinking that should traverse one full revolution if the calibration is correct. It seems close to one full rev when i set SPI to 400.

Any recommendations for setting up accurately given this setup with an unknown motor?

Thanks,

Dave

I got a second-hand Sherline 5400 mill with a Xylotex XS-3525/8S-4 controller and unmarked stepper motors. The calibration is off by about 50% [test travel for 1" only goes .5"]. The setup in Stepconf is using 200 Steps/Revolution, and 2 microsteps on each axis. I verified the lead screw thread pitch on the Sherline at 20 tpi with a direct 1:1 connection.

When I try testing the motor at 400 Steps/Rev and 2-Microsteps the Z-Axis works but X-stalls and generally complains. It seems like it's not going a full 1" but that may be an error in my observation while the axis is in motion- I'll do a more accurate measurement tomorrow.

I'm using the "Other" settings for the controller type and have set the timing to 1000, 1000, 200, 200 for Step Time, Step Space Direction Hold and Direction Setup, respectively. That seems to match the data on this site and the datasheet.

A few questions to the community:

Should the number of micro steps change the number of radians/degrees traversed if the steps per revolution is constant [e.g. 200 steps/rev set with (2, 4, or 8 micro steps) should be the same degrees traversed]? - I think not since micro steps should be incremental between a full step -- again, i 'm a bit of a noob wrt Steppers in general so please forgive my ignorance.

Also, how do you jog in single-step increments to test movement in absolute steps? -- I set the TPI on the Z-Axis to one and used the "Test this axis" GUI to "Run" with a "Test Area" of +-1" thinking that should traverse one full revolution if the calibration is correct. It seems close to one full rev when i set SPI to 400.

Any recommendations for setting up accurately given this setup with an unknown motor?

Thanks,

Dave

Please Log in or Create an account to join the conversation.

- big wave

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

16 May 2017 15:59 #93267

by big wave

Replied by big wave on topic Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

Update: after setting the max velocity to .2 from the default 1 its, things seems to smooth out and run accurately.

200 x 8 micro steps velocity .2 IPS acceleration 5 ip s2. Much more than .2 and the motors howl .. stalling. but I'm getting different behavior for the X versus Z -- Z axis seems a bit more tolerant at .4 ips. I'm still not getting why the micro steps are changing how may degrees of travel the motor is turning.

200 x 8 micro steps velocity .2 IPS acceleration 5 ip s2. Much more than .2 and the motors howl .. stalling. but I'm getting different behavior for the X versus Z -- Z axis seems a bit more tolerant at .4 ips. I'm still not getting why the micro steps are changing how may degrees of travel the motor is turning.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21098

- Thank you received: 7205

16 May 2017 17:05 #93270

by tommylight

Replied by tommylight on topic Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

Can you please post your hal and ini file so we can have a look?

Please Log in or Create an account to join the conversation.

- big wave

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

17 May 2017 01:10 #93289

by big wave

Replied by big wave on topic Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

Thanks,

Here are the files. I've got the IPS set at .2 and this seems to be smooth.

Here are the files. I've got the IPS set at .2 and this seems to be smooth.

# Generated by stepconf 1.1 at Tue May 16 09:25:09 2017

# If you make changes to this file, they will be

# overwritten when you run stepconf again

loadrt trivkins

loadrt [EMCMOT]EMCMOT base_period_nsec=[EMCMOT]BASE_PERIOD servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hal_parport cfg="0x378 out"

setp parport.0.reset-time 1000

loadrt stepgen step_type=0,0,0

loadrt pwmgen output_type=1

addf parport.0.read base-thread

addf stepgen.make-pulses base-thread

addf pwmgen.make-pulses base-thread

addf parport.0.write base-thread

addf parport.0.reset base-thread

addf stepgen.capture-position servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf stepgen.update-freq servo-thread

addf pwmgen.update servo-thread

net spindle-cmd-rpm => pwmgen.0.value

net spindle-on <= motion.spindle-on => pwmgen.0.enable

net spindle-pwm <= pwmgen.0.pwm

setp pwmgen.0.pwm-freq 100.0

setp pwmgen.0.scale 1166.66666667

setp pwmgen.0.offset 0.114285714286

setp pwmgen.0.dither-pwm true

net spindle-cmd-rpm <= motion.spindle-speed-out

net spindle-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-cmd-rps <= motion.spindle-speed-out-rps

net spindle-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-at-speed => motion.spindle-at-speed

net spindle-cw <= motion.spindle-forward

net estop-out => parport.0.pin-01-out

net xstep => parport.0.pin-02-out

setp parport.0.pin-02-out-reset 1

net xdir => parport.0.pin-03-out

net ystep => parport.0.pin-04-out

setp parport.0.pin-04-out-reset 1

net ydir => parport.0.pin-05-out

net zstep => parport.0.pin-06-out

setp parport.0.pin-06-out-reset 1

net zdir => parport.0.pin-07-out

net astep => parport.0.pin-08-out

setp parport.0.pin-08-out-reset 1

net adir => parport.0.pin-09-out

net spindle-cw => parport.0.pin-14-out

net spindle-pwm => parport.0.pin-16-out

net xenable => parport.0.pin-17-out

setp stepgen.0.position-scale [AXIS_0]SCALE

setp stepgen.0.steplen 1

setp stepgen.0.stepspace 0

setp stepgen.0.dirhold 21200

setp stepgen.0.dirsetup 21200

setp stepgen.0.maxaccel [AXIS_0]STEPGEN_MAXACCEL

net xpos-cmd axis.0.motor-pos-cmd => stepgen.0.position-cmd

net xpos-fb stepgen.0.position-fb => axis.0.motor-pos-fb

net xstep <= stepgen.0.step

net xdir <= stepgen.0.dir

net xenable axis.0.amp-enable-out => stepgen.0.enable

setp stepgen.1.position-scale [AXIS_1]SCALE

setp stepgen.1.steplen 1

setp stepgen.1.stepspace 0

setp stepgen.1.dirhold 21200

setp stepgen.1.dirsetup 21200

setp stepgen.1.maxaccel [AXIS_1]STEPGEN_MAXACCEL

net ypos-cmd axis.1.motor-pos-cmd => stepgen.1.position-cmd

net ypos-fb stepgen.1.position-fb => axis.1.motor-pos-fb

net ystep <= stepgen.1.step

net ydir <= stepgen.1.dir

net yenable axis.1.amp-enable-out => stepgen.1.enable

setp stepgen.2.position-scale [AXIS_2]SCALE

setp stepgen.2.steplen 1

setp stepgen.2.stepspace 0

setp stepgen.2.dirhold 21200

setp stepgen.2.dirsetup 21200

setp stepgen.2.maxaccel [AXIS_2]STEPGEN_MAXACCEL

net zpos-cmd axis.2.motor-pos-cmd => stepgen.2.position-cmd

net zpos-fb stepgen.2.position-fb => axis.2.motor-pos-fb

net zstep <= stepgen.2.step

net zdir <= stepgen.2.dir

net zenable axis.2.amp-enable-out => stepgen.2.enable

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

net tool-number <= iocontrol.0.tool-prep-number

net tool-change-loopback iocontrol.0.tool-change => iocontrol.0.tool-changed

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

dave@gmuncher:~/Desktop/sherline_Xylotex3525_8S4$ # Generated by stepconf 1.1 at Tue May 16 09:25:09 2017

# If you make changes to this file, they will be

# overwritten when you run stepconf again

[EMC]

MACHINE = sherline_Xylotex3525_8S4

DEBUG = 0

[DISPLAY]

DISPLAY = axis

EDITOR = gedit

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

ARCDIVISION = 64

GRIDS = 10mm 20mm 50mm 100mm 1in 2in 5in 10in

MAX_FEED_OVERRIDE = 1.2

MIN_SPINDLE_OVERRIDE = 0.5

MAX_SPINDLE_OVERRIDE = 1.2

DEFAULT_LINEAR_VELOCITY = 0.10

MIN_LINEAR_VELOCITY = 0

MAX_LINEAR_VELOCITY = 0.20

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/dave/linuxcnc/nc_files

INCREMENTS = .1in .05in .01in .005in .001in .0005in .0001in

PYVCP = custompanel.xml

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

BASE_PERIOD = 100000

SERVO_PERIOD = 1000000

[HAL]

HALUI = halui

HALFILE = sherline_Xylotex3525_8S4.hal

HALFILE = custom.hal

POSTGUI_HALFILE = custom_postgui.hal

[HALUI]

# add halui MDI commands here (max 64)

[TRAJ]

AXES = 3

COORDINATES = X Y Z

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_VELOCITY = 0.10

MAX_VELOCITY = 0.20

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 0.2

MAX_ACCELERATION = 15.0

STEPGEN_MAXACCEL = 18.75

SCALE = 32000.0

FERROR = 0.05

MIN_FERROR = 0.01

MIN_LIMIT = -0.01

MAX_LIMIT = 9.0

HOME_OFFSET = 0.0

[AXIS_1]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 0.2

MAX_ACCELERATION = 5.0

STEPGEN_MAXACCEL = 6.25

SCALE = 32000.0

FERROR = 0.05

MIN_FERROR = 0.01

MIN_LIMIT = -0.01

MAX_LIMIT = 4.0

HOME_OFFSET = 0.0

[AXIS_2]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 0.2

MAX_ACCELERATION = 5.0

STEPGEN_MAXACCEL = 6.25

SCALE = 32000.0

FERROR = 0.05

MIN_FERROR = 0.01

MIN_LIMIT = -9.0

MAX_LIMIT = 0.01

HOME_OFFSET = 0.0

dave@gmuncher:~/linuxcnc/configs/sherline_Xylotex3525_8S4$ Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21098

- Thank you received: 7205

17 May 2017 09:23 #93293

by tommylight

Replied by tommylight on topic Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

At a glance it all looks good. What drives? Xylotex or something else? Check the motor current on the drives, if they are nema 17 up to 1Amp should be ok, some can do more. Check if the motors get warm after 5 to 10 minutes of work or siting idle but locked, they should just start to get warm in that time frame. Can you turn the motors or screws by hand? Try that with motors off to check for binding, and with motors on to see how much torque they have at stand stil.

Regards,

Tom

Regards,

Tom

Please Log in or Create an account to join the conversation.

- big wave

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

18 May 2017 05:14 #93325

by big wave

Thanks Tom!. Things seem to be well behaved now. Last night, I was able to home the thing and dry run the Linux Logo program.

I had to reverse the Y and Z direction pins to the so the tool path directions aligned to the displayed coordinate system. At .2IPS everything seems to be working. I'm not sure what the steppers are.

-D

Replied by big wave on topic Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

At a glance it all looks good. What drives? Xylotex or something else? Check the motor current on the drives, if they are nema 17 up to 1Amp should be ok, some can do more. Check if the motors get warm after 5 to 10 minutes of work or siting idle but locked, they should just start to get warm in that time frame. Can you turn the motors or screws by hand? Try that with motors off to check for binding, and with motors on to see how much torque they have at stand stil.

Regards,

Tom

Thanks Tom!. Things seem to be well behaved now. Last night, I was able to home the thing and dry run the Linux Logo program.

I had to reverse the Y and Z direction pins to the so the tool path directions aligned to the displayed coordinate system. At .2IPS everything seems to be working. I'm not sure what the steppers are.

-D

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19754

- Thank you received: 4586

21 May 2017 00:39 #93411

by andypugh

Replied by andypugh on topic Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

The only real unknowns with mystery steppers is the wiring, the steps per rev (but anything other than 200 would be very unusual) and the current rating.

They turn, so the wiring is right, they go the right distance, so steps per rev is right, that just leaves current. You can increase the current setting until they get hot, then stop. Steppers get hotest when moving slowly (actually when stopped, but some drives reduce current when stopped). If the steppers don't actually burn you, then they are OK. But you might want to run a bit below that level if you don't need the performance.

They turn, so the wiring is right, they go the right distance, so steps per rev is right, that just leaves current. You can increase the current setting until they get hot, then stop. Steppers get hotest when moving slowly (actually when stopped, but some drives reduce current when stopped). If the steppers don't actually burn you, then they are OK. But you might want to run a bit below that level if you don't need the performance.

Please Log in or Create an account to join the conversation.

- big wave

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

21 May 2017 16:47 #93441

by big wave

Replied by big wave on topic Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

Thanks Andy,

Everything seems to be working but the feed rate seems quite slow or else the motors stall. I have the speed set at .2 ips. Lead screw on the Sherline is 20 turns/inch. Does that sound normal? The stepper motors look pretty beefy like they could handle more - but I cannot find any specs for these. The Xilotex controller specifies a max output of 2.5A at 35 volts max.

-Dave

Everything seems to be working but the feed rate seems quite slow or else the motors stall. I have the speed set at .2 ips. Lead screw on the Sherline is 20 turns/inch. Does that sound normal? The stepper motors look pretty beefy like they could handle more - but I cannot find any specs for these. The Xilotex controller specifies a max output of 2.5A at 35 volts max.

-Dave

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19754

- Thank you received: 4586

22 May 2017 14:28 #93478

by andypugh

So, the motors stall at 240 rpm? That is slightly low. (I had a machine that would only run to 300rpm). What supply voltage are you using for the drives?

You seem to have 4-wire steppers, so there is no scope for swapping to parallel wiring.

The slow speed is mainly due to the fine pitch of the screws, I think. Ballscrew machines tend to use 5 TPI or thereabouts.

Replied by andypugh on topic Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

Everything seems to be working but the feed rate seems quite slow or else the motors stall. I have the speed set at .2 ips. Lead screw on the Sherline is 20 turns/inch.

So, the motors stall at 240 rpm? That is slightly low. (I had a machine that would only run to 300rpm). What supply voltage are you using for the drives?

You seem to have 4-wire steppers, so there is no scope for swapping to parallel wiring.

The slow speed is mainly due to the fine pitch of the screws, I think. Ballscrew machines tend to use 5 TPI or thereabouts.

Please Log in or Create an account to join the conversation.

- big wave

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

22 May 2017 15:28 #93483

by big wave

Not sure, I will check later this eve. I got the controller already built with a power supply and assumed if was fine. I've seen a couple youtube videos showing a Sherline moving quite a bit faster than that.

Replied by big wave on topic Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

Everything seems to be working but the feed rate seems quite slow or else the motors stall. I have the speed set at .2 ips. Lead screw on the Sherline is 20 turns/inch.

So, the motors stall at 240 rpm? That is slightly low. (I had a machine that would only run to 300rpm). What supply voltage are you using for the drives?

You seem to have 4-wire steppers, so there is no scope for swapping to parallel wiring.

The slow speed is mainly due to the fine pitch of the screws, I think. Ballscrew machines tend to use 5 TPI or thereabouts.

Not sure, I will check later this eve. I got the controller already built with a power supply and assumed if was fine. I've seen a couple youtube videos showing a Sherline moving quite a bit faster than that.

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- Need Help Setting up: Sherline Mill + XS-3525/8S-4 + Mystery Stepper

Time to create page: 0.098 seconds