G41 and G42 Input path error

- RobotMatic

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 199

- Thank you received: 25

16 Aug 2017 00:44 #97541

by RobotMatic

G41 and G42 Input path error was created by RobotMatic

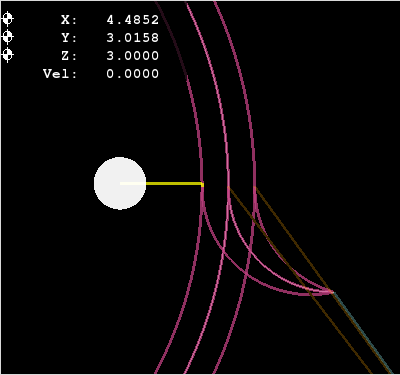

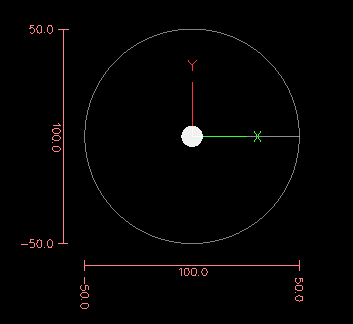

Since 2008 I use Linuxcnc. I find a serious problem in generating compensated paths with G41-G42. Linuxcnc requires me to generate auxiliary movements to be able to generate my complete trajectory. When the tool enters the programmed profile, it is placed tangent to both axes, and leaves incomplete a section of my trajectory.

In this time I have seen many improvements to the software, and I can not understand why this has not been solved. In the manual, they explain how the compensation works and consider that this way of working is correct, but it is not !!!!!.

Linuxcnc must allow me to enter and exit the trajectory at the same point without missing a part.I am very grateful to be able to use Linuxcnc in the equipment that we manufacture in Argentina RobotMatic CNC. I hope that the developers can consider my observation and solve this problem.

thank!!

In this time I have seen many improvements to the software, and I can not understand why this has not been solved. In the manual, they explain how the compensation works and consider that this way of working is correct, but it is not !!!!!.

Linuxcnc must allow me to enter and exit the trajectory at the same point without missing a part.I am very grateful to be able to use Linuxcnc in the equipment that we manufacture in Argentina RobotMatic CNC. I hope that the developers can consider my observation and solve this problem.

thank!!

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

17 Aug 2017 02:07 #97606

by Todd Zuercher

Replied by Todd Zuercher on topic G41 and G42 Input path error

I'm not sure what you want the behavior to be. Other industrial controls (Fanuc and some others) I've used have similar behavior and limitations as Linuxcnc when using tool offsets.

Please Log in or Create an account to join the conversation.

- RobotMatic

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 199

- Thank you received: 25

17 Aug 2017 17:40 #97663

by RobotMatic

Replied by RobotMatic on topic G41 and G42 Input path error

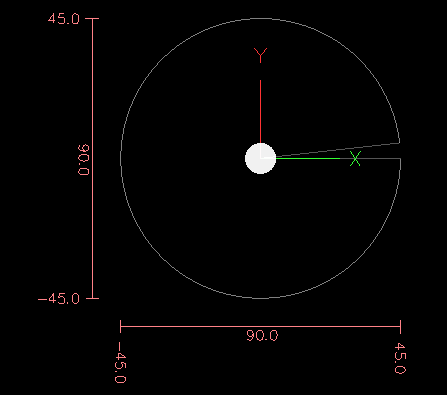

Linuxcnc can not generate a full circle offset with G41 or G42. At the point of entry it moves tangentially and loses the trajectory, to be able to solve this it is necessary to generate auxiliary trajectories. Fanuc, Fagor, Siemens do not have this problem. The trajectory runs completely with or without G41-G42. Again I mention that in the manual of linuxcnc indicate this error as correct.

It is very important that this error be corrected. It is not possible to perform tuning work with linuxcnc. Thank you very much for answering

It is very important that this error be corrected. It is not possible to perform tuning work with linuxcnc. Thank you very much for answering

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

17 Aug 2017 19:02 - 17 Aug 2017 20:01 #97667

by Todd Zuercher

Replied by Todd Zuercher on topic G41 and G42 Input path error

I thought Fanuc required a lead in move equal to or greater than the tool offset for G41/G42 (as does Linuxcnc)

If your lead in move is radial to your circle, you get a defect at the start of the circle equal to your tool offset. The Fanuc controls I've used behave the same. (or so I thought.)

If your lead in move is radial to your circle, you get a defect at the start of the circle equal to your tool offset. The Fanuc controls I've used behave the same. (or so I thought.)

Last edit: 17 Aug 2017 20:01 by Todd Zuercher.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

17 Aug 2017 19:55 #97669

by Todd Zuercher

Replied by Todd Zuercher on topic G41 and G42 Input path error

Please Log in or Create an account to join the conversation.

- RobotMatic

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 199

- Thank you received: 25

17 Aug 2017 21:21 #97674

by RobotMatic

Replied by RobotMatic on topic G41 and G42 Input path error

Please Log in or Create an account to join the conversation.

- RobotMatic

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 199

- Thank you received: 25

17 Aug 2017 23:30 #97677

by RobotMatic

Replied by RobotMatic on topic G41 and G42 Input path error

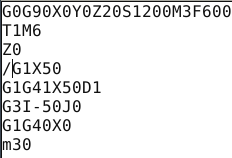

The example shows the simplest complete circular interpolation that a cnc machine can generate (G3I-50J0). Linuxcnc can not do it with G41, it loses a section of the circumference. Fanuc Generates complete interpolation with G41. Soon I will run this same code on a Fanuc controller so you can see the difference. Thank you very much

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

18 Aug 2017 02:22 #97682

by Todd Zuercher

Replied by Todd Zuercher on topic G41 and G42 Input path error

I wonder if this behavior was the same before the introduction of version 2.7 and the new trajectory planner?

Please Log in or Create an account to join the conversation.

- RobotMatic

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 199

- Thank you received: 25

18 Aug 2017 22:56 #97724

by RobotMatic

Replied by RobotMatic on topic G41 and G42 Input path error

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

19 Aug 2017 03:01 #97728

by Todd Zuercher

Replied by Todd Zuercher on topic G41 and G42 Input path error

I tested it with 2.6.12 on a VM and the behavior was the same.

The following user(s) said Thank You: RobotMatic

Please Log in or Create an account to join the conversation.

Time to create page: 0.126 seconds