×

Forum Header

CNC4030Z-S setup

- CNCPL

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

18 Jan 2020 17:56 #155106

by CNCPL

CNC4030Z-S setup was created by CNCPL

Hello,

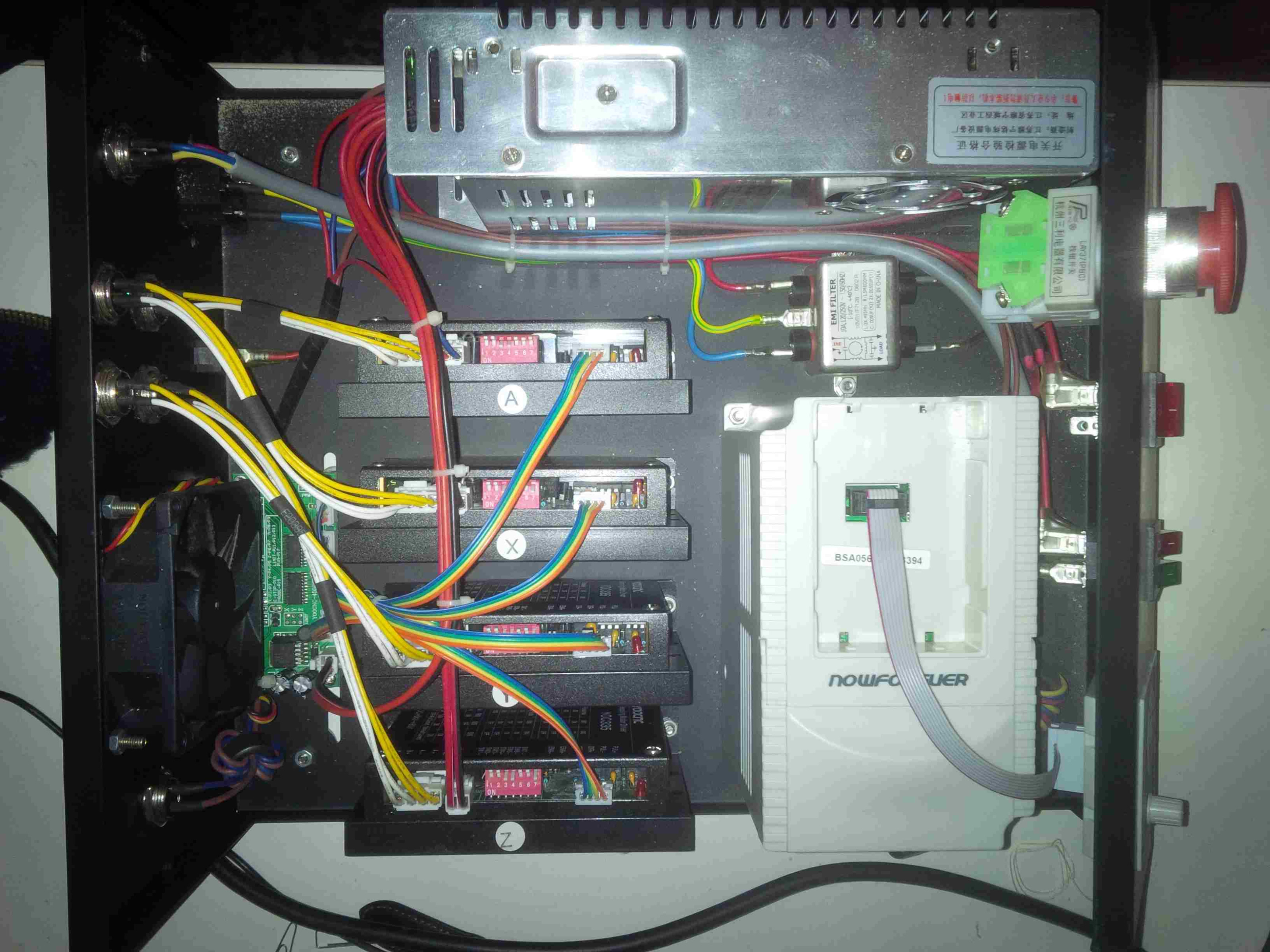

Can anyone help with the StepConf setup for my machine? It's a small Chinese (Shenzhen Liyang Welding Equipment Ltd?) 4-axis gantry router. Importing the Mach3 configuration file in the StepConf Wizard didn't work. There were no error messages, but neither were the fields populated with Mach3 values, so I decided to do a fresh setup. I use the 2.7.* branch of LinuxCNC, updated today.

The Chinese manufacturers/sellers are notorious for not providing a detailed list of the machine's components and their specifications, so I both looked inside the controller box to find out more and read the LinuxCNC documentation and forum posts. Yet there still are things I don't understand. Anyway, here's the Mach3 settings that I got from the seller (in metric units; Steps per, Velocity, Acceleration, Step Pulse, Dir Pulse):

X 320, 2500, 200, 3, 1

Y 320, 2500, 200, 3, 1

Z 320, 700, 150, 3, 1

A 13.33, 500, 100, 3, 5

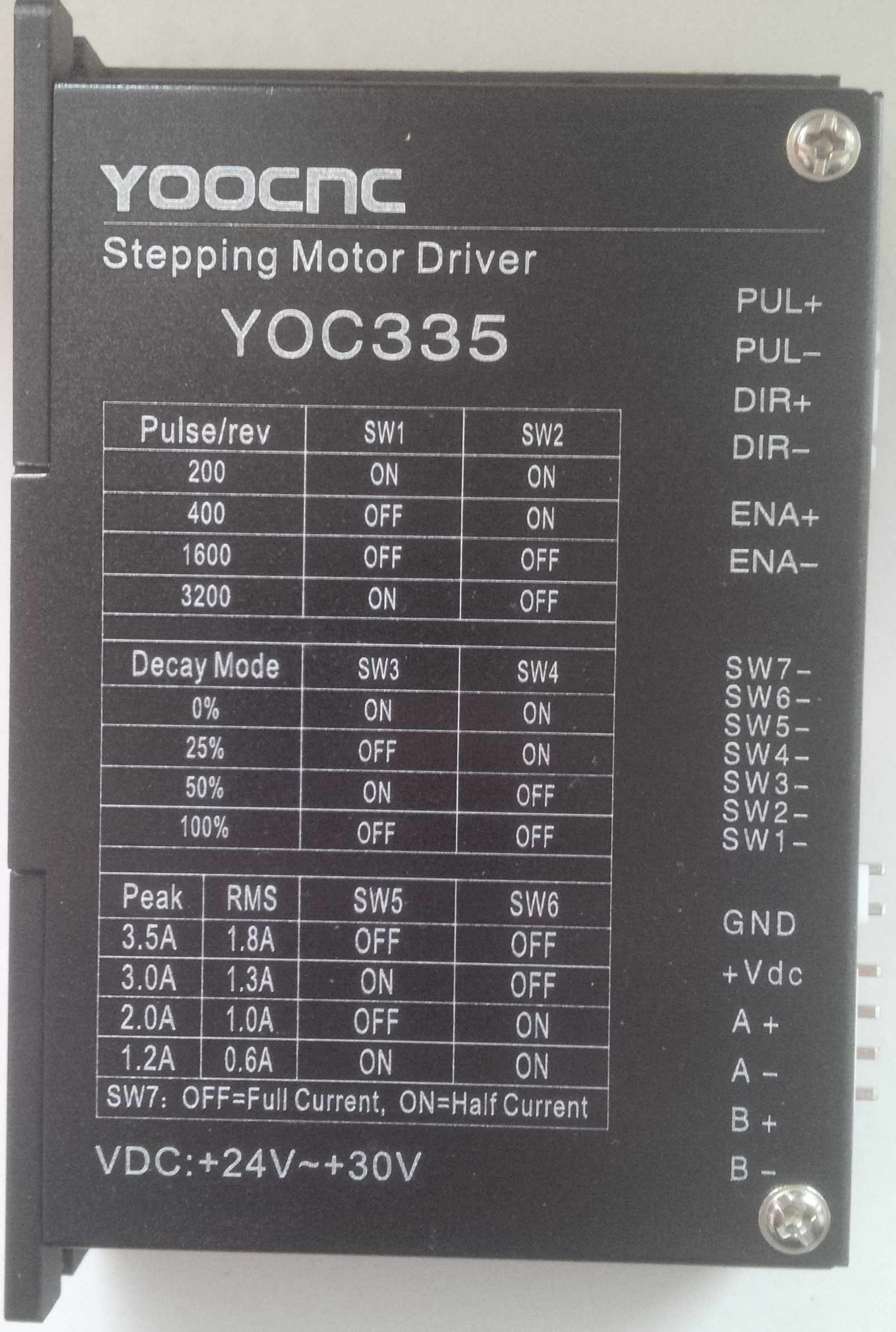

The driver is YOC335 (based on the TOSHIBA TB6560AHQ JAPAN 418GA1 chip).

What values would you recommend for Step Space, Step Time, Direction Hold and Direction Setup? Are these in any way related to the Mach3's Step Pulse and Dir Pulse?

The Base Period Maximum Jitter is 34665.

Here's the parallel port Motor Outputs setup in Mach3 (does 'Step Low=yes' equal to checking the 'Invert' box in StepConf Wizard?):

X Axis enabled=yes, Step Pin#=2, Dir Pin#=3, Dir Low=no, Step Low=yes

Y Axis enabled=yes, Step Pin#=4, Dir Pin#=5, Dir Low=no, Step Low=yes

Z Axis enabled=yes, Step Pin#=6, Dir Pin#=7, Dir Low=no, Step Low=yes

A Axis enabled=yes, Step Pin#=8, Dir Pin#=9, Dir Low=no, Step Low=yes

Input Signals:

EStop enabled=yes, Pin Number=10, Active Low=yes

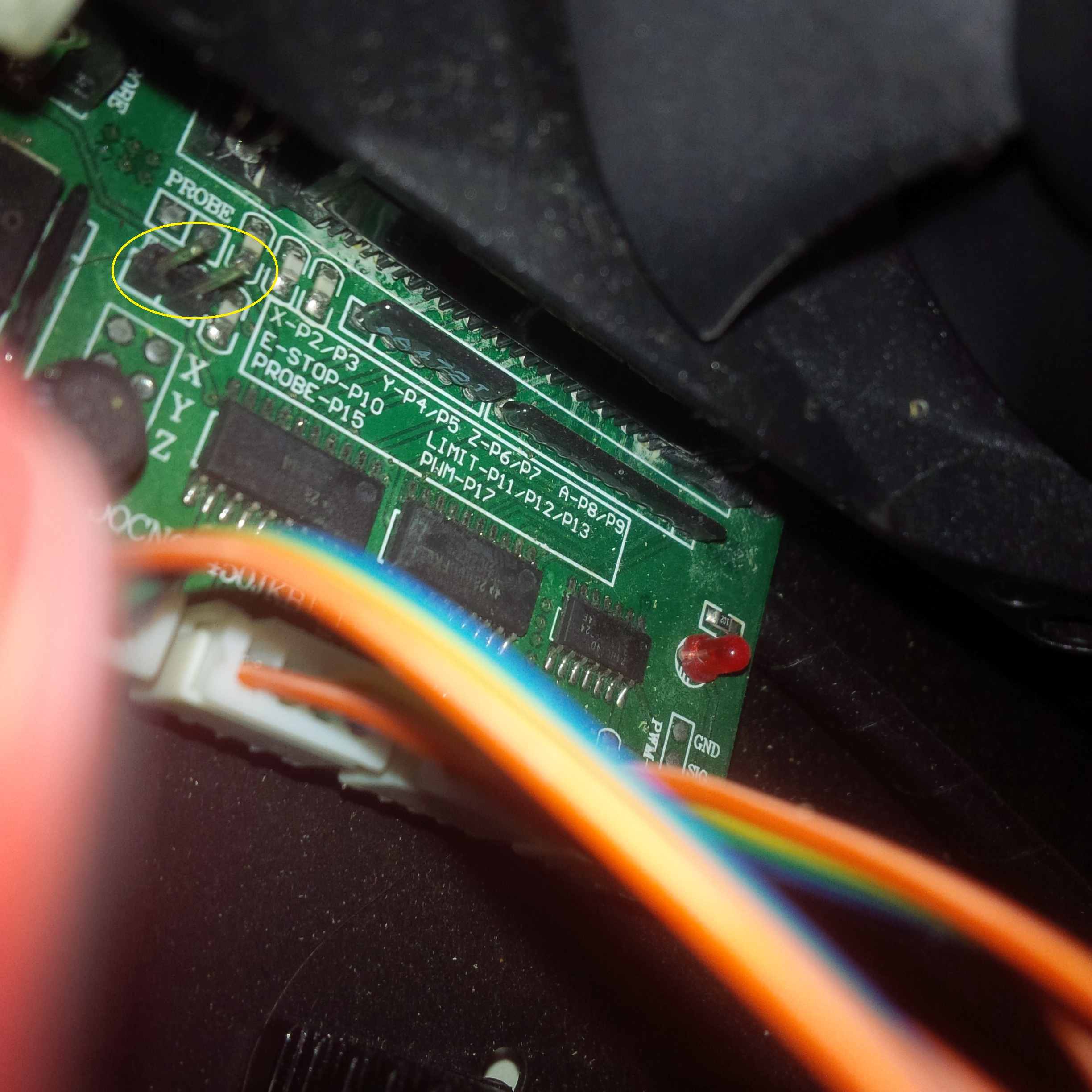

The YOOCNC-450JKB board parallel port pin settings are as follows:

X-P2/P3

Y-P4/P5

Z-P6/P7

A-P8/P9

E-STOP-P10

PROBE-P15

LIMIT-P11/P12/P13

PWM-P17

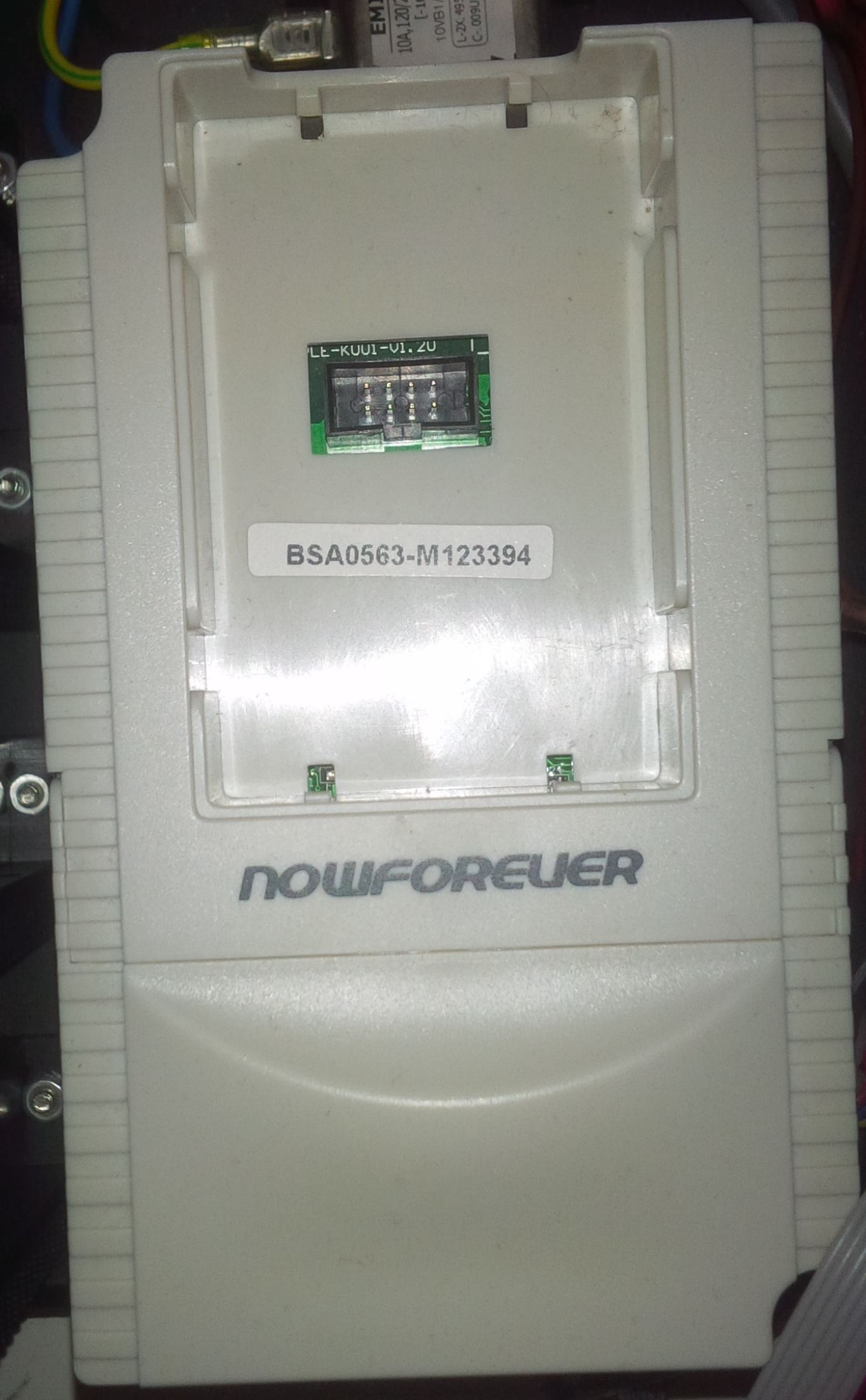

I have a tool length probe, so I suppose I should configure it to use pin# 15? Any idea if (and on which pin) I should use the 'Amplifier Enable' value? Also, there are two prongs on the circuit board, labelled as ESTOP (see attached picture). Any idea what they are for? Also, the spindle is a 0.8KW water-cooled CHANGSHENG GDZ-65-800, coupled with a VFD NOWFOREVER BSA056-M123394. Is software control from LinuxCNC possible, or can it be done only from the external panel?

The stepper motors for the X, Y and Z axes are the 'Type 57 two-phase 3A', and for the A axis, 'Type 57 1.5A'. I played with a stepper motor spreadsheet for Mach3 and found out that the Motor steps per revolution was 200 and driver microstepping /8. The ballscrew for XYZ is a 1605, but I've seen both 5mm and 4mm values. What value should I substitute for Leadscrew Pitch? As for the A axis, the gear reduction value is 3 (as in '3 revolutions of the stepper pulley = 1 revolution of the chuck), but should the Pulley teeth (Motor: Leadscrew) be entered as 3:1 or 1:3? The number of teeth on the motor pulley is 20, and of the lathe chuck pulley is 60. The belt is a HTD 273-3M, pitch length = 273, number of teeth = 91.

As I understand, I need to divide the Mach3-based Maximum Velocity by 60 (sec). Does the Maximum Velocity mean a rapid move or a feed move? For my machine it's 5000mm/min and 2500, respectively. Is the Maximum Acceleration the same as in Mach3, or do I need to convert that number?

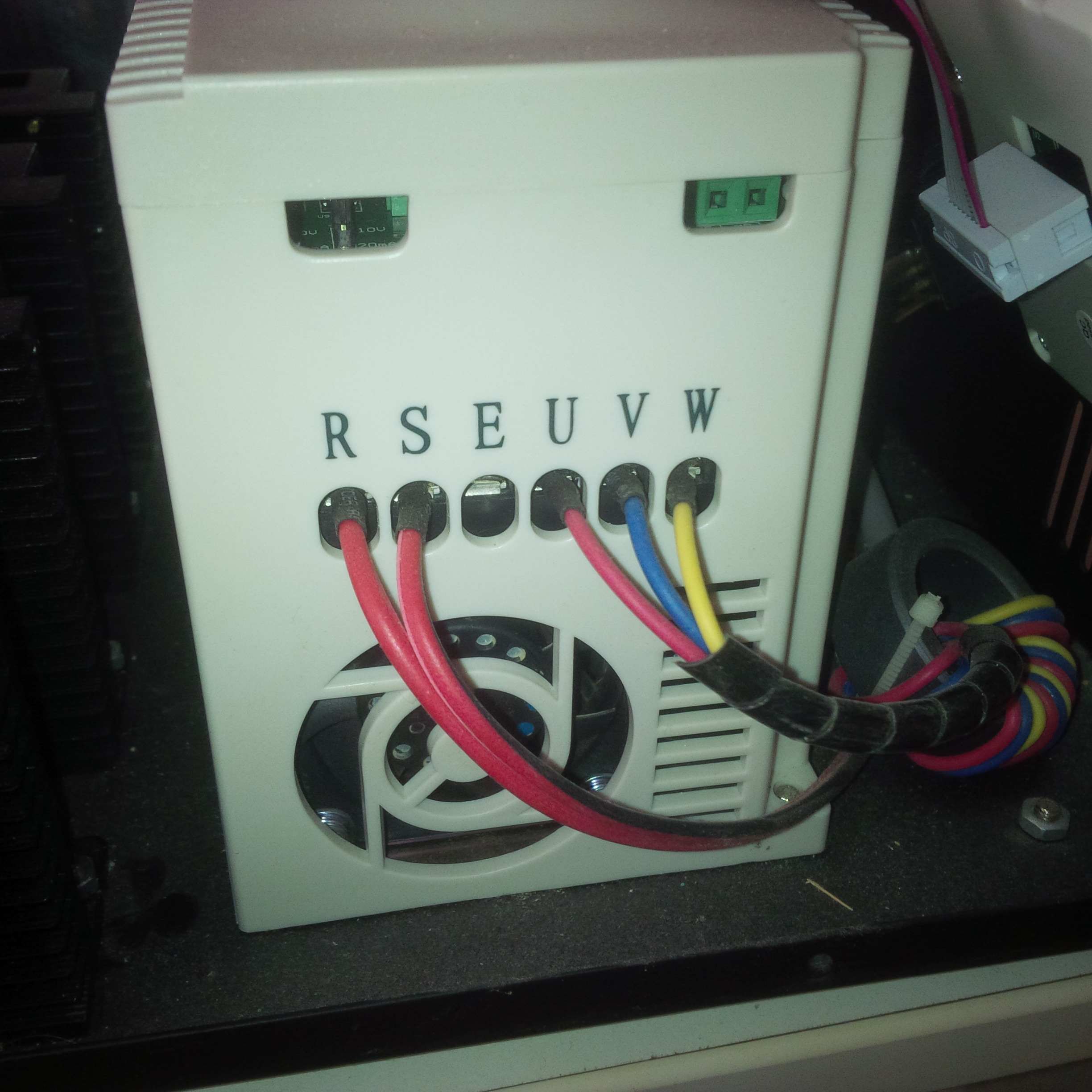

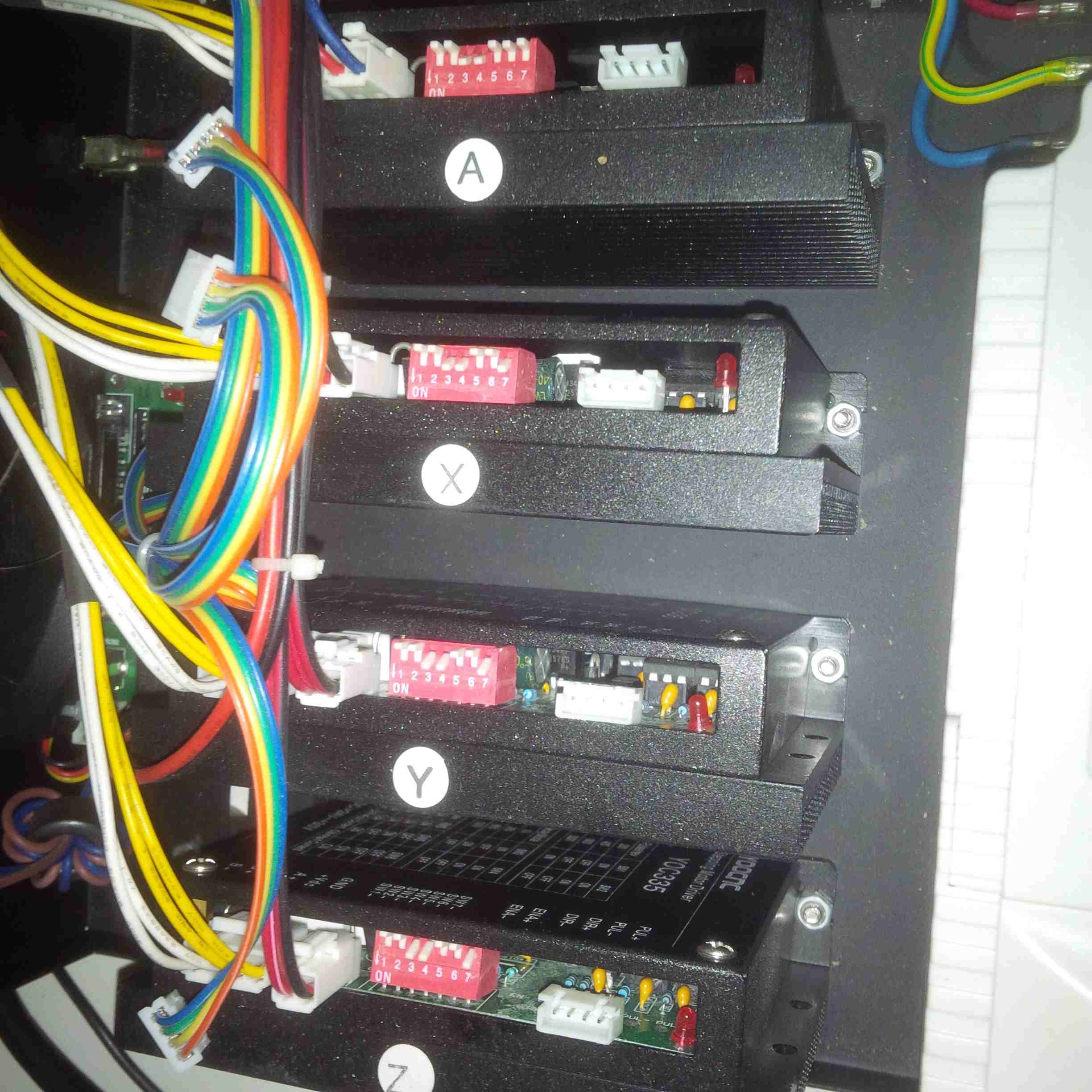

Finally, are the settings on the drivers themselves (see attached picture) OK, or do I need to change them? Ideally, I'd like to get the most of the machine without frying it. I don't know whether or not e.g. there are different driver/motor setups depending on the intended machineable material (my priority is accuracy, but I also want to try machining aluminium), so I'll appreciate any advice on how you would set up this machine.

Cheers,

G.

Can anyone help with the StepConf setup for my machine? It's a small Chinese (Shenzhen Liyang Welding Equipment Ltd?) 4-axis gantry router. Importing the Mach3 configuration file in the StepConf Wizard didn't work. There were no error messages, but neither were the fields populated with Mach3 values, so I decided to do a fresh setup. I use the 2.7.* branch of LinuxCNC, updated today.

The Chinese manufacturers/sellers are notorious for not providing a detailed list of the machine's components and their specifications, so I both looked inside the controller box to find out more and read the LinuxCNC documentation and forum posts. Yet there still are things I don't understand. Anyway, here's the Mach3 settings that I got from the seller (in metric units; Steps per, Velocity, Acceleration, Step Pulse, Dir Pulse):

X 320, 2500, 200, 3, 1

Y 320, 2500, 200, 3, 1

Z 320, 700, 150, 3, 1

A 13.33, 500, 100, 3, 5

The driver is YOC335 (based on the TOSHIBA TB6560AHQ JAPAN 418GA1 chip).

What values would you recommend for Step Space, Step Time, Direction Hold and Direction Setup? Are these in any way related to the Mach3's Step Pulse and Dir Pulse?

The Base Period Maximum Jitter is 34665.

Here's the parallel port Motor Outputs setup in Mach3 (does 'Step Low=yes' equal to checking the 'Invert' box in StepConf Wizard?):

X Axis enabled=yes, Step Pin#=2, Dir Pin#=3, Dir Low=no, Step Low=yes

Y Axis enabled=yes, Step Pin#=4, Dir Pin#=5, Dir Low=no, Step Low=yes

Z Axis enabled=yes, Step Pin#=6, Dir Pin#=7, Dir Low=no, Step Low=yes

A Axis enabled=yes, Step Pin#=8, Dir Pin#=9, Dir Low=no, Step Low=yes

Input Signals:

EStop enabled=yes, Pin Number=10, Active Low=yes

The YOOCNC-450JKB board parallel port pin settings are as follows:

X-P2/P3

Y-P4/P5

Z-P6/P7

A-P8/P9

E-STOP-P10

PROBE-P15

LIMIT-P11/P12/P13

PWM-P17

I have a tool length probe, so I suppose I should configure it to use pin# 15? Any idea if (and on which pin) I should use the 'Amplifier Enable' value? Also, there are two prongs on the circuit board, labelled as ESTOP (see attached picture). Any idea what they are for? Also, the spindle is a 0.8KW water-cooled CHANGSHENG GDZ-65-800, coupled with a VFD NOWFOREVER BSA056-M123394. Is software control from LinuxCNC possible, or can it be done only from the external panel?

The stepper motors for the X, Y and Z axes are the 'Type 57 two-phase 3A', and for the A axis, 'Type 57 1.5A'. I played with a stepper motor spreadsheet for Mach3 and found out that the Motor steps per revolution was 200 and driver microstepping /8. The ballscrew for XYZ is a 1605, but I've seen both 5mm and 4mm values. What value should I substitute for Leadscrew Pitch? As for the A axis, the gear reduction value is 3 (as in '3 revolutions of the stepper pulley = 1 revolution of the chuck), but should the Pulley teeth (Motor: Leadscrew) be entered as 3:1 or 1:3? The number of teeth on the motor pulley is 20, and of the lathe chuck pulley is 60. The belt is a HTD 273-3M, pitch length = 273, number of teeth = 91.

As I understand, I need to divide the Mach3-based Maximum Velocity by 60 (sec). Does the Maximum Velocity mean a rapid move or a feed move? For my machine it's 5000mm/min and 2500, respectively. Is the Maximum Acceleration the same as in Mach3, or do I need to convert that number?

Finally, are the settings on the drivers themselves (see attached picture) OK, or do I need to change them? Ideally, I'd like to get the most of the machine without frying it. I don't know whether or not e.g. there are different driver/motor setups depending on the intended machineable material (my priority is accuracy, but I also want to try machining aluminium), so I'll appreciate any advice on how you would set up this machine.

Cheers,

G.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

18 Jan 2020 18:05 #155107

by PCW

Replied by PCW on topic CNC4030Z-S setup

For step timings I would use

steptime 5000

stepspace 5000

dirsetup 20000

dirhold 20000

As these will work with almost any hardware

( note that LinuxCNC timing values are in nanoseconds rather than your listed microseconds )

steptime 5000

stepspace 5000

dirsetup 20000

dirhold 20000

As these will work with almost any hardware

( note that LinuxCNC timing values are in nanoseconds rather than your listed microseconds )

The following user(s) said Thank You: CNCPL

Please Log in or Create an account to join the conversation.

- CNCPL

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

19 Jan 2020 16:38 #155161

by CNCPL

Replied by CNCPL on topic CNC4030Z-S setup

Thanks, I'll try these parameters.

As for the rotary axis, I found out that the pulley belt's pitch is 3mm. Can I substitute this number for the A Axis Leadscrew Pitch? Also, if the gear reduction is 3x, should I enter it as 3:1 or 1:3?

What about the Leadscrew Pitch for the 1605 ballscrew? Is 5mm okay?

I still don't know if the Maximum Velocity is related to a rapid or a feed move, if I should tick the 'Invert' boxes for the axes' 'Step' and if/where I should use 'Amplifier Enable' option. Finding the answers to these questions would let me finish a basic configuration of the machine.

As for the rotary axis, I found out that the pulley belt's pitch is 3mm. Can I substitute this number for the A Axis Leadscrew Pitch? Also, if the gear reduction is 3x, should I enter it as 3:1 or 1:3?

What about the Leadscrew Pitch for the 1605 ballscrew? Is 5mm okay?

I still don't know if the Maximum Velocity is related to a rapid or a feed move, if I should tick the 'Invert' boxes for the axes' 'Step' and if/where I should use 'Amplifier Enable' option. Finding the answers to these questions would let me finish a basic configuration of the machine.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4598

26 Jan 2020 17:00 #155820

by andypugh

Replied by andypugh on topic CNC4030Z-S setup

Many of your questions can be answered by trial and error. (Particulary the step invert question, try both, see which works)

The rotary axis scale is more related to the pulley ratio than the belt pitch. It might be easiest to calculate by hand then edit the INI file to put in the correct steps-per-degree number. Stepconf tries to be helpful but ends up making non-leadscrew systems hard to configure.

But, as a first attempt, choose a "leadscrew pitch" of 360 degrees, then put in the microstep and pulley ratios as they actually are.

The rotary axis scale is more related to the pulley ratio than the belt pitch. It might be easiest to calculate by hand then edit the INI file to put in the correct steps-per-degree number. Stepconf tries to be helpful but ends up making non-leadscrew systems hard to configure.

But, as a first attempt, choose a "leadscrew pitch" of 360 degrees, then put in the microstep and pulley ratios as they actually are.

The following user(s) said Thank You: CNCPL

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

26 Jan 2020 17:05 - 26 Jan 2020 17:06 #155823

by bbsr_5a

Replied by bbsr_5a on topic CNC4030Z-S setup

you are set to 1600 Pulses per 5mm if the motor is direct mounted to the 1605

it is in strepconf 200Motor 8Microsteps at 5mm pitch

DO NOT POWER THIS DRIVERS WITHOUT STEPPERS CONNECTED THEY WILL FLAME SPARKEL WITHIN Milliseconds

it is in strepconf 200Motor 8Microsteps at 5mm pitch

DO NOT POWER THIS DRIVERS WITHOUT STEPPERS CONNECTED THEY WILL FLAME SPARKEL WITHIN Milliseconds

Last edit: 26 Jan 2020 17:06 by bbsr_5a.

The following user(s) said Thank You: CNCPL

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21152

- Thank you received: 7222

26 Jan 2020 21:23 #155858

by tommylight

????????????????????

Never did any drive go out in flames when powered without a motor connected, NEVER !

Do not disconnect the motor wires while the drive is powered and enabled, that can kill the drives, NOT always.

Replied by tommylight on topic CNC4030Z-S setup

DO NOT POWER THIS DRIVERS WITHOUT STEPPERS CONNECTED THEY WILL FLAME SPARKEL WITHIN Milliseconds

????????????????????

Never did any drive go out in flames when powered without a motor connected, NEVER !

Do not disconnect the motor wires while the drive is powered and enabled, that can kill the drives, NOT always.

Please Log in or Create an account to join the conversation.

- CNCPL

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

27 Jan 2020 13:07 #155898

by CNCPL

Replied by CNCPL on topic CNC4030Z-S setup

Thanks, guys, I think I'm all set for a basic setup of the X, Y and Z axes. As for the rotary axis, I'll try the following:

MSPR = 200

microstepping = 8

pulley teeth = 20:60 (three turns of the motor = one turn of the rotary chuck)

leadscrew pitch = 360 (?)

When I had one guy help me set up the machine under Mach3, he opened the control box but I'm not sure if he only inspected the factory DIP switch settings or if he tampered with them. Assuming that the 'ON' position is down (cp. pictures in my original post), the settings are as follows: Pulse/rev 1600, Decay Mode 0%, Peak 3.5A / RMS 1.8A. Half Current for the XYZ, Full Current for the A axis (the XYZ motors are '57 type [two-phase] 3A', the A motor '57 type [two-phase] 1.5A'). Does that seem OK to you?

MSPR = 200

microstepping = 8

pulley teeth = 20:60 (three turns of the motor = one turn of the rotary chuck)

leadscrew pitch = 360 (?)

When I had one guy help me set up the machine under Mach3, he opened the control box but I'm not sure if he only inspected the factory DIP switch settings or if he tampered with them. Assuming that the 'ON' position is down (cp. pictures in my original post), the settings are as follows: Pulse/rev 1600, Decay Mode 0%, Peak 3.5A / RMS 1.8A. Half Current for the XYZ, Full Current for the A axis (the XYZ motors are '57 type [two-phase] 3A', the A motor '57 type [two-phase] 1.5A'). Does that seem OK to you?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4598

05 Feb 2020 13:26 #156588

by andypugh

Replied by andypugh on topic CNC4030Z-S setup

Is this working now? (catching up)

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

05 Feb 2020 14:00 - 05 Feb 2020 14:02 #156593

by bbsr_5a

Replied by bbsr_5a on topic CNC4030Z-S setup

on a Rotary you shoudt go for 800Steps per Motor revolution

your Drives only got 1600

this gives you a better smoother Devider of the 360Deg

so the Ratio is 3:1

EQ (1600*3) /360

Scale is 13.3333333 to be set steps per deg

your Drives only got 1600

this gives you a better smoother Devider of the 360Deg

so the Ratio is 3:1

EQ (1600*3) /360

Scale is 13.3333333 to be set steps per deg

Last edit: 05 Feb 2020 14:02 by bbsr_5a.

The following user(s) said Thank You: CNCPL

Please Log in or Create an account to join the conversation.

- CNCPL

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

06 Feb 2020 00:12 #156609

by CNCPL

Replied by CNCPL on topic CNC4030Z-S setup

@andypugh

Yes, I will still attempt to fine-tune it (as it is now, when jogging '+', the Y axis is towards me, Z goes up, A turns counterclockwise) but I got all the axes to work. The ESTOP Out @PIN 10 needn't be inverted, though, unlike in Mach3, because otherwise the machine isn't powered. I did find it out by trial and error without frying anything! Also, the 'Amplifier Enable' parameter isn't needed, apparently.

@bbsr_5a

Indeed, 13.33 was the correct value for steps per degree in Mach3. Configuring the rotary axis in StepConf seems more complicated...

(Meanwhile, I found it intriguing that, in the 'Test this axis', StepConf wizard would always dial down my proposed Maximum Velocity for the X and Y axes from 83.33 mm/s to 62.92 mm/s (it was impossible to set it any higher). For the A axis test window, the upper limit was 12.5 deg/sec. Is it the Wizard's way of suggesting me the right values or what?)

Is it normal for the rotary axis stepper motor to produce audible spikes every 3 seconds or so when turning continuously (please excuse my ignorance...)? I'm still unsure if the current (i.e. electrical) settings of the drivers are correct (see my previous post).

Yes, I will still attempt to fine-tune it (as it is now, when jogging '+', the Y axis is towards me, Z goes up, A turns counterclockwise) but I got all the axes to work. The ESTOP Out @PIN 10 needn't be inverted, though, unlike in Mach3, because otherwise the machine isn't powered. I did find it out by trial and error without frying anything! Also, the 'Amplifier Enable' parameter isn't needed, apparently.

@bbsr_5a

Indeed, 13.33 was the correct value for steps per degree in Mach3. Configuring the rotary axis in StepConf seems more complicated...

(Meanwhile, I found it intriguing that, in the 'Test this axis', StepConf wizard would always dial down my proposed Maximum Velocity for the X and Y axes from 83.33 mm/s to 62.92 mm/s (it was impossible to set it any higher). For the A axis test window, the upper limit was 12.5 deg/sec. Is it the Wizard's way of suggesting me the right values or what?)

Is it normal for the rotary axis stepper motor to produce audible spikes every 3 seconds or so when turning continuously (please excuse my ignorance...)? I'm still unsure if the current (i.e. electrical) settings of the drivers are correct (see my previous post).

Please Log in or Create an account to join the conversation.

Time to create page: 0.327 seconds