- Configuring LinuxCNC

- Advanced Configuration

- ClassicLadder

- CL logic to make LCNC buttons work like industrial machines

CL logic to make LCNC buttons work like industrial machines

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4698

- Thank you received: 1441

03 Jan 2021 03:41 #193925

by Todd Zuercher

Replied by Todd Zuercher on topic CL logic to make LCNC buttons work like industrial machines

I think he was. Having tried it myself in the past,. not sure I'd recommend it.

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7289

- Thank you received: 2128

03 Jan 2021 09:29 #193937

by cmorley

Replied by cmorley on topic CL logic to make LCNC buttons work like industrial machines

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

05 Jan 2021 07:11 #194122

by Mike_Eitel

Replied by Mike_Eitel on topic CL logic to make LCNC buttons work like industrial machines

Sorry for late answer

This file is ASCII. Easy to edit.

With a bit fiddeling you can understand f.x. that one rung is one line.

So moving a line to another position moves it.

I remember that i also replaced var names.... etc.

Mike

This file is ASCII. Easy to edit.

With a bit fiddeling you can understand f.x. that one rung is one line.

So moving a line to another position moves it.

I remember that i also replaced var names.... etc.

Mike

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

05 Jan 2021 07:16 #194123

by Mike_Eitel

Replied by Mike_Eitel on topic CL logic to make LCNC buttons work like industrial machines

Honestly, i find CL a pain in the...

But to write real simple plc logic much more efficient than hal.

I'm a fan of iec61131.

Mike

But to write real simple plc logic much more efficient than hal.

I'm a fan of iec61131.

Mike

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

05 Jan 2021 07:26 #194125

by rodw

Me too, I've never bothered to look at CL. becasue I've never programmed a PLC.

I'd just write a custom component in C which I think is Linuxcnc's jewel in the crown.

Its funny, there has barely been a mention of CL for ages and all of a sudden a few people are discussing it.

Replied by rodw on topic CL logic to make LCNC buttons work like industrial machines

Honestly, i find CL a pain in the...

But to write real simple plc logic much more efficient than hal.

I'm a fan of iec61131.

Mike

Me too, I've never bothered to look at CL. becasue I've never programmed a PLC.

I'd just write a custom component in C which I think is Linuxcnc's jewel in the crown.

Its funny, there has barely been a mention of CL for ages and all of a sudden a few people are discussing it.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

05 Jan 2021 07:41 #194126

by Mike_Eitel

Replied by Mike_Eitel on topic CL logic to make LCNC buttons work like industrial machines

Make's sence to me.

If you are coming from standart automation world, plc programing is the absolute best way to go. C can only be acceptet for specialities. I f.x. dislike C as IT does not prevent me from my typos in concern of theses dam... ; 's. ;-()

Mike

If you are coming from standart automation world, plc programing is the absolute best way to go. C can only be acceptet for specialities. I f.x. dislike C as IT does not prevent me from my typos in concern of theses dam... ; 's. ;-()

Mike

The following user(s) said Thank You: rodw, The Feral Engineer

Please Log in or Create an account to join the conversation.

- nkp

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 39

07 Jan 2021 18:16 - 07 Jan 2021 19:14 #194388

by nkp

Replied by nkp on topic CL logic to make LCNC buttons work like industrial machines

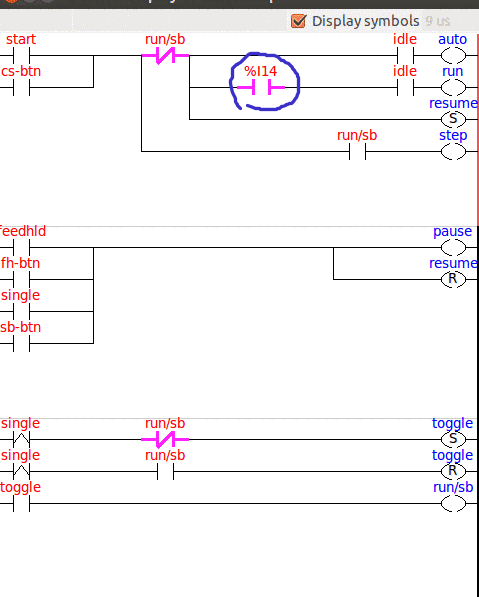

I10 - ?

I11 - ?

I13 - ?

==============================

When you first start the program, almost always an error:

can't do that (EMC_TRAJ_SET_TELEOP_ENABLE) in auto mode with the interpreter paused

Lcnc 2.7 Axis

PS

The scheme needs improvement

net mode:is:auto classicladder.0.in-14 halui.mode.is-auto

I11 - ?

I13 - ?

==============================

When you first start the program, almost always an error:

can't do that (EMC_TRAJ_SET_TELEOP_ENABLE) in auto mode with the interpreter paused

Lcnc 2.7 Axis

PS

The scheme needs improvement

net mode:is:auto classicladder.0.in-14 halui.mode.is-auto

Attachments:

Last edit: 07 Jan 2021 19:14 by nkp.

Please Log in or Create an account to join the conversation.

- nkp

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 39

07 Jan 2021 21:07 #194416

by nkp

Replied by nkp on topic CL logic to make LCNC buttons work like industrial machines

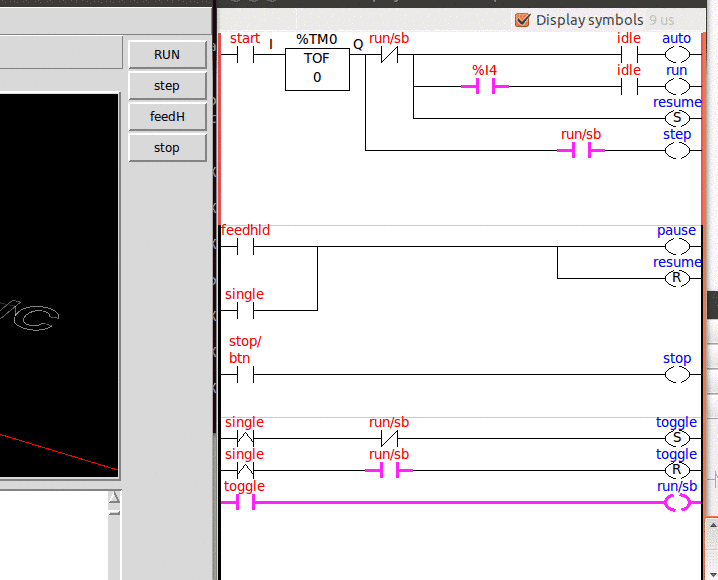

This works fine.

net auto classicladder.0.in-00 pyvcp.run

net feed-hold classicladder.0.in-01 pyvcp.feedhold

net program-idle classicladder.0.in-02 halui.program.is-idle

net single-block classicladder.0.in-03 pyvcp.step

net mode:is:auto classicladder.0.in-04 halui.mode.is-auto

net btn-stop classicladder.0.in-05 pyvcp.stop

net auto-mode-select classicladder.0.out-00 halui.mode.auto

net cycle-start classicladder.0.out-01 halui.program.run

net feed-resume classicladder.0.out-03 halui.program.resume

net single-block-select classicladder.0.out-04 halui.program.step

net program-stop classicladder.0.out-05 halui.program.stop

net feed-hold-select classicladder.0.out-02 halui.program.pause

net auto classicladder.0.in-00 pyvcp.run

net feed-hold classicladder.0.in-01 pyvcp.feedhold

net program-idle classicladder.0.in-02 halui.program.is-idle

net single-block classicladder.0.in-03 pyvcp.step

net mode:is:auto classicladder.0.in-04 halui.mode.is-auto

net btn-stop classicladder.0.in-05 pyvcp.stop

net auto-mode-select classicladder.0.out-00 halui.mode.auto

net cycle-start classicladder.0.out-01 halui.program.run

net feed-resume classicladder.0.out-03 halui.program.resume

net single-block-select classicladder.0.out-04 halui.program.step

net program-stop classicladder.0.out-05 halui.program.stop

net feed-hold-select classicladder.0.out-02 halui.program.pause

Attachments:

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

08 Jan 2021 16:04 #194510

by bevins

Replied by bevins on topic CL logic to make LCNC buttons work like industrial machines

Its funny, there has barely been a mention of CL for ages and all of a sudden a few people are discussing it.

I use at least a few rungs on every machine I do. There is always something easier to do in CL than HAL.

I once did a point to point Biesse with the zones, photocells pushbuttons and green lites's using CL.

Please Log in or Create an account to join the conversation.

- The Feral Engineer

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 79

- Thank you received: 22

15 Jan 2021 18:03 - 15 Jan 2021 18:08 #195471

by The Feral Engineer

I don't get any error messages when I use it (2.8.1). I have made a few changes to it since I posted this, nothing crazy, just centralized the grouping of the physical and gamepad buttons I was using. Pressing cycle start should bring the machine to auto mode, not alarm. I did, however, add halui.mode.is-auto to I6 after posting my file here.

To answer your other question, I10, I11 and I12 (formerly i13) are for a different circuit. Those are assignments to two separate probe circuits, using separate inputs and an internal relay to switch between them.

Long story short, my machines have a hardwired tool setter mounted to the table and a spindle probe. Both setter and probe are NC, so when the spindle probe is disconnected from the machine, the signal is broken, so the probe is in a constant trigger state. I12 is a relay that flags mcodes using sets probe-relay true/false. I12 is tied to both a classicladder input signal as well as spindle inhibit, so when the spindle probe is active, the spindle cannot rotate.

see attached. I commented at the top of each rung section. I make little tutorial videos on basic CL and HAL for youtube, so sometimes my samples get attached to my CL files, but they don't usually get in the way.

Replied by The Feral Engineer on topic CL logic to make LCNC buttons work like industrial machines

I10 - ?

I11 - ?

I13 - ?

==============================

When you first start the program, almost always an error:

can't do that (EMC_TRAJ_SET_TELEOP_ENABLE) in auto mode with the interpreter paused

Lcnc 2.7 Axis

PS

The scheme needs improvement

net mode:is:auto classicladder.0.in-14 halui.mode.is-auto

I don't get any error messages when I use it (2.8.1). I have made a few changes to it since I posted this, nothing crazy, just centralized the grouping of the physical and gamepad buttons I was using. Pressing cycle start should bring the machine to auto mode, not alarm. I did, however, add halui.mode.is-auto to I6 after posting my file here.

To answer your other question, I10, I11 and I12 (formerly i13) are for a different circuit. Those are assignments to two separate probe circuits, using separate inputs and an internal relay to switch between them.

Long story short, my machines have a hardwired tool setter mounted to the table and a spindle probe. Both setter and probe are NC, so when the spindle probe is disconnected from the machine, the signal is broken, so the probe is in a constant trigger state. I12 is a relay that flags mcodes using sets probe-relay true/false. I12 is tied to both a classicladder input signal as well as spindle inhibit, so when the spindle probe is active, the spindle cannot rotate.

see attached. I commented at the top of each rung section. I make little tutorial videos on basic CL and HAL for youtube, so sometimes my samples get attached to my CL files, but they don't usually get in the way.

Last edit: 15 Jan 2021 18:08 by The Feral Engineer.

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- ClassicLadder

- CL logic to make LCNC buttons work like industrial machines

Time to create page: 0.156 seconds