Closing the servo loop with HAL mesa 7i76

- PCW

-

- Away

- Moderator

-

- Posts: 19089

- Thank you received: 5268

setp hm2_7i76e.0.encoder.00.filter 0

Would be safer

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 5034

- Thank you received: 1467

One possibility is that you are running into the encoder maximum

count rate. To test this, you might try turning off the encoder filter bit

in the hal file.

Is this a matter of commenting out this line setp hm2_7i76e.0.encoder.00.filter 1

I have never used hal scope but will give it a try.

Thanks for the support.

You can't really accurately tune the PID for running closed loop without using Halscope. (At least I can't imagine a way) You are going to have to learn how to do that. Then follow one of the velocity servo tuning tutorials.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2247

- Thank you received: 483

Not sure of the defaults so:

setp hm2_7i76e.0.encoder.00.filter 0

Would be safer

Ok tried it with filter setting to 1 same result

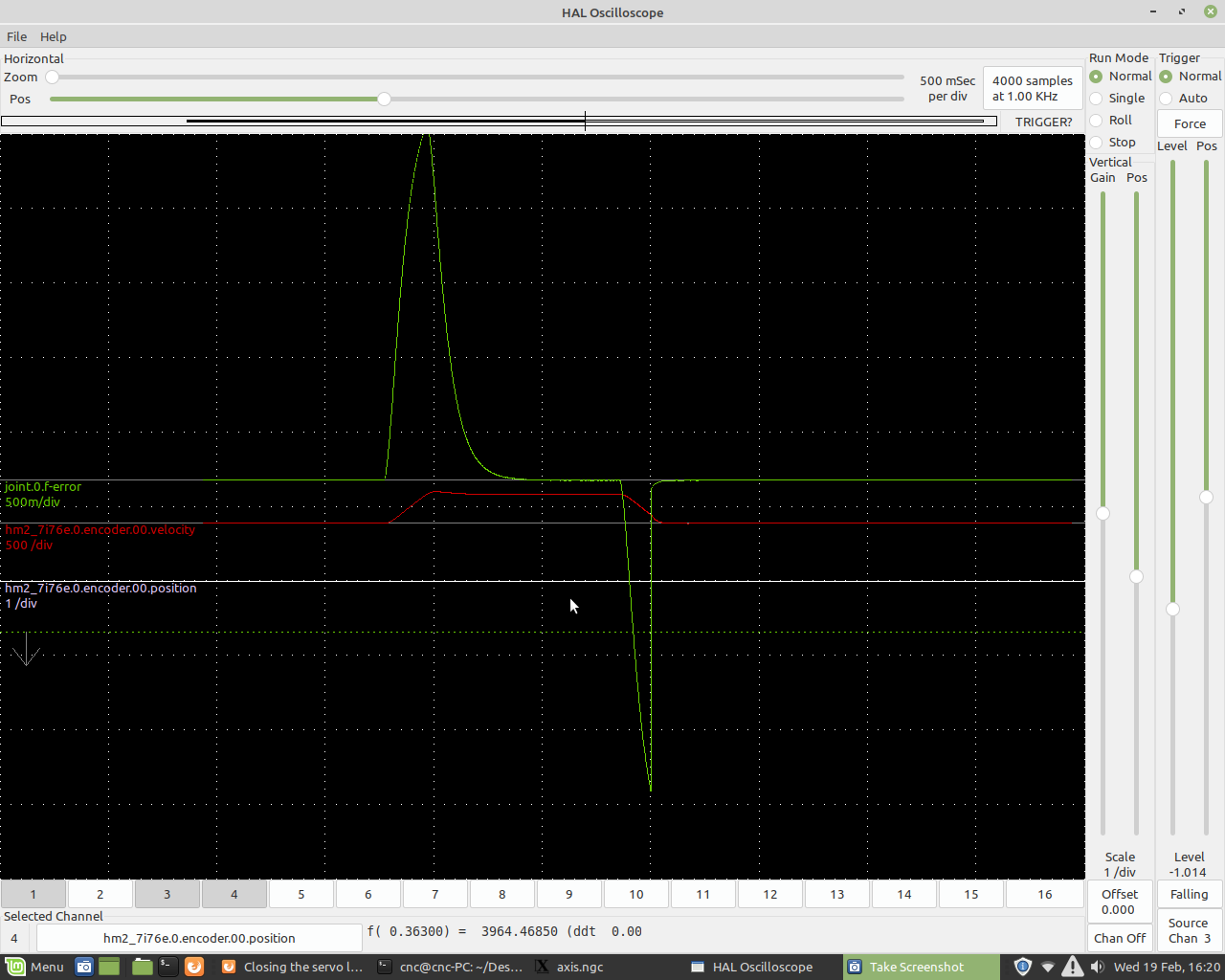

Now I have delved into the mystery of hal scope

Does this help. Triggered from following error

Not sure if I have done it correct

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 20593

- Thank you received: 7009

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 5034

- Thank you received: 1467

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2247

- Thank you received: 483

From that image it looks like one of two problems (or a combination of the 2). Either you need alot more P (you have P=10 now) or your motor/drive can't match the max acceleration settings you have set in your ini file.

The motor and drive are a matched pair. this only happens in closed loop.

I will experiment with the P (perhaps I should give it some of my tablets for my P)

Thanks for the interest.

edit this is step/dir setup

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 19089

- Thank you received: 5268

The motor and drive are a matched pair. this only happens in closed loop.

You only _see_ the error in closed loop. its very likely its still there in open loop mode, but not detected

To me it looks like Todds second suggestion, you are exceeding the drives acceleration settings

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2247

- Thank you received: 483

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 5034

- Thank you received: 1467

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

- Posts: 1129

- Thank you received: 533

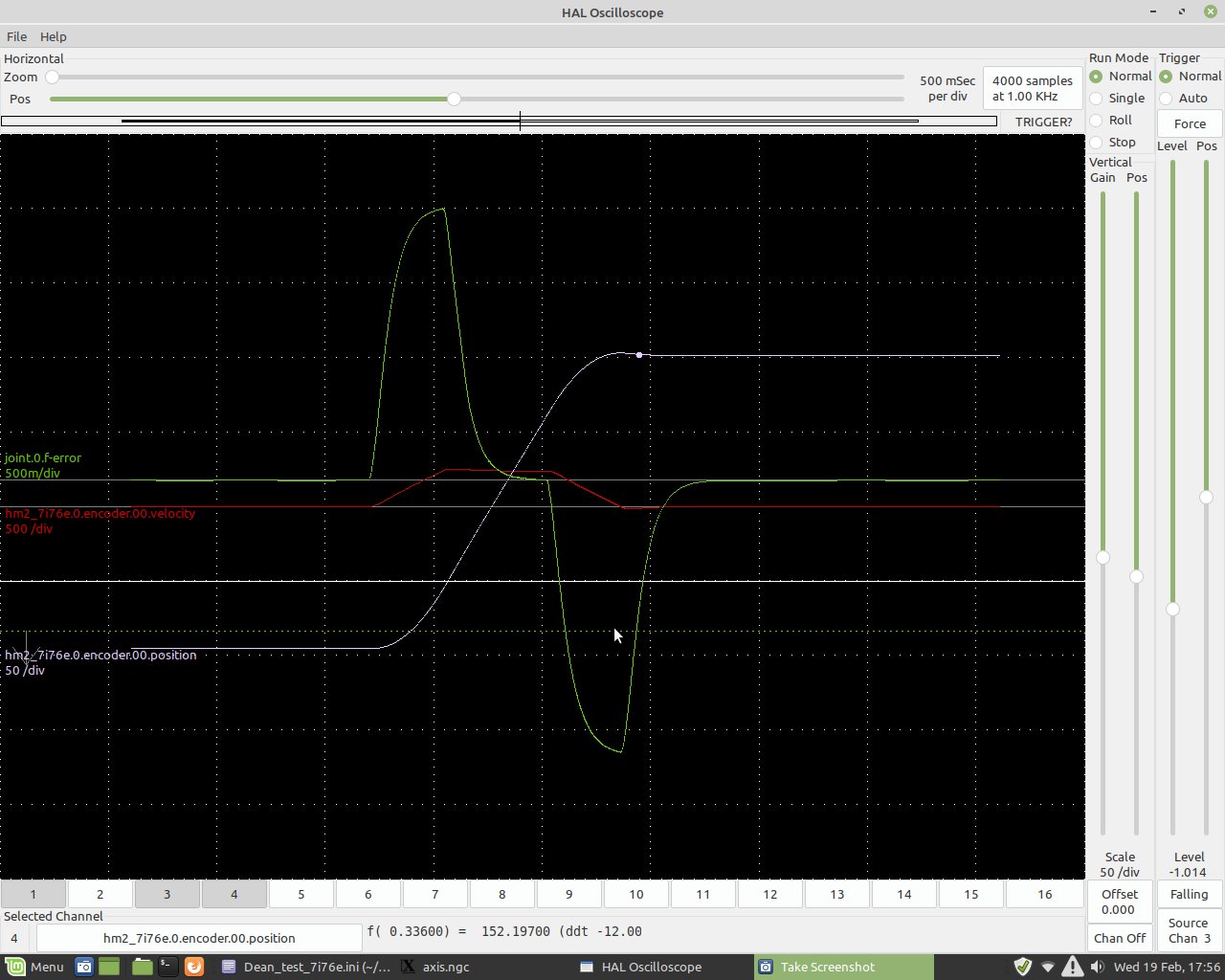

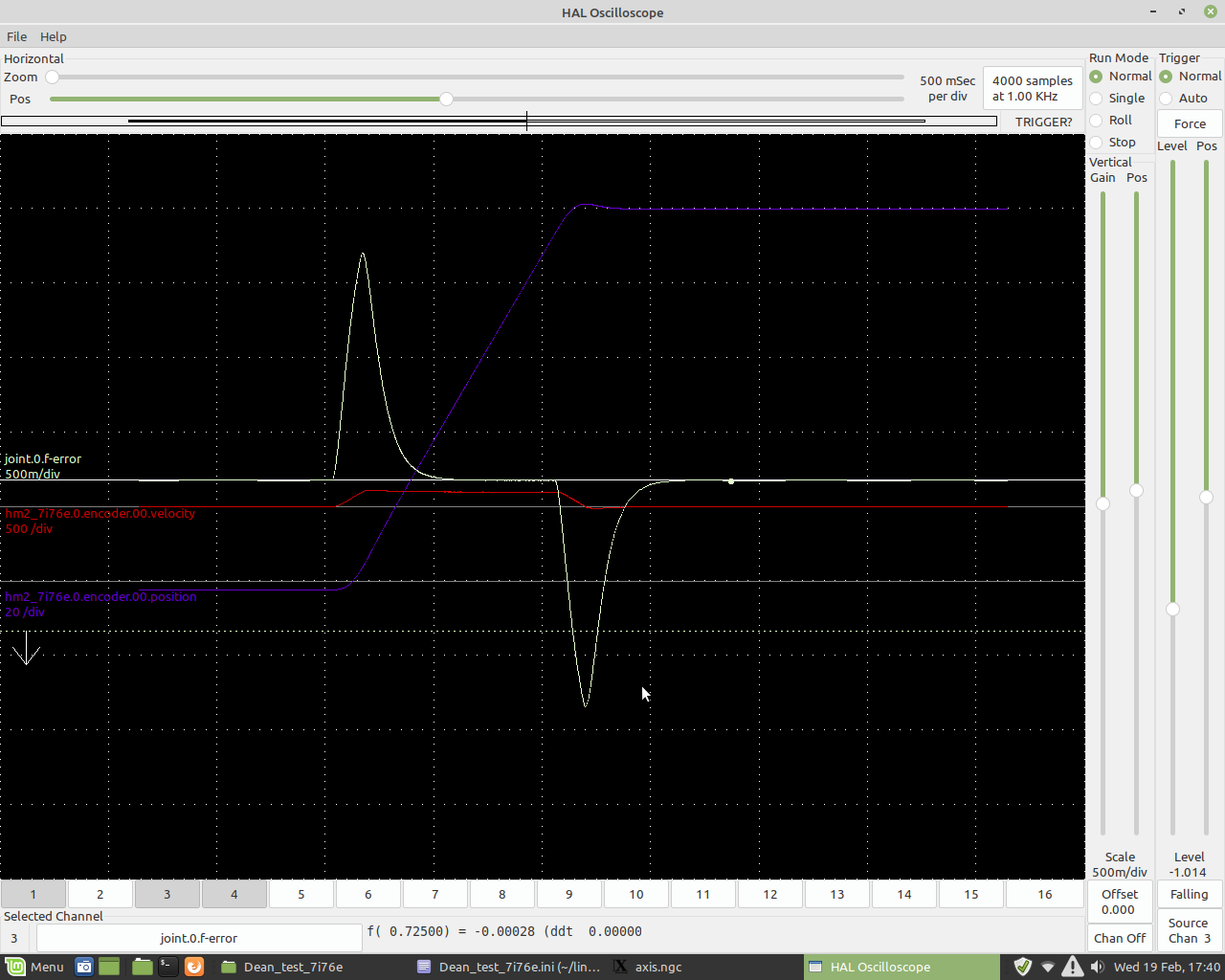

Try something more like 200mm/sec/sec. (You probably should use your servo drive's configuring software to increase the acceleration there or at least look up what it is set for, there is no reason to be guessing at these numbers.)

That is my problem with buying the China AC servo motors and drives. They are cheap but the software they use to tune them is pretty crap and most of the manuals I have read are garbage. But I do agree they do have their place. It would be great if one could understand Chinese!

Please Log in or Create an account to join the conversation.