G41 and G42 Input path error

- RobotMatic

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 25

31 Aug 2017 11:34 #98278

by RobotMatic

Replied by RobotMatic on topic G41 and G42 Input path error

It is not the programmer who must add an additional line to generate the same desired path with G41. Linuxcnc must possess the intelligence of being able to enter a compensated path in the same way that it enters without it. Your answer is not a solution to the problem that I am posing, in more complex programs this line should be added many times, and that is not correct. I am planting the correction of this situation since 2008 and I can not make the developers interested in solving such a serious problem. Linuxcnc is a great application, it should not work in this way, Fanuc and all other controls do not require any additional line, allowing comfort to the programmer for very complicated work, for example in the area of mold manufacturing. For example, to make a linuxcnc cavity allows me to perform a roughing by cad-cam sistem, but it does not allow me to adjust the measurement using G41 and the tool table, I must generate many termination programs with different adjustment measures until the correct one, if this error is corrected, only a program with g41 and table are needed.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4688

- Thank you received: 1433

31 Aug 2017 12:21 #98279

by Todd Zuercher

Replied by Todd Zuercher on topic G41 and G42 Input path error

If you want action taken on this, have you brought it up on the Developers mailing list?

sourceforge.net/p/emc/mailman/

Or posted a bug report?

github.com/LinuxCNC/linuxcnc/issues

sourceforge.net/p/emc/mailman/

Or posted a bug report?

github.com/LinuxCNC/linuxcnc/issues

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4688

- Thank you received: 1433

31 Aug 2017 13:26 #98287

by Todd Zuercher

Replied by Todd Zuercher on topic G41 and G42 Input path error

Please Log in or Create an account to join the conversation.

- RobotMatic

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 25

01 Sep 2017 13:19 #98336

by RobotMatic

Replied by RobotMatic on topic G41 and G42 Input path error

Dear Todd, thank you very much for your reply. The image that you posted is an excelent example of the diference between linux cnc and fanuc. I will try to convence linuxcnc developers to resolve this problem.

Best regards!

Best regards!

Please Log in or Create an account to join the conversation.

- RobotMatic

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 25

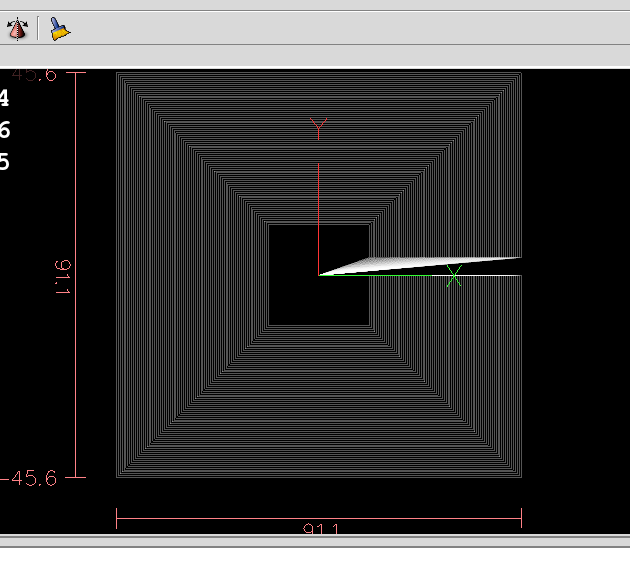

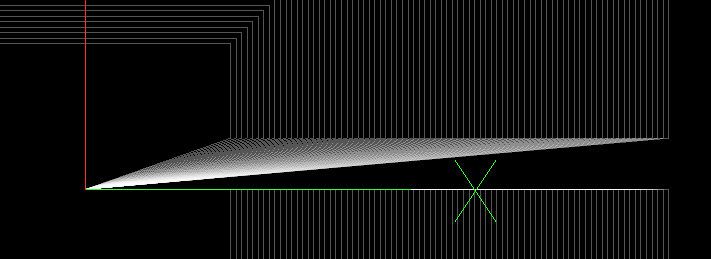

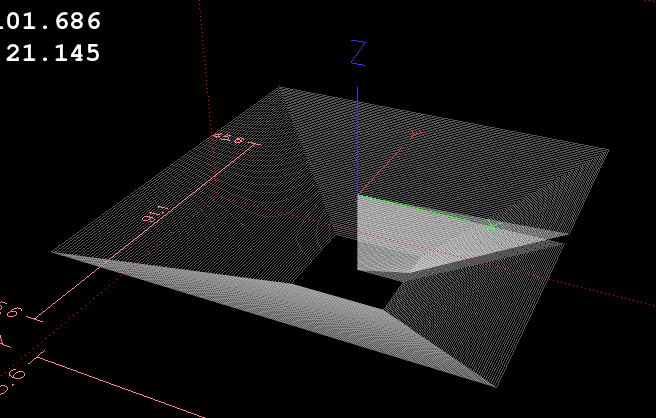

22 Sep 2017 22:48 #99290

by RobotMatic

Replied by RobotMatic on topic G41 and G42 Input path error

Please Log in or Create an account to join the conversation.

- crisiacuf

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 0

20 Nov 2017 13:26 #102056

by crisiacuf

Replied by crisiacuf on topic G41 and G42 Input path error

Hello all,

I am a noob in G code so please bare with me.

I am encountering an error with G41 "Lenght of cutter compensation entry move is not greater than the tool radius" near line 13 of my code below.

I am using the Linuxcnc non random processor for Camworks but my cam software is Solidworks CAM(based on Camworks too)

To make the cam working I am making some unorthodox(I think) modification in the G code but the G41 error is killing me slowly now

This is the beginning of the Gcode my postprocessor is outputing:

( PART NAME=2mm )

( MACHINE=LINUXCNC )

G21 G17

G91 G28 Z0

G28 X0 Y0

(1.5MM CRB3FL 25 LOC)

N1( T03 M06)

S12000 M03

M08

G90 G54 G00 X36.7 Y17.04

T01 G43 Z-3. H03

G01 Z-7. F662.94

G41 D23 X36.7 Y16. F1988.82

X37. F2651.76

X54.284

X56.409 Y43.

X54.914

I manually copy the first line from another G code to make it work with my machine(I use automatic tool length measure) and delete the N1( )

G17 G21 G40 G90

(1.5MM CRB3FL 25 LOC)

T03 M06

S12000 M03

M08

G90 G54 G00 X36.7 Y17.04

T01 G43 Z-3. H03

G01 Z-7. F662.94

G41 D23 X36.7 Y16. F1988.82

X37. F2651.76

X54.284

X56.409 Y43.

X54.914

The G41 line is in the beginning of the next step but for simplicity I am posting just a section.

Can somebody advice me how to fix this? And maybe what to use to modify the post processor?

I also tried an arc entry move before perpendicular to no avail

I am a noob in G code so please bare with me.

I am encountering an error with G41 "Lenght of cutter compensation entry move is not greater than the tool radius" near line 13 of my code below.

I am using the Linuxcnc non random processor for Camworks but my cam software is Solidworks CAM(based on Camworks too)

To make the cam working I am making some unorthodox(I think) modification in the G code but the G41 error is killing me slowly now

This is the beginning of the Gcode my postprocessor is outputing:

( PART NAME=2mm )

( MACHINE=LINUXCNC )

G21 G17

G91 G28 Z0

G28 X0 Y0

(1.5MM CRB3FL 25 LOC)

N1( T03 M06)

S12000 M03

M08

G90 G54 G00 X36.7 Y17.04

T01 G43 Z-3. H03

G01 Z-7. F662.94

G41 D23 X36.7 Y16. F1988.82

X37. F2651.76

X54.284

X56.409 Y43.

X54.914

I manually copy the first line from another G code to make it work with my machine(I use automatic tool length measure) and delete the N1( )

G17 G21 G40 G90

(1.5MM CRB3FL 25 LOC)

T03 M06

S12000 M03

M08

G90 G54 G00 X36.7 Y17.04

T01 G43 Z-3. H03

G01 Z-7. F662.94

G41 D23 X36.7 Y16. F1988.82

X37. F2651.76

X54.284

X56.409 Y43.

X54.914

The G41 line is in the beginning of the next step but for simplicity I am posting just a section.

Can somebody advice me how to fix this? And maybe what to use to modify the post processor?

I also tried an arc entry move before perpendicular to no avail

Please Log in or Create an account to join the conversation.

- RobotMatic

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 25

20 Nov 2017 13:47 - 20 Nov 2017 13:51 #102060

by RobotMatic

Replied by RobotMatic on topic G41 and G42 Input path error

let me try the code and I'll tell you

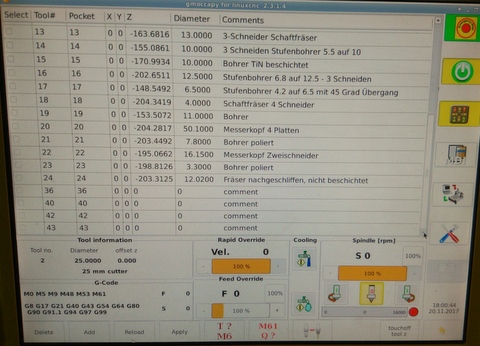

can you show an image of your tool table?

can you show an image of your tool table?

Last edit: 20 Nov 2017 13:51 by RobotMatic.

Please Log in or Create an account to join the conversation.

- crisiacuf

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 0

20 Nov 2017 16:14 #102064

by crisiacuf

Replied by crisiacuf on topic G41 and G42 Input path error

Does it matter?

Please Log in or Create an account to join the conversation.

- RobotMatic

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 25

20 Nov 2017 16:26 #102065

by RobotMatic

Replied by RobotMatic on topic G41 and G42 Input path error

yes. G41 reads the value stored in the position of the tool table to use it. Your program does not load the value. you must do it manually or with the instruction G10 L. If this value is greater than the input path, it will give you an error. for example. There is no way to use G41 compensation without using the tool table. for that is this !!!!!!!!

D23 indicates the reading position in the table.

What is the value of Radio tool in position 23?

D23 indicates the reading position in the table.

What is the value of Radio tool in position 23?

Please Log in or Create an account to join the conversation.

- crisiacuf

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 0

20 Nov 2017 16:49 - 20 Nov 2017 17:10 #102067

by crisiacuf

Sorry, but until this day I survived without needing to edit the tool table. I read about G41 arguments already but i have no idea where the postprocessor takes D23 from.

But Isn't the tool declared T03?

On position 23 in my tool table there is a 3 mm tool indeed. But where is "23" coming from? Blackmagic gcode ? In Solidworks CAM tool 3 has ID16.

I tried deleting D23 but same error message.

Replied by crisiacuf on topic G41 and G42 Input path error

Sorry, but until this day I survived without needing to edit the tool table. I read about G41 arguments already but i have no idea where the postprocessor takes D23 from.

But Isn't the tool declared T03?

On position 23 in my tool table there is a 3 mm tool indeed. But where is "23" coming from? Blackmagic gcode ? In Solidworks CAM tool 3 has ID16.

I tried deleting D23 but same error message.

Last edit: 20 Nov 2017 17:10 by crisiacuf.

Please Log in or Create an account to join the conversation.

Time to create page: 0.388 seconds