- GCode and Part Programs

- G&M Codes

- G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

- +Jan+

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 16

15 Nov 2021 16:44 - 15 Nov 2021 21:55 #226589

by +Jan+

G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis was created by +Jan+

I have a small problem with dynamic tool length measurement with G43.1.

I call via remap a macro on this basis:

My adapted macro looks like this

My Z axis has the following specification

[AXIS_Z]

MAX_VELOCITY = 100.0

MAX_ACCELERATION = 700.0

MIN_LIMIT = -300.0

MAX_LIMIT = 0.01

My workflow is as follows.

1. tool measurement via the macro above

2. define Z0 (for the tests I set it far away from machine limits)

3. start program

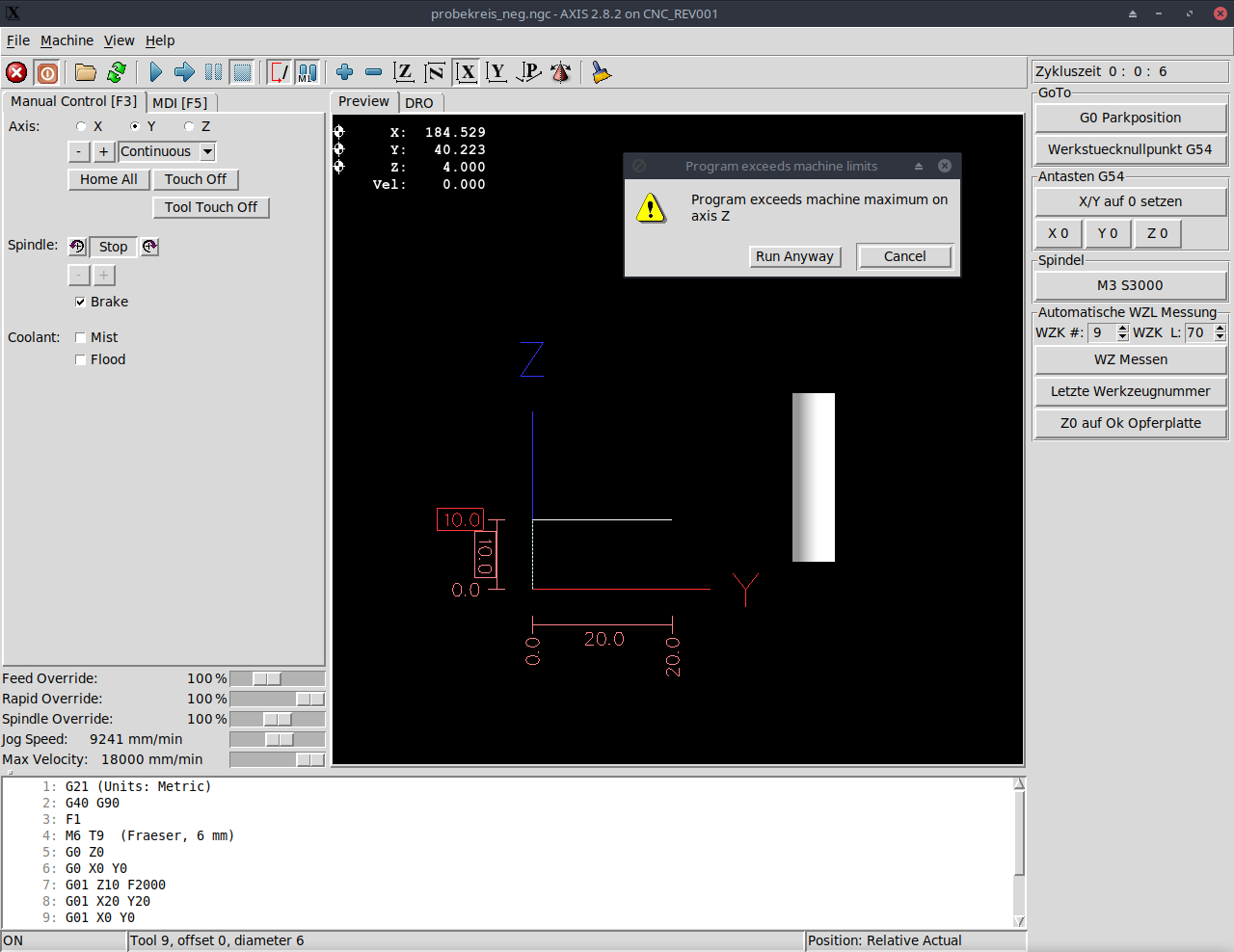

If I now start a program I get the message, "Program Exceeds machine maximum on axis Z.". As far as I could understand, the error occurs when the machine is moved to different Z heights in the program run.

For example, this code works here:

G21 (Units: Metric)

G40 G90

F1

M6 T9 ( Cutter, 6 mm)

G0 Z10

G0 X0 Y0

G01 Z10 F2000 (same height)

G01 X20 Y20

G01 X0 Y0

G0 Z10

M05 M30

This one as well:

G21 (Units: Metric)

G40 G90

F1

M6 T9 (Cutter, 6 mm)

G0 Z0

G0 X0 Y0

G01 Z0 F2000 (same height)

G01 X20 Y20

G01 X0 Y0

G0 Z0

M05 M30

This however not only with the above mentioned error message:

G21 (Units: Metric)

G40 G90

F1

M6 T9 (Cutter, 6 mm)

G0 Z0

G0 X0 Y0

G01 Z10 F2000 (different height)

G01 X20 Y20

G01 X0 Y0

G0 Z0

M05 M30

If I then click on "Run anyway", the program runs through to the end of the cycle without any problems. However, since I have to click the message away every time and thus cannot use my external hardware start button, I would like to solve the problem. Does anyone have a troubleshooting approach?

Best wishes

Jan

I call via remap a macro on this basis:

My adapted macro looks like this

o<messen_eng> sub

M64P10

#1700=1200 (Tool change X position)

#1701=0 (Tool change Y position)

#1702=-1 (Tool change Z position)

#1800=-100 (Position safe Z/Starting point for G38.2 move)

#1801=1279.125 (position probe X)

#1802=2498 (position probe Y)

#1900=#<_coord_system> (Store coordinate system only G54 till G59)

o500 if [#<_current_tool> EQ #<_selected_tool>]

;(debug, Tool already in spindle)

o500 else

M5

G54

G90 G0

G53 Z#1702 (Go to tool change Z position)

G53 X#1700 Y#1701 (Go to tool change XY position)

M6 T#<_selected_tool>

#4999=#5400. (save actually loaded tool... for another macro)

G43.1 Z0 (TLO reset)

G53 X#1801 Y#1802 (Go to probe position)

G53 Z#1800 (Go to save Z position)

G91

G38.2 Z-197.5 F850 (probing fast)

G1 Z2.0 F150 (go up a bit)

G38.2 Z-2.25 F25 (probing slow)

#2000=[#5063+#5223] (Switching point+zero Offset)

#2001=[#2000-#2002+#2003](new - diff + old)

#2002=[#2000] (Save old switch point)

#2003=[#2001] (Save old offset)

G1 Z5.0 F500 (go up away from sensor)

G90 G0

G43.1 Z#2001 (TLO set)

G53 Z#1800 (Go to save Z position)

G53 Z#1702 (Go to tool change Z position)

#1803=1 (State tool already measured)

;(debug, Differenz ist: #2001)

(Restore old zero (only G54 to G59)

o100 if[#1900 EQ 540]

G54

o100 endif

o101 if[#1900 EQ 550]

G55

o101 endif

o102 if[#1900 EQ 560]

G56

o102 endif

o103 if[#1900 EQ 570]

G57

o103 endif

o104 if[#1900 EQ 580]

G58

o104 endif

o500 endif

M65P10

o<messen_eng> endsub

M2My Z axis has the following specification

[AXIS_Z]

MAX_VELOCITY = 100.0

MAX_ACCELERATION = 700.0

MIN_LIMIT = -300.0

MAX_LIMIT = 0.01

My workflow is as follows.

1. tool measurement via the macro above

2. define Z0 (for the tests I set it far away from machine limits)

3. start program

If I now start a program I get the message, "Program Exceeds machine maximum on axis Z.". As far as I could understand, the error occurs when the machine is moved to different Z heights in the program run.

For example, this code works here:

G21 (Units: Metric)

G40 G90

F1

M6 T9 ( Cutter, 6 mm)

G0 Z10

G0 X0 Y0

G01 Z10 F2000 (same height)

G01 X20 Y20

G01 X0 Y0

G0 Z10

M05 M30

This one as well:

G21 (Units: Metric)

G40 G90

F1

M6 T9 (Cutter, 6 mm)

G0 Z0

G0 X0 Y0

G01 Z0 F2000 (same height)

G01 X20 Y20

G01 X0 Y0

G0 Z0

M05 M30

This however not only with the above mentioned error message:

G21 (Units: Metric)

G40 G90

F1

M6 T9 (Cutter, 6 mm)

G0 Z0

G0 X0 Y0

G01 Z10 F2000 (different height)

G01 X20 Y20

G01 X0 Y0

G0 Z0

M05 M30

If I then click on "Run anyway", the program runs through to the end of the cycle without any problems. However, since I have to click the message away every time and thus cannot use my external hardware start button, I would like to solve the problem. Does anyone have a troubleshooting approach?

Best wishes

Jan

Attachments:

Last edit: 15 Nov 2021 21:55 by +Jan+.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

16 Nov 2021 18:33 - 16 Nov 2021 18:33 #226670

by andypugh

Replied by andypugh on topic G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

I think that the problem here might be that probing always fails in the preview.

Judicious use of

Might fix the problem.

Judicious use of

O100 IF [#<_task> EQ 0]

simulate probe

O100 ELSE

actually probe

O100 ENDIFMight fix the problem.

Last edit: 16 Nov 2021 18:33 by andypugh.

Please Log in or Create an account to join the conversation.

- +Jan+

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 16

17 Nov 2021 14:26 - 17 Nov 2021 14:26 #226736

by +Jan+

Replied by +Jan+ on topic G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

I'm afraid that I'm not judicious enough to implement that accordingly  .

.

Can you please describe the workaround in more detail?

Thanks in advance

Jan

Can you please describe the workaround in more detail?

Thanks in advance

Jan

Last edit: 17 Nov 2021 14:26 by +Jan+.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

17 Nov 2021 14:37 #226737

by andypugh

Replied by andypugh on topic G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

It's hard to know without context.

One thing to look at... What does your code do if the probe fails to find the sensor?

One thing to look at... What does your code do if the probe fails to find the sensor?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

17 Nov 2021 14:45 #226739

by andypugh

Replied by andypugh on topic G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

Looking at the preview interpreter:

github.com/LinuxCNC/linuxcnc/blob/master...sai/saicanon.cc#L397

It looks like the tool point moves to 0.254mm short of the programmed probe end position, but does not set the "probe success" parameter flag.

The issue that you are seeing is likely to be that the calculated result in preview mode appears to be a very short tool, one with a tip somewhere inside the headstock.

Maybe just skip the whole probe routine if #<_task> EQ 0 ?

github.com/LinuxCNC/linuxcnc/blob/master...sai/saicanon.cc#L397

It looks like the tool point moves to 0.254mm short of the programmed probe end position, but does not set the "probe success" parameter flag.

The issue that you are seeing is likely to be that the calculated result in preview mode appears to be a very short tool, one with a tip somewhere inside the headstock.

Maybe just skip the whole probe routine if #<_task> EQ 0 ?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

17 Nov 2021 14:47 #226740

by andypugh

Replied by andypugh on topic G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

The following user(s) said Thank You: +Jan+

Please Log in or Create an account to join the conversation.

- +Jan+

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 16

17 Nov 2021 23:06 #226805

by +Jan+

Replied by +Jan+ on topic G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

I have now added an If query at the beginning of the tool length measurement as it is implemented for example at Gmoccapy:

Is this implemented correctly?

Unfortunately the problem persists and I don't get a debug message when refreshing the preview.

Best wishes

Jan

o<messen_eng> sub

o100 if [#<_task> EQ 0]

(debug, Task is zero)

o100 return [999]

o100 endif

M64P10

#1700=1200 (Tool change X position)

#1701=0 (Tool change Y position)

#1702=-1 (Tool change Z position)

#1800=-100 (position sicheres Z)

#1801=1279.125 (position probe X)

#1802=2498 (position probe Y)

#1900=#<_coord_system> (Store coordinate system only G54 till G59)

o500 if [#<_current_tool> EQ #<_selected_tool>]

;(debug, Tool already in spindle)

o500 else

M5

G54

G90 G0

G53 Z#1702 (Go to tool change Z position)

G53 X#1700 Y#1701 (Go to tool change XY position)

M6 T#<_selected_tool>

#4999=#5400

G43.1 Z0 (TLO reset)

G53 X#1801 Y#1802 (Go to probe position)

G53 Z#1800 (Go to save Z position)

G91

G38.2 Z-197.5 F850 (probing fast)

G1 Z2.0 F150 (go up a bit)

G38.2 Z-2.25 F25 (probing slow)

#2000=[#5063+#5223] (Switching point+zero Offset)

#2001=[#2000-#2002+#2003](new - diff + old)

#2002=[#2000] (Save old switch point)

#2003=[#2001] (Save old offset)

G1 Z5.0 F500 (go up away from sensor)

G90 G0

G43.1 Z#2001 (TLO set)

G53 Z#1800 (Go to save Z position)

G53 Z#1702 (Go to tool change Z position)

#1803=1 (State tool already measured)

;(debug, Differenz ist: #2001)

(Restore old zero (only G54 to G59)

o200 if[#1900 EQ 540]

G54

o200 endif

o201 if[#1900 EQ 550]

G55

o201 endif

o202 if[#1900 EQ 560]

G56

o202 endif

o203 if[#1900 EQ 570]

G57

o203 endif

o204 if[#1900 EQ 580]

G58

o204 endif

o500 endif

M65P10

o<messen_eng> endsub

M2Is this implemented correctly?

Unfortunately the problem persists and I don't get a debug message when refreshing the preview.

Best wishes

Jan

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

17 Nov 2021 23:53 #226809

by andypugh

Replied by andypugh on topic G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

I think that the o100 in front of the return is wrong.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

18 Nov 2021 03:29 #226822

by JohnnyCNC

Replied by JohnnyCNC on topic G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

Last year I did a remap based on the same one you based yours on. I used the the QTDragon GUI, 3DProbe, eBay tool setter, and TTS tooling. My remap handles both fixed length tools and variable length tools. Variable length tools get automatically measured right after the tool change and fixed length tool use the length listed in the tool table. I remember getting that error while working through my remap but I don't recall the exact cause. You may find some clues by looking at my remap. You can find it

posted here

John

John

Please Log in or Create an account to join the conversation.

- d2inventory

- Offline

- Senior Member

-

Less

More

- Posts: 41

- Thank you received: 10

18 Nov 2021 11:04 - 18 Nov 2021 14:58 #226853

by d2inventory

this is how you exit the subroutine.

btw, can you reproduce your error in a SIM config? I wasn't able to.

I managed to reproduce it and the above if clause fixed the issue as andy suggested.

Also if you're using a button type of touch probe you should debounce it, mine bounces for a few milliseconds so I used a 5ms debounce.

linuxcnc.org/docs/html/hal/rtcomps.html#_debounce

Replied by d2inventory on topic G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

o100 if [#<_task> EQ 0]

(debug, Task is zero)

o<messen_eng> return

o100 endifthis is how you exit the subroutine.

I managed to reproduce it and the above if clause fixed the issue as andy suggested.

Also if you're using a button type of touch probe you should debounce it, mine bounces for a few milliseconds so I used a 5ms debounce.

linuxcnc.org/docs/html/hal/rtcomps.html#_debounce

Last edit: 18 Nov 2021 14:58 by d2inventory.

Please Log in or Create an account to join the conversation.

- GCode and Part Programs

- G&M Codes

- G43.1 Dynamic Tool Length Measurement - Program Exceeds machine maximum on axis

Time to create page: 0.141 seconds