Having trouble with Coordinate System on multihead router.

- HueyHQ

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

29 Sep 2019 08:12 - 29 Sep 2019 20:22 #146543

by HueyHQ

Having trouble with Coordinate System on multihead router. was created by HueyHQ

This has me so incredibly stumped after a couple of hours, I have to ask for help. I've only cut a few pieces, so still new at this.

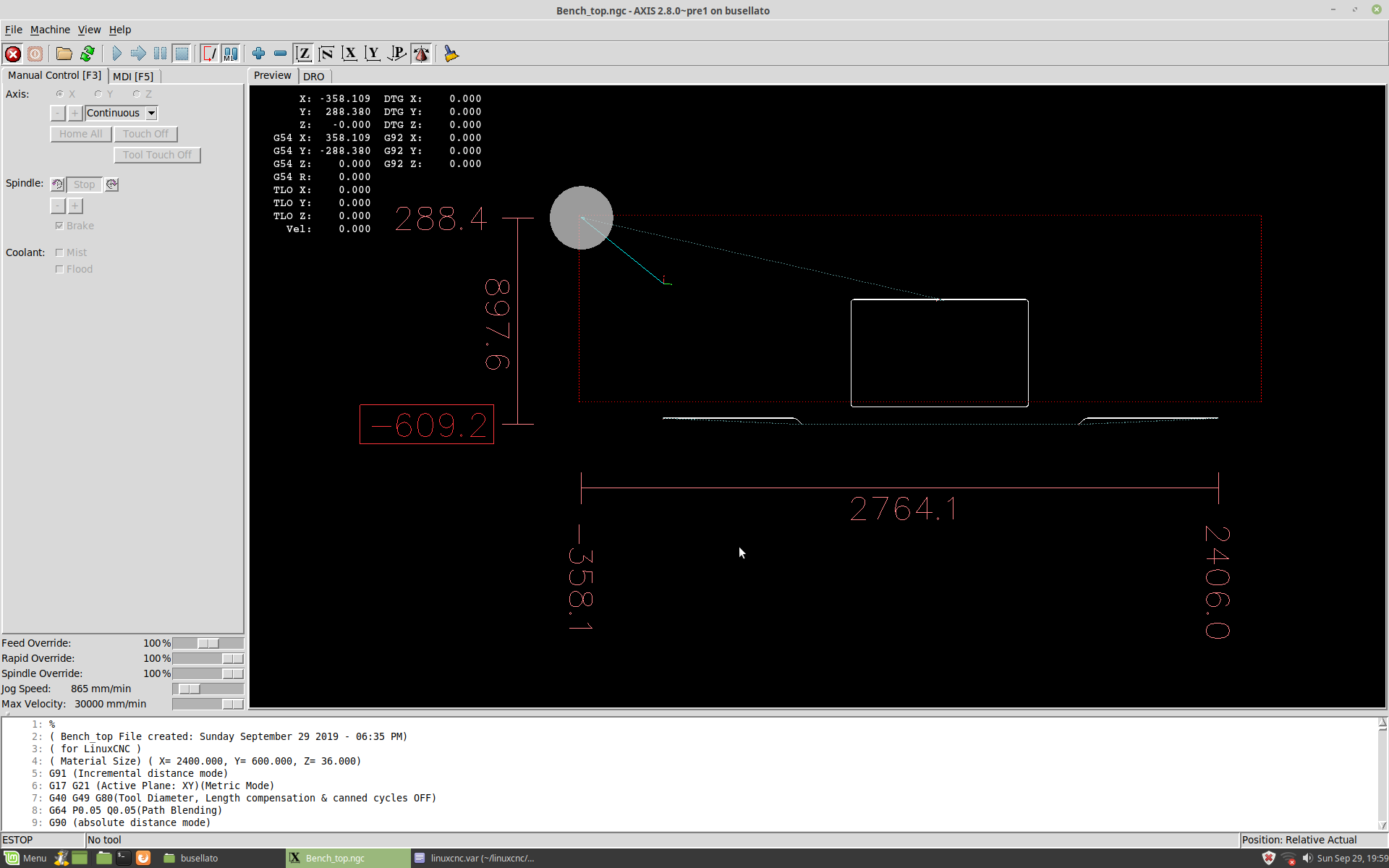

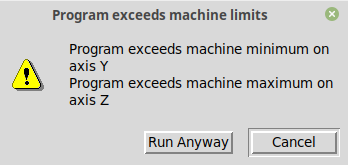

When I try to run my program, I get Y minimum and Z minimum out of machine limits. The preview confirms the problem in red.

The frustrating part is that I ran a test cut on a thinner piece just before, and all I did was touch-off the thicker piece!

In my tool table, T1 has an offset of 0,0 and my main router spindle T21 has an offset of -271.5,282.75.

I used T1 to set up G54 X/Y coordinates, then used T21 to set G54 Z and touch-off the tool length, seeing as it was the only tool I was going to use. (This is something I've never done before as I see the Z in the the tool table is 0.)

The only entries in linuxcnc.var are:which looks about right (altho' I don't understand why the Z parameter is zero?).

It's as if the tool offset is not being applied to the G54 parameters, but the program appears outside the machine limits at load so I wouldn't expect them to.

I tried setting G54 to T21 but doesn't seem to make any difference (the var params might be from that point).

The head of my Gcode looks like this:(Don't know why the G91, then the G90 - any ideas accepted!)

I apply a G43 after the tool change, but I've changed it since to be done in the toolchange remap function.

I've attached my HAL and INI files just in case, but don't really think they are an issue; I strongly suspect it is some simple switch in the GUI I've missed.

Thanks in advance,

Jon

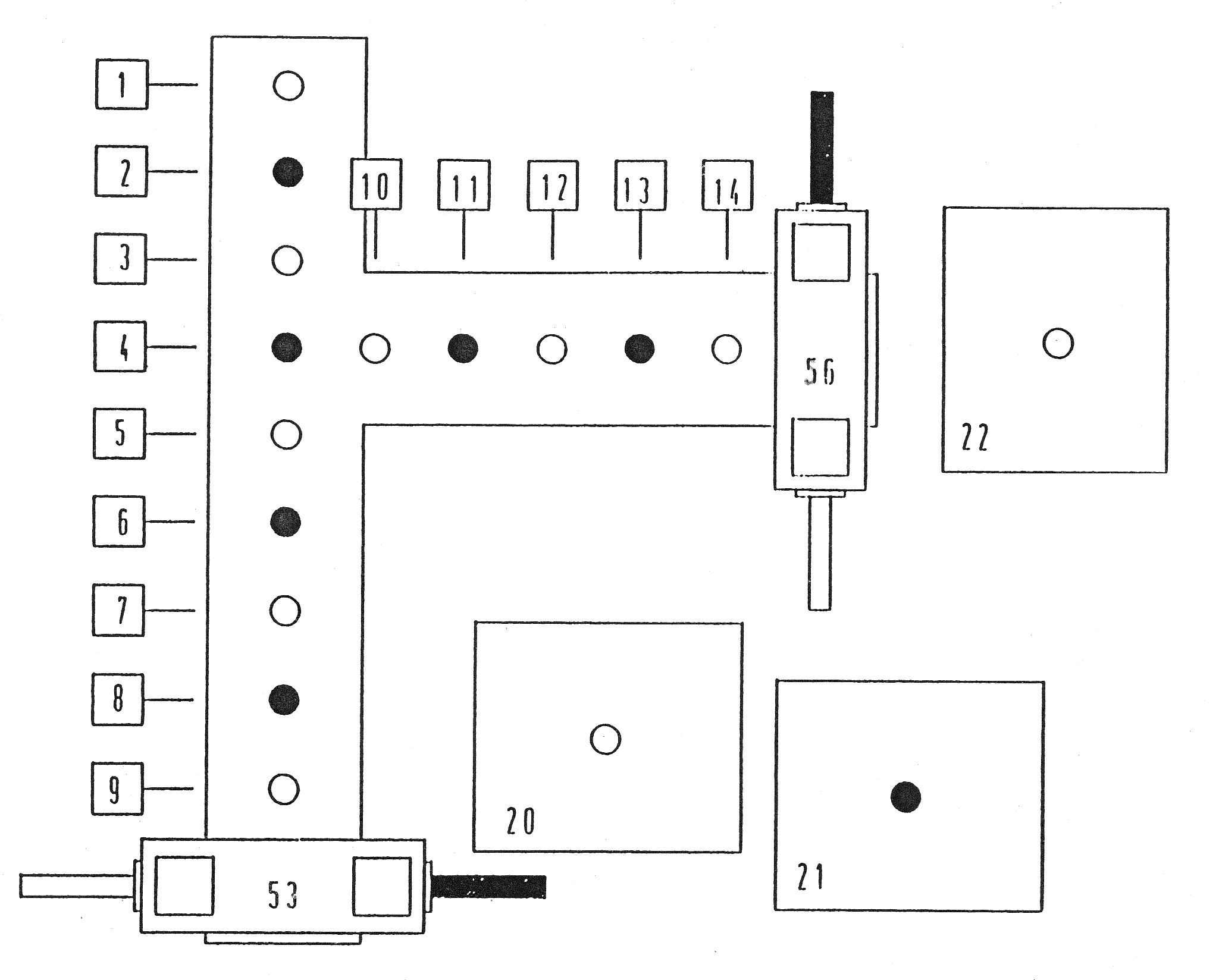

EDIT: My spindle configuration is like this, altho' not fully populate in tool.tbl yet:

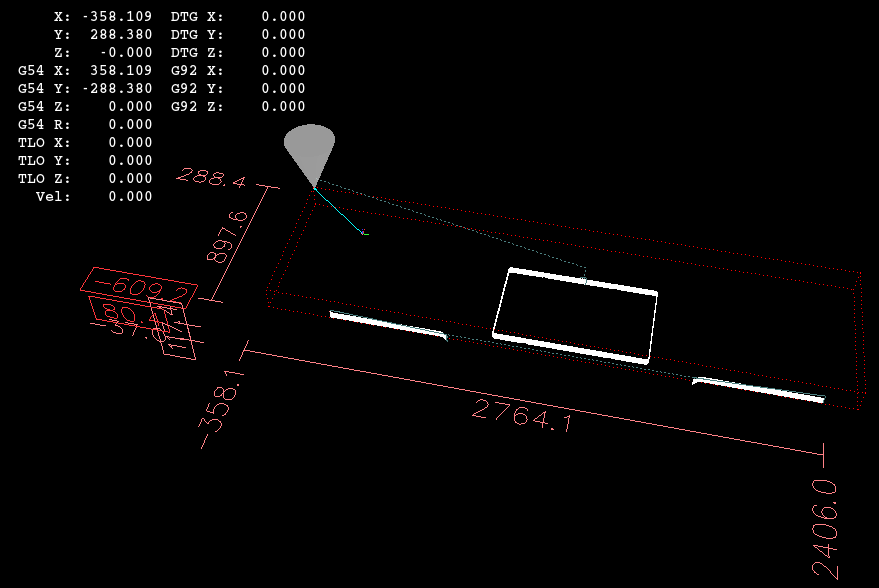

View in perspective mode showing error in Y and Z:

Actual error message:

When I try to run my program, I get Y minimum and Z minimum out of machine limits. The preview confirms the problem in red.

The frustrating part is that I ran a test cut on a thinner piece just before, and all I did was touch-off the thicker piece!

In my tool table, T1 has an offset of 0,0 and my main router spindle T21 has an offset of -271.5,282.75.

I used T1 to set up G54 X/Y coordinates, then used T21 to set G54 Z and touch-off the tool length, seeing as it was the only tool I was going to use. (This is something I've never done before as I see the Z in the the tool table is 0.)

The only entries in linuxcnc.var are:

5220 1.000000

5221 358.108649

5222 -288.380267It's as if the tool offset is not being applied to the G54 parameters, but the program appears outside the machine limits at load so I wouldn't expect them to.

I tried setting G54 to T21 but doesn't seem to make any difference (the var params might be from that point).

The head of my Gcode looks like this:

( Bench_top File created: Sunday September 29 2019 - 06:35 PM)

( for LinuxCNC )

( Material Size) ( X= 2400.000, Y= 600.000, Z= 36.000)

G91 (Incremental distance mode)

G17 G21 (Active Plane: XY)(Metric Mode)

G40 G49 G80(Tool Diameter, Length compensation & canned cycles OFF)

G64 P0.05 Q0.05(Path Blending)

G90 (absolute distance mode)

G94 (feed rate mode)

M7

T21 M6 ;End Mill (12 mm)

G43 H21

M03 S11100

G54 (Coordinate System)

G00 X-6.000 Y-582.000 Z15.000 F21800.0

G00 X-6.000 Y-582.000 Z5.000

G01 Z-3.700 F3600.0 G4 P0.2

G01 X558.432 Y-582.000 F10900.0

G02 X581.868 Y-591.768 I0.000 J-33.000

G01 X581.878 Y-591.777

G01 X581.885 Y-591.785

G01 X595.050 Y-604.950

G01 X599.293 Y-609.192I apply a G43 after the tool change, but I've changed it since to be done in the toolchange remap function.

I've attached my HAL and INI files just in case, but don't really think they are an issue; I strongly suspect it is some simple switch in the GUI I've missed.

Thanks in advance,

Jon

EDIT: My spindle configuration is like this, altho' not fully populate in tool.tbl yet:

View in perspective mode showing error in Y and Z:

Actual error message:

Last edit: 29 Sep 2019 20:22 by HueyHQ. Reason: Added more info with pics

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

29 Sep 2019 13:49 #146562

by pl7i92

Replied by pl7i92 on topic Having trouble with Coordinate System on multihead router.

hi

first the error showes the g-code out of limits in Y nothing to do on Z

so did you Touch_off part G54 with the tool that is zero in tooltable usaly the first all otheres are mesurerd agaiunst this Z value

multitool so did you only got one spindle in playce or are the spindles apart

first the error showes the g-code out of limits in Y nothing to do on Z

so did you Touch_off part G54 with the tool that is zero in tooltable usaly the first all otheres are mesurerd agaiunst this Z value

multitool so did you only got one spindle in playce or are the spindles apart

Please Log in or Create an account to join the conversation.

- HueyHQ

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

29 Sep 2019 18:54 #146610

by HueyHQ

Replied by HueyHQ on topic Having trouble with Coordinate System on multihead router.

There were two out-of-limit errors - I've only shown the Y-error for clarity in the Z-view.first the error showes the g-code out of limits in Y nothing to do on Z

No - I touched off using Tool #1. I'm not sure of the effect of touching off with no tool selected?so did you Touch_off part G54 with the tool that is zero in tooltable usaly the first all otheres are mesurerd agaiunst this Z value

Three router spindles and a bank of drills as per the tooltbl.txt attachedmultitool so did you only got one spindle in playce or are the spindles apart

Please Log in or Create an account to join the conversation.

- HueyHQ

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

29 Sep 2019 21:25 #146627

by HueyHQ

Replied by HueyHQ on topic Having trouble with Coordinate System on multihead router.

I had a thought; I tried to move Y to -600mm with T1 selected and ran into a machine limit error there - maybe LinuxCNC now knows there is a limit for the range of tools?

I'm thinking I might need to change my reference tool to T9.

I'm thinking I might need to change my reference tool to T9.

Please Log in or Create an account to join the conversation.

- HueyHQ

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

30 Sep 2019 00:46 #146656

by HueyHQ

Replied by HueyHQ on topic Having trouble with Coordinate System on multihead router. - SOLVED (CAM issue)

I tried systematically changing the reference to T9 and setting the tool heights, with the same result.

Had another look over the G-code and found this in the middle:

The CAM program had added the default tool #1, even though the text said "End Mill (12 mm)" indicating tool #21.

I had to explicitly select T21 again, and all was good again.

Something to watch out for in the future, I guess!

Had another look over the G-code and found this in the middle:

T1 M6 ;End Mill (12 mm)

G43 H1

S12000 M03The CAM program had added the default tool #1, even though the text said "End Mill (12 mm)" indicating tool #21.

I had to explicitly select T21 again, and all was good again.

Something to watch out for in the future, I guess!

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

30 Sep 2019 06:45 - 30 Sep 2019 06:47 #146684

by pl7i92

Replied by pl7i92 on topic Having trouble with Coordinate System on multihead router.

what cam are you using

can you post a image of this realy interesting tool setup on the mashine

can you post a image of this realy interesting tool setup on the mashine

Last edit: 30 Sep 2019 06:47 by pl7i92.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

30 Sep 2019 10:43 #146703

by bevins

Replied by bevins on topic Having trouble with Coordinate System on multihead router.

Huey, Would you mind sharing your remap files? I would like to look at them.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

30 Sep 2019 13:43 #146710

by pl7i92

Replied by pl7i92 on topic Having trouble with Coordinate System on multihead router.

i guess it will be a real interesting remap to be public so many use a sqare Toolholder or even a cube on all sides

Please Log in or Create an account to join the conversation.

- HueyHQ

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

01 Oct 2019 06:50 #146783

by HueyHQ

Yeah, sure.

Fairly basic, but it works. I think I learnt about it from you, Bob - except I avoided the Python way!

Replied by HueyHQ on topic Having trouble with Coordinate System on multihead router.

Huey, Would you mind sharing your remap files? I would like to look at them.

Yeah, sure.

Fairly basic, but it works. I think I learnt about it from you, Bob - except I avoided the Python way!

The following user(s) said Thank You: bevins

Please Log in or Create an account to join the conversation.

- HueyHQ

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

01 Oct 2019 07:17 - 01 Oct 2019 07:19 #146787

by HueyHQ

I'm using an older version of Vectric Aspire - came with the machine, and it works mostly for what I need.

The images are not the best; I am away from home and these are the only ones I found:

Replied by HueyHQ on topic Having trouble with Coordinate System on multihead router.

what cam are you using

can you post a image of this realy interesting tool setup on the mashine

I'm using an older version of Vectric Aspire - came with the machine, and it works mostly for what I need.

The images are not the best; I am away from home and these are the only ones I found:

Attachments:

Last edit: 01 Oct 2019 07:19 by HueyHQ.

Please Log in or Create an account to join the conversation.

Time to create page: 0.149 seconds