×

Forum Header

Wantai SS880 drivers with DB25-1205 BOB

- hIGGI

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 3

01 Mar 2019 21:06 #127459

by hIGGI

Wantai SS880 drivers with DB25-1205 BOB was created by hIGGI

Hello

I just got Wantai SS880 drivers, 86HBM80-1000-1 motors and DB25-1205 BOB

I wired it in and managed to get it turning in LinuxCNC.

Is there someone actually using this setup, and willing/able to provide best settings for both drivers, wiring and of course settings in linuxcnc configuration?

I am sure i will reach limits of the BOB and will eventually upgrade it to something more advance / faster (Mesa?), but for beginning, i would like to try setup i have now.

Plan is to use these motors in direct drive setup on RF45 clone benchtop milling machine, with double ballnut ballscrews (RM2005)

Thanks

I just got Wantai SS880 drivers, 86HBM80-1000-1 motors and DB25-1205 BOB

I wired it in and managed to get it turning in LinuxCNC.

Is there someone actually using this setup, and willing/able to provide best settings for both drivers, wiring and of course settings in linuxcnc configuration?

I am sure i will reach limits of the BOB and will eventually upgrade it to something more advance / faster (Mesa?), but for beginning, i would like to try setup i have now.

Plan is to use these motors in direct drive setup on RF45 clone benchtop milling machine, with double ballnut ballscrews (RM2005)

Thanks

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

02 Mar 2019 14:19 #127508

by pl7i92

Replied by pl7i92 on topic Wantai SS880 drivers with DB25-1205 BOB

your bob is limited to

2000

so best to go for stable is 2500 2500 5000 8000 in stepconf wizard

as on a BASE of 100000 Internal take your latency around 25000 up to max 150000

as on a Regular start tuning on 40 VEL 120ACC METRIC

go ut the ACC by 50 on a TEST movement 5mm +-

till it stals out

around 750 Shoudt be the MAX on 800Steps per mm

then set it to 550 ACC

and start Vel UP to the limit around 120mm/sec

reduce to 80 and you are a Fine working setup

2000

so best to go for stable is 2500 2500 5000 8000 in stepconf wizard

as on a BASE of 100000 Internal take your latency around 25000 up to max 150000

as on a Regular start tuning on 40 VEL 120ACC METRIC

go ut the ACC by 50 on a TEST movement 5mm +-

till it stals out

around 750 Shoudt be the MAX on 800Steps per mm

then set it to 550 ACC

and start Vel UP to the limit around 120mm/sec

reduce to 80 and you are a Fine working setup

Please Log in or Create an account to join the conversation.

- hIGGI

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 3

19 Jan 2020 19:37 #155178

by hIGGI

Replied by hIGGI on topic Wantai SS880 drivers with DB25-1205 BOB

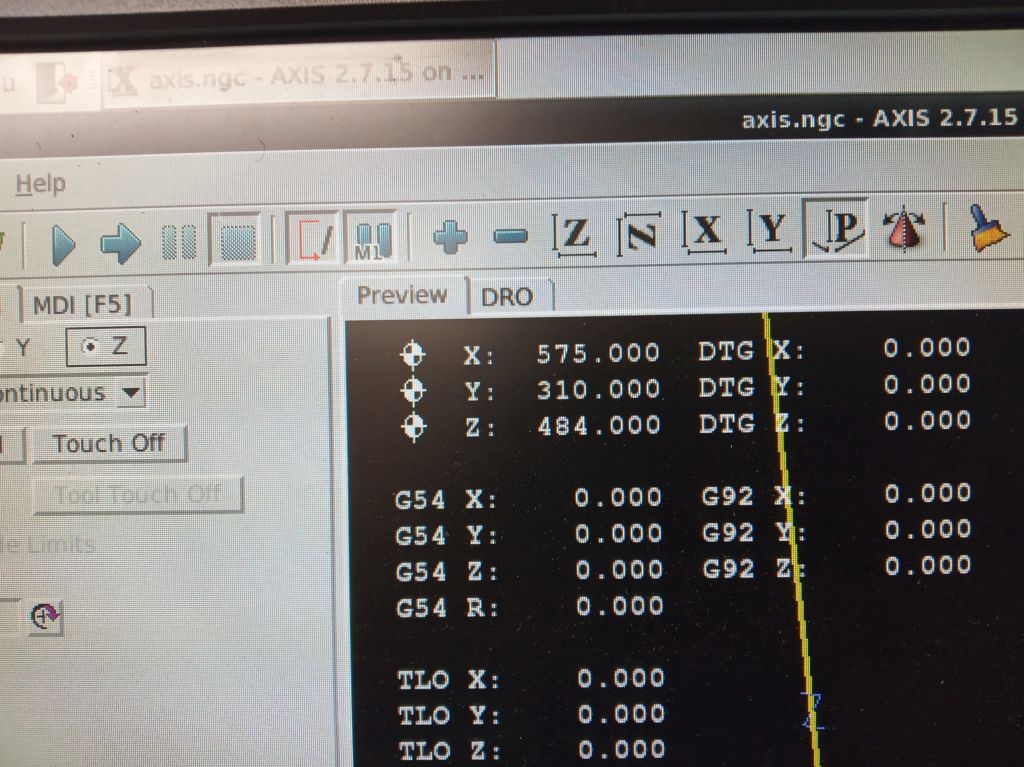

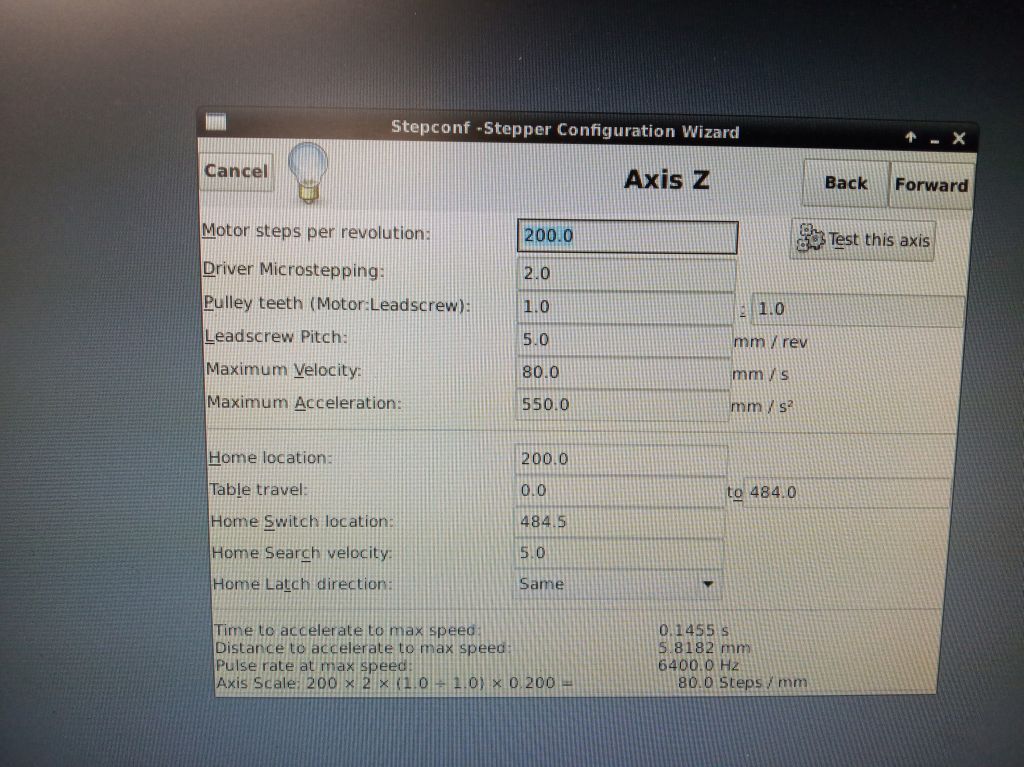

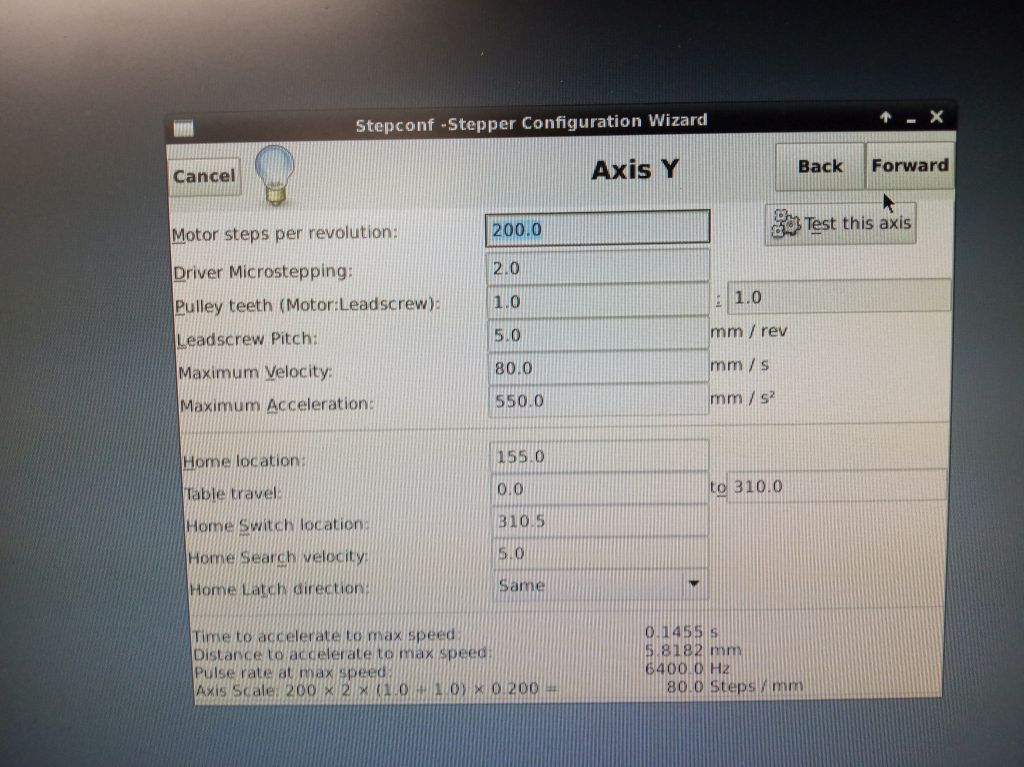

Here is my current setttings :

linuxcnc version 2.7.15

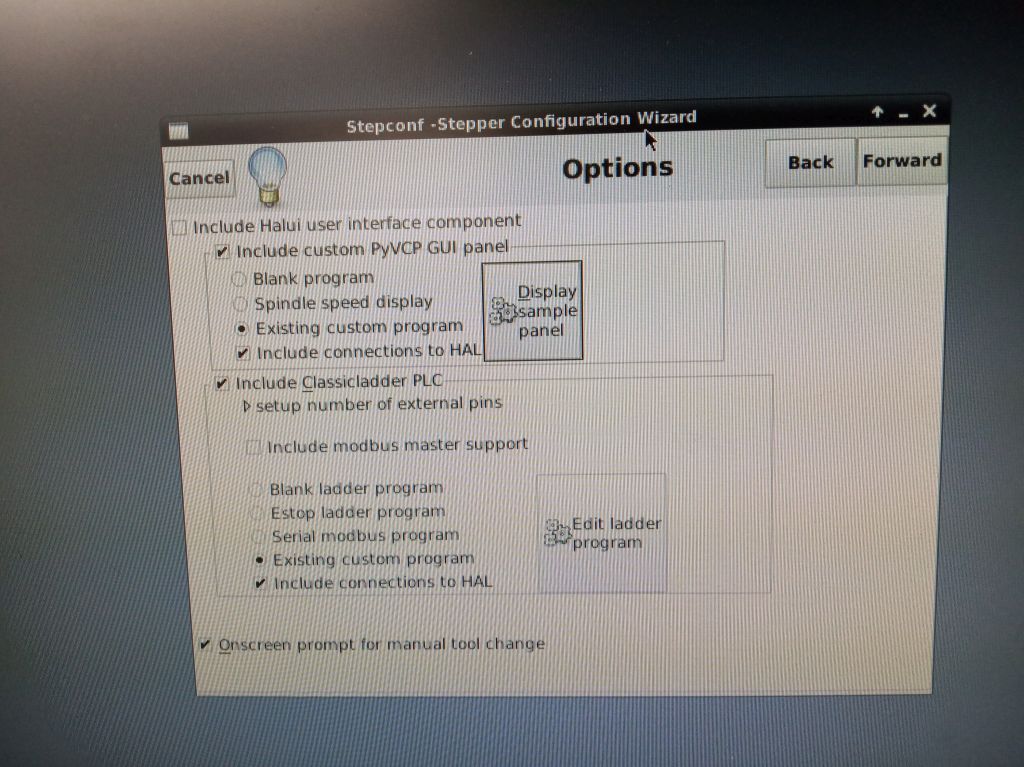

stepconf

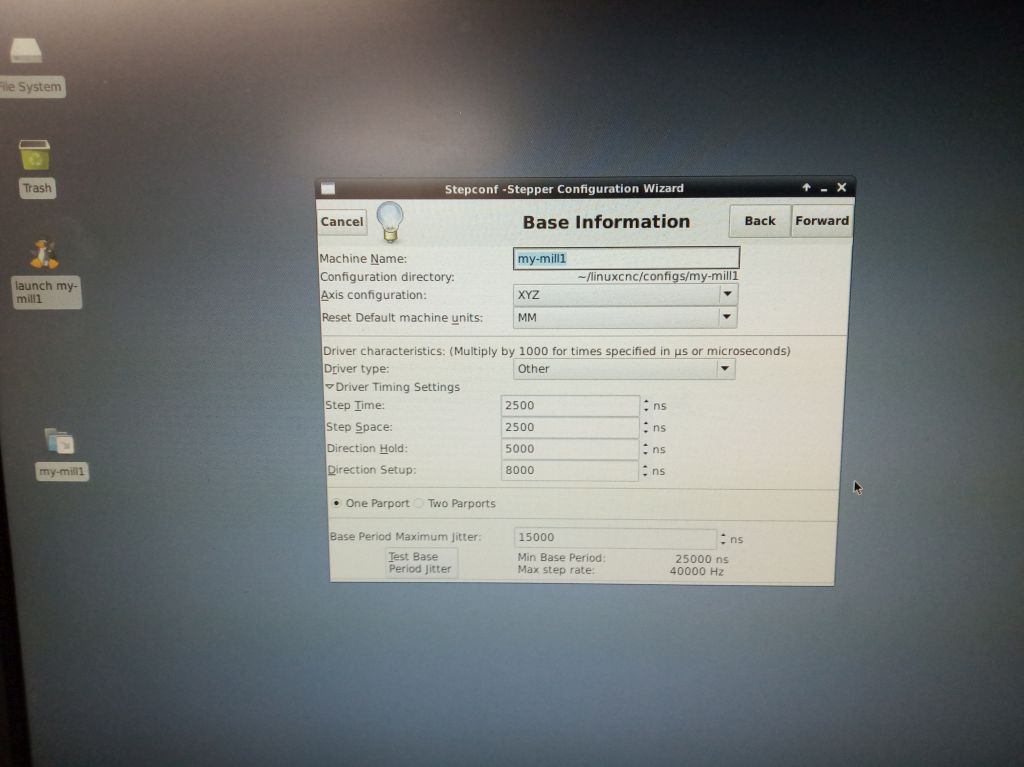

base info :

XYZ

MM

Other

5000

5000

20000

20000

one parport

base period 15000

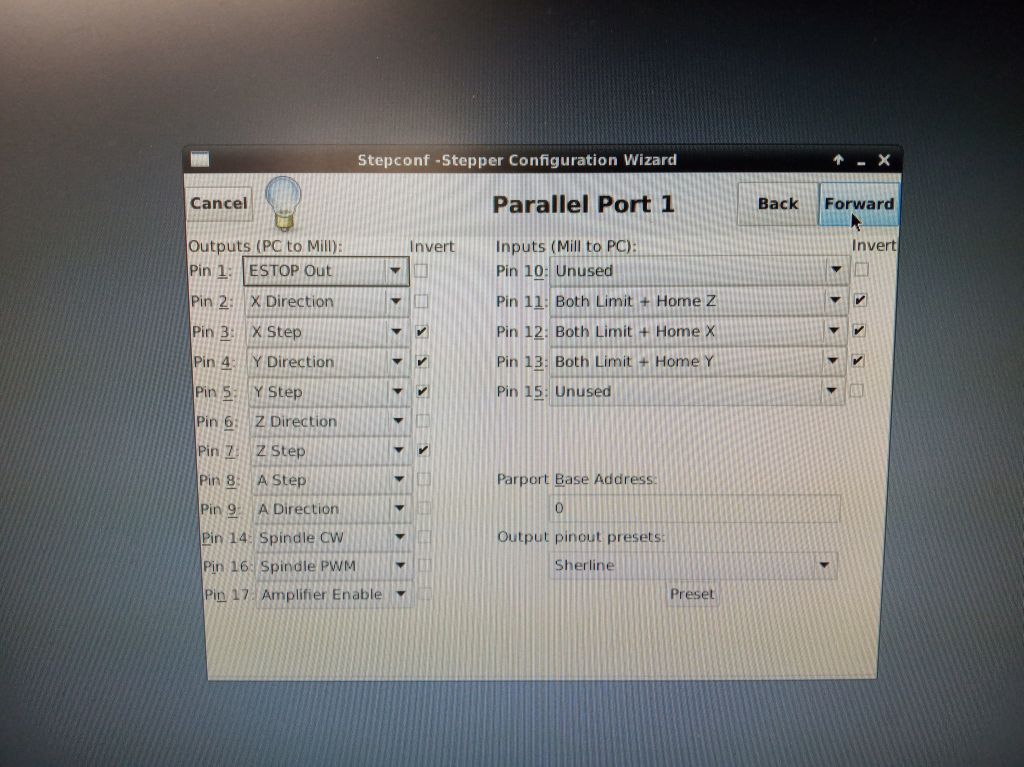

par port1

pin2 Y setp invert on

pin3 Y direction invert on

par port base 0

output pinout presets : Sherline

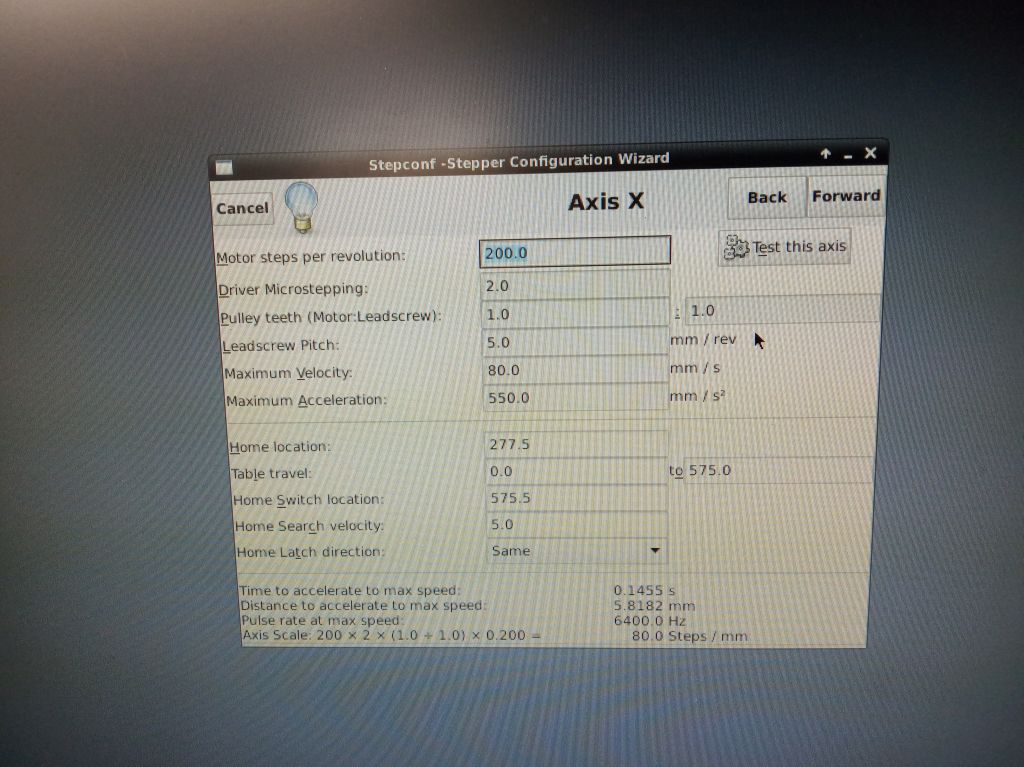

Axis Y setup

steps per revoltion 200

driver microstepping 2

ratio 1:1

pitch 5

max velocity 25

max accel 750

wiring :

on BOB P2 goes to PUL- , P3 goes to DIR-, 5V from BOB goes to PUL+ and DIR+

all dip switches on driver are down (ON)

SW1 = down edge

SW2 = CW

SW3,4,5,6 = default

things are moving, responding

next step is wiring and setting up proximity switches (PNP, NO) which i have mounted on each end of the travel ways

linuxcnc version 2.7.15

stepconf

base info :

XYZ

MM

Other

5000

5000

20000

20000

one parport

base period 15000

par port1

pin2 Y setp invert on

pin3 Y direction invert on

par port base 0

output pinout presets : Sherline

Axis Y setup

steps per revoltion 200

driver microstepping 2

ratio 1:1

pitch 5

max velocity 25

max accel 750

wiring :

on BOB P2 goes to PUL- , P3 goes to DIR-, 5V from BOB goes to PUL+ and DIR+

all dip switches on driver are down (ON)

SW1 = down edge

SW2 = CW

SW3,4,5,6 = default

things are moving, responding

next step is wiring and setting up proximity switches (PNP, NO) which i have mounted on each end of the travel ways

Please Log in or Create an account to join the conversation.

- hIGGI

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 3

19 Jan 2020 20:32 #155187

by hIGGI

Replied by hIGGI on topic Wantai SS880 drivers with DB25-1205 BOB

PNP NO switches wired in via 4N35 optocoupler

lj12a3--4-Z/BY

2 limit switches per axis

12V power

1kOhm resistor

12V to brown wire of switch

gnd to blue wire of switch + pin2 of octocoupler

black wire of switch via 1k resistor to pin1 of optocoupler

pin 5 of optocoupler to gnd of BOB signal in part

pin 4 if optocoupler to P13 on BOB

2 switches wired in parallel (black to black, blue to blue, brown to brown), using one optocoupler per axis

so far tested on the table, seems to work ok

homing sequence on the Y axis tested, of course will need to adjust on the machine

i will try to write/document my setup here for future reference

of course, if anybody sees anything out of ordinary or wrong settings, please comment

lj12a3--4-Z/BY

2 limit switches per axis

12V power

1kOhm resistor

12V to brown wire of switch

gnd to blue wire of switch + pin2 of octocoupler

black wire of switch via 1k resistor to pin1 of optocoupler

pin 5 of optocoupler to gnd of BOB signal in part

pin 4 if optocoupler to P13 on BOB

2 switches wired in parallel (black to black, blue to blue, brown to brown), using one optocoupler per axis

so far tested on the table, seems to work ok

homing sequence on the Y axis tested, of course will need to adjust on the machine

i will try to write/document my setup here for future reference

of course, if anybody sees anything out of ordinary or wrong settings, please comment

Please Log in or Create an account to join the conversation.

- hIGGI

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 3

22 Jan 2020 21:15 #155456

by hIGGI

Replied by hIGGI on topic Wantai SS880 drivers with DB25-1205 BOB

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

25 Jan 2020 17:05 #155737

by bbsr_5a

Replied by bbsr_5a on topic Wantai SS880 drivers with DB25-1205 BOB

Cool

why only 80steps per mm

get some Microstepping in to get over 100steps 0,01

on a RF45/50 you can use a Timing Belt system 20/25 Teeth I=1,25 to get the sfu2005 to a 400stepwide

dont forget to iincrease the BASE to 100000=100K as of the MACH3 5axis Board

and the REALY good Thing increase the MIN_Ferror to 0,25 and the Ferror to 4

You wont loose a Step but you can go G0 at full speed and as like a 3D printer BUF with very little StepsWIDTH in G1

doesent the 880 need 2800 MIN i got a Machine at 3200 running 6000mm/min at 1200ACC

why only 80steps per mm

get some Microstepping in to get over 100steps 0,01

on a RF45/50 you can use a Timing Belt system 20/25 Teeth I=1,25 to get the sfu2005 to a 400stepwide

dont forget to iincrease the BASE to 100000=100K as of the MACH3 5axis Board

and the REALY good Thing increase the MIN_Ferror to 0,25 and the Ferror to 4

You wont loose a Step but you can go G0 at full speed and as like a 3D printer BUF with very little StepsWIDTH in G1

doesent the 880 need 2800 MIN i got a Machine at 3200 running 6000mm/min at 1200ACC

Please Log in or Create an account to join the conversation.

- hIGGI

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 3

25 Jan 2020 17:18 #155739

by hIGGI

Replied by hIGGI on topic Wantai SS880 drivers with DB25-1205 BOB

Honestly in lot of cases i am not sure about lot of things.

Right now i want to get gmoccapy and probe app running and there is still more hardware adjustments to be made. Not planning on belt drive.

By mircostepping u mean adjustmens in software or at the drivers? (dip switches)

I will try suggested changes, thanks!

Right now i want to get gmoccapy and probe app running and there is still more hardware adjustments to be made. Not planning on belt drive.

By mircostepping u mean adjustmens in software or at the drivers? (dip switches)

I will try suggested changes, thanks!

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

26 Jan 2020 13:07 #155806

by bbsr_5a

Replied by bbsr_5a on topic Wantai SS880 drivers with DB25-1205 BOB

the DIP swiches and the software

if you got 400Steps Per Rev set and Scale is 80

use 800 DIP and 160 Software that will give yu more precice and Faster ACC

if you got 400Steps Per Rev set and Scale is 80

use 800 DIP and 160 Software that will give yu more precice and Faster ACC

Please Log in or Create an account to join the conversation.

- hIGGI

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 3

27 Jan 2020 19:39 #155942

by hIGGI

Replied by hIGGI on topic Wantai SS880 drivers with DB25-1205 BOB

I just tried DIP settings to 800 and changed 160 scale and its maybe too fast, because its throwing out following error after sudden stop. Reverted back to 400/ 80

As well Z axis needs slow down, without air struts/counterweight its stalling motor/driver.

I am still fooling around with it, will post the ini files once i get it closer to useable state.

As well Z axis needs slow down, without air struts/counterweight its stalling motor/driver.

I am still fooling around with it, will post the ini files once i get it closer to useable state.

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

28 Jan 2020 11:19 - 28 Jan 2020 11:23 #155994

by bbsr_5a

Replied by bbsr_5a on topic Wantai SS880 drivers with DB25-1205 BOB

if it is a small machine around 1meter less ad you are on Direct mount Steper no Timingbelt

yuu shoudt consider no more then VEL 40 and ACC 120

the MIN Ferror to 0,25 the MAX to 2

then you are able to get full speed within 0,3mm at 400steps 5mm pitch

from there you can go 800/160 and testout

the Z shoudt always be at 20VEL 80ACC with a 120StepgenACC

then it is up to you to test the max and do a 75% downconfig

if you want a High Speed drill press you need "more /Better gardware and Mashine Setings "

Like 72V DM556 or beter Mesa 7i96 /7i76 Timingbelt Driven 4Nm Nema 24 steppers or above to get to WORKNIG Milling 100VEL at 750ACC

THe RF50+ Mashine Type has quite a mass on Z

so the Direct Drive causes the Stepper in the First step to pull the max A out of the SS880 they dont provide this the internal on datasheet is 10%-25% 33% 50% 80% 100% stepup

from deep standby so take the ACC down and you wll be in good setup

AS Well as you dont need that mutch WAY

yuu shoudt consider no more then VEL 40 and ACC 120

the MIN Ferror to 0,25 the MAX to 2

then you are able to get full speed within 0,3mm at 400steps 5mm pitch

from there you can go 800/160 and testout

the Z shoudt always be at 20VEL 80ACC with a 120StepgenACC

then it is up to you to test the max and do a 75% downconfig

if you want a High Speed drill press you need "more /Better gardware and Mashine Setings "

Like 72V DM556 or beter Mesa 7i96 /7i76 Timingbelt Driven 4Nm Nema 24 steppers or above to get to WORKNIG Milling 100VEL at 750ACC

THe RF50+ Mashine Type has quite a mass on Z

so the Direct Drive causes the Stepper in the First step to pull the max A out of the SS880 they dont provide this the internal on datasheet is 10%-25% 33% 50% 80% 100% stepup

from deep standby so take the ACC down and you wll be in good setup

AS Well as you dont need that mutch WAY

Last edit: 28 Jan 2020 11:23 by bbsr_5a.

Please Log in or Create an account to join the conversation.

Time to create page: 0.294 seconds