M19 spindle orient

- dinkata

- Offline

- Premium Member

-

- Posts: 101

- Thank you received: 1

Anybody to has HAL or INI files?

LinuxCNC samples ar at no help.

Thank You in advance!

Please Log in or Create an account to join the conversation.

- raglanlittlejohn

- Offline

- Senior Member

-

- Posts: 76

- Thank you received: 9

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 4704

- Thank you received: 1443

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

- Posts: 101

- Thank you received: 1

but I do not find how to set a speed (RPM or RPS ) for M19M19 Orient Spindle

M19 R- Q- [P-]

R Position to rotate to from 0, valid range is 0-360 degrees

Q Number of seconds to wait until orient completes. If motion.spindle.is_oriented does not become true within Q timeout an error occurs.

P Direction to rotate to position.

0 rotate for smallest angular movement (default)

1 always rotate clockwise (same as M3 direction)

2 always rotate counterclockwise (same as M4 direction)

M19 is cleared by any of M3,M4,M5.

Spindle orientation requires a quadrature encoder with an index to sense the spindle shaft position and direction of rotation.

INI Settings in the [RS274NGC] section.

ORIENT_OFFSET = 0-360 (fixed offset in degrees added to M19 R word)

HAL Pins

motion.spindle-orient-angle (out float) Desired spindle orientation for M19. Value of the M19 R word parameter plus the value of the [RS274NGC]ORIENT_OFFSET ini parameter.

motion.spindle-orient-mode (out s32) Desired spindle rotation mode. Reflects M19 P parameter word, Default = 0

motion.spindle-orient (out bit) Indicates start of spindle orient cycle. Set by M19. Cleared by any of M3,M4,M5. If spindle-orient-fault is not zero during spindle-orient true, the M19 command fails with an error message.

motion.spindle-is-oriented (in bit) Acknowledge pin for spindle-orient. Completes orient cycle. If spindle-orient was true when spindle-is-oriented was asserted, the spindle-orient pin is cleared and the spindle-locked pin is asserted. Also, the spindle-brake pin is asserted.

motion.spindle-orient-fault (in s32) Fault code input for orient cycle. Any value other than zero will cause the orient cycle to abort.

motion.spindle-locked (out bit) Spindle orient complete pin. Cleared by any of M3,M4,M5.

Please Log in or Create an account to join the conversation.

- raglanlittlejohn

- Offline

- Senior Member

-

- Posts: 76

- Thank you received: 9

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 4704

- Thank you received: 1443

Please Log in or Create an account to join the conversation.

- raglanlittlejohn

- Offline

- Senior Member

-

- Posts: 76

- Thank you received: 9

Why not set the encoder scale for the hardware encoder counter for your 360 degrees, then use a scale component on the position output by encoder counter to get your per rev number?

I thought it would be easier to leave the hardware encoder alone for speed measurement, then use separate software encoders for the orient part. I found it very difficult to understand the orient process. Finding the correct float to connect to the orient pins took ages.

I can see a scale component would be better for getting the rev number.

Would using a software encoder cause any problems?. The orient process would be very slow compared to spindle speed counting, so the software encoder should be fast enough.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 4704

- Thank you received: 1443

Please Log in or Create an account to join the conversation.

- raglanlittlejohn

- Offline

- Senior Member

-

- Posts: 76

- Thank you received: 9

Please Log in or Create an account to join the conversation.

- raglanlittlejohn

- Offline

- Senior Member

-

- Posts: 76

- Thank you received: 9

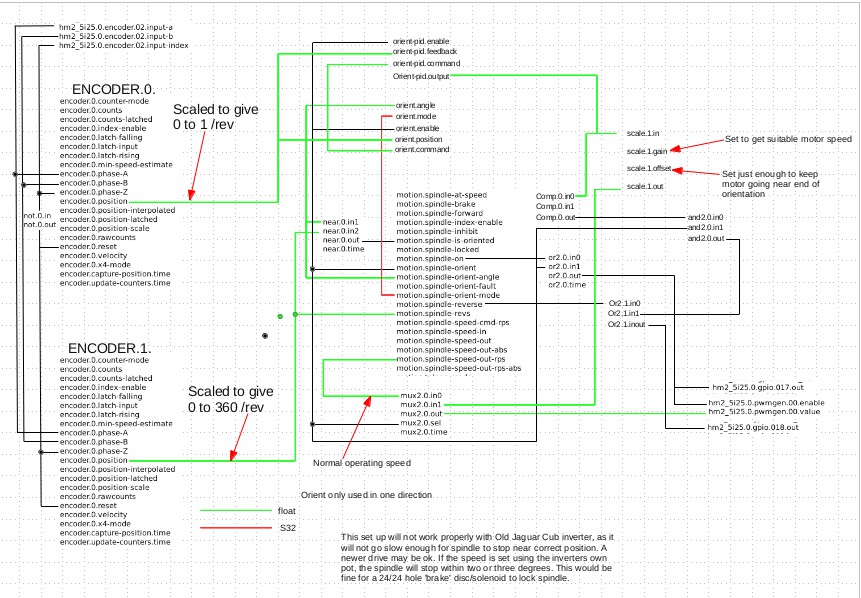

Here is the orient schematic with hardware encoder only. Seems to work ok.

Please Log in or Create an account to join the conversation.