Having trouble with Coordinate System on multihead router.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

01 Oct 2019 08:28 - 01 Oct 2019 08:30 #146789

by bevins

Nice job. yeah I have to learn it this way.NGC remap. python with a complicated remap has issues.

I just got another machine and am going to try it with ngc remap. THis machine has no tool changer but two spindles and a drill bank.

Cool machine BTW....

Replied by bevins on topic Having trouble with Coordinate System on multihead router.

Huey, Would you mind sharing your remap files? I would like to look at them.

Yeah, sure.

Fairly basic, but it works. I think I learnt about it from you, Bob - except I avoided the Python way!

Nice job. yeah I have to learn it this way.NGC remap. python with a complicated remap has issues.

I just got another machine and am going to try it with ngc remap. THis machine has no tool changer but two spindles and a drill bank.

Cool machine BTW....

Last edit: 01 Oct 2019 08:30 by bevins.

Please Log in or Create an account to join the conversation.

- terans1085

-

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 0

01 Oct 2019 13:11 - 01 Oct 2019 13:12 #146803

by terans1085

Replied by terans1085 on topic Having trouble with Coordinate System on multihead router.

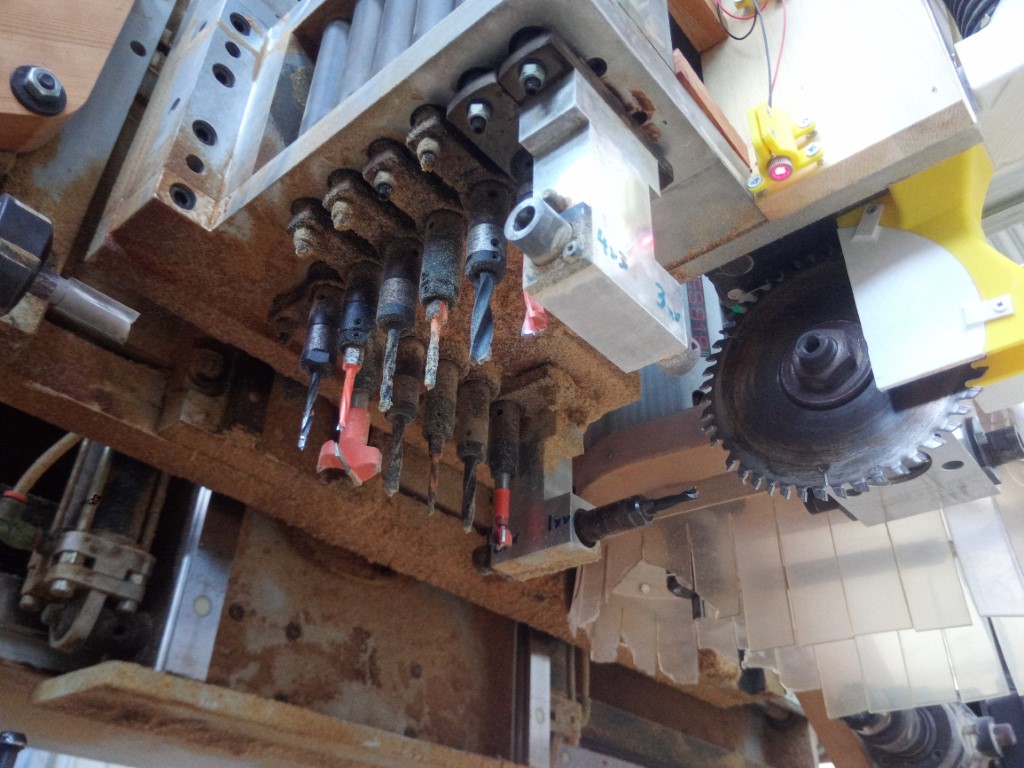

Hi I have a similar router with a similar boring head. When working with the boring head, my CAM will always select the tooltable offsets of tool 1 using "H1 G43" then the actual coordinate is subtracted/added to the gcodes depending on which drill is needed (since the drills are standard pitched at 32mm for this setup and saved in CAM setup).

Also an interesting point is that the CAM is able to activate multiple drills at one go for, say, high speed drilling of shelf supports at standard 32mm intervals.

Also an interesting point is that the CAM is able to activate multiple drills at one go for, say, high speed drilling of shelf supports at standard 32mm intervals.

Attachments:

Last edit: 01 Oct 2019 13:12 by terans1085.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

01 Oct 2019 13:58 #146808

by bevins

How are you adding the offset if you always use H1 G43?

Replied by bevins on topic Having trouble with Coordinate System on multihead router.

Hi I have a similar router with a similar boring head. When working with the boring head, my CAM will always select the tooltable offsets of tool 1 using "H1 G43" then the actual coordinate is subtracted/added to the gcodes depending on which drill is needed (since the drills are standard pitched at 32mm for this setup and saved in CAM setup).

Also an interesting point is that the CAM is able to activate multiple drills at one go for, say, high speed drilling of shelf supports at standard 32mm intervals.

How are you adding the offset if you always use H1 G43?

Please Log in or Create an account to join the conversation.

- terans1085

-

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 0

01 Oct 2019 14:08 #146810

by terans1085

Replied by terans1085 on topic Having trouble with Coordinate System on multihead router.

The offset is added in the CAM, including all the diameters of the drills attached. When "Drill Block" is selected as a toolpath in CAM, it automatically offsets the output gcode with respect to drill 1 (H1 G43)

Attachments:

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

01 Oct 2019 14:23 #146812

by bevins

I must have misunderstood something. Yeah, g43 HX takes the offsets in tool table.

Replied by bevins on topic Having trouble with Coordinate System on multihead router.

The offset is added in the CAM, including all the diameters of the drills attached. When "Drill Block" is selected as a toolpath in CAM, it automatically offsets the output gcode with respect to drill 1 (H1 G43)

I must have misunderstood something. Yeah, g43 HX takes the offsets in tool table.

Please Log in or Create an account to join the conversation.

- HueyHQ

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

01 Oct 2019 21:56 #146832

by HueyHQ

Luckily for me, Bob has been quite prolific on this forum!

I have Z-setter on order with the intention of making it a permanent fixture somewhere, then remap an NGC subroutine to automatically set the tool height for a single tool, or all tools, depending on the parameter given. Should make changing tools a lot simpler, esp. if I ever want to gang-drill, and then change back.

Thanks for sharing!

Replied by HueyHQ on topic Having trouble with Coordinate System on multihead router.

Excellent! It's really good to know who else has a similar setup - where were you months ago when I started?!?Hi I have a similar router with a similar boring head.

Luckily for me, Bob has been quite prolific on this forum!

Likewise. Altho' I think I will probably set it up for different drill sizes for use on-demand. There may come a time when I will want to gang-drill, but I don't see any need for the near future.Also an interesting point is that the CAM is able to activate multiple drills at one go for, say, high speed drilling of shelf supports at standard 32mm intervals.

I have Z-setter on order with the intention of making it a permanent fixture somewhere, then remap an NGC subroutine to automatically set the tool height for a single tool, or all tools, depending on the parameter given. Should make changing tools a lot simpler, esp. if I ever want to gang-drill, and then change back.

Thanks for sharing!

Please Log in or Create an account to join the conversation.

- craigs711btm

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

03 Dec 2023 14:59 #287100

by craigs711btm

Replied by craigs711btm on topic Having trouble with Coordinate System on multihead router.

have you got the drill bank all working now ?

I started a rover 15 2 years ago I've got it all working apart from the drill bank and the spindle to go up and down when being used.

I believe my machine is almost identical to yours but I only have one spindle no atc to worry about.

id love to get this machine up and running and any pointers would be amazing. I also use vetric software for most my drawings

I started a rover 15 2 years ago I've got it all working apart from the drill bank and the spindle to go up and down when being used.

I believe my machine is almost identical to yours but I only have one spindle no atc to worry about.

id love to get this machine up and running and any pointers would be amazing. I also use vetric software for most my drawings

Please Log in or Create an account to join the conversation.

- HueyHQ

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

03 Dec 2023 18:46 #287119

by HueyHQ

Replied by HueyHQ on topic Having trouble with Coordinate System on multihead router.

Yup, it's all going for a couple of years now - works well!

What do you need to get it going? I think it's all in the HAL and INI files where the pins are connected to the spindle signals.

Attach those two files and we'll have a look.

I'm using an older version of LinuxCNC as I have been able to get the toolchanger working in the latest, so it may be beneficial for me to help you out!

What do you need to get it going? I think it's all in the HAL and INI files where the pins are connected to the spindle signals.

Attach those two files and we'll have a look.

I'm using an older version of LinuxCNC as I have been able to get the toolchanger working in the latest, so it may be beneficial for me to help you out!

Please Log in or Create an account to join the conversation.

- craigs711btm

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

03 Dec 2023 19:00 #287125

by craigs711btm

Replied by craigs711btm on topic Having trouble with Coordinate System on multihead router.

I will add the files tomorrow I don't have a copy with me unfortanly.

I've taken the atc spindle off mine to put it on my flatbed machine as its got the drill bank and i only need one tool in this one … hopefully.

how do you call the tools on the tool bank now with tool numbers from cam ? and then the remap takes care of energising the relay for the motor and whichever tool needs to be down ? do you use the tool table for the offsets.

would be amazing to get the drill bank going this has been a 2 year project when i can find time and its annoying me now keep looking at it

I've taken the atc spindle off mine to put it on my flatbed machine as its got the drill bank and i only need one tool in this one … hopefully.

how do you call the tools on the tool bank now with tool numbers from cam ? and then the remap takes care of energising the relay for the motor and whichever tool needs to be down ? do you use the tool table for the offsets.

would be amazing to get the drill bank going this has been a 2 year project when i can find time and its annoying me now keep looking at it

Please Log in or Create an account to join the conversation.

- craigs711btm

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

03 Dec 2023 19:02 #287126

by craigs711btm

Replied by craigs711btm on topic Having trouble with Coordinate System on multihead router.

i have had all the spindles popping down all the wiring side is done so its just the coding side of it now to make do its thing.

are you still using vetric for cad/cam

are you still using vetric for cad/cam

Please Log in or Create an account to join the conversation.

Time to create page: 0.151 seconds