Control Panel setup

- Duc

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

20 Apr 2014 21:18 #46138

by Duc

Hmmmm.

Wonder if Ive run into a limit with mux16 or something. Changing nothing for the code except what servo-thread is turned off I can get the mux output to function.

foincr will work if jogincr, mvoincr, soincr servo threads are commented out

jogincr will work if foincr, mvoincr, soincr servo threads are commented out

if more than one is active then all will fail to operate correctly or at all. The inputs into the mux function will toggle correctly such as jogincr.sel0, jogincr.sel1 ..etc but the jogincr.out -f will not change. I see this with all the outputs for the mux functions.

Replied by Duc on topic Control Panel setup

Here is a hint, comment out the addf then run your config and if your using Axis open the Show Hal Configuration window to see the pin names. If your not running Axis you can open a terminal and say halcmd show pin and that will give you a list of all your pins. Also in the terminal window you can see the functions you created with loadrt and loadusr by saying halcmd show function. These will be the names you need to use with addf.

When you use the name option like:

loadrt mux16 names=jogincr,foincr,mvoincr,soincr

the pin name will be jogincr,foincr,mvoincr,soincr

so the addf line will be

addf jogincr servo-thread

JT

Hmmmm.

Wonder if Ive run into a limit with mux16 or something. Changing nothing for the code except what servo-thread is turned off I can get the mux output to function.

foincr will work if jogincr, mvoincr, soincr servo threads are commented out

jogincr will work if foincr, mvoincr, soincr servo threads are commented out

if more than one is active then all will fail to operate correctly or at all. The inputs into the mux function will toggle correctly such as jogincr.sel0, jogincr.sel1 ..etc but the jogincr.out -f will not change. I see this with all the outputs for the mux functions.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 19162

- Thank you received: 5297

20 Apr 2014 21:49 #46140

by PCW

Replied by PCW on topic Control Panel setup

Maybe a bug in mux16, can you try numbered mux16 instead of named ones?

(mux16.0,mux16.1 etc)

(mux16.0,mux16.1 etc)

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

21 Apr 2014 01:45 #46147

by BigJohnT

Replied by BigJohnT on topic Control Panel setup

I suspect you still have a coding error. I set up two mux16's using names and they work fine in the 2.5.4 simulator.

my postgui.hal file

my pyvcp-panel.xml file

JT

my postgui.hal file

loadrt mux16 names=fred,barny

addf fred servo-thread

addf barny servo-thread

# setup mux16

setp fred.use-graycode 1

setp fred.in01 1.0

setp fred.in02 2.0

setp fred.in03 3.0

setp fred.in04 4.0

setp fred.in05 5.0

setp fred.in06 6.0

#setp mux16.0.in07 7.0

#setp mux16.0.in08 8.0

setp fred.in09 7.0

setp fred.in10 8.0

setp fred.in11 9.0

setp fred.in12 10.0

setp fred.in13 11.0

setp fred.in14 12.0

setp barny.use-graycode 1

setp barny.in01 1.0

setp barny.in02 2.0

setp barny.in03 3.0

setp barny.in04 4.0

setp barny.in05 5.0

setp barny.in06 6.0

#setp mux16.0.in07 7.0

#setp mux16.0.in08 8.0

setp barny.in09 7.0

setp barny.in10 8.0

setp barny.in11 9.0

setp barny.in12 10.0

setp barny.in13 11.0

setp barny.in14 12.0

# connect the inputs to the wsum component

net bit-1f fred.sel0 <= pyvcp.input-1

net bit-2f fred.sel1 <= pyvcp.input-2

net bit-4f fred.sel2 <= pyvcp.input-3

net bit-8f fred.sel3 <= pyvcp.input-4

net bit-1b barny.sel0 <= pyvcp.input-5

net bit-2b barny.sel1 <= pyvcp.input-6

net bit-4b barny.sel2 <= pyvcp.input-7

net bit-8b barny.sel3 <= pyvcp.input-8

# connect the output to the pyvcp number display

net sum-out-1 pyvcp.mux-out-1 <= fred.out-s

net sum-out-2 pyvcp.mux-out-2 <= barny.out-smy pyvcp-panel.xml file

<?xml version='1.0' encoding='UTF-8'?>

<pyvcp>

<!--

Include your PyVCP panel here.

The contents of this file will not be overwritten when you run stepconf again.

-->

<checkbutton>

<halpin>"input-1"</halpin>

<text>"Input 1"</text>

</checkbutton>

<checkbutton>

<halpin>"input-2"</halpin>

<text>"Input 2"</text>

</checkbutton>

<checkbutton>

<halpin>"input-3"</halpin>

<text>"Input 3"</text>

</checkbutton>

<checkbutton>

<halpin>"input-4"</halpin>

<text>"Input 4"</text>

</checkbutton>

<s32>

<halpin>"mux-out-1"</halpin>

<font>("Helvetica",12)</font>

<format>"4i"</format>

</s32>

<checkbutton>

<halpin>"input-5"</halpin>

<text>"Input 1"</text>

</checkbutton>

<checkbutton>

<halpin>"input-6"</halpin>

<text>"Input 2"</text>

</checkbutton>

<checkbutton>

<halpin>"input-7"</halpin>

<text>"Input 3"</text>

</checkbutton>

<checkbutton>

<halpin>"input-8"</halpin>

<text>"Input 4"</text>

</checkbutton>

<s32>

<halpin>"mux-out-2"</halpin>

<font>("Helvetica",12)</font>

<format>"4i"</format>

</s32>

</pyvcp>JT

Please Log in or Create an account to join the conversation.

- Duc

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

21 Apr 2014 08:50 #46158

by Duc

Replied by Duc on topic Control Panel setup

I was able to get the code working by switching to the numbers instead of words. Later on I will try with shorter words to see if that is the problem.

I thank you both for the help you have provide. All the knobs work as much as can be from mux16 till I change to 2.6.

I thank you both for the help you have provide. All the knobs work as much as can be from mux16 till I change to 2.6.

Please Log in or Create an account to join the conversation.

- Duc

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

28 Apr 2014 03:12 - 28 Apr 2014 03:13 #46383

by Duc

Replied by Duc on topic Control Panel setup

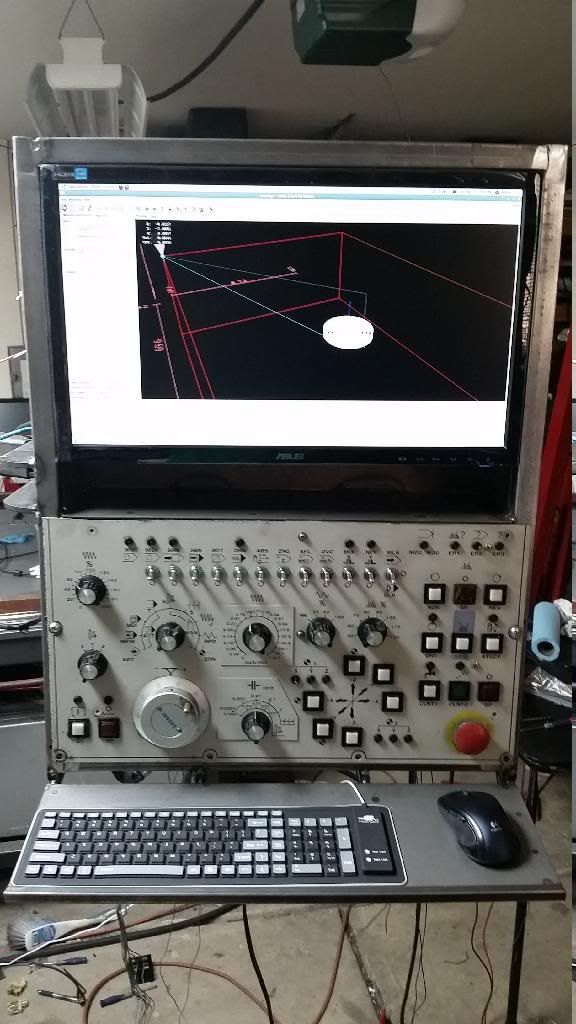

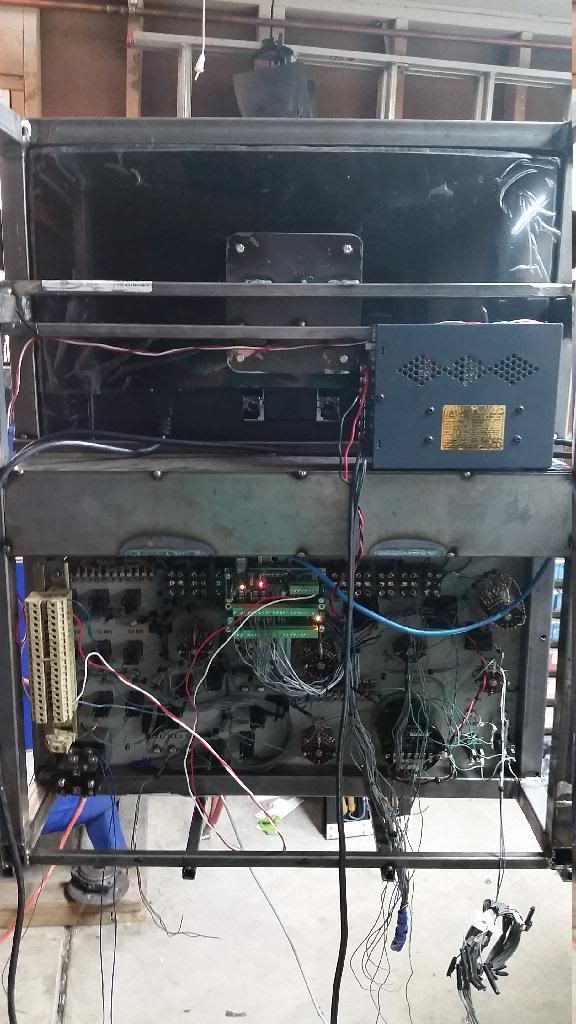

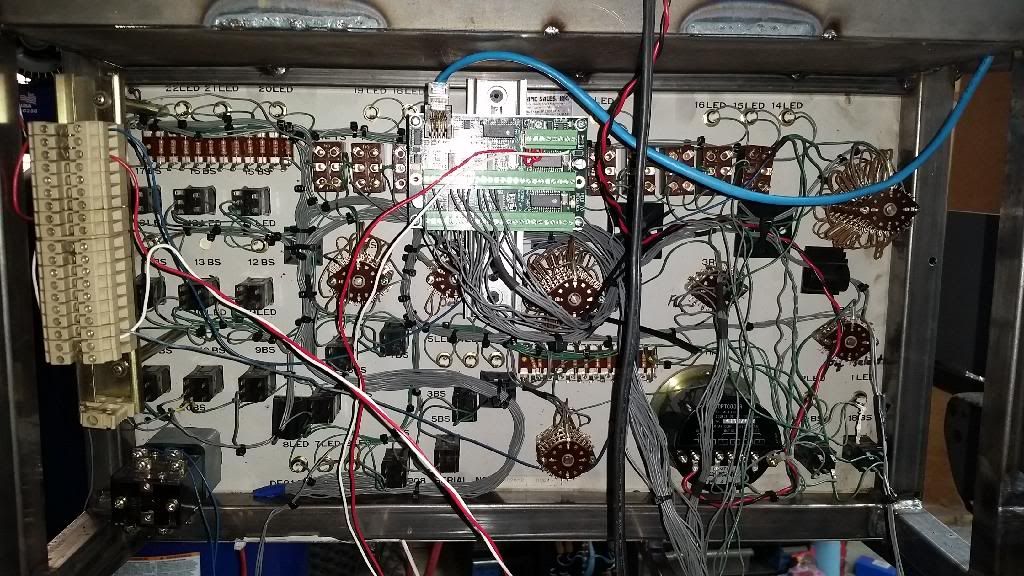

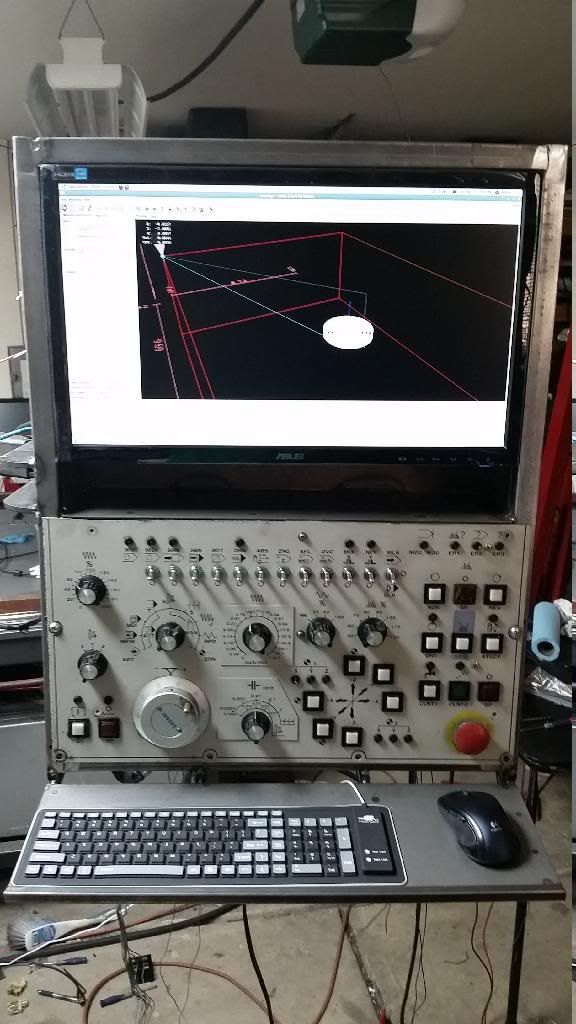

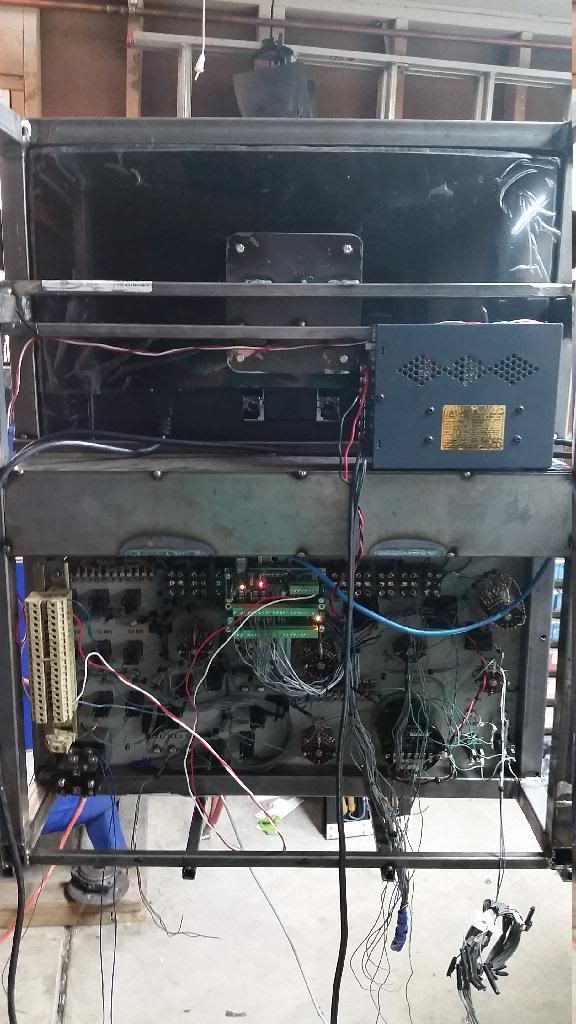

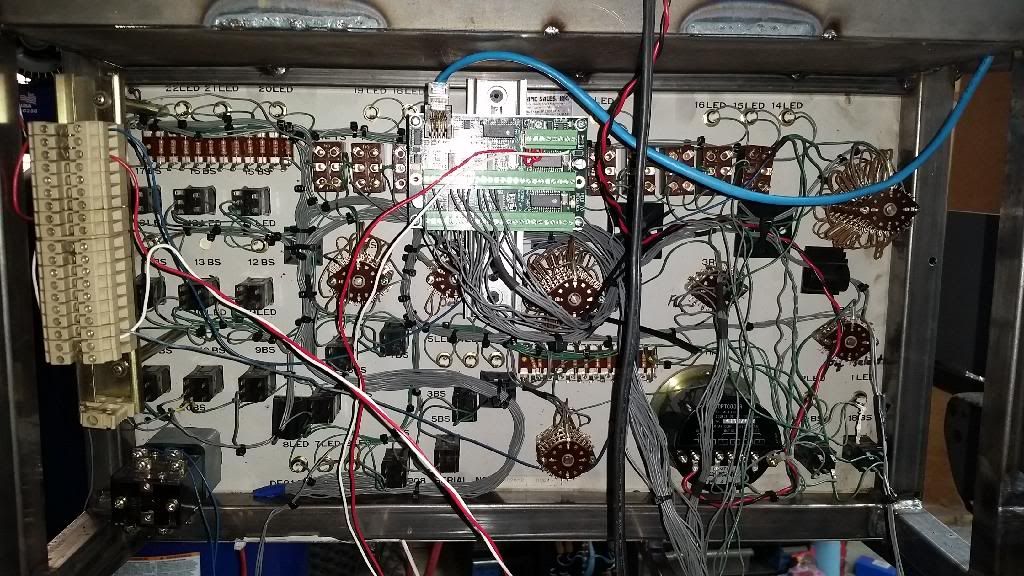

Current pictures of the panel setup. Still finalizing design and wiring before removing everything for painting. The area between the monitor and the panel is for storing dail calipers and other stuff.

Tons more wiring needs to happen before I consider it done.

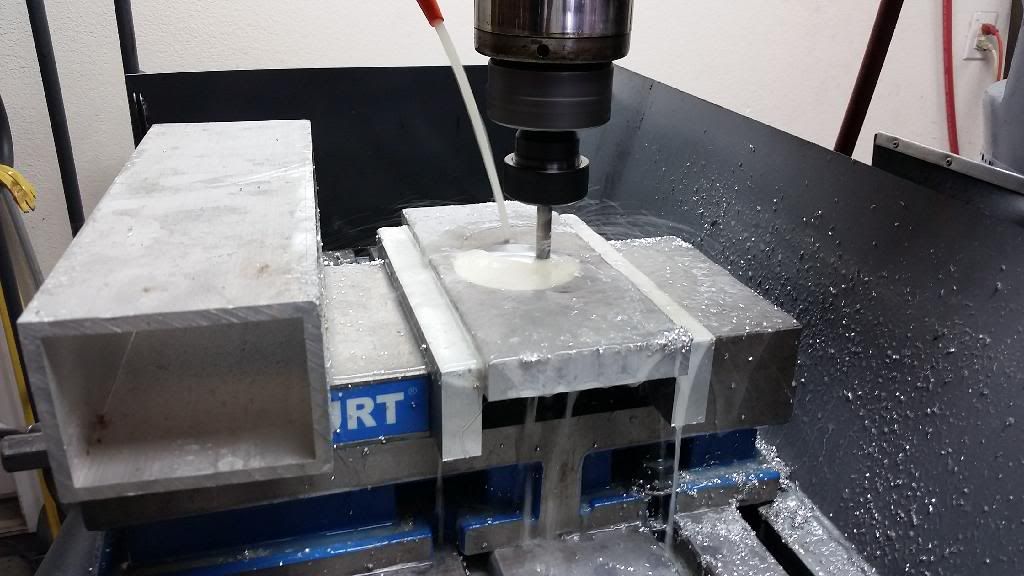

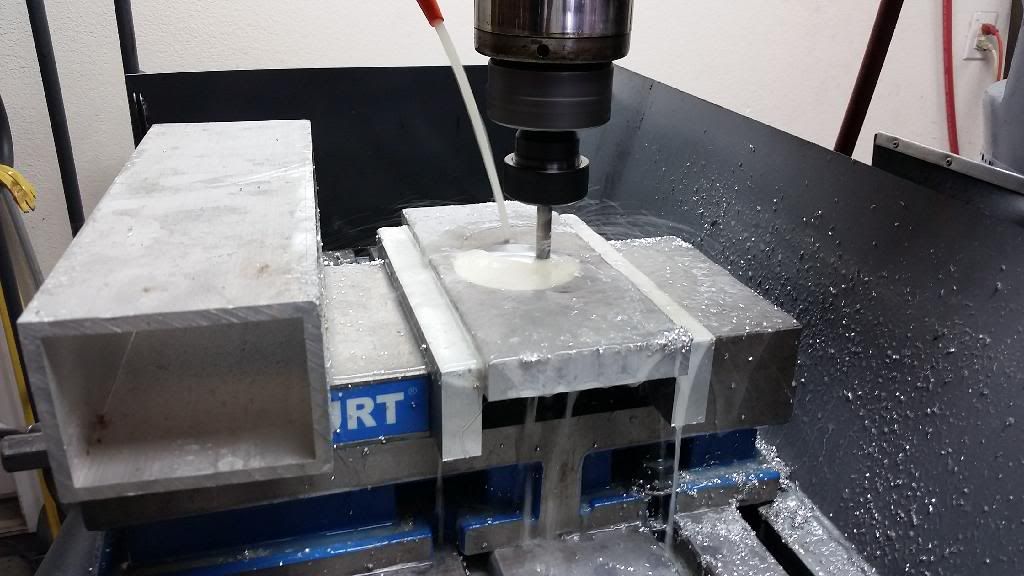

I ran a test cut on some AL 7075 for checking the backlash. 3in circle that I will have the QC department at work check on the CMM.

Max feedrate selection works perfect.

Current issues.

Feed override

1. Feed override percent changes on the screen but doesnt effect the feedrate when cutting.

Spindle RPM

Same problem as feed overide. I can see the slider change on the screen but no change in RPM of the spindle. The HZ on the VFD screen doesnt not change with the override percent selected.

Any ideas

Tons more wiring needs to happen before I consider it done.

I ran a test cut on some AL 7075 for checking the backlash. 3in circle that I will have the QC department at work check on the CMM.

Max feedrate selection works perfect.

Current issues.

Feed override

1. Feed override percent changes on the screen but doesnt effect the feedrate when cutting.

Spindle RPM

Same problem as feed overide. I can see the slider change on the screen but no change in RPM of the spindle. The HZ on the VFD screen doesnt not change with the override percent selected.

Any ideas

Last edit: 28 Apr 2014 03:13 by Duc.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 23543

- Thank you received: 5015

28 Apr 2014 04:09 #46388

by andypugh

Does changing the value on-screen have any effect?

Replied by andypugh on topic Control Panel setup

Are you using the Axis intterface? Is it the conventional FO slider that moves, or did you add another one?1. Feed override percent changes on the screen but doesnt effect the feedrate when cutting.

Does changing the value on-screen have any effect?

Please Log in or Create an account to join the conversation.

- Duc

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

28 Apr 2014 05:25 #46393

by Duc

Using the axis screen and the conventional FO slider does move. I have not added another one.

I will have to test after dinner if it makes a difference if I move it.

Replied by Duc on topic Control Panel setup

Are you using the Axis intterface? Is it the conventional FO slider that moves, or did you add another one?1. Feed override percent changes on the screen but doesnt effect the feedrate when cutting.

Does changing the value on-screen have any effect?

Using the axis screen and the conventional FO slider does move. I have not added another one.

I will have to test after dinner if it makes a difference if I move it.

Please Log in or Create an account to join the conversation.

- Duc

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

28 Apr 2014 06:15 #46398

by Duc

Replied by Duc on topic Control Panel setup

Adjusting the sliders by the way of the mouse does not cause any change in the feedrate or rpm. I wonder if I broke the link between the sliders when I inserted the knob codes.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 23543

- Thank you received: 5015

28 Apr 2014 06:46 #46400

by andypugh

Can we have a look at your HAL file?

Replied by andypugh on topic Control Panel setup

I wonder if I broke the link between the sliders when I inserted the knob codes.

Can we have a look at your HAL file?

Please Log in or Create an account to join the conversation.

- Duc

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

28 Apr 2014 06:51 #46401

by Duc

Here is the current .Hal file. The timedelay stuff is commented out due to errors.

Replied by Duc on topic Control Panel setup

I wonder if I broke the link between the sliders when I inserted the knob codes.

Can we have a look at your HAL file?

Here is the current .Hal file. The timedelay stuff is commented out due to errors.

# Generated by PNCconf at Sun Jan 6 10:34:22 2002

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

#loadrt timedelay count=1

loadrt abs count=1

loadrt trivkins

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt probe_parport

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=1 num_pwmgens=0 num_3pwmgens=0 num_stepgens=5 sserial_port_0=0200 "

setp hm2_5i25.0.watchdog.timeout_ns 10000000

loadrt mux16 count=4

loadrt ilowpass

#addf timedelay.0 servo-thread

addf ilowpass.0 servo-thread

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf mux16.0 servo-thread #jogincr

addf mux16.1 servo-thread #Feedrate overide

addf mux16.2 servo-thread

addf mux16.3 servo-thread

addf hm2_5i25.0.write servo-thread

addf hm2_5i25.0.pet_watchdog servo-thread

addf abs.0 servo-thread

# external output signals

# external input signals

# ---COOLANT CONROL ---

net coolant-flood hm2_5i25.0.7i76.0.0.output-01

# ---LUBRICATION SYSTEM ---

# --- SPINDLE-BRAKE ---

net spindle-brake hm2_5i25.0.7i76.0.0.output-00

#net spindle-brake => timedelay.0.in

#net spindle-delayed timedelay.0.out-b => hm2_5i25.0.7i76.0.0.output-00

#setp timedelay.0.on-delay 3

#setp timedelay.0.off-delay 0

# --- BOTH-HOME-X ---

net both-home-x <= hm2_5i25.0.7i76.0.0.input-00

# --- BOTH-HOME-Y ---

net both-home-y <= hm2_5i25.0.7i76.0.0.input-01

# --- MAX-HOME-Z ---

net max-home-z <= hm2_5i25.0.7i76.0.0.input-03

# --- MIN-Z ---

net min-z <= hm2_5i25.0.7i76.0.0.input-04

# --- JOINT-SELECT-a-X ---

net joint-select-a <= hm2_5i25.0.7i84.0.1.input-00

# --- JOINT-SELECT-b-Y ---

net joint-select-b <= hm2_5i25.0.7i84.0.1.input-01

# --- JOINT-SELECT-c-Z ---

net joint-select-c <= hm2_5i25.0.7i84.0.1.input-02

# --- JOINT-SELECT-d-A ---

net joint-select-d <= hm2_5i25.0.7i84.0.1.input-03

# --- JOG-INCR-A ---

net jog-incr-a <= hm2_5i25.0.7i84.0.1.input-11

# --- JOG-INCR-B ---

net jog-incr-b <= hm2_5i25.0.7i84.0.1.input-10

# --- JOG-INCR-C ---

net jog-incr-c <= hm2_5i25.0.7i84.0.1.input-09

# --- Feedrate overide - FO-INCR-A ---

net fo-incr-a <= hm2_5i25.0.7i84.0.1.input-08

# --- FO-INCR-B ---

net fo-incr-b <= hm2_5i25.0.7i84.0.1.input-07

# --- FO-INCR-C ---

net fo-incr-c <= hm2_5i25.0.7i84.0.1.input-06

# --- FO-INCR-D ---

net fo-incr-d <= hm2_5i25.0.7i84.0.1.input-05

# --- Spindle override - SO-INCR-A ---

net so-incr-a <= hm2_5i25.0.7i84.0.1.input-25

# --- SO-INCR-B ---

net so-incr-b <= hm2_5i25.0.7i84.0.1.input-26

# --- SO-INCR-C ---

net so-incr-c <= hm2_5i25.0.7i84.0.1.input-27

# --- Max velocity override - MVO-INCR-A ---

net mvo-incr-a <= hm2_5i25.0.7i84.0.1.input-20

# --- MVO-INCR-B ---

net mvo-incr-b <= hm2_5i25.0.7i84.0.1.input-21

# --- MVO-INCR-C ---

net mvo-incr-c <= hm2_5i25.0.7i84.0.1.input-22

# --- MVO-INCR-D ---

net mvo-incr-d <= hm2_5i25.0.7i84.0.1.input-23

#*******************

# AXIS X

#*******************

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.00.dirsetup [AXIS_0]DIRSETUP

setp hm2_5i25.0.stepgen.00.dirhold [AXIS_0]DIRHOLD

setp hm2_5i25.0.stepgen.00.steplen [AXIS_0]STEPLEN

setp hm2_5i25.0.stepgen.00.stepspace [AXIS_0]STEPSPACE

setp hm2_5i25.0.stepgen.00.position-scale [AXIS_0]STEP_SCALE

setp hm2_5i25.0.stepgen.00.step_type 0

setp hm2_5i25.0.stepgen.00.control-type 0

setp hm2_5i25.0.stepgen.00.maxaccel 5.0

setp hm2_5i25.0.stepgen.00.maxvel 2.1

net x-pos-fb axis.0.motor-pos-fb <= hm2_5i25.0.stepgen.00.position-fb

net x-pos-cmd axis.0.motor-pos-cmd => hm2_5i25.0.stepgen.00.position-cmd

net x-enable axis.0.amp-enable-out => hm2_5i25.0.stepgen.00.enable

# ---setup home / limit switch signals---

net both-home-x => axis.0.home-sw-in

net both-home-x => axis.0.neg-lim-sw-in

net both-home-x => axis.0.pos-lim-sw-in

#*******************

# AXIS Y

#*******************

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.01.dirsetup [AXIS_1]DIRSETUP

setp hm2_5i25.0.stepgen.01.dirhold [AXIS_1]DIRHOLD

setp hm2_5i25.0.stepgen.01.steplen [AXIS_1]STEPLEN

setp hm2_5i25.0.stepgen.01.stepspace [AXIS_1]STEPSPACE

setp hm2_5i25.0.stepgen.01.position-scale [AXIS_1]STEP_SCALE

setp hm2_5i25.0.stepgen.01.step_type 0

setp hm2_5i25.0.stepgen.01.control-type 0

setp hm2_5i25.0.stepgen.01.maxaccel 2.5

setp hm2_5i25.0.stepgen.01.maxvel 2.1

net y-pos-fb axis.1.motor-pos-fb <= hm2_5i25.0.stepgen.01.position-fb

net y-pos-cmd axis.1.motor-pos-cmd => hm2_5i25.0.stepgen.01.position-cmd

net y-enable axis.1.amp-enable-out => hm2_5i25.0.stepgen.01.enable

# ---setup home / limit switch signals---

net both-home-y => axis.1.home-sw-in

net both-home-y => axis.1.neg-lim-sw-in

net both-home-y => axis.1.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.02.dirsetup [AXIS_2]DIRSETUP

setp hm2_5i25.0.stepgen.02.dirhold [AXIS_2]DIRHOLD

setp hm2_5i25.0.stepgen.02.steplen [AXIS_2]STEPLEN

setp hm2_5i25.0.stepgen.02.stepspace [AXIS_2]STEPSPACE

setp hm2_5i25.0.stepgen.02.position-scale [AXIS_2]STEP_SCALE

setp hm2_5i25.0.stepgen.02.step_type 0

setp hm2_5i25.0.stepgen.02.control-type 0

setp hm2_5i25.0.stepgen.02.maxaccel 2.5

setp hm2_5i25.0.stepgen.02.maxvel 2.1

net z-pos-fb axis.2.motor-pos-fb <= hm2_5i25.0.stepgen.02.position-fb

net z-pos-cmd axis.2.motor-pos-cmd => hm2_5i25.0.stepgen.02.position-cmd

net z-enable axis.2.amp-enable-out => hm2_5i25.0.stepgen.02.enable

# ---setup home / limit switch signals---

net max-home-z => axis.2.home-sw-in

net min-z => axis.2.neg-lim-sw-in

net max-home-z => axis.2.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

# ---digital potentionmeter output signals/setup---

setp hm2_5i25.0.7i76.0.0.spinout-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i76.0.0.spinout-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

setp hm2_5i25.0.7i76.0.0.spinout-scalemax [SPINDLE_9]OUTPUT_SCALE

net abs-vel-cmd abs.0.out => hm2_5i25.0.7i76.0.0.spinout

net spindle-enable => hm2_5i25.0.7i76.0.0.spinena

net spindle-cw => hm2_5i25.0.7i76.0.0.output-04

net spindle-ccw => hm2_5i25.0.7i76.0.0.output-05

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd abs.0.in <= motion.spindle-speed-out

net spindle-enable <= motion.spindle-on

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

net jog-x-pos halui.jog.0.plus

net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.jog.0.analog

net joint-select-b halui.joint.1.select

net y-is-homed halui.joint.1.is-homed

net jog-y-pos halui.jog.1.plus

net jog-y-neg halui.jog.1.minus

net jog-y-analog halui.jog.1.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

net jog-z-pos halui.jog.2.plus

net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.jog.2.analog

net jog-selected-pos halui.jog.selected.plus

net jog-selected-neg halui.jog.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---jog button signals---

sets jog-speed 1.000000

## MPG stuff##########

# ---jogwheel signals to mesa encoder - shared MPG---

net joint-selected-count <= hm2_5i25.0.7i84.0.1.enc0

setp hm2_5i25.0.encoder.00.filter true

setp hm2_5i25.0.encoder.00.counter-mode true

# ---mpg signals---

# for axis x MPG

setp axis.0.jog-vel-mode 0

net selected-jog-incr => axis.0.jog-scale

net joint-select-a => axis.0.jog-enable

net joint-selected-count => axis.0.jog-counts

# for axis y MPG

setp axis.1.jog-vel-mode 0

net selected-jog-incr => axis.1.jog-scale

net joint-select-b => axis.1.jog-enable

net joint-selected-count => axis.1.jog-counts

# for axis z MPG

setp axis.2.jog-vel-mode 0

net selected-jog-incr => axis.2.jog-scale

net joint-select-c => axis.2.jog-enable

net joint-selected-count => axis.2.jog-counts

##connect jog incr override increments

net jog-incr-a => mux16.0.sel0

net jog-incr-b => mux16.0.sel1

net jog-incr-c => mux16.0.sel2

net jog-incr-d => mux16.0.sel3

net selected-jog-incr <= mux16.0.out-f

setp mux16.0.debounce-time 0.200000

setp mux16.0.use-graycode False

setp mux16.0.suppress-no-input False

setp mux16.0.in00 0.0001

setp mux16.0.in01 0.001

setp mux16.0.in02 .01

setp mux16.0.in03 .1

setp mux16.0.in04 1

# connect feed overide increments - switches

setp halui.feed-override.count-enable true

setp halui.feed-override.direct-value true

setp halui.feed-override.scale .01

net feedoverride-incr => halui.feed-override.counts

net fo-incr-a => mux16.1.sel0

net fo-incr-b => mux16.1.sel1

net fo-incr-c => mux16.1.sel2

net fo-incr-d => mux16.1.sel3

net feedoverride-incr <= mux16.1.out-s

setp mux16.1.debounce-time 0.200000

setp mux16.1.use-graycode False

setp mux16.1.suppress-no-input False

setp mux16.1.in00 0.000000

setp mux16.1.in01 10.000000

setp mux16.1.in02 20.000000

setp mux16.1.in03 30.000000

setp mux16.1.in04 40.000000

setp mux16.1.in05 50.000000

setp mux16.1.in06 60.000000

setp mux16.1.in07 70.000000

setp mux16.1.in08 80.000000

setp mux16.1.in09 90.000000

setp mux16.1.in10 100.000000

setp mux16.1.in11 110.000000

setp mux16.1.in12 120.000000

setp mux16.1.in13 130.000000

setp mux16.1.in14 140.000000

setp mux16.1.in15 150.000000

# connect max velocity overide increments - switches

setp halui.max-velocity.count-enable true

setp halui.max-velocity.direct-value true

setp halui.max-velocity.scale 0.016670

net max-vel-override-incr => halui.max-velocity.counts

net mvo-incr-a => mux16.2.sel0

net mvo-incr-b => mux16.2.sel1

net mvo-incr-c => mux16.2.sel2

net mvo-incr-d => mux16.2.sel3

net max-vel-override-incr <= mux16.2.out-s

setp mux16.2.debounce-time 0.200000

setp mux16.2.use-graycode False

setp mux16.2.suppress-no-input False

setp mux16.2.in00 0.000000

setp mux16.2.in01 1.000000

setp mux16.2.in02 2.000000

setp mux16.2.in03 4.00000

setp mux16.2.in04 6.00000

setp mux16.2.in05 8.00000

setp mux16.2.in06 10.00000

setp mux16.2.in07 20.00000

setp mux16.2.in08 30.00000

setp mux16.2.in09 40.00000

setp mux16.2.in10 50.00000

setp mux16.2.in11 60.00000

setp mux16.2.in12 70.0000

setp mux16.2.in13 80.0000

setp mux16.2.in14 90.0000

setp mux16.2.in15 100.0000

# connect spindle overide increments

setp halui.spindle-override.count-enable true

setp halui.spindle-override.direct-value true

setp halui.spindle-override.scale .01

net spindleoverride-incr => halui.spindle-override.counts

net so-incr-a => mux16.3.sel0

net so-incr-b => mux16.3.sel1

net so-incr-c => mux16.3.sel2

net spindleoverride-incr <= mux16.3.out-s

setp mux16.3.debounce-time 0.200000

setp mux16.3.use-graycode False

setp mux16.3.suppress-no-input False

setp mux16.3.in00 100.000000

setp mux16.3.in01 90.000000

setp mux16.3.in02 70.000000

setp mux16.3.in03 80.000000

setp mux16.3.in04 110.000000

setp mux16.3.in05 120.000000

setp mux16.3.in06 60.000000

setp mux16.3.in07 50.000000

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

Please Log in or Create an account to join the conversation.

Time to create page: 0.130 seconds